KYOWA WGA-910A Instruction Manual

Instrumentation amplifier

Hide thumbs

Also See for WGA-910A:

- Instruction manual (150 pages) ,

- Instruction manual (44 pages) ,

- Instruction manual (40 pages)

Advertisement

Generally, company names and trade names described in this Instruction Manual are trademarks or registered

trademarks of the companies.

This Instruction Manual may not be copied or reproduced, in whole or part, without consent of KYOWA.

Copyright © Kyowa Electronic Instruments Co., Ltd. All rights reserved.

The contents of the Instruction Manual are subjected to change without prior notice.

Please follow the safety precautions and other precautions described in this manual.

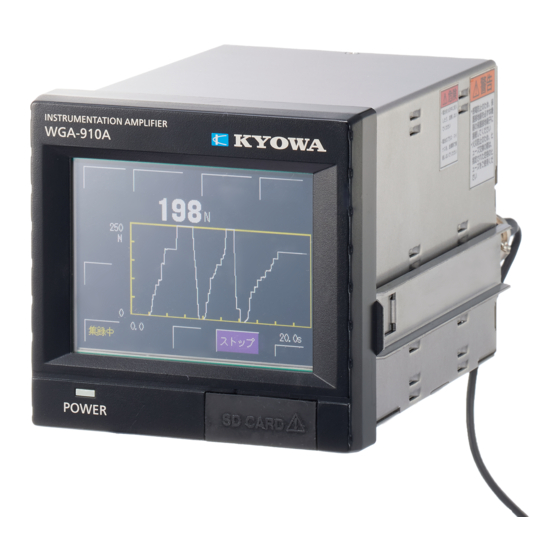

INSTRUMENTATION AMPLIFIER

Thank you for purchasing KYOWA's product WGA-910A Instrumentation

Amplifier.

Read this Instruction Manual carefully in order to make full use of the high

performance capabilities of the product.

Do not use the product in methods other than described in this Manual.

INSTRUCTION MANUAL

IM-A-1140E December 2023

WGA-910A

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KYOWA WGA-910A

- Page 1 Generally, company names and trade names described in this Instruction Manual are trademarks or registered trademarks of the companies. This Instruction Manual may not be copied or reproduced, in whole or part, without consent of KYOWA. Copyright © Kyowa Electronic Instruments Co., Ltd. All rights reserved.

- Page 3 OPTIONS···································································································································· 1 SAFETY PRECAUTIONS ··············································································································· 2 PRECAUTIONS ON CE MARKING ································································································· 5 NOTATIONS USED IN THE INSTRUCTION MANUAL ······································································· 6 IMPORTANT PRECAUTIONS WHEN USING WGA-910A ··································································· 6 1. OUTLINE OF PRODUCT ············································································································ 7 1-1. OUTLINE ··························································································································· 7 1-2. FEATURES ························································································································· 7 1-3.

- Page 4 6-3-3. Measure Mode Setting ····································································································· 67 6-3-4. Descriptions of the operation mode ····················································································· 78 6-3-5. How WGA-910A works with HOLD and RESET commands ····················································· 90 6-3-6. Relationship between control input and comparator output when the operation mode with two hold values ··························································································································...

- Page 5 8-4. OPERATION AND FUNCTION OF THE COM. SETTING (COMMUNICATION SETTING) ············ 175 9. TROUBLESHOOTING ············································································································ 177 9-1. POWER SWITCH CANNOT TURN ON THE WGA-910A ·························································· 177 9-2. DISPLAYING ERRORS ······································································································ 177 9-3. DISPLAY VALUE OR MONITOR OUTPUT DOES NOT CHANGE ············································· 180 9-4.

- Page 6 STANDARD ACCESSORIES The WGA-910A comes with the following standard accessories. When unpacking, check to be sure that all the listed accessories are included. Instruction Manual 1 (CD-R) *1 Product Warranty Software License Agreement *1. Including a PC software and a setting file for wave comparison mode.

- Page 7 (hereinafter referred to as the WGA-910A). For safe use of the WGA-910A, do not forget to read the “Safety Precautions” prior to use. Kyowa Electronic Instruments Co., Ltd. assumes no liability for any damages resulting from user’s failure to comply with the safety precautions.

- Page 8 Operators must be cautioned that use of an extension power cable with no ground conductor disables the protective ground function. Check the Instruction Manual in advance, connect the power cable to the WGA-910A and connect the power plug to an outlet.

- Page 9 After the power ON, always preheat the product for approximately 30 minutes. ● Cleaning. When the product gets dirty, clean the product with a dry soft cloth. When dust exists inside the WGA-910A, clean it by using an air blow gun. Do not touch electronic parts.

- Page 10 CAUTION SD cards ●The capacity of the SDHC card, compatible to the product, is up to 32 GB. The product does not support the SDXC cards 64 GB or more. Never insert the SDXC cards 64 GB or more. ●About the setting file for wave comparison mode. This file is for which the saved comparison waveform data is saved.

- Page 11 Essential precautions required when handling the product. MEMO Reference items required when handling the product. IMPORTANT PRECAUTIONS WHEN USING WGA-910A NOTE The output signal (voltage/current) when the transducer cable is broken. When the transducer cable is broken, the product may output the following output signal (voltage/current).

- Page 12 ・Capable of editing a setting value and saving it to the SD card. ●Updating the firmware ・Capable of updating the firmware by loading the written program in the SD card after mounting the WGA-910A to a control panel. ●Various checking functions ・Capable of checking the WGA-910A and sensor.

-

Page 13: Table Of Contents

1-3. MODEL The WGA-910A series has 6 models including the optional units. Customers are required to purchase the products compatible to you. The number of channels, Model Option input format WGA-910A-0 None WGA-910A-1 WGA-910A-2 Load (strain) WGA-910A-3 RS-485 WGA-910A-4 CC-Link WGA-910A-12 BCD・D/A... - Page 14 2. CONTROLS AND FUNCTIONS 2-1. FRONT PANEL 2-1-1. Measuring Window (Number) Swi t ch Hol d Zer o Det ect i ng M easur e 1 Hol di ng Ti m e Peak 999. 99 500. 00 - 150. 00 - 999.

- Page 15 2-1-2. Measuring Window (Zoom In Number) Swi t ch Zer o Switch key Display changes in order from “Number” - “Zoom in number” - “Waveform” by pressing the Switch key. Comparator status lamp When turning ON the comparator outputs, the [HH] and [HI] light up in red, [OK] lights up in white, and [LO] and [LL] light up in yellow.

- Page 16 2-1-3. Measuring Window (Waveform) Cursor ON key The “Cursor” window appears to display a cursor. Switch key Display changes in order from “Number” - “Zoom in number” - “Waveform” by pressing the Switch key. Measured value Displays a measured value with unit. Y axis end point Displays the end point of the Y-axis that is set in the “Y-axis setting”...

- Page 17 2-1-4. Measuring Window (Cursor) Swi t ch Cur sor O FF Det ect M ove 300.00 -200.00 10.0 Cur sor Cursor OFF key The cursor disappears and gets back to the “Waveform display” window. Switch key The Switch key is displayed in gray and no key operation can be performed. Measured value Displaying a measurement waveform data (value of the Y-axis) at the yellow point on the cursor.

- Page 18 2-1-5. Measuring Window (Number) Swi t ch Hol d Zer o Det ect i ng Hol di ng Bl ock Peak-Bot t om M easur e 1 Peak HI -1 500. 00 LO -1 -999. 99 Bot t om HI -2 500.

- Page 19 2-1-6. Measuring Window (Zoom In Number) Swi t ch Zer o Peak Bot t om Switch key Display changes in order from “Number View Dual Display” - “Zoom In Number View Dual Display” - “Waveform View Dual Display” by pressing the Switch key.

