Summary of Contents for Beckhoff EP2911-0001

- Page 1 Operating Instructions | EN EP2911-0001 Head station for pneumatic valves with safe shut-off 2024-04-22 | Version: 1.0.0...

-

Page 3: Table Of Contents

Version numbers .......................... 7 References ............................ 7 Staff qualification .......................... 8 Safety and instruction........................ 9 Beckhoff Support and Service...................... 10 Notes on information security...................... 11 2 For your safety ............................ 12 Duty of care ............................. 12 General safety instructions...................... 13 2.2.1... - Page 4 9 Local process image.......................... 45 Input .............................. 45 Output ............................. 45 10 Maintenance and cleaning ........................ 46 11 Decommissioning ........................... 47 11.1 Disposal ............................ 47 11.1.1 Returning to the vendor.................... 47 12 Appendix .............................. 48 12.1 Volatility ............................ 48 12.2 Focus of certificates ........................ 49 Version: 1.0.0 EP2911-0001...

-

Page 5: Notes On The Documentation

Notes on the documentation Disclaimer Beckhoff products are subject to continuous further development. We reserve the right to revise the operating instructions at any time and without prior announcement. No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in these operating instructions. -

Page 6: Limitation Of Liability

Modifications and changes to the hardware and/or software configuration that go beyond the documented options are prohibited and nullify the liability of Beckhoff Automation GmbH & Co. KG. The following is excluded from the liability: •... -

Page 7: Version Numbers

The original documentation is written in German. All other languages are derived from the German original. Product features Only the product properties specified in the current operating instructions are valid. Further information given on the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative. References Output Title / description Not in use. -

Page 8: Staff Qualification

• Independently identify, avoid and eliminate sources of hazard. • Apply relevant standards and directives. • Implement specifications from accident prevention regulations. • Evaluate, prepare and set up the workplaces. • Evaluate, optimize and execute work independently. Version: 1.0.0 EP2911-0001... -

Page 9: Safety And Instruction

Warning of damage to property or environment NOTICE Notes The environment, equipment, or data may be damaged. Information on handling the product This information includes, for example: Recommendations for action, assistance or further information on the product. EP2911-0001 Version: 1.0.0... -

Page 10: Beckhoff Support And Service

The employees support you in the programming and commissioning of sophisticated automation systems. Hotline: +49 5246/963-157 E-mail: support@beckhoff.com Web: www.beckhoff.com/support Training Training in Germany takes place in our training center at the Beckhoff headquarters in Verl, at subsidiaries or, by arrangement, at the customer's premises. Hotline: +49 5246/963-5000 E-mail: training@beckhoff.com Web: www.beckhoff.com/training... -

Page 11: Notes On Information Security

Notes on the documentation Notes on information security The products of Beckhoff Automation GmbH & Co. KG (Beckhoff), insofar as they can be accessed online, are equipped with security functions that support the secure operation of plants, systems, machines and networks. -

Page 12: For Your Safety

• ISO 13849-1, Safety of machinery – Safety-related parts of control systems – Part 1: General principles for design Beckhoff is not responsible for the safe operation of the system. No disposal in domestic waste Products marked with a crossed-out waste bin must not be disposed of with domestic waste. -

Page 13: General Safety Instructions

Engineering tools allowed are TE9000 - TwinCAT 3 Safety Editor and TE9200 - TwinSAFE Loader. Use only the latest versions of the engineering tools. You will find this on the Beckhoff website. Procedures or engineering tools that deviate from this are not covered by the certificate. This is especially true for externally generated xml files for the TwinSAFE import. -

Page 14: During Operation

De-energize and switch off components before working on them Check all safety-relevant equipment for functionality before working on the TwinSAFE component. Secure the working environment. Secure the machine or plant against being inadvertently started up. Observe the chapter Decommissioning [} 47]. Version: 1.0.0 EP2911-0001... -

