Summary of Contents for Panasonic SQ4-C11

- Page 1 Controller for Safety Liquid Leak Sensor SQ4-A Series SQ4-C11 Instruction Manual MJE-SQ4C11 No.0095-80V 2024.4 industry.panasonic.com/...

- Page 2 MEMO MJE-SQ4C11 No,0095-80V...

- Page 3 Thank you for purchasing Panasonic Industry controller SQ4-C11 for safety liquid leak sensor SQ4-A series. Read this instruction manual carefully and thoroughly for the correct and optimum use of this device. Kindly keep this manual in a convenient place for quick reference.

-

Page 4: Table Of Contents

Contens Chapter 1 Introduction ······································································· 5 1-1 Attention Marks·············································································· 5 1-2 Safety Precautions ········································································· 5 1-3 Regulations And Standards ······························································ 8 ······················································ 8 Chapter 2 Before using this device ····················································· 9 2-1 Features ······················································································ 9 2-2 Names and Functions of Parts ·························································· 9 2-3 Mounting / Removal ······································································12 2-3-1 Mounting / Removal of Controller ···············································... -

Page 5: Chapter 1 Introduction

Introduction Chapter 1 Introduction 1-1 Attention Marks This instruction manual employs the following attentions marks , depending on the degree of the danger to call operator’s attention to each particular action. Read the following explanation of these marks thoroughly and observe these notices without fail. If you ignore the advice with this mark, death or serious injury could result. - Page 6 Introduction The machine designer, installer, employer and operator are solely responsible to ensure that all applicable legal requirements relating to the installation and the use in any appli- instruction manual are followed. Whether this device functions as intended to and systems including this device comply with safety regulations depends on the appropriateness of the application, installation, maintenance and operation.

- Page 7 Introduction Wiring Be sure to carry out the wiring in the power supply OFF condition. All electrical wiring should conform to the regional electrical regulations and laws. The wiring should be done by engineer(s) having the special electrical knowledge. Do not run the sensor wires together with high-voltage lines or power lines or put them together in the same raceway.

-

Page 8: Regulations And Standards

Introduction 1-3 Regulations And Standards This device complies with the following regulations and standards. EU Machinery Directive 2006/42/EC EMC Directive 2014/30/EU RoHS Directive 2011/65/EU British Legislation Machinery Regulations 2008/1597 EMC Regulations 2016/1091 RoHS Regulations 2012/3032 - Applicable Standards EN 55011 Class A, EN 61000-6-2 ANSI/UL 508, CAN/CSA C22.2 No.14 <Regulations in Korea>... -

Page 9: Chapter 2 Before Using This Device

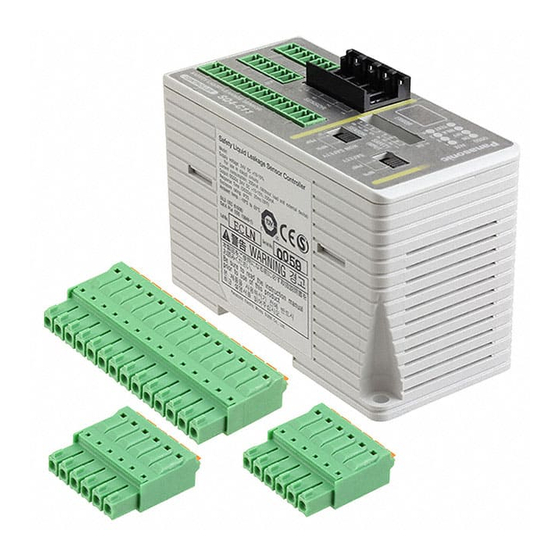

Before using this device Chapter 2 Before using this device 2-1 Features This device and safety liquid leak sensor SQ4-A series are combined for operation. Maximum of 4 safety liquid leak sensors can be connected to this device. With the output polarity selection switch of the controller, the control output 1 / 2 (OSSD 1 / 2) can be switched to the PNP / NPN output. - Page 10 Parts description Names Functions Sensor monitor output 1 indicator (Orange) [AUX1] Sensor monitor output 2 indicator Light up when auxiliary detection output of each sensor is ON. (Orange) [AUX2] Chapter 5 Trou- Sensor monitor output 3 indicator bleshooting.” (Orange) [AUX3] Sensor monitor output 4 indicator (Orange) [AUX4] It lights in 7 segments for an error.

- Page 11 Parts description Names Functions Terminal Description names Reset input terminal Not used When the safety input 1 / 2 is in contact mode, it is connected to the SI+ terminal 16 Input terminal block (6 poles) for power supply. When safety input mode is invalid and it is in semiconductor input mode, not used.