- Page 20 2-1-7. Measuring Window (Waveform) Swi t ch Cur sor O N W ave Cl ear Peak Bot t om 903. 17 -245. 68 300.00 Y-axi s -200.00 10.0 REC O N X-axi s St ar t LO CK Cursor ON key The “Cursor”...

- Page 21 Manufacture: TAJIMI ELECTRONICS CO., LTD. Pin No. Signal Name +BV (Red) -SIG (White) -BV (Black) +SIG (Green) Shield TEDS (+) (Yellow) TEDS (-) (Blue) Connector pin assignment of the WGA-910A MEMO Cable colors described the above are KYOWA’s standard color codes.

- Page 22 Cover: FCN-360C008-B FUJITSU COMPONENT LINITED Pin No. Signal Name Connector pin assignment of the WGA-910A Protective grounding terminal To prevent an electronic shock hazard, be sure to ground the terminal. Fitting metal For mounting a panel. Terminal board for monitor...

- Page 23 ・Never connect the signals to reserve pin. MEMO The pin No. 9 [Healthy] is for checking the power (ON) of the WGA-910A. The open collector output becomes ON when turning ON the WGA-910A and becomes OFF when turning OFF the WGA-910A. (*1) The pin No.

- Page 24 3. CONNECTION 3-1. PROCEDURES FOR MEASUREMENTS This section describes necessary operations to be conducted prior to the actual measurements. Section 3-2 To mount the WGA-910A Mount the WGA-910A on the panel. on the panel ↓ Section 3-3-1 To connect transducers Connect various transducers to the WGA-910A.

- Page 25 3-2. INSTALLATION ONTO A PANEL To install the WGA-910A to a panel, prepare the panel according to the specified panel cut dimensions shown at the right. Then, install the WGA-910A by referring to the following instructions. 1) Cut out the panel according to the panel cut dimensions.

- Page 26 3-3-1. Connecting transducer ・Input connector is NDIS one-touch connector. ・When using a KYOWA’s transducer with the NDIS standard connector at the tip of the cable, the both TEDS- compatible and non-TEDS-compatible sensors (excluding six-wire system remote sensing) can be directly connected to an input connector ・When using the KYOWA’s sensor without a connector at the tip of the cable or when using other manufactures...

-

Page 27: Model

3-3-2. Connecting Control Input ・Compatible connector of the cable side is as follows. Connector PCR-S36FS+ Manufacture: HONDA TSUSHIN KOGYO CO., LTD. model: Case model: PCR-LS36LA Manufacture: HONDA TSUSHIN KOGYO CO., LTD. ・Pin numbers and signal names of the control input are as follows. Pin No. - Page 28 3-3-3. Connecting Control Output ・The control output signal is open collector output and sink type. ・Compatible connector of the cable side is as same as that of the control input side. ・Pin numbers and signal names of the control output are as follows. Pin No.

-

Page 29: Wga-910A-0

・Use a commercially available RS-232C/USB conversion adapter, etc. when there is no COM port for the RS-232C is attached to your PC. WGA-910A PC side: D-sub 9 pin NOTE Do not forget to turn OFF both WGA-910A and the external device before connection. Or, correct operation may not be obtained or may cause damage. - Page 30 ・In addition, for connecting more than 30-m long cable or using outdoors, take special countermeasures against noise. ・Do not solder the wire or mount the press-fit terminal. ・Be sure to turn OFF the WGA-910A before connecting cables. NOTE 2 ・Despite executing of no-load ZERO or digital zero, a monitor output does not change.

- Page 31 3-3-6. Connecting AC Power ■Connecting terminal block for AC power ・It is recommended to attach insulating coated press-fit terminals to the connecting wires. ・Remove a cover from the terminal board. ・Before connecting the solderless terminals and power cable, remove screws as described in the right figure. ・After completing terminal block wirings, do not forget to cover the terminal block.

- Page 32 Before connecting the power cable to the AC outlet, check the power voltage. The operating power voltage of the WGA-910A is from 100 to 240 VAC, 50/60 Hz, 20 VA or less. Be sure to keep this operating power voltage.

- Page 33 3-4. SD Card ・Capable of updating a setting value of the WGA-910A by reading the setting value that is saved in the SD card. ・Capable of saving the setting value of the WGA-910A in the SD card. ・Capable of saving a recorded waveform in the SD card by pressing the Start key on the “Waveform” window.

- Page 34 4. BASIC OPERATION PROCEDURES 4-1. SETTING TREE Bridge voltage No-load Zero Manual Input Cal. Sens. Regist. Cal. TEDS Auto Cal. Actual Load Cal. TEDS Part Cal. Unit Calibration TEDS Reading Ope. TEDS Ope. Setting ZERO during TEDS Numeric Reg. Cal. TEDS Info.

- Page 35 X-axis Setting X-axis End P. Y-axis Start P. Y-axis Setting Y-axis End P. Start Mode of Wave Wave Display Setting Passed Level Level Passed Way Key Lock Hold Time of Wave Set Initialize Meas. Select Signal Backlight Time System Language Clock Comp.

- Page 36 4-2. CONFIGURING WINDOWS OUTLINE <Number> <Zoom in Number> <Waveform> Swi t ch Cur sor O N W ave Cl ear 300.00 Y-axi s -200.00 10.0 REC O N X-axi s St ar t LO CK < When an operation mode with two hold values is selected > Swi t ch Cur sor O N W ave Cl ear...

- Page 37 4-3. BASIC OPERATION OF SETTING Setting windows appear as follows. Measuring 1) Reading the setting window Window Press the Set key on the “Measuring” window. Setting 2) Select main item Window Press the target main item key on the “Setting” window. Main item key Main item 3) Select each item...

- Page 38 4-4. HOW TO OPERATE WAVEFORM AND CURSOR WINDOWS ■“Waveform” window Press the Start key. Displaying waveform starts when conditions which were set in the “Waveform” window are satisfied. After pressing the Start key, the key changes to the Stop key. Press the Stop key to stop loading the waveform data. While loading the waveform, no key operation other than the Stop key can be performed and all keys other than the key are displayed in gray.

- Page 39 ■“Cursor” window While stopping the loading of the waveform, press the Cursor ON key to display the “Cursor” window. Detect Move Key Cursor OFF Key The cursor moves directly to the Gets back to the “Waveform” Detecting point. When detecting the two hold values, as you press the key, the detecting Displays the data of the Y-axis point changes as the Hold value1 →...

- Page 40 5. CALIBRATION 5-1. OUTLINE OF CALIBRATION The WGA-910A has 4 calibration methods; manual input calibration, TEDS-based automatic calibration, partial calibration based on TEDS calibration data, and numeric value registering calibration. Manual input calibration: Enters the calibration data manually. The manual input calibration includes the "Sensitivity registering calibration" that calibrates data by registering a sensitivity value written in the test data sheet of transducers and "Actual load calibration"...

- Page 41 5-2. PROCEDURES OF CALIBRATION Measuring Window Setting Window Calibration Window Manual Input TEDS-based Partial Calibration Numeric Regist Cal. Calibration Automatic based on TEDS Calibration Calibration Data Manual Input Cal. TEDS TEDS Numeric Auto Part Regist Cal. Bridge Voltage TEDS Auto Cal. No-load ZERO TEDS Part Cal.

- Page 42 5-3. HOW TO CALIBRATE 5-3-1. Calibration Window <How to operate> 1) Press the Set key on the “Measuring” window. 2) Press the Calibration key on the “Setting” window. 5-3-2. Manual Input Calibration Conducts calibration by manual setting in order of excitation voltage, no-load zero, Sensitivity registering calibration or in order of actual load calibration and unit.

