Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Buchi SyncorePlus

- Page 1 Operation Manual SyncorePlus...

- Page 2 CH-9230 Flawil 1 E-Mail: quality@buchi.com BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experience, especially with respect to structure, illustrations and technical details. This manual is copyrighted. Information from it may neither be reproduced, distributed, or used for competitive purposes, nor made available to third parties.

-

Page 3: Table Of Contents

Cover ........................... 16 Type plate ............................ 17 Scope of delivery .......................... 17 Technical data ........................... 17 3.5.1 SyncorePlus......................... 17 3.5.2 Ambient conditions....................... 18 3.5.3 Materials .......................... 18 Transport and storage........................ 19 Transport ............................ 19 Storage .............................. 19 Lifting the instrument ......................... 19 Operation Manual SyncorePlus... - Page 4 Help with faults .......................... 41 Troubleshooting .......................... 41 Error messages .......................... 42 Changing the fuse.......................... 44 Taking out of service and disposal.................... 45 10.1 Taking out of service.......................... 45 10.2 Disposal ............................. 45 10.3 Returning the instrument ........................ 45 Operation Manual SyncorePlus...

- Page 5 Gaskets and plugs ....................... 52 11.2.6 Sample preparation rack...................... 53 11.2.7 Condenser ........................... 54 11.2.8 Receiving flask........................ 54 11.2.9 Cocking lever ........................ 54 11.2.10 Sleeves .......................... 54 11.2.11 Accessories SPE configuration.................... 55 11.2.12 Sensors.......................... 57 11.2.13 Tubing .......................... 58 11.2.14 Hose barbs........................... 58 11.2.15 Tools ............................ 59 11.2.16 Service .......................... 59 Operation Manual SyncorePlus...

-

Page 6: About This Document

Indicates a danger that could result in damage to property. 1.2 Symbols The following symbols are displayed in this operation manual or on the device: 1.2.1 Warning symbols Symbol Meaning General warning Instrument damage Hot surface Hand injuries Dangerous electrical voltage Breakable items 6/60 Operation Manual SyncorePlus... -

Page 7: Mark-Ups And Symbols

1.4 Connected instruments In addition to this operation manual, follow the instructions and specifications in the documentation for the connected instruments. Operation Manual SyncorePlus 7/60... -

Page 8: Safety

The use of the instrument other than described in proper use and specified in technical data is use other than that intended. The operator is responsible for damages or hazards that are caused by use other than that intended. Especially the following uses are not permitted: 8/60 Operation Manual SyncorePlus... -

Page 9: Location Of Warning Signs On The Product

BÜCHI Labortechnik AG Safety | 2 2.3 Location of warning signs on the product Fig. 1: Location of warning signs Symbol Meaning Hot surface Hand injuries Operation Manual SyncorePlus 9/60... -

Page 10: Protection Devices

They are familiar with the contents of these operating instructions and the applicable safety regulations and apply them. — They are able on the basis of their training or professional experience to assess the risks associated with the use of the instrument. 10/60 Operation Manual SyncorePlus... -

Page 11: Residual Risks

Safety-related incidents that occur while using the instrument should be reported to the manufacturer (quality@buchi.com). BUCHI service technicians Service technicians authorized by BUCHI have attended special training courses and are authorized by BÜCHI Labortechnik AG to carry out special servicing and repair measures. -

Page 12: High Internal Pressure

Unauthorized modifications can affect safety and lead to accidents. Use only genuine BUCHI accessories, spare parts and consumables. Carry out technical changes only with prior written approval from BUCHI. Only allow changes to be made by BUCHI service technicians. BUCHI accepts no liability for damage, faults and malfunctions resulting from unauthorized modifications. -

Page 13: Product Description

The vapor is converged and reheated in the cover. Then it passes on via the vacuum hose to the condenser. There, the latent heat of the vapor is transferred to the coolant fluid so that the vapor condenses. Operation Manual SyncorePlus 13/60... -

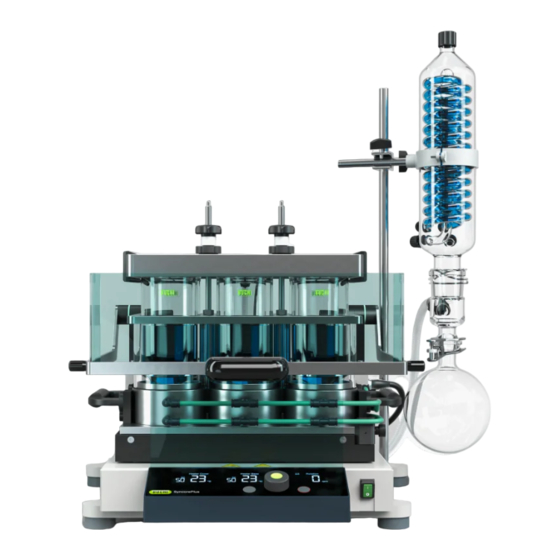

Page 14: Configuration

3.2.1 Front view Fig. 3: Front view Protective cover Heating base Screws fixing cover Connection cover Venting slots Crush protection Unbalance compensation adjustment 8 Handle protective cover On/Off master switch 10 Control panel 11 Handle protective cover 14/60 Operation Manual SyncorePlus... -