-

Page 12: Mounting / Removal

The controller can be mounted on the 35mm width DIN rail. Step 1 Fit the tab on the opposite side of the DIN rail stopper into the 35mm width DIN rail. DIN rail stopper 35mm width DIN rail Step 1 Step 2 Push the controller to the other side of the DIN rail stopper. - Page 13 separately). The tightening torque should be 1.2N·m or less. Mounting holes dimension 40mm M4mm M4 pan head screw (Purchase separately) 92mm MJE-SQ4C11 No. 0095-80V...

-

Page 14: Wiring

Wiring 2-4 Wiring Take countermeasure against the system to be applied for this device so as not to carry out the dangerous performance caused by the earth failure. Failure to do so could cause invalid for the system stop, resulting in death or serious injury. In order that the output is not turned ON due to earth fault of control output 1 / 2 (OSSD 1 / 2) wires, be sure to ground to 0V side (PNP output) / +24V side (NPN output). -

Page 15: I/O Circuit Diagrams

Wiring <Reference> Manual / Auto reset can be selected by the wiring of the reset input terminals (X1, X2, and X3). <Manual reset> <Auto reset> Back check circuit Back check circuit Back check circuit Back check circuit is required. is not required. is required. - Page 16 Wiring When the sensor is ON, the controller self-diagnoses the output circuit. When feedback of the OFF signal is given, the controller evaluates that the output circuit is nor- mal. If feedback of the OFF signal is not given, the controller evaluates that the output circuit or wiring has an error and the control outputs 1 / 2 (OSSD 1 / 2) maintains OFF status.

-

Page 17: Connecting To The Terminal Block Of The Controller

Wiring In connection to the terminal block of the controller, mount a single wire or stranded wire (lead insert it to the back of the hole. When it is correctly inserted, it is locked and not removed by pulling. If it is pulled with strong force, it may be disconnected. -

Page 18: A Series

Wiring When wiring safety liquid leak sensor to this device, mount easy insulation displacement con- nector CN-EP Used easy insulation displacement connector depends on type of safety liquid leak sensor, so refer table below. Also, In case the cable of the safety liquid leak sensor is extended, use different type of displacement conecotor. - Page 19 Wiring Wire Pull it gently easy insulation displacement connector that has been crimped once cannot be reused. easy insulation displacement connector Use optional CN-EP2 (for PVC cable, 5 pcs. / set) and CN-EP3 (for PFA cable, 5 pcs. / set) or recommended parts. •...

- Page 20 Wiring Step 1 Pull it out from this device while holding the lock release lever of easy insulation dis- placement connector. Easy insulation displacement connector Pull Hold lock release lever When pulling out the easy insulation displacement connector, be sure to hold the lock release lever.

-

Page 21: Chapter 3 Functions

Functions Chapter 3 Functions 3-1 Self-diagnosis Function This device is equipped with a self-diagnosis function. The device performs self-diagnosis when the power is supplied and during operation. If an error is found, lockout occurs at the time and the control outputs 1 / 2 (OSSD 1 / 2) are Chapter 5 Troubleshooting”... -

Page 22: Auto Reset

Functions 30ms or more Open Reset input Short- circuit Sensor detection output 20ms or less 100ms or less Control output 1 / 2 (OSSD 1 / 2) 3-2-2 Auto reset When the detecting output of sensor is ON (without liquid leak), control outputs 1 / 2 (OSSD 1 / 2) can be automatically ON. -

Page 23: Test Input Function

Functions 3-3 Test Input Function It is the function to check normal operation by turning ON / OFF control outputs 1 / 2 (OSSD 1 / 2) of the controller without generating a liquid leak condition at the sensor. When the test input terminal between T1 and T2 is open, valid operation can be selected, and when it is shorted, invalid operation (normal operation) can be selected. -

Page 24: Safety Input Function

Functions 3-4 Safety Input Function It is the function to control outputs 1 / 2 (OSSD 1 / 2) of this device with the safety contact con- nected to safety input terminals SIN1 and SIN2 or the detection signal of the safety sensor. When safety inputs 1 / 2 are OFF, control outputs 1 / 2 (OSSD 1 / 2) are forcibly OFF. - Page 25 = 7ms + 20ms + 10ms =37ms When connecting control output terminal Y1 of other SQ4-C11 and safety input terminal SIN1, and connecting control output terminal Y2 of other SQ4-C11 and safety input terminal SIN2, it can also be used as serial connection. SIN1...