- Page 43 (2) No-Load ZERO Loads the output voltage of the sensor with no-load applied and registers it as a reference of a total zero. No-load zero adjustment range is same with the measuring range. <Setting range> (-3.2000 to +3.2000 mV/V; display only) <How to operate>...

- Page 44 (3-a) Sensitivity Regist. Cal. (Sensitivity Registering Calibration) Inputs the rated capacity and rated output described in the Test Data Sheet for equivalent calibration with the actual load when the actual load cannot be applied to the sensor. Suppose that you are using a transducer with the “Rated Capacity: 200 kN”...

- Page 45 3) Press the Register key. The “Sens. Registering” window on the upper left blinks and the “Rated Output” is registered. Sens. Regi s- Sensi t i vi t y r eg- Ret ur n i st er i ng t er i ng Blinks Rd.

- Page 46 (3-b) Actual Load Cal. (Actual Load Calibration) Actual load is applied to the sensor for the calibration. Displays the output when an actual load is applied as the rated output. Suppose that you are using a transducer with the “Rated Capacity: 200 kN” and “Rated Output: 2.0040 mV/V.”...

- Page 47 (4) Unit Set the target unit. Refer to “11-2 UNIT LIST” for available unit. In order to display “kgf,” do as follows. <Setting range> Refer to “11-2 UNIT LIST.” <How to operate> 1) Select the type of the unit first and press the target key. Uni t 4 / 4 Ret ur n...

- Page 48 5-3-3. TEDS Auto Cal. (TEDS-based Automatic Calibration) The calibration is automatically conducted by reading the required information for the calibration (applied voltage, rated output, and unit) from the TEDS built-in sensor and the calibration data that is saved inside is overwritten. However, the “TEDS-based Automatic Calibration”...

- Page 49 NOTE “TEDS Error” window blinks when the TEDS information cannot read correctly or TEDS information value is out of specifications. After stopping the reading of the TEDS information, the “TEDS Error” window blinks approx. 3 seconds. After that, the current calibration value is displayed. At this time, the calibration value is not updated.

- Page 50 5-3-4. TEDS Part Cal. (Partial Calibration Based on TEDS Calibration Data) Only the selected information from the TEDS built-in sensor (select one or multiples from the applied voltage, rated display, rated output, unit) is updated the calibration data that was saved internally and calibrated automatically. However, the “Partial Calibration Based on TEDS Calibration Data”...

- Page 51 6) The calibration starts and the “TEDS Calibration” window on the TEDS Cal i - Conduct i ng TEDS Ret ur n M easur e Cal i br at i on br at i on upper left blinks. Ex. Vol t . Rd.

- Page 52 5-3-5. Numeric Value Registering Calibration The numeric value registering calibration calibrates data by changing the initial value. Execute the numeric value registering calibration after the actual load calibration and sensitivity registering calibration. The numeric value registering calibration is used for pressure transducers for absolute pressure measurement or when already load is applied and unable to obtain the actual load state.

- Page 53 MEMO When executing the numeric value registering calibration with communication during measurements or settings, the 【Registering ini. val.】 window blinks Regi st er i ng Regi st er i ng Swi t ch Hol d Zer o M easur e i ni .

- Page 54 NOTE The zero point value that is obtained by the key operation is maintained even if the WGA-910A is turned OFF. 3) After conducting the digital zero and gets back to the “Measuring” window, the Zero key changes to yellow.

- Page 55 At that time, it is required to conduct the digital zero again after turning ON the WGA-910A. 6-1-2. TEDS Ope. Setting (Setting TEDS Operation) The TEDS function of the WGA-910A reads the applied voltage, rated output, rated capacity, and unit from the TEDS built-in sensor and automatically calibrates them.

- Page 56 <How to operate> 1) Press the TEDS Info. Display key on the “TEDS Ope. Setting” window. 2) After pressing the Read key, the WGA-910A starts reading the TEDS I nf o. Di spl ay Ret ur n M easur e...

- Page 57 (4) Supplemental explanations of the TEDS function (1) Executing the TEDS calibration at the initial value. Set the sensor in no-load state and conduct the calibration with the TEDS. The no-load zero is automatically conducted and the display value is set to “0 (or additional value)” when the Execute is selected in the “ZERO during TEDS”...

- Page 58 Pay attention when using an extension cable to the sensor. ・Connecting non-TEDS-compatible sensor. After disappearing the “TEDS Error” display, the calibration value of the TEDS information is not applied and the WGA-910A operates with the calibration values that are registered before the TEDS calibration.

- Page 59 6-2. INPUT SETTING 6-2-1. Smoothing Smoothing is a function whereby fluctuations of the display values are made stable by eliminating unnecessary noise component. Though the most popular noise at the site is a hum noise due to the AC power, noise due to the motor in the control system also generates frequently.

- Page 60 (2) Minimum Scale (division) Sets the minimum digit that changes the number. However, the minimum scale not only suppresses the variation of the display value but also not to update the display value higher than the requiring resolution. Displays the setting values of the minimum scale according to the preset decimal position that was set in the rated display of the calibration.

- Page 61 (3) Moving Average Conducts the moving average for the preset times for filtering. <Setting value> None, 2, 4, 8, 16, 32, 64, 128, 256, 512, 1024, and 2048 times <How to operate> 1) Press the Moving Average key on the “Smoothing” window. 2) Press the △...

- Page 62 6-2-2. Zero Compensation Automatically corrects subtle zero point drifts. It effectively reduces measurement error inducible to zero drifts on a sensor or on the WGA-910A as well as zero drifts caused by deposits on a measuring object. (1) Zero Tracking Conducts digital zero and automatically sets the display value to “0”...

- Page 63 (2) Zero nearly zero Means least significant digit fixed at zero. Automatically sets the display number of the least significant digit (the rightmost digit) to “0” when the measuring value is within the setting range of + and - directions. The Min.

- Page 64 6-2-4. Original Value (Sensor Output Value) Displays the current output value of the sensor on the monitor. After pressing the Display key, the output value is measured for every 0.5 second and displayed in both units “mV/V” and “με.” <Setting Range> -3.2000 to 3.2000 (mV/V) (-6400.0 to 6400.0 με) <How to operate>...

- Page 65 6-3. MEAS. COND. SETTING (SETTING MEASURING CONDITION) Capable of storing setting values of the comparison setting and measuring mode setting to the measuring condition file and capable of changing the measuring condition No. by the key operation, control input, or communication command. The number of the measuring condition files is 32 for the key operation, 16 for the control input, and 32 for the communication command.

- Page 66 ■Switching the measurement conditions with the control input. For the “Control Input” on the “Meas. Select Signal” window only. Switch the ON/OFF of the control input’s “Measurement condition select 0 to 3” as the following table. Measuring Measurement Measurement Measurement Measurement Condition Condition...

- Page 67 6-3-2. Comparison Setting Compares a measured value with a compared value, and puts out the result. The comparison result is obtained from the control I/O connector as an open collector output. In addition, colors of the comparator status lamps on the “Measuring” window change. Capable of preventing chattering or erroneous operations of comparator outputs by setting hysteresis (non-sensitive zone) within a compared value.

- Page 68 <Direct operations from the “Measuring” window> 1) Press any of the HH HI LO LL key on the “Measuring” window. 2) The window changes to the setting window of the target compared HH Com par ed Val ue Ret ur n M easur e values.

- Page 69 (3) Comparator Out. Logic Common to all comparators. Sets the output logic (open collector logic) of comparators. <Setting Range> Negative Logic Comparator output is ON when the comparison result is ON. (Active low) Positive Logic Comparator output is OFF when the comparison result is OFF. (Active high) <How to operate>...

