Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

ISO 9001 Certified

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

Tel: 866-777-6060

Fax: 866-777-6383

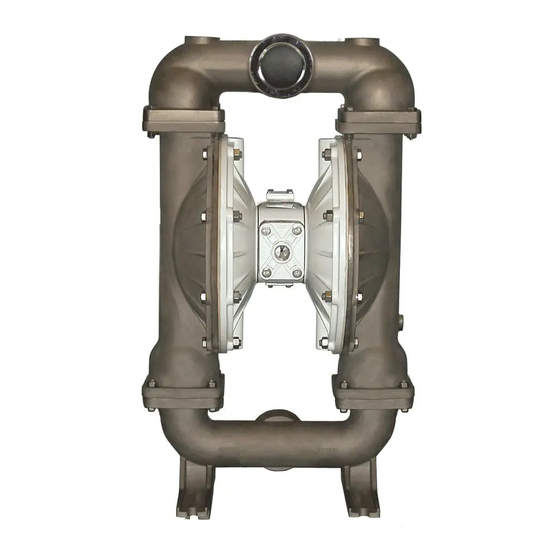

Model T30

Food Processing Metallic

Design Level 1

Springer Pumps, LLC

.

s a n d p i p e r p u m p

c o m

Website: www.springerpumps.com

Int'l: +001 267 404 2910

Advertisement

Table of Contents

Summary of Contents for Warren rupp SANDPIPER T30 Series

- Page 1 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867 SANDPIPERPUMP.COM © Copyright 2017 Warren Rupp, Inc. All rights reserved s a n d p i p e r p u m p c o m Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com...

- Page 2 The use of non-OEM replacement parts will void (or negate) agency certifications, including CE, ATEX, CSA, 3A and EC1935 compliance (Food Contact Materials). Warren Rupp, Inc. cannot ensure nor warrant non-OEM parts to meet the stringent requirements of the certifying agencies.

-

Page 3: Table Of Contents

MODEL SPECIFIC Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Explanation of Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ..5 • Principle of Pump Operation • Recommended Installation Guide • Troubleshooting Guide SECTION 3: EXPLODED VIEW ......8 •... -

Page 4: Explanation Of Nomenclature

MODEL SPECIFIC Explanation of Pump Nomenclature Your Model #: T __ ____ ____ (fill in from pump nameplate) Pump Pump Check Design Wetted Diaphragm/ Check Valve Non-Wetted Porting Pump Muffler Pump Brand Size Valve Level Material Check Valve Seat Material Options Style Options... -

Page 5: Performance

MODEL SPECIFIC UNIVERSAL ALL AODD Performance T30 METALLIC MODEL G30 Metallic Performance Curve SUCTION/DISCHARGE PORT SIZE Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. •... -

Page 6: Dimensional Drawings

Dimensional Drawings T30 Metallic Dimensional Tolerance:±1/8" 16.72 15.75 FRONT VIEW SIDE VIEW DISCHARGE PORT 4.22 4" SANITARY TRI-CLAMP FERRULE 33.30 32.30 29.96 30.96 17.14 SUCTION PORT 4" SANITARY TRI-CLAMP FERRULE 3.34 2.34 4X 2.46 4X .62 4.22 2.50 14.50 11.76 19.64 12.62 12.00... - Page 7 T30 Metallic Flanged Dimensional Tolerance:± 1/8" 16.72 15.75 FRONT VIEW 4.15 DISCHARGE PORT 3" RAISED FACE ANSI STYLE (150# LB) FLANGE OR 80 DIN (10 BAR) FLANGE 36.75 35.75 31.84 32.84 SUCTION PORT 3" RAISED FACE ANSI STYLE (150# LB) FLANGE OR 80 DIN 19.00 (10 BAR) FLANGE 5.18...

