Table of Contents

Advertisement

Quick Links

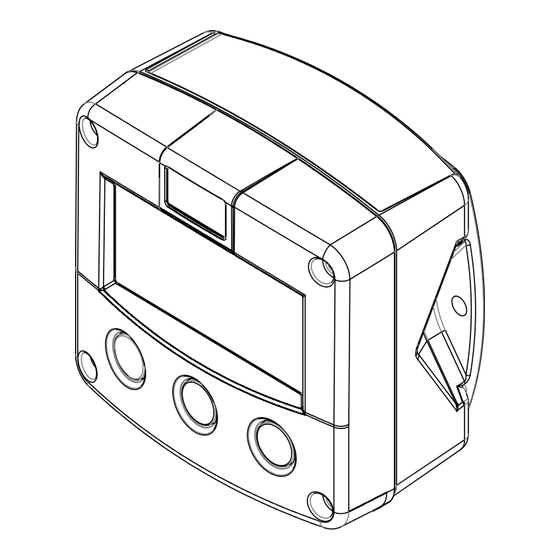

F112-A

FLOW RATE INDICATOR / TOTALIZER

with linearization, analog and pulse outputs

Signal input flowmeter: (0)4-20 mA

Signal outputs: (0)4-20 mA / 0-10 V ref. flow rate and pulse ref. total

Options: Intrinsically safe, Modbus communication, external reset and

backlight

F-Series - Field mounted indicators for safe and hazardous areas.

More info: www.fluidwell.com/fseries

Advertisement

Table of Contents

Summary of Contents for Fluidwell F112-A

- Page 1 Signal input flowmeter: (0)4-20 mA Signal outputs: (0)4-20 mA / 0-10 V ref. flow rate and pulse ref. total Options: Intrinsically safe, Modbus communication, external reset and backlight F-Series - Field mounted indicators for safe and hazardous areas. More info: www.fluidwell.com/fseries...

-

Page 2: Safety Instructions

The F112-A must be installed in accordance with the EMC guidelines (Electro Magnetic Compatibility). • Connect a proper grounding to the metal enclosure as indicated if the F112-A has an incoming power or signal line which carries a hazardous live voltage. The Protective Earth (PE) wire may never be disconnected or removed. -

Page 3: About The Manual

This manual describes the standard unit as well as the available options. For additional information, please contact your supplier. A hazardous situation may occur if the F112-A is not used for the purpose it was designed for or is used incorrectly. Please carefully note the information in this manual indicated by the pictograms: A "warning !"... -

Page 4: Table Of Contents

Page 4 TABLE OF CONTENTS SAFETY INSTRUCTIONS........................2 DISPOSAL OF ELECTRONIC WASTE ....................2 SAFETY RULES AND PRECAUTIONARY MEASURES ..............2 ABOUT THE MANUAL ........................3 WARRANTY AND TECHNICAL SUPPORT ..................3 TABLE OF CONTENTS ........................4 INTRODUCTION ........................6 System description ...................... - Page 5 Page 5 5.2.2 Installations based on ATEX or IECEx certificate ..........37 Electrical data – Annex 1 ..................38 5.2.3 5.2.4 Power supply wiring .................... 40 5.2.5 Sensor supply ..................... 40 Terminal connectors Intrinsically Safe applications – Type XI ........41 5.3.1 Terminal 26-29: Type CT - Communication ............

-

Page 6: Introduction

This manual describes the unit with a (0)4-20mA input from the flowmeter. Other versions are available to process pulse signals. One flowmeter with a (0)4-20mA signal output can be connected to the F112-A. To power the sensor, several options are available. - Page 7 Page 7 Configuration of the unit The F112-A is designed for use in many types of applications. For that reason, a setup menu is available to program the F112-A according to your specific requirements. The setup includes several important features, such as span, engineering units, signal selection, power management (to extend battery life-time), etc.

-

Page 8: Operational

Page 8 2 OPERATIONAL GENERAL INFORMATION This chapter describes the daily use of the F112-A. This instruction is meant for users / operators. • This device may only be operated by persons who are authorized and trained by the operator of the facility. All instructions in this manual are to be observed. - Page 9 Page 9 ▪ Clear total The value for total can be reset. To do so, press the CLEAR/► key twice. When the key is pressed once, the text "PUSH CLEAR" is shown. To avoid a reset at this stage, press another key other than the CLEAR/►...