- Page 70 NOTE The comparator with selecting “Not use” in the “Using Comparator” window, compared value keys on the “Comparison Setting” and “Measuring” windows are invalid. For example, when selecting the HH and LL comparators to Unused, the HH Compared Value and LLCompared Value keys on the “Comparison Setting” window are invalid, the target keys, the current setting values, and the descriptions are displayed in gray.

- Page 71 (5) Relation between the comparator outputs and hysteresis width and behaviors of comparator status lamps. HH comparator (or HI1 comparator) When the measured value exceeds the HH compared value, the HH comparator output is turned ON and [HH] lamp lights up in red. When the measured value lowers the (HH compared value - hysteresis width), the HH comparator output is turned OFF and [HH]...

- Page 72 6-3-3. Measure Mode Setting Capable of setting various operating modes of the measurement. In addition, capable of setting the display mode and comparison mode. The measurement is controlled by the key and control inputs operations. In addition, operation statuses can be checked with the comparator status lamps on the “Measuring” window as follows.

- Page 73 Outline of each operation mode The outline of each operation mode is shown below. For detailed operation, refer to "6-3-4" onward. MEMO "Block *** Hold" is an operation to designate the detection block of hold value by control command or key operation. "Time *** Hold"...

- Page 74 Block Inflection Hold Specify the detection block with the control command or the like. In the detection block, the measuring value that suddenly changed is detected. Hold displays the point (inflection point) where the input suddenly changed in the detection block. Time Inflection Hold Specify the detection block with the setting value.

- Page 75 <How to operate> 1) Press the Set key on the “Measuring” window. 2) Press the Meas.Cond.Setting key on the “Setting” window. 3) Press the Measure Mode Setting key on the “Meas. Cond. Setting” window. M eas. Cond. Set t i ng Ret ur n M easur e 4) Press the Operation Mode key on the “Measure Mode Setting (1/3)”...

- Page 76 (2) Detect Time Sets the Detect Time is the width of the detection block when set to Time *** Hold. <Setting Range> 0.00 to 9.99 (sec) <How to operate> 1) Press the Detect Time key on the “Measure Mode Setting (1/3)” M eas.

- Page 77 ON at the time. The comparator output is turned ON when the display value is exceeding the HI compared value and the WGA-910A is in holding block. After resetting, the comparator output is turned OFF.

- Page 78 (5) Display Mode Selects the display operation of the hold value from the two modes. When "Normal", "Peak hold", "Bottom hold", "Arbitrary hold", “Pre.Comp.Peak” , “Pre.Comp.Bottom” are set in "Operation mode", "Display mode" setting is invalid. <Setting Range> Normal Disp. The hold value is always updated and displayed in response to changes of the input in the detecting block.

- Page 79 (6) Detection Trigger Level Sets the level for the trigger applied in “Inflection Hold” and “Maximal/minimal Hold”. M eas. Cond. Set t i ng Ret ur n M easur e <Setting Range> The oper at i on m ode of m easue- O per at i on M ode m ent i s set .

- Page 80 (8) Inflection point discrimination time Sets the time to discriminate the inflection point of the measured value. M eas. Cond. Set t i ng Ret ur n M easur e The oper at i on m ode of m easue- <Setting Range>...

- Page 81 (10) Extreme value discrimination setting Sets the width and magnitude to discriminate the Maximal value and minimal value. The setting is available in “Time MAX/min Hold”and “Block MAX/min Hold”. <Setting Range> Width: 1 to 99999 (count) Magnitude: 0.1 to 5.0 (times) M eas.

- Page 82 (11) Initial value for compare with measuring value in previous value comparing mode Sets the initial value to compare with measuring value in “Block/Time Previous Value Comparison *** Hold”. <Setting range> -99999 to 99999 (count) <How to operate> 1) Press the Next key on”Meas.Cond.Setting”window and display “Meas.Cond.Setting (3/3)”.

- Page 83 MEMO ・Short circuit the terminals between the Control I/O connector No. 35 or 36 (Input COM) and No. 20 (Hold Command). The hold command is turned ON and the WGA-910A operates with the preset measuring mode. ・Short circuit the terminals between the Control I/O connector No. 35 or 36 (Input COM) and No. 21 (Reset).

- Page 84 Press the Hold key the first time to hold the display value at the time. Though you cannot see, the WGA-910A is detecting the peak (bottom) value after the lapse of the delay time. Press the Hold key for the second time to display the peak (bottom) value until that moment.

- Page 85 Press the Hold key for the first time to hold the display value at the time. Though you cannot see, the WGA-910A is detecting the peak (bottom) value after the lapse of the delay time. After the lapse of the detecting block (detecting time), the peak value (bottom value) before then appears.

- Page 86 (5) Bottom Hold In the detection block, the Bottom value is detected and displayed. ●Settable items: “Delay time” (A) Behavior with control input signal When the HOLD command is turned ON and after the lapse of delay time, the bottom value is detected and indicated until the HOLD command is turned OFF.

- Page 87 (B) Behavior with key operation Press the Hold key for the first time to hold the display value at the time. Though you cannot see, the WGA-910A is detecting the peak value and bottom value after the lapse of the delay time.

- Page 88 Press the Hold key for the first time to hold the display value at the time. Though you cannot see, the WGA-910A is detecting the average value after the lapse of the delay time. Press the Hold key for the second time to hold the average value.

- Page 89 (9) Block Inflection Hold/ Time Inflection Hold <Behavior> When the delay time elapses after the hold command is turned on, the trigger wait state is entered. The measured value crosses the trigger level, it becomes the detection block. Measure the difference between "change in measured value at discrimination time t1" and "change in measured value at discrimination time t2"...

- Page 90 (α) Normal Display Mode (Block Inflection Hold) ●Settable items: “Delay Time”, “Comparison Mode”, “Display Mode”, “Detection trigger level, ”Detection trigger way”, ”Inflection point discrimination time”, ”Inflection point discrimination value” (A) Behavior with control input signal Wait for the trigger after the delay time has elapsed since the hold command was turned ON.

- Page 91 (10) Block Maximal, minimal Hold/Time Maximal, minimal Hold <Behavior> When the delay time elapses after the hold command is turned on, the trigger wait state is entered. The measured value crosses the trigger level, it becomes the detection section. The point A when the difference between the peak value A point and the bottom value B point in the detection section is greater than or equal to the extreme value discrimination width is a candidate for the maximum value.

- Page 92 (α) Normal Display Mode (Block Maximal / minimal Hold) ●Settable items: “Delay Time”, “Comparison Mode”, “Display Mode”, “Detection trigger level, ”Detection trigger way”, “Extreme value discrimination”, (A) Behavior with control input signal Wait for the trigger after the delay time has elapsed since the hold command was turned ON.

- Page 93 (11) Two point hold mode <Behavior> This mode performs a combination of Peak hold / Bottom hold and Averaging / Arbitrary point hold. Please check "6-3-3. Measure Mode Setting (1) Operation Mode" for hold value assignment. The function of the comparator switches as follows. When hold value 1 and hold value 2 are OK, OK lights up.

- Page 94 (B) Behavior with key operation Press the Hold key the first time to hold the display value at the time. Though you cannot see, the WGA-910A is detecting the peak value after the lapse of the delay time. Press the Hold key for the second time to display the peak value until that moment.

- Page 95 6-3-5. How WGA-910A works with HOLD and RESET commands The WGA-910A works as follow during detecting, holding, and normal blocks by turning ON/OFF the “HOLD command” and “RESET command.” [Example] Block-specified peak...

- Page 96 6-3-6. Relationship between control input and comparator output when the operation mode with two hold values (Example) [Block Peak-Bottom] NOTE For the [Block Peak-Bottom] and [Time Peak-Bottom]: When the measured value is within the HI-1 and LO-1 of the Peak Value or within the HI-2 and LO-2 of the Bottom Value, the OK lamp on the target window lights up in white.

