Table of Contents

Advertisement

Quick Links

Published 09/21

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

®

BUSH HOG

2501 Griffin Ave.

Selma, AL 36703

334-874-2700

www.bushhog.com

OPERATOR'S MANUAL

© 2021 Alamo Group Inc.

CPG Series

Compact Pluggers

Models CPG48, CPG60, CPG72

CAR Series

Compact Aerator

Models CAR48, CAR60, CAR72

Part No. 50078871

$0.00

Advertisement

Table of Contents

Summary of Contents for Bush Hog CPG Series

- Page 1 CPG Series Compact Pluggers Models CPG48, CPG60, CPG72 CAR Series Compact Aerator Models CAR48, CAR60, CAR72 Published 09/21 Part No. 50078871 OPERATOR’S MANUAL This Operator's Manual is an integral part of the safe operation of this machine and must be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment.

- Page 2 BEFORE YOU START! Read the safety messages on the implement and shown in your manual. Observe the rules of safety and common sense! For future reference, record your Bush Hog product model number and serial number. Dealer Telephone Model Number...

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY SECTION ......................1-1 General Safety Instructions and Practices ......................1-2 Operator Safety Instructions and Practices ....................... 1-3 Equipment Operation Safety Instructions and Practices ..................1-5 Connecting or Disconnecting Implement Safety Instructions and Practices ............1-7 Maintenance and Service Safety Instructions and Practices ................1-7 Storage and Parking Safety Instructions and Practices .................. - Page 4 Hauling the Tractor and Implement ........................4-23 TROUBLESHOOTING GUIDE ........................4-24 MAINTENANCE SECTION ....................5-1 LUBRICATION INFORMATION ......................... 5-2 SPOONS ................................5-3 STORAGE ................................. 5-3 PROPER TORQUE FOR FASTENERS ......................5-3...

-

Page 5: Safety Section

SAFETY SECTION Safety Section 1-1... -

Page 6: General Safety Instructions And Practices

SAFETY General Safety Instructions and Practices A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to the owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings, and observing certain precautions. -

Page 7: Operator Safety Instructions And Practices

SAFETY Repeated or substantial breathing of hazardous dusts, including crystalline silica, could cause fatal or serious respiratory disease including silicosis. Concrete, masonry, many types of rock, and various other materials contain silica sand. California lists respirable crystalline silica as a substance known to cause cancer. Operation of this equipment under certain conditions may generate airborne dust particles that could contain crystalline silica. - Page 8 SAFETY Always read carefully and comply fully with the manufacturer’s instructions when handling oil, solvents, cleansers, and any other chemical agent. (SG-22) KEEP AWAY FROM ROTATING ELEMENTS to prevent entanglement and possible serious injury or death. (SG-24) Never allow children to play on or around Tractor or Implement. Children can slip or fall off the Equipment and be injured or killed.

-

Page 9: Equipment Operation Safety Instructions And Practices

SAFETY Equipment Operation Safety Instructions and Practices There are obvious and hidden potential hazards in the operation of this implement as in all power-driven or pulled equipment. REMEMBER! This machine is often operated in rough terrain conditions that include tall grass, weeds, gullies, holes, slopes, hidden obstructions and the like. - Page 10 SAFETY Never allow children to operate, ride on, or come close to the Tractor or Implement. Usually, 16-17 year-old children who are mature and responsible can operate the implement with adult supervision, if they have read and understand the Operator’s Manuals, been trained in proper operation of the tractor and Implement, and are physically large enough to reach and operate the controls easily.

-

Page 11: Connecting Or Disconnecting Implement Safety Instructions And Practices

SAFETY Connecting or Disconnecting Implement Safety Instructions and Practices Always shut the Tractor completely down, place the transmission in park, and set the parking brake before you or anyone else attempts to connect or disconnect the Implement and Tractor hitches. (S3PT-15) Maintenance and Service Safety Instructions and Practices Never crawl under a raised Implement supported solely by the Tractor 3-Point hitch. -

Page 12: Storage And Parking Safety Instructions And Practices

SAFETY Periodically inspect all moving parts for wear and replace when necessary with authorized service parts. Look for loose fasteners, worn or broken parts, and leaky or loose fittings. Make sure all pins have cotter pins and washers. Serious injury may occur from not maintaining this machine in good working order. -