-

Page 10: Configuration

Make sure that the unit is not being used for any application when altering the settings. 3.2.1 ENTERING SETUP-LEVEL Configuration of the F112-A is done at SETUP-level, which can be reached at all times while the F112-A remains fully operational. At SETUP-level the display will deactivate the indicator and... -

Page 11: Programming Sequence

Page 11 Use the control panel to navigate through SETUP-level PROG-key When a function is selected, this key is used to start the programming sequence. When only a function group is selected (and no function), this key is used to scroll back a function group (e.g. -

Page 12: Returning To Operator-Level

In order to return to the operator level, press the PROG-key for three seconds. When no keys are pressed for 2 minutes, SETUP-level will be left automatically. CONFIGURATION SETTINGS All settings of the F112-A can be set via the control panel. The following paragraphs give a detailed description of each setting. 3.3.1... -

Page 13: Menu 1 - Total

1200; 2400; 4800; 9600; 9600HP; 19200; 38400 ADDRESS 1 - 247 MODE bus-rtu; bus-asc; off DATABITS 8 bits, 7 bits PARITY none, even, odd OTHERS MODEL F112-A SOFTWARE VERSION nn:nn:nn SERIAL NO. nnnnnnn PASSWORD 0000 - 9999 TAG-NR 0000000 - 9999999 3.3.2 MENU 1 - TOTAL... -

Page 14: Menu 3 - Display

When used with the internal battery option (type PB/PC), the user can expect reliable measurement over a long period of time. The F112-A has several smart power management functions to extend the battery life time significantly. Two of these functions can be set. -

Page 15: Menu 5 - Flowmeter

3.3.6 MENU 5 - FLOWMETER FLOWMETER FORMULA The F112-A can process the (0)4-20mA signal in two ways, Interpolation or Square root: • Interpolation: the signal is processed linear: R = S x I • Square root: for differential pressure: R = S √ I... -

Page 16: Menu 6 - Linearize

Page 16 MENU 6 – LINEARIZE 3.3.7 The linearization function is available to approximate the real flow curve better than in a one-step linear way. This to obtain a more accurate flow rate, total and accumulated total as well as the analog and pulse output at any flowmeter frequency. -

Page 17: Menu 7 - Analog Output

Page 17 LINEARIZE 6.1... PERCENTAGE / M- The percentage is shown at the bottom line of the display. With value 0%, FACTOR 1 ... F the M-Factor is disabled. The M-Factor (MF) is shown at the top-line of the display. The minimum value to be entered is 0.000001 and the maximum value is 9.999999. -

Page 18: Menu 8 - Pulse Output

Page 18 FILTER This setting is used to stabilize the output signal. With the help of this digital filter a more stable but less actual representation of the flow rate can be obtained. The filter principle is based on three input values: the filter level (01-99), the last calculated flow rate and the last average value. -

Page 19: 3.3.11 Menu A - Others

Page 19 3.3.11 MENU A - OTHERS OTHERS MODEL For support and maintenance it is important to have information about the characteristics of the F112-P. Your supplier will ask for this information in SOFTWARE the case of a serious breakdown or to assess the suitability of your model VERSION for upgrade considerations. -

Page 20: Installation

• The F112-A may only be operated by persons who are authorized and trained by the operator of the facility. All instructions in this manual are to be observed. •... -

Page 21: Handling The F-Series Enclosure

The F1-Series can be supplied as suitable for Safe Area or Hazardous Area. Suitability for Intrinsic Safety is indicated in the model code by Type XI (e.g. F112-A-XI). For Intrinsically Safe applications: Installation and identification labels are shown in chapter 5. -

Page 22: Opening / Removing The Cover

Page 22 Terminal label Also on the inside, a terminal label is placed to indicate the location of the terminals and settings for the sensor supply configuration switches. Fig. 9: Identification – Example of F1-Series terminal label (safe area) Serial number and year of production The serial number can be reviewed on the identification label or in SETUP-menu Others. -

Page 23: Mechanical Installation

Page 23 MECHANICAL INSTALLATION DIMENSIONS – ALUMINUM AND STAINLESS STEEL ENCLOSURES 4.4.1 Fig. 10: Dimensions – Aluminum and stainless steel enclosures FW_F112-A_M_v2201-01_EN.docx... -

