Summary of Contents for Flowserve Valtek VR

-

Page 1: Valtek Vr

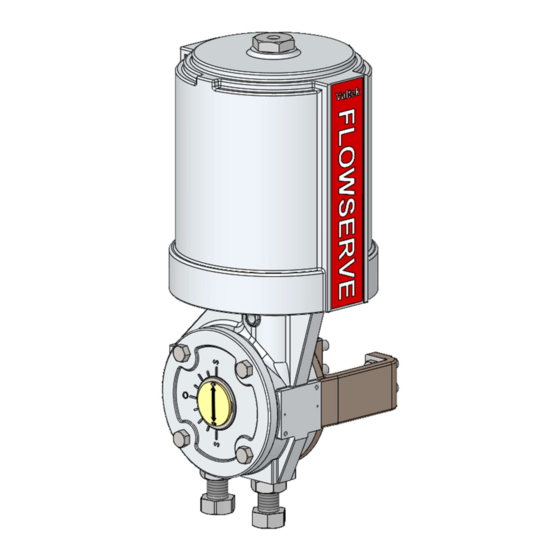

USER INSTRUCTIONS Valtek VR Spring Cylinder Rotary Actuators These instructions must be read prior to installing, operating, and maintaining this equipment. - Page 2 The Valtek VR actuator, cylinder and positioner are designed for supply pressures up to 150 psi (10.3 bar) for sizes VR25, VR50, VR100 and 80 psi for VR200 (5.5 bar), making very high torques attainable. The actuator uses a rocking piston for direct conversion of linear motion to rotary motion.

-

Page 3: Table Of Contents

Valtek VR Spring Cylinder Rotary Actuators Contents Valtek VR ............................1 Scope of Manual ........................4 Intended Use .......................... 4 Valtek VR Modification ......................4 Safety ............................4 Design ............................ 4 5.1 Spring ............................. 4 Packaging and Transport ......................5 Storage ........................... -

Page 4: Scope Of Manual

The Valtek VR consists of the cylinder, transfer case, yoke and connecting parts. The actuator is designed with a high level of interchangeability allowing the user to assemble the greatest... -

Page 5: Packaging And Transport

6. Packaging and Transport resinous, see also ISO 2230. Upon arrival on site, store the Valtek VR actuator on a solid Pay close attention to shipping marks and base in a cool, dry closed room. Until its installation, the actuator transport pictograms. -

Page 6: Unpacking

Do Although Valtek VR can be mounted in any not remove the cover plate when the valve in service or position, mounting the cylinder vertically is the pressurized. - Page 7 Stroke Stop Jam Nut (Item No. 330) (Item No. 347) Figure 2: Sectional View of Valtek VR Actuator Note: Item numbers correspond directly to the bill of material; refer to it for specific part number Page 7 of 13 VLAIM031-14 (EN/AQ) May 2023...

-

Page 8: Removing Rotary Actuators From Valtek Valve Bodies

Valtek VR Spring Cylinder Rotary Actuators Remove spring button and spring. Care must be taken not to damage the sliding seal assembly or actuator stem O-ring when removing the actuator stem. Remove the actuator stem locknut. The piston and piston ... -

Page 9: Mounting Rotary Actuators On Valtek Valve Bodies

Valtek VR Spring Cylinder Rotary Actuators Install splined lever arm into transfer case through cover Ensure that the cylinder retaining ring is plate/yoke openings. completely seated in the cylinder groove, Slide actuator stem through the top opening of transfer case else serious personnel injury may occur. -

Page 10: Reversing The Actuator Action

Valtek VR Spring Cylinder Rotary Actuators indicator returns to the same position with each cycle. The yoke side now becomes the cover plate side and the cover plate side becomes the yoke side. Since this changes Tighten the stroke stop jam nuts. - Page 11 Valtek VR Spring Cylinder Rotary Actuators Actuator Orientations for Valdisk and ShearStream Control Valves Shaft Upstream Shaft Downstream Right-hand Mounting (standard) Right-hand Mounting (optional) Air-to-Open Air-to-Close Fail Closed Fail Open Air-to-Close Air-to-Open Fail Open Fail Closed Air-to-Open Air-to-Close Fail Closed...

-

Page 12: Troubleshooting Guide

Table 2: Troubleshooting recommendations. 15. Disposal The valve should be professionally disassembled and Up to 95 % of the Valtek VR rotary actuator is metal. The reassembled. Metal parts should be scrapped, with the remaining materials are synthetic, rubber, paint and lubricants. - Page 13 Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve product might be used in numerous application under a wide variety of industrial service conditions.

Need help?

Do you have a question about the Valtek VR and is the answer not in the manual?

Questions and answers