- Page 97 6-3-7. Motion Detect This function outputs the control output "Motion Detect" when input signal is determined “stable”. Compare the current measured value with the measured value of 0.25 msec ago (one sampling before). If the result falls within the stability detection range for a set time, it judges that it is "stable" and turns on the control output. The setting related to the function is "Motion Detect Function Enable/Disable", "Motion Detect Width", "Motion Detect Time", and "Motion Detect Logic".

- Page 98 (1) Motion Detect Function Enable/Disable To use the Motion Detect Function, enable the Motion Detect Function. <Setting Range> M eas. Cond. Set t i ng Ret ur n M easur e For out put t i ng t he r esul t by Enable・Disable Com par i son Set t i ng com par i ng m easur ed val ue and...

- Page 99 (3) Motion Detect Time Set the Motion Detection Time. <Setting Range> 0.01to9.99 sec <How to operate> 1) Press the M.D.Time key on the “Meas. Cond. Setting (3/3)” window. Com par i son Set t i ng Ret ur n M easur e Det ect i on wi dt h t o be j udged M .

- Page 100 6-3-8. Waveform Comparison Setting ” Waveform Comparison Setting”is the function that compare the input and the waveform and output the ersult. <How to operate> 1) Prepare Prepare the file for Waveform Comparison “WGA910_SET_WAVE.KS”. ●When using the waveform comparison function for the first time Use the file”WGA910_SET_WAVE.KS”...

- Page 101 (1) Set Reference Waveform Acquire the reference waveform for creating the comparison waveform. M eas. Cond. Set t i ng Ret ur n M easur e Register the waveform for the selected measurement condition number. For out put t i ng t he r esul t by Com par i son Set t i ng <...

- Page 102 (2) Waveform comparison HI Make the Waveform comparison HI. The waveform moved by the set value of the reference becomes the Waveform comparison HI. <Setting Range> -99999 to 99999 (count) < How to operate> W avef or m Com p. Set . 1) Press the Waveform Comp.

- Page 103 (3) Waveform comparison LO Make the Waveform comparison LO. The waveform moved by the set value of the reference becomes the Waveform comparison LO. <Setting Range> -99999 to 99999 (count) < How to operate> W avef or m Com p. Set . Ret ur n M easur e 1) Press the Waveform Comp.

- Page 104 (4) Move Waveform Use this when you want to move the comparison waveform up and down. If you have not performed waveform comparison upper limit setting or waveform comparison lower limit setting immediately before, you can display the comparison waveform currently being used and shift it by the set value for that waveform.

- Page 105 (5) Comparison Area Sets the area for waveform comparison. <Setting Range> Start: 0 to X-axis full-scale/2000 End: 0 to X-axis full-scale/2000 <How to operate> 1) Press the Comparison Area key. W avef or m Com p. Set . Ret ur n M easur e Set t he ar ea f or Com par i son Ar ea...

- Page 106 (6) Register Waveform Save the comparison waveform to the SD card. <How to operate> W avef or m Com p. Set . Ret ur n M easur e 1) Press the Register Waveform key. Set t he ar ea f or Com par i son Ar ea wavef or m com par i son.

- Page 107 NOTE In the following cases, an error is displayed and the SD Error of the control output is turned ON. If data can be read from SD card, SD Error will turn OFF. The waveform comparison function is enable, but the SD card is not set. ...

- Page 108 (8) Operation of waveform comparator output Control output "Waveform comparator HI", "Waveform comparator OK", "Waveform comparator LO" operation will be explained. The state of the control output changes as shown in the table below. Control output Control output State "Waveform comparator HI", "Waveform comparator OK"...

- Page 109 NOTE ・The waveform comparison function works only on the “Waveform” window. ・Waveform comparison does not function when a waveform command is input on the “Measuring window” (Number). At this time, the control output (Waveform comparator HI, Waveform comparator OK, Waveform comparator LO) holds the previous state.

- Page 110 6-4. WAVE DISPLAY SETTING (SETTING WAVEFORM DISPLAY) Setting X-Y axis of the waveform display screen, selected from the Start Mode of Wave, trigger level condition of the waveform display, set the Hold Time of Wave. 6-4-1. Setting X-axis Selects and sets the end point of the X-axis (time axis) of the waveform display. Waveform is displayed with 1 screen up to the X axis end point.

- Page 111 <The number of the waveform data in one window> MEMO The number of the waveform data in one window is 2001 data (including the data at the 0.0 sec.). The averaging value data that is sampled during the interval in the following table is loaded as a waveform data when the X-axis is set other than “0.5 sec.”...

- Page 112 6-4-2. Setting Y-axis Sets the start and end point of the Y-axis (measured value) of the waveform display. <Setting Range> Start point: -99999 to 99999 (count, Decimal point and unit should be considered.) End point: 250, 500, 1000, 2000, 5000, 10000, 20000, 50000, 100000, 200000 (count, Decimal point and unit should be considered.) <Operations for the start point of the Y-axis>...

- Page 113 Push t he t ar get key and ' Resi st er ' Set the Start Mode of Wave to “(Wave Comp.) External Trigger Mode”. Resi st er key. MEMO The following functions have functions equivalent to those of WGA - 900A. [WGA-910A] [WGA-900A] External Trigger Mode Auto Mode → Trigger Mode Normal Mode →...

- Page 114 After displaying the waveform of one window until the end point of the X-axis, the WGA-910A becomes trigger condition waiting mode and holds the waveform without updating it. MEMO Satisfying trigger condition means starts displaying the waveform when the measured value passed the preset level in the Passed Level and the measured value passed as presetting in the Level Passed Way.

- Page 115 Press the Start key or turn ON and OFF (MIN interval: 3 ms) the “Waveform Command” to set the WGA-910A in the trigger condition waiting mode. After that, the WGA-910A starts displaying the waveform when the measured value satisfies the trigger condition.After displaying the waveform to...

- Page 116 6-4-4. Passed Level (Trigger Level) Sets a passed level of the measured value as the trigger condition. The Passed Level key is invalid and displayed in gray if the “External Trigger Mode” or “Wave Comp. External Trigger Mode” is selected. <Setting Range>...

- Page 117 Set the trigger wait time after the end of one screen display. Determine the set value according to the purpose of recording. It takes time to save the SD card because WGA-910A stop the recording every screen. ● None recording →Setting value: 0.00 sec ●...

- Page 118 6-4-7. Record Waveform Data Import the waveform data (drawing screen) and save it on the SD card. Recording settings (ON/OFF) are set by REC key on waveform display screen. Recording starts with "Waveform command" of Control input or REC key on waveform display screen. (1) How to start recording with “Waveform command”...

- Page 119 (2) How to start recording by key operation Contol start/stop of recording by key operation. You can either record at the same time as you start the monitor, or start recording while monitoring the waveform. 1) Setting REC key Set the REC key in advance. “REC ON”: Recording can start at the start of drawing.

- Page 120 X axis is 5.0 s, 10.0 s, 20.0 s, 50.0 s, 100.0 s: The WGA-910A always saves continuous waveform data. X axis is 0.5 s, 1.0 s, 2.0 s: Since the WGA-910A prioritizes the writing process than the saving process, the WGA- 910A does not save waveform data continuously when changing windows.

- Page 121 ・If recording the waveform is started with many files or large capacity file saved in the SD card, it seems that the WGA-910A stops while waveform data is saved to the SD card. In addition, the WGA-910A may not immediately get back to the state before displaying the waveform unless the Stop key is pressed.

- Page 122 6-5. INITIAL SETTING 6-5-1. Meas. Select Signal (Measuring Condition Selecting Signal) Sets a signal for selecting a measuring condition number. Sets the measuring condition No. by pressing △ ▽ key on the “Meas. Cond. Setting” ・For key operation: window. ・For control input: Sets the measuring condition No.