-

Page 8: Principle Of Pump Operation

UNIVERSAL ALL AODD Principle of Pump Operation Air-Operated Double Diaphragm (AODD) pumps are powered by compressed air or nitrogen. The main directional (air) control valve distributes ① compressed air to an air chamber, exerting uniform pressure over the inner surface of the diaphragm . -

Page 9: Recommended Installation Guide

UNIVERSAL ALL AODD, EXCEPT FLAP Recommended Installation Guide Available Accessories: 1. Surge Suppressor Unregulated Air Supply to Surge 2. Filter/Regulator Surge Suppressor Suppressor 3. Air Dryer Pressure Gauge Shut-Off Valve Note: Surge Suppressor and Pipe Connection (Style Optional) Piping must be supported after the flexible connection Flexible Connector Discharge... -

Page 10: Troubleshooting Guide

UNIVERSAL ALL SANDPIPER, EXCEPT FLAP Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds air Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure). (Does not apply to high pressure 2:1 units). -

Page 11: Composite Repair Parts Drawing

MODEL SPECIFIC Composite Repair Parts Drawing Torque: 90 in. lbs. ITEM NO. (10 N-m) Torque: 360 in. lbs. (Alum and Stainless) (40 N-m) 500 in. lbs. (Cast Iron) (56 N-m) Torque: 90 in. lbs. (10 N-m) PTFE FITTED Torque:Plate to Plate 60 Ft-lbs (720 In-lbs) Elastomeric 80 Ft-lbs (960 In-lbs) Santoprene and PTFE Service &... -

Page 12: Composite Repair Parts List

MODEL SPECIFIC Composite Repair Parts List Item Part Number Description Item Part Number Description 031.183.313 Air Valve Assy (w/ aluminum center-epoxy coated) 518.143.110 TC Manifold, Suction - 4" Tri-Clamp 031.179.000 Air Valve Assy - Stainless Center 518.144.110 TC Manifold, Discharge - 4" Tri-Clamp 050.014.351 Ball, Check - FDA Santoprene 545.007.115... -

Page 13: Material Codes

UNIVERSAL ALL SP Material Codes - The Last 3 Digits of Part Number 000..Assembly, sub-assembly; 364..EPDM Rubber • Delrin and Hytrel are registered tradenames of E.I. DuPont. and some purchased items Color coded: BLUE 010..Cast Iron 365..Neoprene Rubber • Nylatron is a registered tradename 015..Ductile Iron Color coded: GREEN of Polymer Corp. -

Page 14: Air Distribution Valve Assembly

Air Distribution Valve Assembly Air Distribution Valve Servicing Air Valve Assembly Parts List See repair parts drawing, remove screws. (Use w/Aluminum centers only) Item Part Number Description Step 1: Remove Hex Head Cap Screws (1-F). 031.183.313 Air Valve Assembly 1-A 095.109.313 Body, Air Valve Step 2: Remove end cap (1-E). -

Page 15: Pilot Valve Assembly

MODEL SPECIFIC Pilot Valve Assembly Pilot Valve Servicing Pilot Valve Assembly Parts List With Pilot Valve removed from pump. Item Part Number Description Step 1: Remove snap ring (4-F). 095.110.313 Pilot Valve Assembly Step 2: Remove sleeve (4-B), inspect O-Rings (4-C), 4-A 095.095.313 Valve Body 4-B... - Page 16 MODEL SPECIFIC Intermediate Assembly Drawing Intermediate Repair Parts List Intermediate Assembly Drawing Item Part Number Description Step 1: Remove plunger, actuator (29) from center of 114.024.313 Bracket, Intermediate intermediate pilot valve cavity. 114.024.110 Bracket, Intermediate Step 2: Remove Ring, Retaining (30), discard. 135.034.506 Bushing, Plunger 560.001.360...

- Page 17 Diaphragm Service Drawing, Non-Overlay sandpiperpump Model T30 Metallic • t30mdl1sm-rev0717 Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

-

Page 18: Diaphragm Servicing

UNIVERSAL ALL SP Diaphragm Servicing Step 1: With manifolds and outer chambers Step 8: On opposite side of pump, thread the removed, remove diaphragm assemblies from remaining assembly onto the diaphragm rod. Using a diaphragm rod. DO NOT use a pipe wrench or similar torque wrench, tighten the assembly to the diaphragm tool to remove assembly from rod. - Page 19 Warren Rupp, Inc. (“Warren Rupp”) warrants to the original end-use purchaser that no product sold by Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory.

- Page 20 UNIVERSAL ALL SP Declaration of Conformity Manufacturer: Warren Rupp, Inc., 800 N. Main Street, Mansfield, Ohio, 44902 USA certifies that SANDPIPER Air-Operated Double Diaphragm Food Processing Pump Models ® and Tranquilizer Surge Suppressor Models comply with the European Community Regulations: ®...

Need help?

Do you have a question about the SANDPIPER T30 Series and is the answer not in the manual?

Questions and answers