Page 15: Rear View

Product description | 3 3.2.2 Rear view 9 10 Fig. 4: Rear view Tap hole Fuse Mains power supply Type plate Chapter 3.3 “Type plate”, page 17 BUCHI standard communication port BUCHI standard communication port (COM) (COM) Cooling water valve Reserve (marked (marked Ventilation slots... -

Page 16: Cover

3 | Product description BÜCHI Labortechnik AG 3.2.3 Cover Fig. 5: Cover top Sealing Clamping nut Connector cover Vacuum connection Fig. 6: Cover bottom Handle Sealing disk Screw cap Support disk 16/60 Operation Manual SyncorePlus... -

Page 17: Type Plate

50/60 Hz 50/60 Hz Power consumption 1250 W 1250 W 1400 W Power consumption heater cover 120 W 120 W 120 W Rotation speed range 60 - 400 rpm 60 - 400 rpm 60 - 400 rpm Operation Manual SyncorePlus 17/60... -

Page 18: Ambient Conditions

Vacuum hose Ribbed PFA Condenser Borosilicate glass Sealing discs Rack R4 and R-6 PTFE coating Glass with residual volume appendix Borosilicate glass Glass R-4 and Glass R-6 Sealing discs, Rack R-24, R48 and R-96 Polyethylene Crush protection 18/60 Operation Manual SyncorePlus... -

Page 19: Transport And Storage

4.3 Lifting the instrument NOTICE Dragging the instrument can damage the feet of the instrument. Lift the instrument when positioning or re-locating. Lift the instrument at the points indicated ((1) + (3) and (2) + (3)). Operation Manual SyncorePlus 19/60... -

Page 20: Installation

Risk of instrument damage because of not suitable power supply cables. Not suitable power supply cables can cause bad performance or an instrument damage Use only BUCHI power supply cables. Precondition: The electrical installation is as specified on the type plate. -

Page 21: Securing Against Earthquakes

5.6 Installing the condenser NOTE Choose the tap hole according to your installation. Position tap hole see Chapter 3.2 “Configuration”, page 14 5.6.1 Installing the condenser Attach the support rod to the instrument. Attach the cross sleeve to the support rod. Operation Manual SyncorePlus 21/60... -

Page 22: Connecting The Coolant To The Condenser

5.6.2 Connecting the coolant to the condenser Install the coolant hoses onto the hose nipples. Secure the coolant hoses in place with a hose clip. Attach the prepared coolant hoses onto the condenser. 22/60 Operation Manual SyncorePlus... -

Page 23: Connecting The Vacuum Pump To The Condenser

Vapor temperature sensor. Incl. cap nut, seal 11060707 GL14 Measures the vapor temperature inside the system. Meant to be used with the Interface I-300 Pro. Only for vapor temperature, can not be upgraded to AutoDest sensor. Operation Manual SyncorePlus 23/60... -

Page 24: Installing The Waste Vessel (Spe Configuration Only)

In combination with AutoDest sensor for auto- mated distillation of residual solvent. Meant to be used with AutoDest sensor 11059225, Adapter cable for SyncorePlus 11069477, In- terface I-300 Pro and S-type condenser. Attach the sensor to the condenser. Attach the plug onto the VacuBox. - Page 25 NOTICE! Push the hose 3 cm in the waste bottle Attach the waste line to the waste bottle. Attach the cross sleeve to the support rod. Attach the waste vessel to the support rod. Attach the waste tube onto the waste bottle. Operation Manual SyncorePlus 25/60...

- Page 26 5 | Installation BÜCHI Labortechnik AG Attach the waste tube onto the condenser. 26/60 Operation Manual SyncorePlus...

-

Page 27: Preparing The Instrument For A Configuration

Put the rack on the heater base. Make sure that there are no spaces between rack and heater base. Secure the rack in place with the screws on both sides. Fill water into the rack. Operation Manual SyncorePlus 27/60... - Page 28 Put the heater cover on the instrument. Connect the heater cover to the instrument. If using a rack with 24 or more positions, place a spring in each hole. Put the sample tubes in the rack. Close the protective cover. 28/60 Operation Manual SyncorePlus...