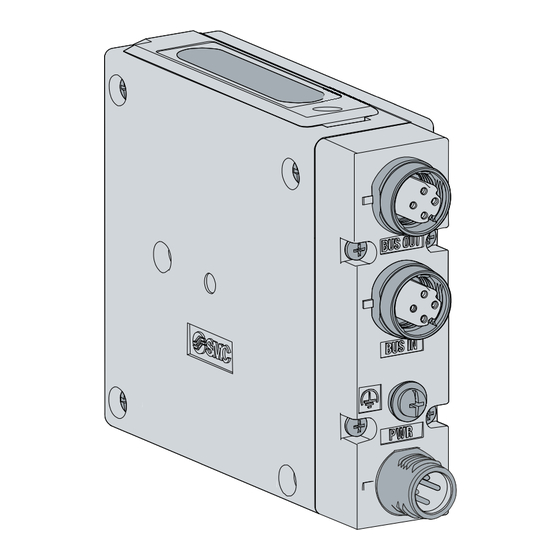

Page 15: Product Overview

For more information, see the chapter BUS OUT and BUS IN [} 40]. EtherCAT connector EtherCAT connection for Port 2 BUS OUT M12 4-pin socket, D-coded For more information, see the chapter BUS OUT and BUS IN [} 40]. EP2911-0001 Version: 1.0.0... -

Page 16: Product Description

• The functional part controls up to 32 downstream pneumatic valves. • The higher-level, safety-related part safely shuts down the power supply to up to 32 valves. The TwinSAFE component has an internal two-channel structure based on a 1oo2 structure. Version: 1.0.0 EP2911-0001... -

Page 17: Laser Image

WW = calendar week of manufacture JJ = year of manufacture SW = software version HW = hardware version Serial number Product designation Vendor's logo QR code to read out the serial number TÜV-SÜD test mark for functional safety EP2911-0001 Version: 1.0.0... -

Page 18: Intended Use

This applies in particular to the use cases defined by Beckhoff Automation, which have been fully tested and certified and whose properties and operating conditions can be guaranteed. Use cases beyond this are regarded as inappropriate and require the approval of Beckhoff Automation. -

Page 19: Technical Data

Technical data Technical data Product data The current certificates of all TwinSAFE products with the underlying standards and directives can be found at https://www.beckhoff.com/en-en/support/download-finder/certificates-approvals/. 4.1.1 Hardware Hardware data Explanation Electrical data • Supply voltage U 24 V (-15 % / +20 %) The supply voltage U supplies the internal logic (control voltage). -

Page 20: Software

When 100% is reached, no further write access is possible and the device goes into the Global Shutdown state as soon as another write access occurs. For further information, please refer to the chapter Global Shutdown [} 25]. • Protocol TwinSAFE SC Version: 1.0.0 EP2911-0001... -

Page 21: Target Failure Measures

TwinSAFE component are not required. 5.04E-09 9.54E-06 MTTF High High, 99 % >99 % Conforms to IEC 61508:2010. Performance Level Conforms to EN ISO 13849-1:2015. Category Conforms to EN ISO 13849-1:2015. Element classification Type B In accordance with EN 61508-2:2010 Chapter 7.4.4.1.2 and 7.4.4.1.3. EP2911-0001 Version: 1.0.0... -

Page 22: Environmental Conditions

Technical data Environmental conditions Beckhoff products are designed for operation under certain environmental conditions, which vary according to the product. The following specifications must be observed for operation and environment in order to achieve the optimum service life of the products as well as to ensure product safety. - Page 23 The following example shows the calculation for a TwinSAFE component at an operating altitude of 4000 m. Permissible maximum ambient temperature up to 2450 m above sea level = 50 °C Permissible maximum ambient temperature up to 4000 m above sea level = 50°C * 0.8 = 40 °C EP2911-0001 Version: 1.0.0...