- Page 26 Functions ON and No. 2 and 4 to OFF, and open the safety input terminals of SIN1 / SIN2, SIN+ / SIN-, SI+ / SI- and SO+ / SO-. Safety input mode setting switch NC (normal close) type Operation for ON Operation for OFF Contact input mode (Safety contact)

-

Page 27: Auxiliary Output Function (Non-Safety Output)

Functions This device is equipped with auxiliary output as non-safety application. Terminal Names Description Lockout output OFF for lockout Auxiliary output Negative logic output of control output 1 / 2 (OSSD 1 / 2) AUX1 Sensor monitoring output 1 Monitor output corresponding to detection auxiliary output of sensor No. 1 AUX2 Sensor monitoring output 2 Monitor output corresponding to detection auxiliary output of sensor No. -

Page 28: Chapter 4 Maintenance

Maintenance Chapter 4 Maintenance <Reference> Chapter 5 Troubleshooting” and contact a professional engineer for the details. Contact us if you are not sure about the corrective action. device is operated in a failed condition without inspection, there may be a risk of death or severe injury. -

Page 29: Chapter 5 Troubleshooting

Troubleshooting Chapter 5 Troubleshooting Symptom Cause Remedy Connect the power supply correctly. Power is not supplied. The power voltage is out of the All indicators are OFF Set the power voltage correctly. Connectors are not securely Connect connectors securely. connected. Test input indicator Short-circuit the test input terminals between T1 Test input is opened... - Page 30 Troubleshooting Display Symptom Cause Remedy The safety input mode setting Set the safety input mode setting switch and Setting error of switch and the sensor connection the sensor connection number setting switch safety input mode number setting switch are set to correctly.

- Page 31 Type Controller for safety liquid leak sensor SQ4-A series Model No. SQ4-C11 Power voltage 24V DC %, Ripple P-P10% or less Consumption current 200mA or less Number of connecting 4 units (with easy insulation displacement connector) sensor PNP output type / NPN output type can be connected. (Mixture is not allowed.) PNP / NPN open collector transistor (switch type) <Selecting PNP output>...

- Page 32 Type Controller for safety liquid leak sensor SQ4-A series Model No. SQ4-C11 Sensor connection number Incorporated setting function Overvoltage category Protection structure IP20 (IEC) (However, it should be in IP54 protection structure of control panel) Degree of pollution -10 to +55°C (No dew condensation or icing allowed.)

- Page 33 Options 6-2 Option Model No. Applicable sensor Description CN-EP2 SQ4-A21- For PVC cable CN-EP3 SQ4-A22- For PFA cable MJE-SQ4C11 No. 0095-80V...

-

Page 34: Dimensions

2-ø4.4 mounting hole 37.5 35.5 DIN-rail 35mm width matching (6.5) (72.2) (82.5) MJE-SQ4C11 No. 0095-80V... -

Page 35: Chapter 7 Others

Others Chapter 7 Others 7-1 Glossary This directive and regulations is for an assembly of linked parts or Machinery Directive / components, energized by an electricity, compressed air or oil pres- Machinery Regulations sure, etc. and at least one of which moves, and a component which The directives and regulations is to any electric or electronic devic- EMC Directive / es which will create more than a limited amount of RF interference,... -

Page 36: Ce Marking Declaration Of Conformity

- 2011/65/EU RoHS Applicable Standards: - IEC 61508-1 - EN 55011 - IEC 61508-2 - EN 61000-6-2 - IEC 61508-3 - EN IEC 63000 Authorised Representative: Panasonic Marketing Europe GmbH Panasonic Testing Centre Winsbergring 15, 22525 Hamburg, Germany MJE-SQ4C11 No. 0095-80V... -

Page 37: Ukca Marking Declaration Of Conformity

- 2012/3032 RoHS - IEC 61508-1 - EN 55011 - IEC 61508-2 - EN 61000-6-2 - IEC 61508-3 - EN IEC 63000 Panasonic UK, a branch of Panasonic Marketing Europe GmbH Maxis 2, Western Road, Bracknell, Berkshire, RG12 1RT MJE-SQ4C11 No. 0095-80V... - Page 38 Revision history Revision date Revision item 1st edition October 1, 2010 ― 2nd edition November 10, 2010 ― 3rd edition January 5, 2011 ― 4th edition June 1, 2011 ― 5th edition January 20, 2013 ― 6th edition January 15, 2016 ―...

- Page 39 (1) Panasonic Industry’s sole obligation and liability under this warranty is limited to the repair or replacement, or refund of the pur- chase price, of a defective Product, at Panasonic Industry’s option. (2) THE REPAIR, REPLACEMENT, OR REFUND IS THE EXCLUSIVE REMEDY OF THE PURCHASER, AND ALL...

- Page 40 Panasonic Industry Co., Ltd. 1006, Oaza Kadoma, Kadoma-shi, Osaka 571-8506, Japan https://industry.panasonic.com/ Please visit our website for inquiries and about our sales network. © Panasonic Industry Co., Ltd. 2010-2024 April, 2024 MJE-SQ4C11 No. 0095-80V...

Need help?

Do you have a question about the SQ4-C11 and is the answer not in the manual?

Questions and answers