- Page 123 6-5-2. System (1) Key Lock Select lock (inhabit changing) or release. The Return key is invalid and displayed in gray in locked state. The Set key changes to the Lock key after the window gets back to the “Measuring” window. Press the Lock key with the locked state.

- Page 124 (2) Set Initialize Initializes the saved setting value to the default value. However, the calibration value is not initialized. <Setting Range> Input Set: Initializes setting values of the input setting. Meas. Cond. Set: Initializes setting values of the measuring condition setting. Wave Disp.

- Page 125 (3) Backlight Time Sets a lighting time of the backlight. The backlight goes off if you don’t touch the panel for the preset time. Touch the panel for lighting up. <Setting Range> 0 to 99 (minute) <How to operate> 1) Press the Backlight Time key on the “System (1/2)” window. Syst em Ret ur n M easur e...

- Page 126 (5) Clock Adjusts date and time of the built-in clock. <Setting Range> Year, Month, Day, Hour, Minute, Second (2000/01/01 00:00:00~2099/12/31 23:59:59) <How to operate> Syst em Ret ur n M easur e 1) Press the Clock key on the “System (2/2)” window. The t i m e of bui l t -i n cl ock i s Cl ock set .

- Page 127 6) Comparison Display Color Change the color of the “Measuring” window according to the comparison result. <Setting Range> Normal, All Red, All White, All Yellow <How to operate> 1) Press the Comp. Display Color key on the “System (2/2)” window. Syst em Ret ur n M easur e...

- Page 128 (7) Display Stability To stabilize the numerical display, average processing is performed on the measured value. MEMO ・The average processing performed by the display stabilization function has no effect on comparison judgment and hold value detection. <Setting Range> Enable・Disable <How to operate> 1) Press the Display Stability key on on the “System (2/2)”...

- Page 129 Checks that the ROM, RAM, and EEPROM have no fault. Press the Execute key to start the memory check. The result is displayed after a short time. When an error occurs, the WGA-910A turns ON the control output “Abnormal memory.” <How to operate>...

- Page 130 Checks the operation related to the sensor input. Press the Execute key to start the channel check. The result is displayed after a short time. When an error occurs, the WGA-910A turns ON the control output “Abnormal channel.” <Setting Range>...

- Page 131 6-5-4. Operation Check (1) Display Check Checks the display operation. Check items are moved as follows. <Setting Range> Color: Window color automatically changes from Red - Green - Blue - Yellow - Red by pressing the Color key. Backlight: Press the Backlight key to go off the backlight. Touch the window to light up the backlight. <How to operate>...

- Page 132 (2) Touch Panel Check For checking the touch panel operation. <How to operate> 1) Press the Touch Panel Check key on the “Operation Check (1/2)” window. 2) Press a white key on the window to change in yellow. Press the yellow key again to get back to white. Press the Return key to get back to the “Operation Check”...

- Page 133 When an error occurs, the WGA-910A turns ON the control output “Communication error.” Press the Transfer key to transfer data “WGA-910A” that is displayed on the transferring data column. The transferred data from the external device is displayed on the received data column.

- Page 134 (6) D/A Output Check Valid for equipping the optional D/A output (WGA-910A-2) or BCD and D/A output (WGA-910A-12). Capable of checking the operation of the connecting external device by outputting an arbitrary D/A converted voltage. The D/A Output Check key is displayed in gray when the optional D/A output board is not connected.

- Page 135 <Error of the SD card check> Display SD card is not set in WGA-910A. Confirm that SD card is correctly inserted in slot. SD card has no enough the empty capacity. The data cannot be saved no more.

- Page 136 Do not remove the SD card until you have received the result. NOTE 3 About error message of the “SD card is not set in WGA-910A. Confirm that SD card is correctly inserted in slot.” The above error message also appears when the SD card is not correctly formatted.

- Page 137 6-5-5. SD CARD SETTING (1) Set Value Save (Saving Setting Value) Capable of saving the all setting values of the WGA-910A to the SD card and capable of checking them with the PC software for the SD card. The control output [SD] is turned ON while saving the setting values.

- Page 138 Press the Return key to get back to the “Confirmation of reading the set values” window. ■About setting value file. File name of the setting value is as follows and the file format is dedicated to the WGA-910A. WGA910_SET.KS Including all setting values (excluding the calibration value). Also includes the measuring condition setting values from No.

- Page 139 ■ About writing/reading the setting value to the SD card and reading the waveform data Capable of writing the setting value to the SD card and capable of reading the setting value and waveform data from the SD card with the PC software for the SD card. Capable of converting the waveform data to the CSV file and displaying the waveform.

- Page 140 This section describes how to display the waveform file name saved in the SD card and delete waveform files. The WGA-910A saves the waveform files in date-based directories. You are able to delete the date-based directories. You are able to delete single waveform file, multiple waveform files, and all waveform files.

- Page 141 <To select/cancel the directory> Vi ew W ave Fi l e Nam e Ret ur n M easur e 1) Select the page by the Next Previous key. Select the directory by the △ ▽ key for highlighting Di r ect or y Di r ect or y 20160330 (background color: white, character color: black).

- Page 142 00119 12. 0KB 20: 40: 33 O ne Sel ect 00118 15. 0KB 20: 00: 00 Do not remove the SD card or turn OFF the WGA-910A. 00117 124. 9KB 19: 40: 32 00116 15. 6KB 19: 10: 11 Al l Sel ect Otherwise, it may cause troubles.

- Page 143 <To delete the directory> Vi ew W ave Fi l e Nam e Ret ur n M easur e 1) Select the directory as described in the <To select/cancel the directory>. Di r ect or y Di r ect or y In the case of this example, the “20160202”...

- Page 144 (4) Format Erases (quick format) the all data saved in the SD card. SD Car d Set t i ng Ret ur n M easur e <How to operate> The al l set val ues excl udi ng Set Val ue Save t he cal i br at i on val ue ar e 1) Press the Format key on the “SD Card Setting (1/2)”...

- Page 145 (5) Update Capable of updating the program version of the WGA-910A to the target version in the SD card. <How to operate> SD Car d Set t i ng Ret ur n M easur e 1) Press the Update key on the “SD Card Setting (2/2)” window.

- Page 146 PVER.h WGA910_A.BIN WGA910_B.BIN WGA910_C.BIN The file format is dedicated to the WGA-910A. NOTE ・Never change the file name. Or, you cannot update the program. ・Save the all 4 programs in the root directory (ex. ¥E Drive) of the SD card.

- Page 147 7. OPERATION TIMING 7-1. CONTROL INPUT (HOLD COMMAND, RESET COMMAND, ZERO COMMAND) 7-1-1. Control Input...

- Page 148 7-1-2. Block-specified 7-1-3. Time-specified...

- Page 149 7-2. COMPARATOR OUTPUT 7-2-1. HI, OK, LO Comparator output...

- Page 150 7-2-2. Waveform Comparator HI, OK, LO output * In the Wave Comp. Trigger Mode 7-3. DELAY TIME OF THE INFLECTION POINT OUTPUT...

- Page 151 7-4. DELAY TIME OF THE EXTREME VALUE OUTPUT *When the judgment magnification is 1.0 times 7-5. DELAY TIME OF MOTION DETECT OUTPUT 7-6. DELAY TIME OF RS-232C OUTPUT Delay time between MAX 30 ms input – RS-232C output:...

- Page 152 7-7. DISPLAYING WAVEFORMS AND OUTPUTTING SD SIGNAL WITH WAVEFORM COMMAND (CONTROL OUTPUT) AND RECORD KEY 7-7-1. External Trigger Mode <Conditions> Measuring condition setting Operation mode: Normal Record Set “Record” to “Rec ON”, input waveform command. NOTE ・You can obtain the typical values with the blank recommended SD card (refer to page 28). ・According to the followings, typical values of the T2~T6 may change with the above values.