-

Page 24: Dimensional Drawing

512 (When using ESTOP blocks with complete input and output mapping. Other blocks may result in a lower maximum number.) TwinSAFE groups maximum 128 TwinSAFE users maximum 40 Standard PLC inputs dynamic (memory-dependent) maximum 1483 bytes Standard PLC outputs dynamic (memory-dependent) maximum 1483 bytes Version: 1.0.0 EP2911-0001... -

Page 25: Lifetime

This operating state is a safe state and temporarily shuts down the software module. An Error Acknowledge resets the operating state. Voltage ratios with functional outputs switched off In the operating state with the functional outputs switched off, there are two special circuit-related features, which are described below. EP2911-0001 Version: 1.0.0... -

Page 26: Switch-On Pulses

The height of this voltage level depends on the resistance of the connected loads and can be found in the following table. Resistance [kΩ] Pulse [V] 14.6 23.5 14.4 18.8 14.4 14.1 14.1 13.7 13.2 12.8 12.3 11.9 11.4 11.4 Version: 1.0.0 EP2911-0001... -

Page 27: Open-Circuit Voltage/Residual Voltage

As the ohmic load on the outputs increases, this residual voltage is reduced according to the following curve. This residual voltage drops when the safe supply switch is shutdown. EP2911-0001 Version: 1.0.0... -

Page 28: Diagnosis

LED on: connection to the following EtherCAT module LED flashes: communication with following EtherCAT module LED off: no connection to the following EtherCAT module Indicates the status of the control voltage U which supplies the internal logic. Version: 1.0.0 EP2911-0001... -

Page 29: Diagnostic Leds

For more information see chapter Environment error codes [} 31]. A global shutdown is present on µC1. For more information, see the chapter Global Shutdown [} 25]. A global shutdown is present on µC2. For more information, see the chapter Global Shutdown [} 25] EP2911-0001 Version: 1.0.0... - Page 30 For more information, see the chapter Global Fault [} 25]. A global fault is present on µC2. For more information, see the chapter Global Fault [} 25]. flickers - An error of a safe input or output module is present. The dashes indicate a Don't-Care state. Version: 1.0.0 EP2911-0001...

- Page 31 Supply voltage µC1 below minimum value Maximum supply voltage µC2 exceeded Supply voltage µC2 below minimum value Maximum internal temperature exceeded Internal temperature below minimum value Valid temperature difference between µC1 and µC2 exceeded Not used Not used General error EP2911-0001 Version: 1.0.0...

-

Page 32: Flashing Codes

Is set via the StartUp list: at 0x0001 the UINT 16 0x000; 0 diagnosis messages are sent to the EtherCAT master via Emergency. 10F3:06 Diagnosis Message 001 Diagnosis message 1 BYTE 32 RO 10F3:45 Diagnosis Message 064 Diagnosis message 64 BYTE 32 RO Version: 1.0.0 EP2911-0001... -

Page 33: Structure Of Diagnosis Messages

Diagnostic messages are stored as text format in the ESI/XML file of the TwinSAFE component. You can find the corresponding message in all available languages via the text ID in the diagnostic message. You can insert the parameters at the appropriate places in the ESI/SML file. EP2911-0001 Version: 1.0.0... -

Page 34: Startup

0x10F3:05 to the startup list (Transition IP, value 0x0001). If new diagnostic messages arrive, they are entered in object 0x10F3 and additionally sent by emergency to the EtherCAT master. Advanced Settings If you want to adjust the behavior of the history: 1. Select "Advanced Settings" The dialog box "Advanced Settings" opens. Version: 1.0.0 EP2911-0001... - Page 35 No saving of "Messages" with "Warning" status in the "Diag history". Disable Errors No saving of "Messages" with "Error" status in the "Diag history". Emergency Additional sending of an emergency object, which is displayed in the "TwinCAT Logger window" Overwrite / Acknowledge This setting is currently not supported. Mode EP2911-0001 Version: 1.0.0...

-

Page 36: Transport And Storage

The TwinSAFE components can be stored for shorter or longer periods. Observe the conditions specified in chapter Environmental conditions. Check the seal for damage Check the barcode sticker used to seal the outer packaging for damage. If the sticker is missing, opened or damaged, please contact Beckhoff Support and Service [} 10]. Version: 1.0.0 EP2911-0001... -

Page 37: Installation

3. Turn the screws [3] into the holes in the head station [1] to screw the head station [1] and the valves [2] together 4. Tighten the screws [3] to the defined tightening torque The tightening torque is 0.6 Nm. EP2911-0001 Version: 1.0.0... - Page 38 Installation The head station has no additional holes for mounting. Details on further installation can be found in the corresponding catalog for valves. Version: 1.0.0 EP2911-0001...

