Table of Contents

Advertisement

Quick Links

Published 08/22

This Operator's Manual is an integral part of the safe operation of this machine and

must be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW

the Safety and Operation Instructions contained in this manual before operating the

equipment.

®

BUSH HOG

2501 Griffin Ave.

Selma, AL 36703

334-874-2700

www.bushhog.com

OPERATOR'S MANUAL

C01-Cover str

©2022 Alamo Group Inc.

EWR

ECONO RAKE

Part No. 50068753

Advertisement

Table of Contents

Summary of Contents for Bush Hog EWR

- Page 1 READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment. C01-Cover str ® BUSH HOG 2501 Griffin Ave. Selma, AL 36703 334-874-2700 www.bushhog.com ©2022 Alamo Group Inc.

- Page 2 To the Owner/Operator/Dealer All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of accidents.

-

Page 3: Table Of Contents

FEDERAL LAWS AND REGULATIONS ....................... 1 - 18 INTRODUCTION SECTION ................2 - 1 ATTENTION OWNER/OPERATOR ........................ 2 - 4 BUSH HOG LIMITED WARRANTY ........................ 2 - 5 ASSEMBLY SECTION...................3 - 1 GENERAL ASSEMBLY ........................... 3 - 2 ASSEMBLY INSTRUCTIONS.......................... 3 - 3 OPERATION SECTION ........ - Page 4 Table of Contents TRACTOR PRE-OPERATION INSPECTION ....................4 - 15 DRIVING THE TRACTOR AND IMPLEMEMT ....................4 - 16 Starting the Tractor ..........................4 - 17 Brake and Differential Lock Setting ......................4 - 17 Driving the Tractor and Rake ........................4 - 18 OPERATING THE TRACTOR AND IMPLEMEMT ..................

-

Page 5: Safety Section

SAFETY SECTION Safety Section 1-1 © 2022 Alamo Group Inc. -

Page 6: Safety Messages

Safety Messages. Always use good common sense to avoid hazards. (SG-2) str Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las medidas de seguridad. (SG-3) str EWR 08/22 Safety Section 1-2 © 2022 Alamo Group Inc. -

Page 7: Operator Safety Instructions And Practices

Never allow children to play on or around Tractor or Implement. Children can slip or fall off the Equipment and be killed or injured. Inadvertent contact with controls can cause the Implement to shift or fall crushing themselves or others. (SG-25) str EWR 08/22 Safety Section 1-3 © 2022 Alamo Group Inc. - Page 8 Stop raking if anyone comes within 25 feet of the Implement to prevent possible passerby injury or death from being struck from a thrown object, entanglement with the rakes, or run over. (SRK-01) str EWR 08/22 Safety Section 1-4 © 2022 Alamo Group Inc.

-

Page 9: Equipment Operation Safety Instructions And Practices

Place the tractor shift lever into a low range or parking gear to prevent the tractor from rolling. Never dismount a Tractor that is moving or while the engine is running. Operate the Tractor controls from the tractor seat only. (SG-9)str EWR 08/22 Safety Section 1-5 © 2022 Alamo Group Inc. - Page 10 In case of mechanical difficulty during operation, place the transmission in the park position, set the parking brake, shut down all power, including the PTO and the engine and remove the key. Wait until all rotating motion has stopped before dismounting. (SG-39) str EWR 08/22 Safety Section 1-6 © 2022 Alamo Group Inc.

-

Page 11: Connecting Or Disconnecting Implement Safety Instructions And Practices

On a fully assembled unit, do not remove the Wing Retaining Strap until hoses are attached to the tractor and the Wing Cylinders are filled with oil. Lower the Wings slowly and carefully. Keep bystanders away during operations. (STI-05) str EWR 08/22 Safety Section 1-7 © 2022 Alamo Group Inc. -

Page 12: Transporting Safety Instructions And Practices

Make certain that at least 20% of the tractor’s weight is on the front wheels to maintain safe steerage. Slow down on rough or uneven surfaces. (STI-01) str EWR 08/22 Safety Section 1-8 © 2022 Alamo Group Inc. -

Page 13: Maintenance And Service Safety Instructions And Practices

Rotating Parts, Blades or Drivelines could turn without warning and cause immediate entanglement, injury or death. (S3PT-11)str Keep fingers clear of adjusting holes. A sudden movement could cause injury or even amputate fingers. KEEP CHILDREN AWAY WHEN MAKING ADJUSTMENTS. (SBL-3)str EWR 08/22 Safety Section 1-9 © 2022 Alamo Group Inc. - Page 14 Be alert to worn component surfaces which have sharp edges. Sharp surfaces can inflict severe laceration injuries if proper hand protection is not worn. (SG- 37) str Cancer and Reproductive Harm www.P65Warnings.ca.gov EWR 08/22 Safety Section 1-10 © 2022 Alamo Group Inc.

