Summary of Contents for CORNING Videodrop

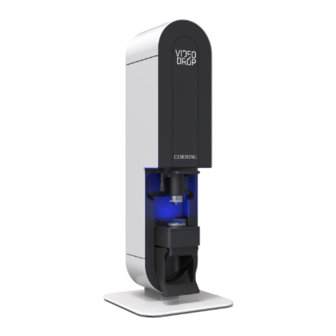

- Page 1 Corning Videodrop ® A device for measuring the size and concentration of nanoparticles in real time and in one drop Instruction Manual Catalog Number: VD-1000...

-

Page 2: Table Of Contents

1.0 Introduction ..........1 6.0 Videodrop Measurement Workflow ..... 12 1.1 Symbols and conventions . -

Page 3: Introduction

Instruction Manual that is as accurate as possible, it may contain technical inaccuracies and/or typographical errors. Corning cannot be held liable for any loss of profit, loss of business, loss of data, business interruption, or for indirect, specific, accidental, or consequential damages of any kind. In the event of damage occurring as a result of a defect (imperfection) or error contained in this Instruction Manual, Corning agrees to send the user a paper or electronic document containing the corrections applied as soon as possible. -

Page 4: Safety Precautions / Mesures De Sécurité

blessures aux yeux peuvent en résulter. Groupe de risque 3. Lors de l’utilisation de l’appareil, utilisez les lunettes de protection fournies. N’abaissez PAS la plate-forme d’échantillonnage et la poignée pendant que l’instrument effectue une mesure. CORNING VIDEODROP... -

Page 5: Electromagnetic Safety / Sécurité Électromagnétique

by Corning. It is strictly forbidden for any third party other than a technician authorized by Corning to open or modify the device. Il est strictement interdit de faire réaliser des opérations de maintenance par un tiers autre qu’un technicien agréé par Corning. -

Page 6: Indications And Precautions For Use / Indications Et Précautions D'utilisation

Safe use is no longer guaranteed in the following cases (non-exhaustive list): The device is visibly damaged. The device is no longer working. After prolonged storage under unfavorable conditions (see Section 10.0). After serious damage suffered during transport. CORNING VIDEODROP... -

Page 7: Safety Related To Maintenance / Sécurité Associée À La

L’appareil sera confié à des techniciens agréés pour inspection. Pour plus d’informations, contactez Videodrop@corning.com. 3.5 Safety related to maintenance / Sécurité associée à la maintenance For all maintenance operations, users will contact Corning by submitting a detailed email message to Videodrop@corning.com, which will then dispatch an authorized technician. - Page 8 Recommendations: Before switching on the LED (Clicking on Record, Preview, or Adjust saturation), always make sure that: The sample holder is placed on the Videodrop. • The handle is in the upper position. • The protective shield is in the lower position.

- Page 9 Blue light risk and thermal retinal risk are 2 types of risks associated with this 450 nm LED. Le risque lumière bleue et le risque rétinien thermique sont les 2 types de risques associés à cette LED 450 nm. No Risk / Risk Group 1: Risk Group 2: Risk Group 3:...

-

Page 10: Overview

PC computer with qvirCLS software installed* PC power cord Monitor Display port video cable Screen power cord Keyboard Mouse Mouse pad (optional) *qvirCLS software will be installed by a Corning technician after purchase. CORNING VIDEODROP... -

Page 11: Front View

5. Lens adjustment micrometer This micrometer is used to adjust the height of the optical system in relation to the sample. This adjustment is initially performed during installation by Corning authorized personnel. It must not be modified by the end user. -

Page 12: Rear View

Connections of the system are performed during the installation by Corning-authorized personnel. 5.1.1 Power supply The Videodrop and the computer must be connected to a main socket using the power cords supplied. 5.1.2 Control interface Connect the USB 2.0 (59.1 in./1.5 m) cable by connecting: The male micro B port to the Videodrop rear female connector: ... -

Page 13: Power

If the slide is not correctly positioned, it can be damaged. 3. Place the upper part of the sample holder and fasten it into position. 5.4 Maintenance Corning recommends an annual preventive maintenance be performed by Corning authorized staff. Instruction Manual... -

Page 14: Videodrop Measurement Workflow

6 .0 Videodrop Measurement Workflow 6.1 Sample loading This schematic details how to load a sample in the Videodrop to perform a measurement. 1. Lower the handle to lower the sample platform. 2. Remove the LED cover. 3. Deposit the sample droplet (5 to 10 µL) to analyze with a pipet in the well centered on the sample slide mounted in the sample holder. -

Page 15: Record And Export A Measurement

After each experimenter. After each type of sample if needed. After the measurement is stopped in the Videodrop software interface. 1. Lower the sample platform using the handle. 2. Raise the protective shield. 3. The sample holder is now accessible. -

Page 16: Software

NOTE: You will not be able to change the sample temperature and viscosity once the sample is created. Kestin J, Sokolov M, Wakeham WA. Viscosity of liquid water in the range -8 °C to 150 °C. JPCRD 7, 941-948 (1978). CORNING VIDEODROP... -

Page 17: Main Interface

3. ADD A COMMENT This optional box allows you to add a comment. For example, you can add your dilution factor. This field is accessible and can be modified during the measurement at any time until export of the results. 4. -

Page 18: Start/Stop A Measurement

The targeted number of particles to track is reached. This video and measurement data are buffered. The maximum number of videos is reached. When Stop is clicked on, the following pop-up appears until the processing of the last video is done. CORNING VIDEODROP... -

Page 19: Export Measurement Results

7.2.2 Export measurement results Export options Click EXPORT to save your data. QvirCLS offers several export options detailed in the table below. Format Description/Content Size* Open with .qvirx Contains all measurement results. 12 Mb qvirCLS 2.7.2 and further versions only Contains only the last image of the last video. - Page 20 The image displayed in the PDF report is the imaged displayed on the software interface when Export is clicked (Raw, processed, or mixed). An example of the PDF report. CORNING VIDEODROP...