Page 13: Transporting Safety Instructions And Practices

SAFETY Transporting Safety Instructions and Practices Be particularly careful when transporting the Implement with the Tractor. Turn curves or go up hills only at a low speed and using a gradual steering angle. Rear mounted implements move the center of gravity to the rear and remove weight from the front wheels. Make certain, by adding front ballast, that at least 20% of the tractor’s weight is on the front wheels to prevent rearing up, loss of steering control or Tractor tip-over. -

Page 14: Concluding Safety Instructions And Practices

These parts are made and tested to Bush Hog specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce equipment performance, void warranties, and present a safety hazard. Use genuine Bush Hog parts for economy and safety. -

Page 15: Decal Location

SAFETY Decal Location NOTE: Bush Hog supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Bush Hog cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 16 SAFETY Decal Location NOTE: Bush Hog supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Bush Hog cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply).

-

Page 17: Decal Description

SAFETY Decal Description CPG/CAR 09/21 Safety Section 1-13 © 2021 Alamo Group Inc. -

Page 18: Federal Laws And Regulations

SAFETY FEDERAL LAWS AND REGULATIONS This section is intended to explain in broad terms the concept and effect of federal laws and regulations concerning employer and employee equipment operators. This section is not intended as a legal interpretation of the law and should not be considered as such. -

Page 19: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1... - Page 20 INTRODUCTION This compact plugger/aerator is designed with care and built with quality materials by skilled workers. Proper assembly, maintenance, and operating practices, as described in this manual, will help the owner/operator get years of satisfactory service from the machine. The purpose of this manual is to familiarize and instruct. The Assembly Section instructs the owner/operator in the correct assembly of the plugger.

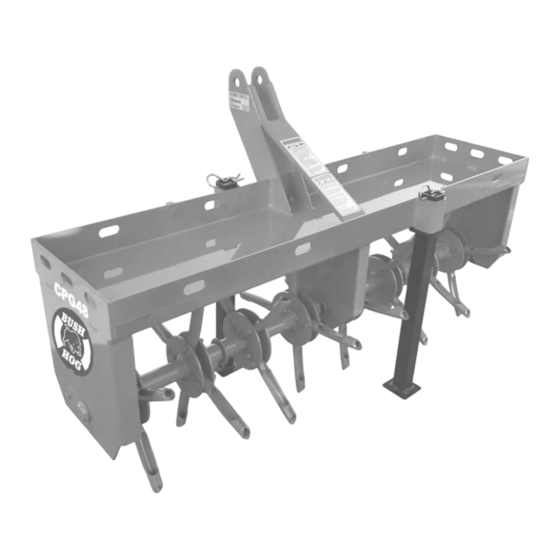

- Page 21 Aerator Plugger Bush Hog’s Compact Pluggers and Aerators are the perfect tool for homeowners to care for lawns by breaking up and aerating compacted dirt with you compact tractor. Our Compact Plugger uses 3/4” hardened spoons attached to independently rotating and greaseable hubs on a 1-1/4”...

- Page 22 INTRODUCTION Attention Owner/Operator BEFORE OPERATING THIS MACHINE: 1. Carefully read the Operator’s Manual, completely understand the Safety Messages and instructions, and know how to operate correctly both the tractor and implement. 2. Fill out the Warranty Card in full. Be sure to answer all questions, including the Serial Number of the implement.

- Page 23 2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident. 3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgment of Bush Hog such use affects its performance, stability or reliability.

-

Page 25: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1... -

Page 26: Assembly And Set-Up

ASSEMBLY Assembly and Set-Up Bush Hog’s Compact Pluggers and Compact Aerators come fully assembled from the factory but make sure to grease each hub before use to ensure longevity and prevent damage. Attachment The implement should be placed on level ground. -

Page 27: Operation Section

OPERATION SECTION Operation Section 4-1... - Page 28 OPERATION CPG SERIES COMPACT PLUGGER & CAR SERIES COMPACT AERATOR OPERATION INSTRUCTIONS Your implements should now be assembled and inspected for any evidence of defective or damaged parts before use. Any evidence of damage should be reported to your dealer immediately.

