Table of Contents

Advertisement

Quick Links

Instructions - Parts List

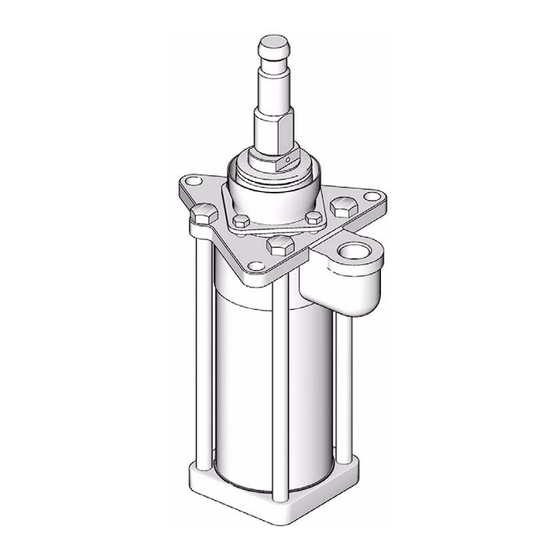

Stainless Steel

1000cc Lower

Designed for low to medium pressure, medium volume circulation of finishing materials.

Important Safety Instructions

Read all warnings and instructions in your 1000cc

Dura-Flo Pump manual 311833. Save these instructions.

See page 2 for Table of Contents.

Model 253596, Series A

Stainless Steel

660 psi (4.55 MPa, 45.5 bar) Maximum Working Pressure

Patent Pending

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 4

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Outlet Housing Mounting Hole Layout . . . . . . . . 10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 12

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 12

311716B

TI8336a

II 2 G

Advertisement

Table of Contents

Summary of Contents for Graco 253596

-

Page 1: Table Of Contents

Graco Standard Warranty ....12 Graco Information ......12... -

Page 2: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable. - Page 3 Warnings WARNING MOVING PARTS HAZARD Moving parts can pinch or amputate fingers and other body parts. • Keep clear of moving parts. • Do not operate equipment with protective guards or covers removed. • Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual.

-

Page 4: Operation

Operation Operation Pressure Relief Procedure 1. Engage trigger lock. 2. Air-Powered Pumps only: Close the bleed-type master air valve. Hydraulic-Powered Pumps only: Close the hydraulic supply line valve first, then the return line valve. 3. Disengage the trigger lock. 4. Hold a metal part of the gun firmly to a grounded metal pail. -

Page 5: Repair

Repair Repair 6. Remove the screws (5) from the packing retainer (2). Remove the packing retainer. • To service the pump assembly, see manual 311833. 7. Screw the tie bolts (4) out of the intake housing (18). • To service the air motor, see manual 311238. 8. - Page 6 Repair d. Place the o-ring (20*) onto the valve seat (13). 4. Place the cylinder (17†) on the intake valve housing (18). e. Use a 2-1/2 in. hex wrench to install the valve 5. Lubricate the displacement rod assembly and slide seat (13) into the displacement rod (1†).

- Page 7 Repair † Apply anti-seize lubricant to piston outer † diameter and all packings. Torque to 57-63 ft-lb (42-46 N•m). Apply medium strength threadlocker. Torque to 75-80 ft-lb (55-59 N•m). Rounded side up. † Lips of v-packings must face down. Leave a 0.020-0.050 in. (0.508-1.27 mm) gap in bearing seam TI8391a 311716B...

-

Page 8: Parts

Parts Parts † † † † † TI8334a1 Apply anti-seize lubricant to piston outer diameter and all packings. Torque to 57-63 ft-lb (42-46 N•m). Apply medium strength threadlocker. Torque to 75-80 ft-lb (55-59 N•m). Rounded side up. Lips of v-packings must face down. Leave a 0.020-0.050 in. - Page 9 Parts Part 253596, Stainless Steel Lower Ref. Part Description 206451 PISTON, displacement † 207171 RETAINER, assy, bearing 100063 PIN, cotter † 102215 SCREW, cap, hex hd 102471 SCREW, cap, hex hd 166053 PIN, str hdls † 166054 PIN, str hdls...

-

Page 10: Technical Data

Technical Data Technical Data Maximum Fluid Working Pressure ....660 psi (4.55 MPa, 45.5 bar) Wetted parts........303 and 304 Grades Stainless Steel, PTFE, Carbon-filled PTFE Outlet Housing Mounting Hole Layout 3.464 in. -

Page 11: Dimensions

Dimensions Dimensions TI8336a Weight (Height) (approx) in. (mm) (Inlet) (Outlet) lb (kg) 18.5 (470) 1-1/2 in. npt(f) 2 in. npt(f) 50 (22.5) 311716B... -

Page 12: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the 253596 and is the answer not in the manual?

Questions and answers