-

Page 21: Create A New File

Export file Select the formats you want to save by checking the corresponding boxes and click OK. Choose the folder location where the selected elements will be saved. The folder name is by default: DATE(YYYYMMDD)_HOUR(HHMMSS)_SAMPLE NAME It can be modified when confirming the folder name before Saving. -

Page 22: Main Interface Parameters

The software will do videos one after the other and accumulate tracked particles until it reaches this number. When this number (or the maximum number of videos in a measurement) is reached, the measurement stops. Range: 0 to 10,000 (tracked particles). CORNING VIDEODROP... - Page 23 DISPLAY Display settings do not modify the results of the measurement, they only modify the visualization. Raw/Processed The slider allows to continuously switch from the Raw image to the Processed image. Raw image. Image captured by Processed image. Image after image the camera without any image processing where nanoparticles are visible.

-

Page 24: Results/Analysis

A window appears where the user can set the minimum size (x min) and the maximum size (x max). 7.2.7 Adjust saturation Camera saturation is displayed in the main window. Its value must be between 90% and 95%. The LED intensity is automatically adjusted between each video to ensure optimal camera saturation. CORNING VIDEODROP... -

Page 25: Advanced Settings (System)

To quickly adjust the LED intensity, there is a dedicated tool called Adjust Saturation. Click System and Adjust Saturation. It will automatically adjust the LED intensity value to reach optimal camera saturation. Once the saturation reaches the recommended range, click OK to close the Adjust Saturation window and go back to the measurement window. - Page 26 Check box. When checked, simultaneous display of the raw image and the processed image side by side. Combined ratio Degree of fade between the raw image and the processed image, corresponds to the position of the cursor in the main interface. Range: 1 to 100. CORNING VIDEODROP...

-

Page 27: Administration

Usernames, sample names are anonymized. Troubleshooting report will be asked by Corning or Corning representative in case of after sale service issues. The Regulated Environment license features and activation procedure are detailed in detailed in the VD-1000-AT instruction manual. -

Page 28: Additional Information

7.5 Additional information For more information on the Videodrop, click on About. The software version and Videodrop serial number are displayed in this window. 7.6 Warning and Error messages 7.6.1 Warning messages The following table summarizes the warning messages that can be displayed in qvirCLS. - Page 29 Load feature is disabled during measurement recording. Measurement aborted because of saturation decrease. The Videodrop detected a saturation decrease during a measurement. It can be due to the opening of the Videodrop. For Check the upper slide/drop contact. optical safety reason, the measurement has been aborted. Follow Make sure sample platform is in upper position.

-

Page 30: Error Messages

7.6.2 Error messages The following table summarizes the error messages that can be displayed in Videodrop. Warning/Information Message Meaning/Recommendations error 4 - Export failed Contact Corning support team (Videodrop@corning.com) or your local representative. error 5 - Export failed error 6 - Camera initialization error... -

Page 31: Switch Off The Device

If this error occurs often, verify USB camera connection cable and/or contact Corning support team (Videodrop@corning.com) or your local representative. Should you have a question about the operation of the Corning® Videodrop, qvirCLS, or if service is required, please email Videodrop@corning.com. 8.0 Switch Off the Device Always switch Off the device in the following sequence: Remove the sample holder from the Videodrop, and discard it accordingly with adapted waste disposal procedure. -

Page 32: Recommended Cleaning Products

9.3 Recommended cleaning products Corning recommends the following products: Pure water, soapy water, 70% Ethanol. Neutral pH detergent (pH 5-8). Recommended disinfection solution (see below) following the specific supplier recommendations. The prohibited cleaning products are: Abrasives (“Cif” type and scouring powders) ... -

Page 33: Technical Specifications

1 USB cable 3.0 micro B (2 m) Consumables Boxes of sample slides 1 box of 50 sample slides Packaging Videodrop parcel and protective foam 34.9 x 16.8 x 15 in. (88.5 x 42.5 x 38 cm) (L x W x H) Instruction Manual... - Page 34 192 mm 180 mm 300 mm 300 mm CORNING VIDEODROP...

-

Page 35: Regulations

(objective protective cover), or damage to paint or finish. Claims for transit damage should be filed with the transportation carrier. In the event this product fails within the specified period of time because of a defect in material or workmanship, contact Corning Customer Service at: USA/Canada 1.800.492.1110, outside the U.S. - Page 36 Not for use in humans. These products are not intended to mitigate the presence of microorganisms on surfaces or in the environment, where such organisms can be deleterious to humans or the environment. Corning Life Sciences makes no claims regarding the performance of these products for clinical or diagnostic applications.

Need help?

Do you have a question about the Videodrop and is the answer not in the manual?

Questions and answers