Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

Certified Quality

ISO 9001 Certified

ISO 14001 Certified

Certified to CSA Technical Letter No, R-14

Certified to ANSI LC6-2008

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

Tel: 866-777-6060

Fax: 866-777-6383

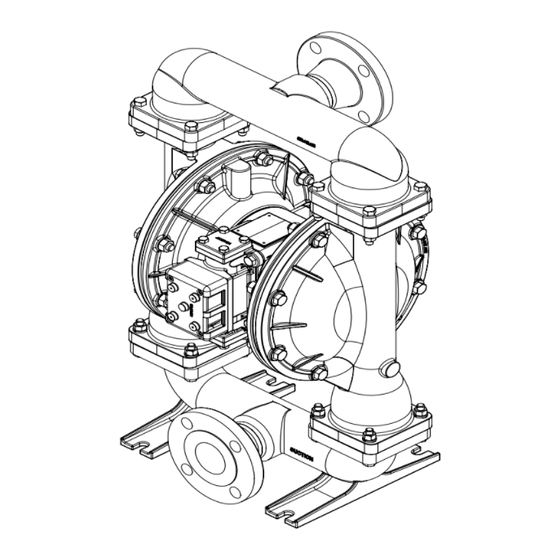

Model G20

Metallic

Design Level 1

Natural Gas-Operated

Diaphragm Pumps

Springer Pumps, LLC

.

s a n d p i p e r p u m p

c o m

Website: www.springerpumps.com

Int'l: +001 267 404 2910

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Warren rupp SANDPIPER G20

- Page 1 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867 SANDPIPERPUMP.COM © Copyright 2017 Warren Rupp, Inc. All rights reserved s a n d p i p e r p u m p c o m Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com...

- Page 2 The use of non-OEM replacement parts will void (or negate) agency certifications, including CE, ATEX, CSA, 3A and EC1935 compliance (Food Contact Materials). Warren Rupp, Inc. cannot ensure nor warrant non-OEM parts to meet the stringent Use safe practices when lifting requirements of the certifying agencies.

-

Page 3: Table Of Contents

MODEL SPECIFIC Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Explanation of Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ..5 • Principle of Pump Operation • Recommended Installation Guide • Troubleshooting Guide SECTION 3: EXPLODED VIEW ......8 •... -

Page 4: Explanation Of Nomenclature

MODEL SPECIFIC Explanation of Pump Nomenclature Your Model #: G __ ____ ____ (fill in from pump nameplate) Pump Pump Check Design Wetted Diaphragm/ Check Valve Non-Wetted Porting Pump Muffler Pump Brand Size Valve Level Material Check Valve Seat Material Options Style Options... -

Page 5: Performance

MODEL SPECIFIC UNIVERSAL ALL AODD Performance G20 METALLIC MODEL G20 Metallic Performance Curve Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. SUCTION/DISCHARGE PORT SIZE The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. •... -

Page 6: Dimensional Drawings

MODEL SPECIFIC Dimensional Drawings G20 Metallic Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 17.03 11.63 432.63 295.34 2"... - Page 7 Dimensional Drawings G20 Metallic - ANSI Flange Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 11.63 295.28 17.03 4.87 432.63...

-

Page 8: Principle Of Pump Operation

UNIVERSAL ALL AODD Principle of Pump Operation Gas-Operated Double Diaphragm pumps are powered by compressed gas, nitrogen or natural gas. The main directional (gas) control valve distributes ① compressed gas to an gas chamber, exerting uniform pressure over the inner surface of the diaphragm . -

Page 9: Recommended Installation Guide

The gas exhaust should ground the regulator, hose, and/or pipe. be piped to an area for safe disposition of the product being pumped, in the event of a diaphragm failure. Available from Warren Rupp Flexible Conductive Connection Gas Shut-Off Valve Pipe Connection... -

Page 10: Troubleshooting Guide

UNIVERSAL ALL SANDPIPER, EXCEPT FLAP Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds gas Increase the inlet gas pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure). (Does not apply to high pressure 2:1 units). -

Page 11: Composite Repair Parts Drawing

MODEL SPECIFIC Composite Repair Parts Drawing Torque: 90 In. Lbs (10 N-m) ITEM PART NUMB 031.183.00 GROUND STRAP, ATTACH EYELET 050.XXX.XX TO ITEM #11 070.006.17 095.110.XX 114.024.XX 132.035.36 135.034.50 165.116.XX 170.052.XX 170.060.XX 170.069.XX 170.006.XX 171.059.XX 196.167.XX 196.168.XX 286.007.XX 286.020.60 360.093.36 360.114.36 360.104.37 360.105.36... -