- Page 153 7-7-2. Wave Comp. External Trigger Mode <Conditions> Measuring condition setting Operation mode: Normal Record Set “Record” to “Rec ON”, input waveform command. Hold Time of Wave 10.0 sec NOTE ・You can obtain the typical values with the blank recommended SD card (refer to page 28). ・According to the followings, typical values of the T2~T6 may change with the above values.

- Page 154 7-7-3. Trigger Mode and Wave Comp. Trigger Mode <Conditions> Measuring condition setting Operation mode: Normal Record Set “Record” to “Rec ON”, input waveform command. NOTE ・You can obtain the typical values with the blank recommended SD card (refer to page 28). ・According to the followings, typical values of the T2~T6 may change with the above values.

- Page 155 7-7-4. Single Mode and Wave Comp. Single Mode <Conditions> Measuring condition setting Operation mode: Normal Record Set “Record” to “Rec ON”, input waveform command. NOTE ・You can obtain the typical values with the blank recommended SD card (refer to page 28). ・According to the followings, typical values of the T3~T4 may change with the above values.

- Page 156 The WGA-910A does not cope with XON/XOFF control and Send Break Signal. 8-2. CONTROL COMMAND The following is an explanation of the formats and kinds of control commands which are output to the WGA-910A from external equipment such as PC.

- Page 157 (2) LIST OF CONTROL COMMANDS Type Contents Command Page Initialize RS line test Output model, etc Initial Transmission mode setting (RS-232C only) settings Command of saving the setting (saving the setting value to the internal memory) Output the displayed value. Read the status.

- Page 158 Type Contents Command Page (17) Measuring condition setting (No.) (18) Key lock setting (19) Set the excitation voltage. SBV* (20) Conduct the no-load zero. ZAD* (21) Conduct the actual load calibration. (22) Conduct the sensitivity registering calibration. (23) Execute numeric value registering calibrations (24) Conduct the TEDS-based automatic calibration.

- Page 159 Output model, etc. Format: SYS<CR> Parameter: None Return value format: WGA-910A-aa, xx. xx, yyyyyyyyy <CR><LF> Serial No. (9-digit) Character string of 0 to 9, A, B, C Program version If the indicated value has no 10th digit, it is filled with ‘0’.

- Page 160 Errors ・Set the mode 10 to stop the outputting. ・When you cannot set the mode. Turn OFF the WGA-910A once and turn ON again to set it to mode 10. (2) Return value of the mode 02 D1±xxxxxx,zz<CR><LF> Sabcdefghi<CR><LF>...

- Page 161 Suppose the current indicated value is larger than +999.99. The return value is as follows. OFL, 03<CR><LF> NOTE The outputted measured value with the [GDT] command is different from the displayed value of the WGA-910A according to the sensor output variation or setting value of the input setting...

- Page 162 152: Language 153: Clock 155:Comparison display color 200:Detection trigger 210:Inflection point discrimination 220:Extreme value discrimination 230:Previous value comparison 260:Motion detect 270:Comparison area 280:Waveform comparison logic Return value format: For details, see each command. (Excluding the options.) 000<CR><LF> Option: None (WGA-910A-0)

- Page 163 (10) [SIC] Content: Control input state Format: SIC <CR> Parameter: none Return value format: a,b,c,d,e,f,g,h,i,j,k,l,m,n,o,p<CR><LF> Control input state (0:OFF, 1:ON) Description and others: The return values abcdefghijklmnop correspond to the state of the control input (pins 19 to 34) at the time of sending the command.

- Page 164 8-3-3. Executing (12) [HLD] Content: Hold command Format: HLD<CR> Parameter: None Return value format: ok<CR><LF> Relevant to the Hold key operation on the touch panel. Description and others For reference:Arbitrary point hold HLD <CR> → Holding interval → RST <CR> Peak hold HLD <CR>...

- Page 165 (15) [CK1] Content: Memory check Format: CK1<CR> Parameter: None Return value format: ok<CR><LF> (when in normal) E-01<CR><LF> (error) (16) [CK2] Content: Conduct channel check. Format: CK2<CR> Parameter: None Return value format: ok<CR><LF> (when in normal) The excitation voltage is error: E-06<CR><LF>...

- Page 166 (19) [SBV] Content: Set the excitation voltage. Format: SBVa<CR> Parameter: 0: 2V 1: 10V Return value format: ok<CR><LF> Description and others Corresponding to the [/M] command. Reading command PRR012<CR> Return value a<CR><LF> 0: 2V 1: 10V (20) [ZAD] Content: Conduct no-load zero. Format: ZAD<CR>...

- Page 167 (23) [VRC] To execute numeric value registering calibrations Content: VRC±x.xxxx<CR> Format: Parameter: ±x.xxxx Initial value of transducers: -3.2000 to 3.2000 (mV/V) Return value format: ok<CR><LF> E-12<CR><LF>(When an error occurs) Description and others The results of the command will be saved. Reading command: PRR011<CR>...

- Page 168 (26) [SZM] Content: Set the additional value. Format: SZM1, ±xxxxxx<CR> Parameter: ±xxxxx -99999 to 99999 (count) Indicated value with a decimal point. If the indicated value has no decimal point, it is filled with ‘0’ from the head. Return value format: ok<CR><LF>...

- Page 169 (28) [SCF] Content: Set the comparison setting. Format: SCFa, b, c, d, e, xxxxxx<CR> Parameter: a, b, c, d, e, xxxxx Hysteresis width: 0 to 9999 (count) Including a decimal point. Comparator output logic 0: Negative logic 1: Positive logic Using comparator LL 0: Use 1: Not use...

- Page 170 (30) [SMF] Content: Set the measuring mode setting. Format: SMFaa, b, c, x. xx, y. yy<CR> Parameter: aa, b, c, x. xx, y. yy Detect time: 0.01 to 9.99 (sec.) Delay time: 0.00 to 9.99 (sec) Comparison mode 0: Normal Comp. 1: Hold Comp.

- Page 171 (31) [STS] Content: Detection trigger Format: STS, a,±xxxxxx<CR> Parameter: a, ±xxxxxx Detection trigger level -99999~99999(count) Indicated value with a decimal point. If the indicated value has no decimal point, it is filled with ‘0s’ from the head. Detection trigger way 0:Rising 1:Falling 2:Both Return value format: ok<CR><LF>...

- Page 172 (33) [SES] Content: Extreme value discrimination Format: SES, xxxxxx, y.y <CR> Parameter: xxxxxx, y.y Magnitude: 0.1 to 5.0 Discrimination value: 1 to 99999(count) Reading command: ok<CR><LF> Description and others: Corresponding to the [/M] command. Reading command: PRR220<CR> Return value format: xxxxxx, y.y <CR><LF>...

- Page 173 (35) [SMD] Content: Motion detect Format: SMDa,xxxxxx, y.yy, z <CR> Parameter: a, xxxxxx, y.yy, z Output Logic: 0:Negative logic 1:Positive logic Motion detect time: 0.01 to 9.99 sec. Motiondetect width:0 to 99999(count) Indicated value with a decimal point. If the indicated value has no decimal point, it is filled with ‘0s’...

- Page 174 (37) [SG2] Content: Set the waveform display setting 1 (start mode of wave, passed level, level passing way, hold time of wave) Format: SG2a, b, ±xxxxxx, yy. y <CR><LF> Parameter: a, b, ±xxxxxx, yy. y Hold time of wave: 0.0 to 99.9 (sec) Indicated value with a decimal point.