-

Page 15: Parts Information

These parts are made and tested to Bush Hog specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce equipment performance, void warranties, and present a safety hazard. Use genuine Bush Hog parts for economy and safety. -

Page 16: Decal Location

SAFETY DECAL LOCATION NOTE: Bush Hog supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Bush Hog cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 17 SAFETY ITEM PART NO. TYPE DESCRIPTION 999001 WARNING Maintain Weight for Steerage D859 WARNING Use Genuine Bush Hog Parts 00763977 INSTRUCT Notice to Owner 50058089 LOGO Bush Hog Logo 94359 REFLECT SMV Sign 02962764 WARNING Pinch Points 52740 WARNING Oil Leak...

-

Page 18: Decal Description

SAFETY DECAL DESCRIPTION EWR 08/22 Safety Section 1-14 © 2022 Alamo Group Inc. - Page 19 SAFETY EWR 08/22 Safety Section 1-15 © 2022 Alamo Group Inc.

- Page 20 SAFETY EWR 08/22 Safety Section 1-16 © 2022 Alamo Group Inc.

- Page 21 SAFETY EWR 08/22 Safety Section 1-17 © 2022 Alamo Group Inc.

-

Page 22: Federal Laws And Regulations

(Refer to U.S. Dept. of Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.) EWR 08/22 Safety Section 1-18 © 2022 Alamo Group Inc. -

Page 23: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1 © 2022 Alamo Group Inc. - Page 24 INTRODUCTION This EWR is designed with care and built with quality materials by skilled workers. Proper assembly, maintenance, and operating practices, as described in this manual, will help the owner/operator get years of satisfactory service from the machine. The purpose of this manual is to familiarize, instruct, and train. The Safety Section is a MUST READ section prior to any use of the rake.

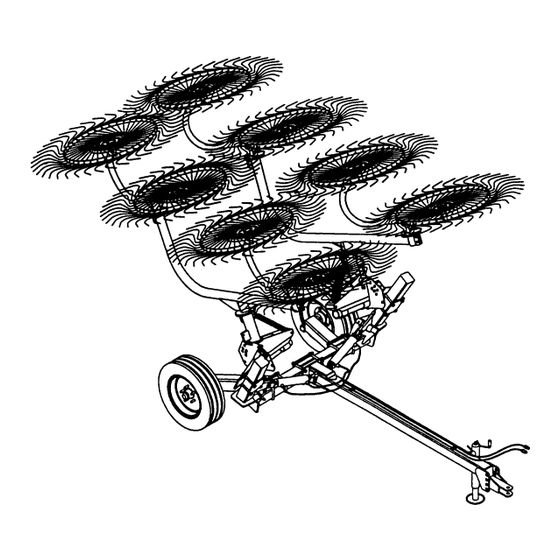

- Page 25 INTRODUCTION The Bush Hog EWR econo rakes provide the best of both worlds; clean efficient raking and budget-minded price. In maximum working widths of 20', 23' and 27’, the ER econo rakes make fast work of big jobs. With a reasonable amount of preventive maintenance, your Rake will provide years of dependable service.

-

Page 26: Attention Owner/Operator

NOTE: Warranties are honored only if completed “Owner Registration and Warranty” forms are received by Bush Hog within thirty days of delivery of the implement. 3. Record the Rake Model and Serial Number on the Warranty page at the front of the Operator’s Manual. -

Page 27: Bush Hog Limited Warranty

2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident. 3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgment of Bush Hog such use affects its performance, stability or reliability. -

Page 29: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1 © 2022 Alamo Group Inc. -

Page 30: General Assembly

Indicates a potentially dangerous situation which, if not avoided, could cause death or severe personal injury, including dangers which are present when protection is removed. Indicates a potentially dangerous situation which, if not avoided, can provoke less severe or minor injuries. EWR 08/22 Assembly Section 3-2 © 2022 Alamo Group Inc. -

Page 31: Assembly Instructions

(A) and fastening it with the plate (7), 16mm x 150mm bolts (27), and nuts (29). 3. Mount wheels (53) to hubs (B) on frame (2) using 16mm nuts (47). EWR 08/22 Assembly Section 3-3 © 2022 Alamo Group Inc. - Page 32 (3) & (4) are hinged to the cart. Fasten pins (12) with pins (33). 6. Attach the cylinders (25) to the lugs (G) and (H) using pins (13) and pins (32). EWR 08/22 Assembly Section 3-4 © 2022 Alamo Group Inc.

- Page 33 H. Place washers (23) and connect the quick release coupling (24) to the straight male ends of hoses (15). Check to make sure that all connections are correctly fastened. J. Attach the hose collar (54) to the lugs on drawbar, fastening on, correctly position (see step 9). EWR 08/22 Assembly Section 3-5 © 2022 Alamo Group Inc.