-

Page 29: Preparing An Analyst Configuration

Tighten the knurl nuts with your hand. 6.2 Preparing an Analyst configuration Make sure that the surface of the heater base is clean. Put the rack on the heater base. Make sure that there are no spaces between rack and heater base. Operation Manual SyncorePlus 29/60... - Page 30 Attach the condenser tubes in place with a hose clip. If appendix is less than 3 mL insert sealing. Fill water into the rack. Attach the vacuum hose to the heater cover. Put the heater cover on the instrument. 30/60 Operation Manual SyncorePlus...

- Page 31 Connect the heater cover to the instrument. Put the sample tubes in the rack. Close the protective cover. Put the heater cover on the rack. NOTICE! Do not tighten the knurl nuts too much. Tighten the knurl nuts with your hand. Operation Manual SyncorePlus 31/60...

-

Page 32: Preparing A Spe Configuration

Put the rack on the heater base. Make sure that there are no spaces between rack and heater base. Secure the rack in place with the screws on both sides. Fill water into the rack. 32/60 Operation Manual SyncorePlus... - Page 33 Attach the vacuum hose to the heater cover. Connect the heater cover to the instrument. Put the cover on the instrument. Put the sample tubes in the rack. Close the protective cover. Put the heater cover on the rack. Operation Manual SyncorePlus 33/60...

-

Page 34: Position Spe Advanced Valves

Tighten the knurl nuts with your hand. Attach the waste line to the valve. Prepare the sample according to your needs. 6.3.1 Position SPE advanced valves Elute Stop Waste The sample flows in the Sample flows in the waste tube 34/60 Operation Manual SyncorePlus... -

Page 35: Operation

The status panel can display the following status: View Status The instrument is ready to start START PAUSE The instrument is carrying out an evaporation Confirm set values A cooling water valve is connected Cooling water valve activated Setting mode Operation Manual SyncorePlus 35/60... -

Page 36: Setting The Evaporation Temperature

Risk of explosion from excessive internal pressure The evaporating flask and/or the condenser could explode if the internal pressure produced by evaporation becomes too great. Make sure that the pressure in the system is never greater than atmospheric pressure. 36/60 Operation Manual SyncorePlus... -

Page 37: Preparing The Instrument

Tap the button ð The instrument stops heating. ð The instrument stops the rotation. Switch off the connected chiller or close the water tap. 7.3.4 Shutting down the instrument Set the On/Off master switch to Off. Operation Manual SyncorePlus 37/60... -

Page 38: Cleaning And Servicing

Do not carry out any servicing and cleaning operations that involve opening the housing. Use only genuine BUCHI spare parts in order to ensure correct operation and preserve the warranty. Carry out the service and cleaning operations described in this section to extend the lifetime of the instrument. -

Page 39: Locking And Unlocking The Rotation

The default setting of the unbalance compensation is 23 mm. This default setting covers all standardized operations. Move the heating plate to the pre-defined stopping position. See Chapter 8.3 “Moving and retrieving the heating plate into a pre-defined position”, page 39 Insert the tool. Operation Manual SyncorePlus 39/60... -

Page 40: Testing The Vortex Movement

Prepare the configuration. See Chapter 6 “Preparing the instrument for a configuration”, page 27 Turn the navigation control to the rotation speed according to the requirements. Make sure that the requested rotation speed is the same as the rotation speed shown on the display. 40/60 Operation Manual SyncorePlus... -

Page 41: Help With Faults

Check the vibration fect. elements. Contact BUCHI Customer Service. Vibration The rotation speed is too high. Reduce rotation speed. Protection shield The fixing screw is loose. Tighten the fixing screw. does not keep the upper position Operation Manual SyncorePlus 41/60... -

Page 42: Error Messages

Voltage during 1000 ms below/ Check power supply or above 30.0 V ±10% instrument for overloading components like wrong external valves or short circuits. Access to EEPROM not possible Restart the instrument. Contact BUCHI Customer Service. 42/60 Operation Manual SyncorePlus... - Page 43 (nominal 115 V), 120 V (nominal 100 V) Acceleration of instrument above Adjust the unbalance 0.126 g during 1 sec. (second compensation. level) One or more parameter out of range Check and reconfigure parameters. Restart the instrument. Contact BUCHI Customer Service. Operation Manual SyncorePlus 43/60...

-

Page 44: Changing The Fuse

Make sure the O-ring on the fuse carrier is not damaged. Replace the defective fuse (1). Screw in the fuse carrier. Connect the power supply cable. If the fuse brakes repeatedly contact the Contact BUCHI Customer Service. 44/60 Operation Manual SyncorePlus... -

Page 45: Taking Out Of Service And Disposal

When disposing, observe the disposal regulations of the materials used. For the used materials see Chapter 3.5 “Technical data”, page 17 or the material labeling on the parts. 10.3 Returning the instrument Before returning the instrument, contact the BÜCHI Labortechnik AG Service Department. https://www.buchi.com/contact Operation Manual SyncorePlus 45/60... -

