Subscribe to Our Youtube Channel

Summary of Contents for Maytag MLG45PDCWW

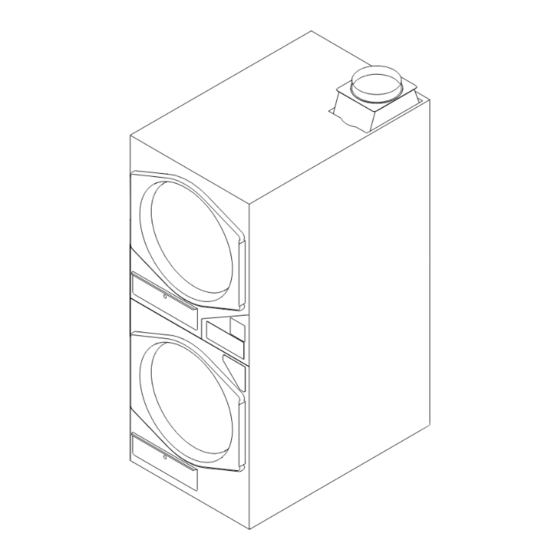

- Page 1 MLG-45PDB Installation Manual Stack Dryer RETAIN THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE Part No. 113489 - 3 (W10185535)

- Page 2 – L’installation et l’entretien doivent être assurés par un installateur ou un service d’entretien qualifié ou par le fournisseur de gaz. Maytag Co. 113489 - 3 (W10185535)

- Page 3 Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1. The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1. 113489 - 3 (W10185535) Maytag Co.

-

Page 4: Table Of Contents

List of Acronyms _______________________ DATA LABEL INFORMATION ........14 American Wire Gauge HVAC Heating, Ventilating, and Air-Conditioning in wc Inches of Water Column L.C.D. Liquid Crystal Display L.E.D. Light Emitting Diode L.P. Liquid Propane Underwriters Laboratory Maytag Co. 113489 - 3 (W10185535) -

Page 5: Specifications

(DIAMETER) PER POCKET (1) 25.4 cm (1) 10” Opti onal INLET PIPE CONNECTION 3/4” M.N.P.T. 8/2/07 NOTE: The manufacturer reserves the right to make changes in specifications at any time without notice or obligation. 113489 - 3 (W10185535) Maytag Co. -

Page 6: Installation Procedures

The dryer must be installed with adequate clearance for air openings into the combustion chamber. IMPORTANT: The dryer must be installed in a location/ environment, which the ambient temperature remains between 40° F (4.44° C) and 130° F (54.44° C). Maytag Co. 113489 - 3 (W10185535) -

Page 7: Dryer Enclosure Requirements

Fire Hazard Use a heavy metal vent. Do not use a plastic vent. Do not use a metal foil vent. Failure to follow these instructions can result in death or fire. 113489 - 3 (W10185535) Maytag Co. - Page 8 NOTE 1 Opening from combustible materials must be 2-inches (5.08 cm) larger than the duct (all the way around). The duct must be centered within this opening. NOTE 2 Distance should be 2 times the diameter of the duct to the nearest obstruction. Maytag Co. 113489 - 3 (W10185535)

- Page 9 NOTE 2 Distance should be 2 times the diameter of the duct to the nearest tumblers or 10-inches (25.4 cm) for individual dryers. obstruction. IMPORTANT: To maintain proper performance, no more than 4 dryers should be connected to 1 main common duct. 113489 - 3 (W10185535) Maytag Co.

-

Page 10: Electrical Information

Remove 3 screws holding down electrical box plate at the meters). 1/9/08 top of the machine. Remove 2 knockouts provided just in front of electrical box and insert 3/4” UL listed strain relief into the holes. Maytag Co. 113489 - 3 (W10185535) -

Page 11: Gas Information

NOTE: Undersized gas piping will result in ignition problems, slow drying, and increased use of energy. Input connection wiring must be sized properly to handle the dryer’s current draw. This information is printed on the dryer’s data label. 113489 - 3 (W10185535) Maytag Co. -

Page 12: Preparation For Operation/Start-Up

NOTE: Undersized gas supply piping can create a low or • Check that the vent is connected to the dryer and is inconsistent pressure, which will result in erratic operation exhausted to the outdoors. of the burner ignition system. Maytag Co. 113489 - 3 (W10185535) -

Page 13: Preoperational Test

NOTE: During the purging period, check to be sure that all purchased. If the distributor cannot be contacted or is gas shutoff valves are open. unknown, contact the Maytag Co. for a distributor in your area. NOTE: When contacting the Maytag Co., be sure to give Tumbler Coating them the correct model number and serial number so that The tumbler is treated with a protective coating. -

Page 14: Adjustments

Weekly Clean lint accumulation from lint chamber, thermostat, and microprocessor temperature sensor area. When contacting Maytag, the information on the data label is 90 Days required to ensure proper service/parts assistance. The data label is located at the lower left rear of the dryer behind the Remove lint from gas valve burner area with a dusting brush back guard.

Need help?

Do you have a question about the MLG45PDCWW and is the answer not in the manual?

Questions and answers