- Page 34 (M). This position is particularly useful for model EWR820. 9. The cart is now completely assembled and we can begin the assembly of the hay rakes. EWR 08/22 Assembly Section 3-6 © 2022 Alamo Group Inc.

- Page 35 EWR1022 Hay Rake. The same procedure applies to the EWR820 and EWR1227. 12. Attach arm (1) to arm (25) using M14x40mm bolts (12) and nuts (3). (EWR1022 & EWR1227) EWR 08/22 Assembly Section 3-7 © 2022 Alamo Group Inc.

- Page 36 (17), and nuts (16) 15. Repeat the procedures for steps 10-14 on the right side of the machine to complete the cart. Shown in the illustration is the EWR1022 model. EWR 08/22 Assembly Section 3-8 © 2022 Alamo Group Inc.

-

Page 37: Operation Section

OPERATION SECTION Operation Section 4-1 © 2022 Alamo Group Inc. - Page 38 EWR ECONO RAKE OPERATING INSTRUCTIONS Bush Hog econo rakes are manufactured with quality material by skilled workers. It is the operator’s responsibility to be knowledgeable of all potential operating hazards and to take every reasonable precaution to ensure oneself, others, animals, and property are not injured or damaged by the hay rake, tractor, or a thrown object.

-

Page 39: Standard Equipment And Specifications

14 MPH 14 MPH Horsepower Required 30 HP 30 HP 30 HP Tire Size 195/70R15 195/70R15 195/70R15 Weight (Approximate) 1200 lbs 1355 lbs 1585 lbs *Ratings based on actual field performance. EWR 08/22 Operation Section 4-3 © 2022 Alamo Group Inc. -

Page 40: Operator Requirements

Serious injury or death to the operator or others could result if the operator is under the influence of drugs or alcohol. (SG-27) str EWR 08/22 Operation Section 4-4 © 2022 Alamo Group Inc. -

Page 41: Tractor Requirements

For most raking conditions, the ER rakes require a tractor with at least 30 HP. Operating the implement with a tractor that does not have adequate power may damage the tractor engine. EWR 08/22 Operation Section 4-5 © 2022 Alamo Group Inc. -

Page 42: Getting On And Off The Tractor

Place the tractor shift lever into a low range or parking gear to prevent the tractor from rolling. Never dismount a Tractor that is moving or while the engine is running. Operate the Tractor controls from the tractor seat only. (SG-9)str EWR 08/22 Operation Section 4-6 © 2022 Alamo Group Inc. -

Page 43: Starting The Tractor

Always shut the Tractor completely down, place the transmission in park, and set the parking brake before you or anyone else attempts to connect or disconnect the Implement and Tractor hitches. (S3PT-15) str EWR 08/22 Operation Section 4-7 © 2022 Alamo Group Inc. -

Page 44: Setting The Implement

The adjustments depend on the pressure of the rake wheels on the ground and the desired swath width. For the EWR820, it is best to set all supports at the low position. EWR 08/22 Operation Section 4-8 © 2022 Alamo Group Inc. -

Page 45: Hitch

(attached at the central hole). They can be attached to the other two holes to be obtain a different rake wheel pressure on the ground. EWR 08/22 Operation Section 4-9 © 2022 Alamo Group Inc. -

Page 46: Pre-Operation Inspection And Service

Make sure all pins have cotter pins and washers. Serious injury may occur from not maintaining this machine in good working order. (SG-21 )str EWR 08/22 Operation Section 4-10 © 2022 Alamo Group Inc. -

Page 47: Tractor Pre-Operation Inspection/Service

Ensure the manual canister is secured to the equipment with the operator’s manual inside. • Ensure all safety signs are in place and legible. Replace missing, damaged, and illegible decals. OPS-U- 0011 str EWR 08/22 Operation Section 4-11 © 2022 Alamo Group Inc. - Page 48 REMOVE the HOSE and have it tested at a Dealer. If oil does penetrate the skin, have the injury treated immediately by a physician knowledgeable and skilled in this procedure. (SG-15) str EWR 08/22 Operation Section 4-12 © 2022 Alamo Group Inc.

- Page 49 • Make sure tires and wheels are in good con- dition. Make sure the wheel lug nuts are tight. OPS-RK-0005 str EWR 08/22 Operation Section 4-13 © 2022 Alamo Group Inc.