Page 46: Appendix

Flushback modul Primery condenser 10 °C Secondery Analyst rack condenser 70 °C 12 - 13 °C 10 °C Chiller 15 - 16 °C 10 °C 11.1.2 Communication connections Vacu StatusLight Vacuum Pump Recirculating SncorePlus Chiller Interface 46/60 Operation Manual SyncorePlus... -

Page 47: Spare Parts And Accessories

BÜCHI Labortechnik AG Appendix | 11 11.2 Spare parts and accessories Use only genuine BUCHI consumables and spare parts in order to ensure correct, safe and reliable operation of the system. NOTE Any modifications of spare parts or assemblies are only allowed with the prior written permission of BUCHI. - Page 48 For Working volumes up to 96 x 10 mL, without glass tubes. Transportation rack Order no. Image Transportationrack R-24 for 50 mL Falcon 11074727 tubes Transport rack for easy preparation and insertion into the polyvap rack 48/60 Operation Manual SyncorePlus...

-

Page 49: Cover

Vacuum Cover R-48 with PE sealing disks 042850 Actively heated vacuum cover with individual sam- ple connection Vacuum Cover R-96 with PE sealing disks 040930 Actively heated vacuum cover with individual sam- ple connection Operation Manual SyncorePlus 49/60... -

Page 50: Flushback Module

038168 rack R-6 Analyst, residual volume 0.3 mL Working volume up to 250 mL Set of 12 graduated glass tubes for EasyFill 046070 rack R-12 Analyst, residual volume 3.0 mL Working volume up to 120 mL 50/60 Operation Manual SyncorePlus... - Page 51 EasyFill rack R-12 Analyst, residual vol- ume 1.0 mL Working volume up to 100 mL Set of 12 graduated amber glass tubes GL45 11056911 for EasyFill rack R-12 Analyst, residual vol- ume 0.3 mL Working volume up to 100 mL Operation Manual SyncorePlus 51/60...

-

Page 52: Gaskets And Plugs

R-6, PTFE Set of 12 sealing disks for Vacuum Cover 040906 R-12, PTFE Set of 24 sealing disks for Vacuum Cover 11081340 R-24, PTFE Set of 24 sealing disks for Vacuum Cover 038489 R-24, PE 52/60 Operation Manual SyncorePlus... -

Page 53: Sample Preparation Rack

040075 positions) Sample holder R-4 (metal rack 1 position) 11062988 Sample preparation rack R-6 (metal rack 6 040076 positions) Sample holder R-6 (metal rack 1 position) 11062989 Sample preparation rack R-12 (metal rack 12 040077 positions) Operation Manual SyncorePlus 53/60... -

Page 54: Condenser

11.2.10 Sleeves Order no. Image Set of 12 appendix sleeves for Analyst glass 11058511 tubes (R-4, R-6, R-12) with 0.3 mL appendix Set of 12 appendix sleeves for Analyst glass 11058510 tubes with 1.0 mL appendix 54/60 Operation Manual SyncorePlus... -

Page 55: Accessories Spe Configuration

SPE Advanced Module format 6 11055465 with 3 way valve and waste vessel SPE Advanced Cover format 6 11055466 with 3 way valve and waste vessel SPE Advanced Module format 12 051164 with 3 way valve and waste vessel Operation Manual SyncorePlus 55/60... - Page 56 051496 12 port waste manifold 051445 6 port waste manifold 11055463 Gasket FPM to waste vessel 040471 Glass cylinder for the SPE waste vessel 051444 FEP tube waste 11064040 condenser including GL 14 caps and seals 56/60 Operation Manual SyncorePlus...

-

Page 57: Sensors

Pro. Only for vapor temperature, can not be up- graded to AutoDest sensor. AutoDest sensor. Incl. cap nut, seal GL14 11081310 and adapter cable for SyncorePlus For automatic distillation. Measures temperature of cooling media and the vapor temperature. Vac- uum is adjusted according to cooling capacity of condenser. -

Page 58: Tubing

In combination with AutoDest sensor for auto- mated distillation of residual solvent. Meant to be used with AutoDest sensor 11059225, Adapter ca- ble for SyncorePlus 11069477, Interface I-300 Pro and S-type condenser. Set AutoDest sensor & AutoDry valve & 11081315... -

Page 59: Tools

Content: Hose barbs, cap nuts, seals. 11.2.15 Tools Order no. Image Hose cutter 019830 Turix wrench 044349 11.2.16 Service Order no. Image SyncorePlus IQ/OQ documentation for first 11071011 installation and operation qualification SyncorePlus Repeating OQ 11071012 Operation Manual SyncorePlus 59/60... - Page 60 11594118 | D en We are represented by more than 100 distribution partners worldwide. Find your local representative at: www.buchi.com...

Need help?

Do you have a question about the SyncorePlus and is the answer not in the manual?

Questions and answers