-

Page 29: Standard Equipment And Specifications

OPERATION Standard Equipment and Specifications Model CPG48 CAR48 CPG60 CAR60 CPG72 CAR72 Product COMPACT COMPACT COMPACT COMPACT COMPACT COMPACT Description PLUGGER AERATOR PLUGGER AERATOR PLUGGER AERATOR Overall 49-7/8” 49-7/8” 62-1/4” 62-1/4” Width Working 43-11/16” 44-15/16” 56-1/4” 57-3/8” 67-7/8” Width Overall 20-5/8”... -

Page 30: Operator Requirements

OPERATION 2. OPERATOR REQUIREMENTS Safe operation of the unit is the responsibility of a qualified operator. A qualified operator has read and understands the implement and tractor Operator’s Manuals and is experienced in implement and tractor operation and all associated safety practices. In addition to the safety messages contained in this manual, safety signs are affixed to the implement and tractor. -

Page 31: Tractor Requirements

OPERATION 3. TRACTOR REQUIREMENTS Operating the plugger/aerator with a tractor that does not meet the following requirements may cause tractor or implement damage and be a potential danger to the operator and passersby. Tractor Requirements and Capabilities • ASABE approved Roll-Over Protective Structure (ROPS) or ROPS cab and seat belt. •... -

Page 32: Boarding The Tractor

OPERATION Do not mount or dismount the Tractor while the tractor is moving. Mount the Tractor only when the Tractor and all moving parts are completely stopped. (SG-12) 4.1 Boarding the Tractor Use both hands and equipped handrails and steps for support when boarding the tractor. Never use control levers for support when mounting the tractor. -

Page 33: Starting The Tractor

OPERATION 5. STARTING THE TRACTOR The operator must have a complete understanding of the placement, function, and operational use of all tractor controls before starting the tractor. Review the tractor operator’s manual and consult an authorized dealer for tractor operation instructions if needed. Essential Tractor Controls: •... -

Page 34: 3-Point Hook-Up

OPERATION IMPORTANT: Scan this QR Code with your smart phone to link to the PAMI Safe Implement Hitching Manual for more information on correctly connecting agricultural tractors to implements. Or type in your internet browser the following web address: www.algqr.com/hme Ops-0008-MISC 6.1 3-Point Hook-Up Attempting to hitch when implement is not on leveled ground could cause the implement to... - Page 35 OPERATION 5. Align upper hitch point from tractor in between upper mounting frame. 6. Using a 3/4” clevis pin (not supplied), secure CAR/CPG to upper hitch point. To avoid serious injury or death clear area to be aerated of debris and other potential hazards.

-

Page 36: Hitching Implement

OPERATION 6.2 Hitching Implement 1. Before hitching and operating your CAR/CPG, make sure each of the hubs are greased. 2. Ensure proper connections with hitch, please see 3-Point Hook-Up. 3. Once securely attached to your tractor, raise implement to assure clearance for jackstand removal. There is one located on the front and rear. -

Page 37: Pre-Operation Inspection And Service

OPERATION 7. PRE-OPERATION INSPECTION AND SERVICE Before each use, a pre-operation inspection and service of the implement and tractor must be performed. This includes routine maintenance and scheduled lubrication, inspecting that all safety devices are equipped and functional, and performing needed repairs. DO NOT operate the unit if the pre-operation inspection reveals any condition affecting safe operation. -

Page 38: Aerator / Plugger Pre-Operation Inspection/Service

OPERATION 7.2 Aerator / Plugger Pre-Operation Inspection/Service Before each use, a complete inspection and service is required to ensure the aerator or plugger is in good and safe working condition. Damaged and/or broken parts should be repaired and/or replaced immediately. To ensure the implement is ready for operation, conduct the following. - Page 39 OPERATION Tractor PRE-OPERATION Inspection Tractor ID#:________________________Make:________________________ Date:______________________________Shift:________________________ Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged. Make sure the implement is resting on the ground or securely blocked up and all hydraulic pressure has been relieved.

- Page 40 OPERATION Aerator PRE-OPERATION Inspection Aerator ID#___________________ Make__________________________ Date: ________________________ Shift__________________________ Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged. Make sure the aerator is resting on the ground or securely blocked up and all hydraulic pressure has been relieved.

- Page 41 OPERATION Plugger PRE-OPERATION Inspection Plugger ID#___________________ Make__________________________ Date: ________________________ Shift__________________________ Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged. Make sure the plugger is resting on the ground or securely blocked up and all hydraulic pressure has been relieved.