Page 24: Dimensions - Non-Metallic Enclosures

Page 24 DIMENSIONS – NON-METALLIC ENCLOSURES 4.4.2 Fig. 11: Dimensions – Non-metallic enclosures FW_F112-A_M_v2201-01_EN.docx... -

Page 25: Mounting

Page 25 4.4.3 MOUNTING The enclosure can be installed by itself or with the aid of a mounting plate in the configurations shown below. When the unit is installed on a wall or onto a meter, please use components and installation techniques that are suitable for the used materials. -

Page 26: Electrical Installation

Metal enclosure When the F112-A is supplied with a metal enclosure (aluminum or stainless steel), the enclosure must be grounded in accordance with national and local electrical codes. -

Page 27: Field Wiring Connections

Within the United States all field wiring must conform to the National Electric Code, NFPA 70, Article 501-4(b). All field wiring enters the F112-A through the bottom of the enclosure and connects to the circuit assembly inside the enclosure. Wiring is routed through cable glands. Please make sure to order the F112-A with the correct drilling pattern and thread (metal) or hole (plastic) sizes. -

Page 28: Sensor Supply

Setting the sensor supply Risk of electrocution - High voltage! Make sure, all the leads to the terminals are disconnected from the F112-A and NEVER connect mains power to the unit when the protection cover has been removed! To set the sensor supply, follow these instructions: 1. -

Page 29: Terminal Connectors Safe Area Applications - Type Xx / Xf

4.5: Electrical Installation and review paragraph 4.5.3 and 4.5.4 before applying any field or power supply wiring. For Intrinsically Safe applications (Type XI): read chapter 5. Following terminal connectors are available on the F112-A when supplied with Type XX: Fig. 14: Overview of terminal connectors - Standard configuration and options 4.6.1... -

Page 30: Terminal 05-06: Scaled Pulse Output R1

Page 30 4.6.2 TERMINAL 05-06: SCALED PULSE OUTPUT R1 Setup 8 (read chapter 3) determines the pulse output function. The maximum pulse frequency of this output is 500Hz. If a relay output option has been supplied, be sure that the output frequency does not exceed 5Hz or else the life-time of the relay will be reduced significantly. -

Page 31: Terminal 07-08: Analog Output

Page 31 4.6.3 TERMINAL 07-08: ANALOG OUTPUT An analog output signal proportional to the flow rate is available as standard and is configured using Setup 7. The following signal type configurations are available, including type AP: loop powered: Type AA An active 4-20mA signal proportional to the flow rate is available with this option. - Page 32 Page 32 Type AI An isolated 4-20mA signal proportional to the flow rate is available with this option. When the output is disabled, a 3.5mA signal will be generated on these terminals. Max. driving capacity 1000 Ohm @ 30VDC. This option can be used with a battery powered unit but the life time of the battery is about 2 - 3 years.

-

Page 33: Terminal 09-11: Flowmeter Input

Fig. 24: Terminal connections - Analog signal input (typical) Type PL – Flowmeter input / power supply With type PL the flowmeter input can be used to power the F112-A. With this type of supply, external sensor supply is not available. -

Page 34: Terminal 26-31: Type Cb / Ch / Ci - Communication (Option)

Page 34 4.6.6 TERMINAL 26-31: TYPE CB / CH / CI - COMMUNICATION (OPTION) Serial communications on hardware layers RS232, RS485 and TTL (intrinsic safety) are possible. Make sure that the hardware layer specific requirements are met to achieve reliable communication and read the Modbus communication protocol and Appendix C. -

Page 35: Intrinsically Safe Applications

The F1-Series can be supplied as suitable for Safe Area or Hazardous Area. Suitability for Intrinsic Safety is indicated in the model code by Type XI (e.g. F112-A-XI). If Type XI is not indicated your device is not suitable for Intrinsically Safe applications! -

Page 36: Electrical Installation In Hazardous Area

Page 36 Terminal label Also on the inside, a terminal label is placed to indicate the location of the terminals and settings for the sensor supply configuration switches. Fig. 30: Identification – Example of F1-Series terminal label (intrinsic safety) ELECTRICAL INSTALLATION IN HAZARDOUS AREA 5.2.1 GENERAL INFORMATION AND INSTRUCTIONS Cautions... -

