Table of Contents

Advertisement

Quick Links

Table of Contents

Engineering Data and Performance Curve............................................................ 1

Explanation of Pump Nomenclature ...................................................................... 2

Dimensions ............................................................................................................ 3

Principle of Operation ............................................................................................ 4

Installation and Start-Up ........................................................................................ 4

Air Supply .............................................................................................................. 4

Air Inlet & Priming .................................................................................................. 4

Installation Guide ................................................................................................... 5

®

Air Exhaust ............................................................................................................ 7

Between Uses ....................................................................................................... 7

Check Valve Servicing ........................................................................................... 7

Diaphragm Servicing ............................................................................................. 7

Pilot Valve .............................................................................................................. 8

Pilot Valve Actuator ................................................................................................ 8

Service Instructions: Troubleshooting ................................................................... 9

Warranty ................................................................................................................ 9

Material Codes .................................................................................................... 10

Composite Repair Parts List ........................................................................... 11-12

Composite Repair Drawing.................................................................................. 13

CE Declaration of Conformity - Machinery .......................................................... 14

CE Declaration fo Conformity - ATEX .................................................................. 15

Warren Rupp, Inc. • A Unit of IDEX Corporation • 800 N. Main St., Mansfield, Ohio 44902 USA

hdf3mdl2sm-rev0316

Tel: 866-777-6060

Fax: 866-777-6383

SERVICE AND OPERATING MANUAL

II 2GD T5

Telephone (419) 524-8388 • Fax (419) 522-7867 • warrenrupp.com

Springer Pumps, LLC

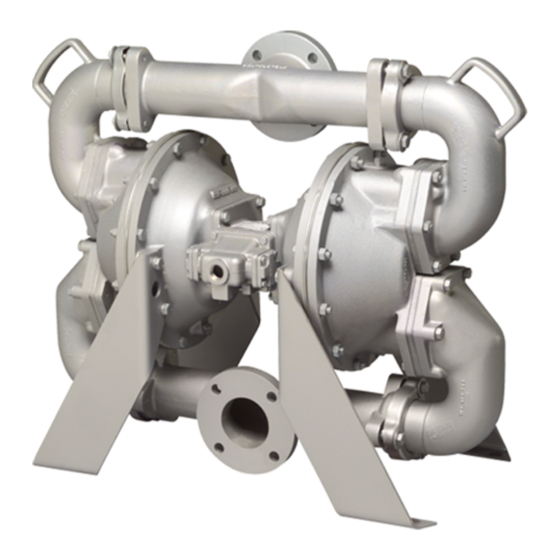

Model HDF3-M & HDF4-M

See pages 15

©Copyright 2016 Warren Rupp, Inc. All rights reserved.

Type 2

Website: www.springerpumps.com

Int'l: +001 267 404 2910

Advertisement

Table of Contents

Summary of Contents for Warren rupp Sandpiper HDF3-M

-

Page 1: Table Of Contents

CE Declaration of Conformity - Machinery ............14 CE Declaration fo Conformity - ATEX ..............15 Warren Rupp, Inc. • A Unit of IDEX Corporation • 800 N. Main St., Mansfield, Ohio 44902 USA Telephone (419) 524-8388 • Fax (419) 522-7867 • warrenrupp.com hdf3mdl2sm-rev0316 ©Copyright 2016 Warren Rupp, Inc. - Page 2 Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty.

-

Page 3: Engineering Data And Performance Curve

Heavy Duty Flap Valve Quality System ISO 9001 Certified HDF3-M Environmental HDF4-M Type 2 Management System ISO 14001 Certified Air-Operated Double Diaphragm Pump See pages 17 & 18 II 2GD T5 for ATEX ratings ENGINEERING, PERFORMANCE & CONSTRUCTION DATA INTAKE/DISCHARGE PIPE SIZE CAPACITY AIR VALVE SOLIDS-HANDLING... -

Page 4: Explanation Of Pump Nomenclature

Explanation of Pump Nomenclature, HDF3-M & HDF4-M MATERIALS OF CONSTRUCTION To order a pump or replacement parts, first enter the Model Number HDF3-M, or HDF4-M, followed by the Type Designation listed below in the far left column. HDF3-M Manifold Outer Inner Outer Inner... -

Page 5: Dimensions

Dimensions: HDF3-M & HDF4-M Dimensions are ± 1/8" Figures in parenthesis = millimeters HDF3-M HDF4 Suction & Four(4) 3/4" dia. thru holes 4" Eight(8) 5/8-11 unc tapped equally spaced on a 6" holes equally spaced on a 7 1/2" Discharge Ports diameter bolt circle diameter bolt circle Dimension "A"... -