Page 12: Composite Repair Parts List

MODEL SPECIFIC Composite Repair Parts List Item Part Number Description Qty. Item Part Number Description Qty. 031.183.000 Aluminum Air Valve Assembly 545.005.330 Nut, Hex 3/8-16 031.183.363 Aluminum Air Valve Assembly - FKM o-rings 545.005.115 Nut, Hex 3/8-16 (w/ stainless hardware) 031.179.000 Stainless Air Valve Assembly - use with option B 545.007.330... -

Page 13: Material Codes

UNIVERSAL ALL SP Material Codes - The Last 3 Digits of Part Number 000..Assembly, sub-assembly; 364..EPDM Rubber • Delrin and Hytrel are registered tradenames of E.I. DuPont. and some purchased items Color coded: BLUE 010..Cast Iron 365..Neoprene Rubber • Nylatron is a registered tradename 015..Ductile Iron Color coded: GREEN of Polymer Corp. - Page 14 MODEL SPECIFIC Gas Distribution Valve Assembly Valve Assembly for Aluminum Mid Sections Natural Gas Assembly Parts List Item Part Number Description 031-183-000 Gas Valve Assembly 095-109-157 Valve Body 031-139-000 Sleeve and Spool Set 132-029-357 Bumper 560-020-360 O-Ring 165-127-157 Cap, End 170-032-330 Capscrew Item...

-

Page 15: Pilot Valve Assembly

MODEL SPECIFIC Pilot Valve Assembly Pilot Valve Assembly Parts List Item Part Number Description 095-110-000 Pilot Valve Assembly 095-095-157 Valve Body 755-052-000 Sleeve (With O-Rings) Pilot Valve Servicing 560-033-360 O-Ring (Sleeve) With Pilot Valve removed from pump. 775-055-000 Spool (With O-Rings) Step 1: Remove snap ring (4-F). -

Page 16: Intermediate Assembly

Intermediate Assembly Intermediate Assembly Drawing INTERMEDIATE REPAIR PARTS LIST Step 1: Remove plunger, actuator (31) from center of Item Part Number Description 114.024.157 Bracket, Intermediate intermediate pilot valve cavity. 114.024.110 Bracket, Intermediate Step 2: Remove Ring, Retaining (32), discard. 135.034.506 Bushing, Plunger Step 3: Remove bushing, plunger (7), inspect for wear 560.001.360... - Page 17 MODEL SPECIFIC Diaphragm Service Drawing, with Overlay Diaphragm Service Drawing, Non-Overlay sandpiperpump Model G20 Metallic • g20mdl1sm-rev0217 Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

-

Page 18: Diaphragm Servicing

UNIVERSAL ALL SP Diaphragm Servicing Step 1: With manifolds and outer chambers Step 4: Push the threaded outer diaphragm removed, remove diaphragm assemblies from plate through the center hole of the diaphragm. diaphragm rod. DO NOT use a pipe wrench or similar Note: Most diaphragms are installed with the tool to remove assembly from rod. -

Page 19: Pumping Hazardous Liquids

UNIVERSAL ALL SP PUMPING HAZARDOUS LIQUIDS When a diaphragm fails, the pumped liquid or fumes enter the natural gas NATURAL GAS EXHAUST ILLUSTRATION end of the pump. Fumes are exhausted into the surrounding environment. When pumping hazardous or toxic materials, the exhaust gas must be piped to an PUMP INSTALLATION AREA SAFE AIR appropriate area for safe disposal. - Page 20 Warren Rupp, Inc. (“Warren Rupp”) warrants to the original end-use purchaser that no product sold by Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory.

- Page 21 The objective of the declaration described is in conformity with the relevant Union harmonisation legislation: Directive 94/9/EC (until April 19, 2016) and Directive 2014/34/EU (from April 20, 2016). Manufacturer: Applicable Standard: Warren Rupp, Inc. EN13463-1: 2001 A Unit of IDEX Corportion EN13463-5: 2003...

Need help?

Do you have a question about the SANDPIPER G20 and is the answer not in the manual?

Questions and answers