Page 37: Installations Based On Atex Or Iecex Certificate

Page 37 5.2.2 INSTALLATIONS BASED ON ATEX OR IECEX CERTIFICATE Installation instructions • For installation under ATEX directive: this Intrinsically Safe device must be installed in accordance with ATEX directive 2014/34/EU and product certificate KEMA 03ATEX1074 X. • For installation under IECEx scheme: this Intrinsically Safe device must be installed in accordance with product certificate IECEx DEK 11.0042X. -

Page 38: Electrical Data - Annex 1

Page 38 ELECTRICAL DATA – ANNEX 1 5.2.3 Annex 1 (model specific) to type XI product certificates KEMA 03ATEX1074 X, IECEx DEK 11.0042X For the combined connection of the different supply, input and output circuits, the installation instructions of the manufacturer shall be observed. From the safety point of view the circuits shall be considered to be connected to earth. - Page 39 Page 39 Active inputs In type of protection intrinsic safey Ex ia IIB/IIIC, only for connection to (Active pulse, 0/4-20mA, a certified intrinsically safe circuit, with following maximum values: 0-10V) 30 V 0 mH (terminals 9 and 10, 0 μF 100 mA terminals 12 and 13, 750 mW...

-

Page 40: Power Supply Wiring

The following types of power supply are available for hazardous area: • Type PX / PD As standard, the F112-A is supplied with terminal 0 and 1 to power the product externally. Additionally, the power supply circuit connected to terminal 1 is looped through to terminal 2 to allow easy installation, e.g. -

Page 41: Terminal Connectors Intrinsically Safe Applications - Type Xi

4. Normally, the F112-A-XI is classified as group IIB/IIIC. Classification of the unit as group IIC is possible under certain conditions, as shown in Annex 1 in the previous paragraph. -

Page 42: Configuration Examples Intrinsically Safe Applications

Page 42 CONFIGURATION EXAMPLES INTRINSICALLY SAFE APPLICATIONS Fig. 33: F112-A-AF-CT-IB-OT-PC-PD-XI - Battery powered - IIB/IIC – IIIC FW_F112-A_M_v2201-01_EN.docx... - Page 43 Page 43 Fig. 34: F112-A-AF-CT-IB-OT-PD-XI – External power supply - IIB/IIC - IIIC FW_F112-A_M_v2201-01_EN.docx...

-

Page 44: Maintenance

Repairs should only be carried out by the manufacturer or his authorized agent. Repair policy If you have any problem with your Fluidwell product and you wish to repair it, please follow the procedure below: a. Obtain a Return Material Authorization (RMA) from your supplier or distributor Together with the RMA, you need to complete a repair form to submit detailed information about the problem. -

Page 45: Battery Replacement Instructions

Page 45 BATTERY REPLACEMENT INSTRUCTIONS 6.3.1 SAFETY INSTRUCTIONS • Handle the battery with the utmost care to prevent a short circuit and damage. A mistreated battery can become unsafe. Unsafe batteries can cause (serious) injury to persons. Do not recharge, crush, disassemble, incinerate, heat above its rated temperature or expose contents to water. -

Page 46: Replace The Battery

Page 46 6.3.2 REPLACE THE BATTERY Before starting the battery replacement procedure, make sure that the marking on the new battery corresponds with the type of installation, as shown in paragraph 6.3.1. Remove the old battery as follows: 1. Open the enclosure as indicated in section 4.3 and carefully remove the cable-connectors. 2. -

Page 47: Appendix A Technical Specification

Page 47 APPENDIX A TECHNICAL SPECIFICATION General Display Type High intensity numeric and alphanumeric LCD, UV-resistant. Digits Seven 17mm (0.67") and eleven 8mm (0.31"). Various symbols and measuring units. Refresh rate User definable: 8 times/sec - 30 secs. Type ZB LCD with LED backlight. - Page 48 Page 48 Power supply Type AP Loop-powered from 4-20mA output signal - 8-30V DC. Power consumption max. 0.5 Watt. Type PB Standard lithium battery - life-time depends upon settings - up to 5 years. SAFE AREA ONLY Type PC Intrinsically Safe lithium battery - life-time depends upon settings - up to 5 years. Type PD 8-24V AC / 8-30V DC;...

- Page 49 Page 49 Inputs Flowmeter Type A (0)4-20 mA, with signal calibration feature at any current within range Accuracy Resolution: 16 bit. Error < 0.025mA / ±0.125% FS. Low level cut-off programmable. Span 0.000010 - 9999999 with variable decimal position. Update time Four times a second. Relationship Linear and square root calculation.