Page 6: Principle Of Operation

SERVICE AND OPERATING MANUAL Model HDF3-M & HD4F-M Type 2 See pages 16 & 17 Heavy Duty Flap Valve II 2GD T5 for ATEX ratings PRINCIPLE OF PUMP OPERATION This flap swing valve pump is powered by compressed air and is a 1:1 pressure ratio design. -

Page 7: Installation Guide

Available from disposition of the product Distributor being pumped, in the event of a diaphragm failure. Available from Warren Rupp hdf3mdl2sm-rev0316 Model HDF3-M & HDF4-M Page 5 Tel: 866-777-6060 Springer Pumps, LLC Website: www.springerpumps.com Fax: 866-777-6383... -

Page 8: Esads+Plus ® : Externally Serviceable Air Distribution System

Proper lubrication of the compressed air supply would entail the use of an air line lubricator (available from Warren Rupp) set to deliver one drop of 10 wt., non-detergent oil for every 20 SCFM of air the pump consumed at its point of operation. -

Page 9: Air Exhaust

that the bumper stays in place allowing the sleeve to press in all the way. Reinstall the spool, opposite end cap, gasket and bumper on the valve body. After inspecting and cleaning the gasket surfaces on the valve body and intermediate, reinstall the valve body on the pump using new gaskets. -

Page 10: Pilot Valve

REASSEMBLY All procedures for reassembling the pump are the reverse of the previous instructions with further instructions as shown: 1. The diaphragm assemblies are to be installed with the natural bulge outward or toward the head of the center screw. Make sure both plates are installed with outer radii against the diaphragm. -

Page 11: Service Instructions: Troubleshooting

TROUBLESHOOTING - For additional information, see the Warren Rupp Troubleshooting Guide. PROBLEM Pump cycles but will not pump. (Note: higher suction lifts require faster cycling speed for priming.) POSSIBLE CAUSES: A. Air leak in suction line. B. Excessive suction lift. -

Page 12: Material Codes

Glass Filled Polypropylene; Color: BLACK Nickel Plated Unfilled Polypropylene; Color: NATURAL PortaPump, Tranquilizer and SludgeMaster are Filled Nylon Polyvinyl Chloride registered tradenames of Warren Rupp, Inc. Food Grade Santoprene; Color: NATURAL Black Vinyl hdf3mdl2sm-rev0316 Model HDF3-M & HDF4-M Page 10 Tel: 866-777-6060 Springer Pumps, LLC Website: www.springerpumps.com... -

Page 13: Composite Repair Parts List

SERVICE AND OPERATING MANUAL Models HDF3-M & See pages 16 & 17 HDF4-M Type 2 II 2GD T5 for ATEX ratings ITEM TOTAL PART NUMBER DESCRIPTION RQD. 070.006.170. Bearing, Sleeve 114.002.010. Bracket, Intermediate 132.022.360. Bumper 135.016.162. Bushing, Threaded, with O-Ring 620.011.114. - Page 14 ITEM TOTAL PART NUMBER DESCRIPTION RQD. 360.014.379. Gasket, Flange 360.014.384. Gasket, Flange 670.006.115. Retainer, Flap Valve 807.016.330. Stud 170.023.330. Capscrew, Hex Head 545.007.330. Nut, Hex 807.018.110. Stud 547.002.115. Nut, Stop 334.020.000. Flange, Follower 360.021.000. Gasket 170.055.330. Capscrew, Hex Head 901.006.330. Flat Washer 170.095.330.

-

Page 15: Composite Repair Drawing

USE WITH HDF4-M ONLY ©2010 Warren Rupp, Inc. All rights reserved. ®SANDPIPER are registered tradenames of Warren Rupp, Inc. hdf3mdl2sm-rev0316 Model HDF3-M & HDF4-M Page 13 Tel: 866-777-6060 Springer Pumps, LLC Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910... -

Page 16: Ce Declaration Of Conformity - Machinery

Warren Rupp, Inc. (“Warren Rupp”) warrants to the original end-use purchaser that no product sold by Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands... -

Page 17: Ce Declaration Fo Conformity - Atex

The objective of the declaration described is in conformity with the relevant Union harmonisation legislation: Directive 94/9/EC (until April 19, 2016) and Directive 2014/34/EU (from April 20, 2016). Manufacturer: Applicable Standard: EN13463-1: 2001 Warren Rupp, Inc. A Unit of IDEX Corportion EN13463-5: 2003 800 North Main Street EN60079-25: 2004 P.O.

Need help?

Do you have a question about the Sandpiper HDF3-M and is the answer not in the manual?

Questions and answers