- Page 175 (40) [SLG] Content: Set the language Format: SLGa <CR> Parameter: 0: Japanese 1: English Return value format: ok<CR><LF> Description and others Corresponding to the [/M] command. Reading command PRR152<CR> Return value a<CR><LF> language (41) [STM] Content: Set clock. Format: STM, uu, vv, ww, xx, yy, zz <CR> Parameter: uu, vv, ww, xx, yy, zz Second: 00 to 59...

- Page 176 (43) [OP1] Content: Set communication (RS-232C and RS-485) Format: OP1, a <CR> Parameter: OP1, a Data Rate 0: 2400 bps 1: 4800 bps 2: 9600 bps 3: 19200 bps Return value format: ok<CR><LF> Description and others Corresponding to the [/M] command. PRR100<CR>...

- Page 177 (46) [SWL] Content: Waveform Comparison Logic Format: SWLa<CR> Parameter: Logic 0:Negative logic, 1:Positive Logic Return value format: ok<CR><LF> Description and others: The setting is saved in SD card. Reading command PRR280<CR> Return value 030, a<CR><LF> Logic...

- Page 178 8-3-5. Other (47) [OP2] Content: Set the BCD output Format: OP2, a, b, c, d, e, f<CR> Parameter: OP2, a, b, c, d, e, f BCD classification (*2) 0:Hold value1 1: Hold value2 2:Measuring value Data form 0: BCD 1: Binary Transmission speed 0: Approx.

- Page 179 (48) [OP3] Content: Set the D/A output. Format: OP3, ±xxxxxx, ±yyyyyy, a<CR> Parameter: OP3, ±xxxxxx, ±yyyyyy, a D/A classification (*2) 0:Hold value1 1: hold value2 2:Measuring value Full display: -99999 to 99999 (count) ZERO display: -99999 to 99999 (count) Both values include a decimal point. If the indicated value has no decimal point, it is filled with ‘0s’...

- Page 180 8-4. OPERATION AND FUNCTION OF THE COM. SETTING (COMMUNICATION SETTING) (1) Communication Speed Sets the communication speed (baud rate) of the RS-232C . <Setting Range> 2400, 4800, 9600, 19200 (bps) <How to operate> 1) Press the Set key on the “Measuring” window. Swi t ch Hol d Zer o...

- Page 181 (2) Transmission Mode Sets the transmission mode of the communication such as the measured value, sending method of the status, operation by the command, etc. <Setting Range> Repeat Output Continuously outputs the measured value and status (such as the HH comparator is ON, etc). Output at Hold Outputs the measured value and status once during the holding time.

- Page 182 9. TROUBLESHOOTING If the WGA-910A does not function as expected or is found unstable, do not immediately take it that the WGA-910A has failed, but check the operating environment for possible causes. This section describes causes of every phenomenon and checking methods.

- Page 183 5) TEDS Error Displaying Stops the reading of the TEDS information. Content: Cause: The TEDS information may not be read correctly or the interface may not corresponding to the IEEE1451.4 Mixed Mode Transducer Interface Class 2. In addition, the transducer may be faulty, cable may be disconnected or may be incorrectly connected.

- Page 184 ■ Error during the measurement :examlpes Swi t ch Hol d Zer o Swi t ch Hol d Zer o Swi t ch Hol d Zer o Swi t ch Hol d Zer o Det ect i ng M easur e 0 Det ect i ng M easur e 0 Det ect i ng...

- Page 185 The “No-load Zero” blinks for 3 seconds. After that, the “Input Value + Over” blinks again if the input value is exceeding +3.2 mV/V. If all this fails to recover normal operation, contact KYOWA or our representatives. 9-3. DISPLAY VALUE OR MONITOR OUTPUT DOES NOT CHANGE ●...

- Page 186 Occurs when a measuring object has an electrical potential of DC or AC. In this case, it is not necessarily to ground the WGA-910A but connect the measuring object and WGA-910A. It should be noted that you cannot solve the trouble with a simple method if there is the inductive interference or if the measuring object has electrical potential.

- Page 187 Maintenance service should be performed at the intervals specified below. (1) Calibration of apparatus An annual maintenance inspection is recommended to ensure the operation and measuring accuracy of the product. Must be returned to KYOWA for the scheduled maintenance inspection. (2) Replacement of limited life parts Item Content...

- Page 188 11. SPECIFICATIONS 11-1. WGA-910A (WGA-910A-0) Number of channel Compatible sensor Strain gage transducers (Connectable TEDS compatible sensor) Compatible bridge Registance 87.5 to 1000 Ω TEDS compatible Interface: Compatible with IEEE1451.4 Mixed Mode Transducer Interface Class 2 Compatible transducer: Should have the information according to IEEE template No.

- Page 189 Measurement condition numbers 32 points (16 for control input) of measurement condition file can be saved. Capable of switching by the key operation, control input, communication command. Comparator setting The number of points: 5 Type: extra high (HH), high (HI), OK, low (LO), extra low (LL). If there are two hold values, they are assigned as follows.

- Page 190 Wave form display X-axis setting: End point: 0.5, 1.0, 2.0, 5.0, 10.0, 20.0, 50.0, 100.0 s Y-axis setting: Start point: -99999 to 99999 End point: 250, 500, 1000, 2000, 5000, 10000, 20000, 50000, 100000, 200000 Start mode of waveform, Passed level, Passed level way, Holding time of waveform WGA displays the waveform of the input variation regardless to the “Operation Mode Set"...

- Page 191 Power supply 100 to 240 V 50/60 Hz, Power consumption: 20 VA or less Dimensions 100 (W) 96 (H) 135 (D) mm (Not include protrusions) × × Weight Approx. 950 g (Not include Option) Operating temperature Humidity -10 to 40 °C, 20 to 85 % (Noncondensing) Compliance Directive 2014/30/EU (EMC) Directive 2014/35/EU (LVD)

- Page 192 11-2. DIMENSIONS Unit:mm...

- Page 193 12. APPENDIX 12-1 LIST OF SETTING ITEM 12-1-1. Calibration Item Function Name Parameter Name Setting Value Initial Value Manual Input Cal. Bridge Voltage 0:2 V, 1:10 V No-Load Zero (-3.2000 to 3.2000 mV/V) (0.000 mV/V) Sens. Regist. Cal. Rated output -3.2000 to 3.2000 mV/V 2.0000 mV/V Rated display...

- Page 194 12-1-3. Measuring Condition Setting Item Function Name Parameter Name Setting Value Initial Value Meas. Cond. Setting 1 to 32 Comparison Setting HH compared value -99999 to 99999 99999 HI compared value -99999 to 99999 10000 LO compared value -99999 to 99999 -10000 LL compared value -99999 to 99999...

- Page 195 Detect Time 0.00 to 9.99 sec. 1.00 sec Delay Time 0.00 to 9.99 sec. 0.00 sec Comparison Mode 0: Normal Comp. Normal Comp. 1: Hold Comp. Display Mode 0: Normal Disp. Normal Disp. 1: Hold Disp. Det. Trigger Level -99999 to 99999 (count) 1000 Det.

- Page 196 12-1-5. Initial Setting Item Function Name Parameter Name Setting Value Initial Value Meas. Select Signal 0: Key Operation, Operation 1: Control Input, 2: Command Key Lock 0: Release, 1: Lock Release System Set Initialize 0: Input Set, 1: Meas. Cond. Set, 2: Wave Disp.

- Page 197 12-2. UNIT LIST The left numbers are command parameters or return value format of the communication (RS-232C/RS-485). Force and Mass Pressure Torque Displacement Others 45 (None) 64 ℃ 01 mN 14 Pa 30 mN・m 39 μm 46 μV 65 K 02 N 15 hPa 31 N・m...

Need help?

Do you have a question about the WGA-910A and is the answer not in the manual?

Questions and answers