-

Page 50: Appendix Bproblem Solving

Page 50 APPENDIX B PROBLEM SOLVING In this appendix, several problems are included that can occur when the F112-A is going to be installed or while it is in operation. Analog output does not function properly: Check: ▪ is the analog output enabled? ▪... -

Page 51: Appendix C Communication Variables

Page 51 APPENDIX C COMMUNICATION VARIABLES General The product is fitted with the Modbus communication protocol and can be equipped with various physical interfaces like RS485 and RS232 (please see device datasheet for available options). The tables below show the various variables that can be accessed through the communication. Currently, the function codes supported are: •... - Page 52 Page 52 Setup variables REGISTER VARIABLE TYPE VALUE / REMARKS ADDRESS TOTAL REGISTERS [d] 32 40033 unit uint16 0=none 3=kg 6= USGAL [h] 0x020 4= lb 7=bbl 2= m 5=GAL [d] 33 40034 decimals uint16 0…3 [h] 0x021 [d] 34 40035 span uint32 1...9999999...

- Page 53 Page 53 REGISTER VARIABLE TYPE VALUE / REMARKS ADDRESS LINEARIZATION REGISTERS [d] 1024 41025 linearization table entry struct The linearization table is an INDEXED [h] 0x400 variable. Reading and writing the entries of the uint24 linearization tables is done by first selecting the entry through the index.

- Page 54 Page 54 REGISTER VARIABLE TYPE VALUE / REMARKS ADDRESS COMMUNICATION REGISTERS [d] 144 40145 speed (Baudrate) uint16 0=1200 3=9600 6=38400 [h] 0x090 1=2400 4=9600HP 2=4800 5=19200 [d] 145 40146 Modbus address uint16 1…247 [h] 0x091 [d] 146 40147 Modbus mode uint16 0: ASCII 1: RTU 2: OFF...

-

Page 55: Appendix D Declaration Of Conformity

Veghel, February 0 e, Fluidwell V, declare under our sole responsibility that the F eries indicators are designed and will operate conform the following applicable uropean Directives and Harmonised tandards, when installed and operated according to the related manuals:... -

Page 56: Index Of This Manual

Page 56 INDEX OF THIS MANUAL accumulated Total ......... 9 flowmeter ............. 15 actual settings ..........58 Flowmeter input ........... 33 Alarm.............. 9 flowrate analog Span ............14 cut-off value ..........17 Flowrate ............8 floating output..........31 Installation ............ 20 flowrate min. -

Page 57: List Of Figures In This Manual

Fig. 32: Terminal connectors Communication (type CT) ..............41 Fig. 33: F112-A-AF-CT-IB-OT-PC-PD-XI - Battery powered - IIB/IIC – IIIC ........42 Fig. 34: F112-A-AF-CT-IB-OT-PD-XI – External power supply - IIB/IIC - IIIC ........43 Fig. 35: Marking Type PC battery: Intrinsically Safe FW-LiBAT-021 (SPC02) ........45 Fig. - Page 58 Page 58 LIST OF CONFIGURATION SETTINGS SETTING DEFAULT DATE : DATE : 1 - TOTAL Enter your settings here 1.1 unit 1.2 decimals 0000000 1.3 span 1600 1.4 decimals span 2 - FLOW RATE 2.1 unit 2.2 time /sec 2.3 decimals 0000000 2.4 span 1600...

- Page 59 0001000 9 - COMMUNICATION 9.1 speed 9600 9.2 address 9.3 mode BUS-RTU 9.4 databits 8 bits 9.5 parity none A - OTHERS A.1 model F112-A A.2 software version 03.04.xx A.3 serial no. nnnnnnn A.4 password 0000 A.5 tag-nr 0000000 FW_F112-A_M_v2201-01_EN.docx...

- Page 60 Fluidwell B.V. PO box 6 Voltaweg 23 Website: www.fluidwell.com 5460 AA Veghel 5466 AZ Veghel Find your nearest representative: www.fluidwell.com/representatives The Netherlands The Netherlands Fluidwell bv - © 2023 - FW_F112-A_M_v2201-01_EN.docx...

Need help?

Do you have a question about the F112-A and is the answer not in the manual?

Questions and answers