-

Page 50: Hay Rake Pre-Operation Inspection

There is no evidence of hydraulic leaks The tires & wheel(s) are in good condition Wheel lug nuts are tight Operator’s Signature: ____________________________________________ DO NOT OPERATE an UNSAFE TRACTOR or IMPLEMENT EWR 08/22 Operation Section 4-14 © 2022 Alamo Group Inc. -

Page 51: Tractor Pre-Operation Inspection

The engine coolant fluid level is full The radiator is free of debris The air filter is in good condition Operator’s Signature: ____________________________________________ DO NOT OPERATE an UNSAFE TRACTOR or IMPLEMENT EWR 08/22 Operation Section 4-15 © 2022 Alamo Group Inc. -

Page 52: Driving The Tractor And Implememt

When operating in traffic always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. (SG-19)str EWR 08/22 Operation Section 4-16 © 2022 Alamo Group Inc. -

Page 53: Starting The Tractor

When operating in traffic, always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. OPS-U- 0013 str EWR 08/22 Operation Section 4-17 © 2022 Alamo Group Inc. -

Page 54: Driving The Tractor And Rake

Special attention should be paid to foreign debris, rough terrain, steep slopes, and passersby and animals in the area. OPS-U- 0015 str EWR 08/22 Operation Section 4-18 © 2022 Alamo Group Inc. -

Page 55: Foreign Debris Hazards

As the severity of raking conditions increase, the ground speed should be decreased by selecting a lower gear to maintain the proper operating PTO speed. OPS-RK-0008 str EWR 08/22 Operation Section 4-19 © 2022 Alamo Group Inc. -

Page 56: Shutting Down The Implement

OPS-U- 0016 str EWR 08/22 Operation Section 4-20 © 2022 Alamo Group Inc. -

Page 57: Disconnecting The Implement From The Tractor

Use the Tongue Jack for lifting the Implement only. Overloading the Tongue Jack can cause failure with possible serious bodily injury or even death. (STI-04) str EWR 08/22 Operation Section 4-21 © 2022 Alamo Group Inc. -

Page 58: Rake Storage

OPS-RK-0010 str Never allow children or other persons to ride on the Tractor or Implement. Falling off can result in death or serious injury. (SG-10)str EWR 08/22 Operation Section 4-22 © 2022 Alamo Group Inc. -

Page 59: Transporting The Tractor And Implement

Use extreme caution and avoid hard applications of the tractor brakes when towing heavy loads at road speeds. Never tow the implement at speeds greater than 20 MPH (32 kph). OPS-U- 0018 str EWR 08/22 Operation Section 4-23 © 2022 Alamo Group Inc. -

Page 60: Transporting

(55) to the two supports (8) and (10) by connecting the hooks (56) to pins (T). The chain must be removed before putting the arms back into the working position. EWR 08/22 Operation Section 4-24 © 2022 Alamo Group Inc. -

Page 61: Transporting On Public Roadways

Consult an authorized tractor dealer for lighting kits and modifications available to upgrade the lighting on older tractor models. OPS-U- 0021str EWR 08/22 Operation Section 4-25 © 2022 Alamo Group Inc. -

Page 62: Hauling The Tractor And Implement

Ensure that the load will be in compliance with the legal limits set for the areas that will be traveled through. OPS-U-0024 EWR 08/22 Operation Section 4-26 © 2022 Alamo Group Inc. - Page 63 If during transport a hard braking, sharp turning, or swerving action was performed, stop at the next safe location to inspect the security of the load. OPS-U- 0026str EWR 08/22 Operation Section 4-27 © 2022 Alamo Group Inc.

-

Page 64: Troubleshooting

Avoid backing with teeth down. Excessive speed on rough terrain. Reduce speed. Narrow or deep ditches or furrows, Avoid or cross slowly. rocky ground. Too much weight on wheels. Raise 3-point slightly. EWR 08/22 Operation Section 4-28 © 2022 Alamo Group Inc. -

Page 65: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1 © 2022 Alamo Group Inc. - Page 66 The machine consists mainly of ferrous material which must be disposed of according to the regulations in force in the country concerned. There is also a small amount of plastic which must be disposed of according to the regulations in force in the country concerned. EWR 08/22 Maintenance Section 5-2 © 2022 Alamo Group Inc.

-

Page 67: Storage

The rods remaining outside the cylinder (whatever reason may be) must be carefully protected with a grease layer. EWR 08/22 Maintenance Section 5-3 © 2022 Alamo Group Inc. -

Page 68: Bolt Torque Values

When replacing bolts, always use the same grade of bolt as used originally. Use the chart as a guide to tightening all bolts. Torque values listed are for general use only. EWR 08/22 Maintenance Section 5-4... - Page 69 TO THE OWNER/OPERATOR/DEALER To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily find the information you need. The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety requirements of tractor operators: REQUIRED OF THE OWNER:...

- Page 70 EWR ECONO RAKE EWR-SOM 08/22 P/N 50068753 Printed U.S.A...

Need help?

Do you have a question about the EWR and is the answer not in the manual?

Questions and answers