-

Page 42: Driving The Tractor And Implement

OPERATION 8. DRIVING THE TRACTOR AND IMPLEMENT Start off driving at a slow speed and gradually increase your speed while maintaining complete control of the tractor and unit. Moving slowly at first will also prevent the tractor from rearing up and loss of steering control. The tractor should never be operated at speeds that cannot be safely handled or which will prevent the operator from stopping quickly during an emergency. -

Page 43: Brake And Differential Lock Setting

OPERATION 8.2 Brake and Differential Lock Setting Make sure the tractor brakes are in good operating condition. Tractor brakes can be set to operate independently allowing single rear wheel braking action or locked together to provide simultaneous rear wheel braking. FOR MOST DRIVING AND OPERATING CONDITIONS, THE BRAKE PEDALS SHOULD BE LOCKED TOGETHER TO PROVIDE... -

Page 44: Operating The Aerator Or Plugger

OPERATION 9.1 Operating the Aerator or Plugger Level the implement from side to side and front to rear using adjustments on the tractor’s 3-point lift. During implement adjustment, keep body, hands and feet clear of spoons or other parts. Compact Pluggers and Aerators should be operated when the ground is moist to achieve the best penetration. The frame can be used as a weight rack (Max 500 lbs.) when conditions require it. -

Page 45: Shutting Down The Implement

OPERATION 10. Shutting Down the Implement To shut down the implement, first bring the tractor to a complete stop. Park the tractor on a level surface, place the transmission in park or neutral and apply the parking brake, lower the attached implement to the ground, shut down the engine, remove the key, before exiting the tractor. -

Page 46: Transporting The Tractor And Implement

OPERATION 12. TRANSPORTING THE TRACTOR AND IMPLEMENT Inherent hazards of operating the tractor and implement and the possibility of accidents are not left behind when you finish working in an area. Therefore, the operator must employ good judgement and safe operation practices when transporting the tractor and implement between locations. -

Page 47: Transporting On Public Roadways

OPERATION Before transporting the tractor on a public roadway or boarding a trailer for transport, the tractor brake pedals should be locked together. Locking the pedals ensures that both wheels brake simultaneously while stopping, especially when making an emergency stop. Use extreme caution and avoid hard applications of the tractor brakes when towing heavy loads at road speeds. - Page 48 OPERATION The SMV (Slow-Moving Vehicle) emblem is universal symbol used to alert drivers of the presence of equipment traveling on roadways at a slow speed. SMV signs are a triangular bright orange with reflective red trim for both easy day and night visibility.

-

Page 49: Hauling The Tractor And Implement

OPERATION 12.2 Hauling the Tractor and Implement Before transporting a loaded tractor and implement, measure the height and width dimensions and gross weight of the complete loaded unit. Ensure that the load will be in compliance with the legal limits set for the areas that will be traveled through. -

Page 50: Troubleshooting Guide

OPERATION 13. TROUBLESHOOTING GUIDE Problem Possible Cause Remedy Tillage depth is insufficient Not enough weight in weight tray. Add weight to the weight tray. Ground is too hard Irrigate field or wait for rain fall. Ground Speed is too fast. Decrease ground speed. -

Page 51: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1... -

Page 52: Lubrication Information

MAINTENANCE Before operating your implement, make sure it is properly lubricated and thoroughly inspected. Only a minimum of time and effort is required to regularly lubricate and maintain this machine to provide long life and trouble-free operation. Block up or support machine securely before putting hands or feet under or working underneath lifted components to prevent CRUSHING INJURY or DEATH from sudden, inadvertent dropping. -

Page 53: Spoons

MAINTENANCE SPOONS When spoons become worn, replace one at a time to ensure proper location and assembly. Store the implement out of the weather when it is not in use. This helps prevent rusting of the spoons and other components. STORAGE Your implement represents an investment from which you should get the greatest possible benefit. - Page 54 MAINTENANCE CPG/CAR 09/21 Maintenance Section 5-4 © 2021 Alamo Group Inc.

- Page 55 TO THE OWNER/OPERATOR/DEALER To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily find the information you need. The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety...

- Page 56 CPG Series Compact Pluggers CAR Series Compact Aerator CPG/CAR -09/21 P/N 50078871 Printed U.S.A...

Need help?

Do you have a question about the CPG Series and is the answer not in the manual?

Questions and answers