-

Page 39: Address Settings

When the safe address is downloaded, the address of the DIP switch is ignored. You can also delete the secure address by downloading and entering the user data. Loading the safe address After deleting the secure address, the address is not 0. EP2911-0001 Version: 1.0.0... -

Page 40: Electrical Installation

The power supply plug is a 5-pin M12 A-coded plug. Pos. Designation Description +24 V for solenoid valves Ground (U 0 V for solenoid valves +24 V for operation of the head station Ground (U 0 V for operation of the head station Not used Version: 1.0.0 EP2911-0001... - Page 41 S_DOUT_00 S_DOUT_01 S_DOUT_02 S_DOUT_03 S_DOUT_04 S_DOUT_05 S_DOUT_06 S_DOUT_07 S_DOUT_08 S_DOUT_09 S_DOUT_11 S_DOUT_10 S_DOUT_12 S_DOUT_13 S_DOUT_14 S_DOUT_15 S_DOUT_17 S_DOUT_16 S_DOUT_19 S_DOUT_18 S_DOUT_21 S_DOUT_20 S_DOUT_22 S_DOUT_23 S_DOUT_25 S_DOUT_24 S_DOUT_26 S_DOUT_27 S_DOUT_28 S_DOUT_29 S_DOUT_31 S_DOUT_30 BLA 2x 17pol Rm200 SMC EP2911-0001 Version: 1.0.0...

-

Page 42: Grounding

• The loads (valve block) should not allow any further external power supply. • The valve blocks to be connected should have at least the same IP protection class as the head station. Version: 1.0.0 EP2911-0001... -

Page 43: Factory Setting Project

For further information on customer-specific projects, please refer to the chapter Customized safety application. The process image of the EP2911-0001 consists of the input and output process image. Detailed information can be found in the following tables. EP2911-0001... -

Page 44: Input

The process image of the output signals consists of 6 bytes of data, 1 byte of which are usage data. Offset Name Data Group Description type Safe Power Supply Error BOOL Safety True: Error in the power supply False: No error Version: 1.0.0 EP2911-0001... -

Page 45: Local Process Image

The local process image of the input signals consists of a maximum of 512 bytes of data. Offset Name Data Group Description type Safe Power Supply Enable BOOL Safety True: Power Supply active False: Power supply inactive; safe state Safe Power Supply ErrAck BOOL Safety Resetting a power supply error EP2911-0001 Version: 1.0.0... -

Page 46: 10 Maintenance And Cleaning

Cleaning by the manufacturer only Do not operate the TwinSAFE component if it is unacceptably dirty. Refer to the technical data for the protection class. Send unacceptably dirty TwinSAFE component to the manufacturer for cleaning. TwinSAFE components are basically maintenance-free. Version: 1.0.0 EP2911-0001... -

Page 47: 11 Decommissioning

In accordance with the WEEE-2012/19/EU directives, you can return used devices and accessories for professional disposal. The transport costs are borne by the sender. Send the used devices with the note "For disposal" to: Beckhoff Automation GmbH & Co. KG Gebäude „Service“ Stahlstraße 31... -

Page 48: 12 Appendix

If there is customer specific data saved on the product, it cannot be ensured that this data might not be restored through for example forensic measures, even after the data is deleted through the provided tool chain. If this data is confidential, the scrapping of the product after usage is recommended to protect this data. Version: 1.0.0 EP2911-0001... -

Page 49: Focus Of Certificates

The current certificates of all TwinSAFE components with the underlying standards and directives can be found at https://www.beckhoff.com/en-en/support/download-finder/certificates-approvals/. If the document refers only to the first four figures of a product (ELxxxx), the certificate is valid for all available variants of the component (ELxxxx-abcd). - Page 51 More Information: www.beckhoff.com/twinsafe Beckhoff Automation GmbH & Co. KG Hülshorstweg 20 33415 Verl Germany Phone: +49 5246 9630 info@beckhoff.com www.beckhoff.com...

Need help?

Do you have a question about the EP2911-0001 and is the answer not in the manual?

Questions and answers