Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Unigas PN91

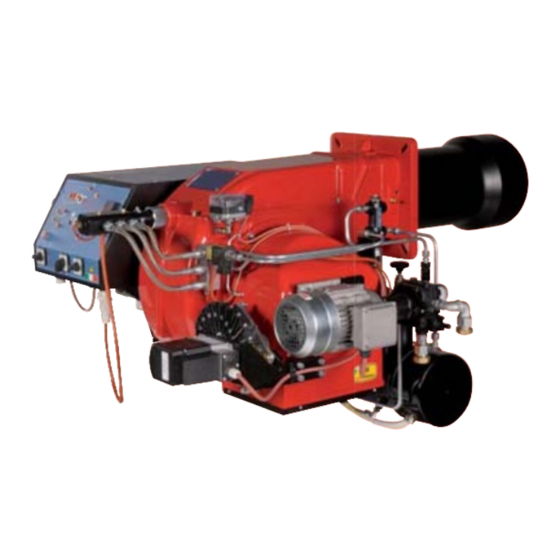

- Page 1 PN91 PN92 PN93 RN510 - PN510 RN515 - PN515 RN520 - PN520 RN525 - PN525 Progressive, Fully-modulating Heavy oil - Light oil Burners MANUAL OF INSTALLATION - USE - MAINTENANCE BURNERS - BRUCIATORI - BRULERS - BRENNER - QUEMADORES - ГОРЕЛКИ...

-

Page 2: General Introduction

DANGERS, WARNINGS AND NOTES OF CAUTION THIS MANUAL IS SUPPLIED AS AN INTEGRAL AND ESSENTIAL PART OF THE PRODUCT AND MUST BE DELIVERED TO THE USER. INFORMATION INCLUDED IN THIS SECTION ARE DEDICATED BOTH TO THE USER AND TO PERSONNEL FOLLOWING PRODUCT INSTALLATION AND MAINTENANCE. -

Page 3: Directives And Standards

3b) FIRING WITH GAS, LIGHT OIL OR OTHER FUELS DIRECTIVES AND STANDARDS Gas burners GENERAL European directives The burner shall be installed by qualified personnel and in compliance -Regulation 2016/426/UE (appliances burning gaseous fuels) with regulations and provisions in force; wrong installation can cause -2014/35/UE (Low Tension Directive) injuries to people and animals, or damage to property, for which the -2014/30/UE (Electromagnetic compatibility Directive) -

Page 4: Symbols Used

Burner data plate Type Model Gas - Light oil burners For the following information, please refer to Year European Directives the data plate: S.Number -Regulation 2016/426/UE (appliances burning gaseous fuels) Output burner type and burner model: must be Oil Flow -2014/35/UE (Low Tension Directive) reported in any communication with the Fuel... -

Page 5: Burner Model Identification

Type PN91 Model (1) BURNER TYPE PN91 - PN92 - PN93 - PN510 - PN515 - PN520 - PN525 N- Heavy oil, viscosity <= 50cSt (7° E) @ 50° C D- Heavy oil, viscosity <= 400cSt (50° E) @ 50° C... - Page 6 C.I.B. UNIGAS BURNER PN510 PN515 PN520 PN525 Output min - max kW 1.314 - 3.953 1.628 - 4.884 2.326 - 6.977 2.000 - 8.000 Fuel D Heavy oil - G - Light oil Oil viscosity See “Burner model identification” table Light oil rate min.

-

Page 7: Performance Curves

C.I.B. UNIGAS Performance Curves PN91 PN92 1200 1600 2000 2400 1200 1600 2000 2400 2800 PN93 100 0 1 500 2000 25 00 3000 35 00 4000 45 00 RN510-PN510 RN515 - PN515 1200 2000 2800 3600 4400 5200 1000... - Page 8 C.I.B. UNIGAS...

- Page 9 POS OIL TRAIN COMBUSTION AIR TRAIN Filter Temperature probe Temperature probe 18 Air damper with actuator Pump and pressure governor Temperature probe Oil distributor 19 Pressure switch - PA Electrical motor Temperature probe Low thermostat - TCI 20 Draught fan with electromotor 33 Pressure gauge with manual valve Minimum pressure switch - POMIN Pressure governor...

- Page 10 B*: SPECIAL BLAST TUBE LENGTHS MUST BE Overall dimensions (mm) AGREED WITH CIB UNIGAS Boiler recommended boiler drilling template A(S*) A(L*) B(S*) B(L*) DD** EE** RN510 1502 1682 1152 1285 RN515 1502 1682 1152 1285 RN520 1502 1682 1152 1285...

-

Page 11: Overall Dimensions (Mm)

C.I.B. UNIGAS B*: SPECIAL BLAST TUBE LENGTHS MUST BE Overall dimensions (mm) AGREED WITH CIB UNIGAS Tipo PN91 1017 1315 1505 1052 PN92 1017 1318 1508 1052 PN92 1017 1318 1508 1052 PN93 1017 1318 1508 1052 PN93 1017 1318... -

Page 12: Installing The Burner

C.I.B. UNIGAS INSTALLING THE BURNER Packing Burners are despatched in wooden crates whose dimensions are: PN91-92-93 1730mm x 1280mm x 1020mm (L x P x H) PN510-515-520-525 1730mm x 1430mm x 1130mm(L x P x H) Packing cases of this type are affected by humidity and are not suitable for stacking. -

Page 13: Electrical Connections

C.I.B. UNIGAS Electrical connections Respect the basic safety rules. Make sure of the connection to the earthing system. do not reverse the phase and neutral connections. Fit a differential thermal magnet switch adequate for connection to the mains. ATTENTION: before executing the electrical connections, pay attention to turn the plant’s switch to OFF and be sure that the burner’s main switch is in 0 position (OFF) too. - Page 14 C.I.B. UNIGAS Fan motor direction ( and pump motor direction only for PN520 - PN525) Once the electrical connection of the burner is performed, remember to check the rotation of the motor. The motor should rotate in an counterclockwise direction looking at cooling fan. In the event of incorrect rotation reverse the three-phase supply and check again the rotation of the motor.

-

Page 15: Oil Pumps

0841211) is required for the transition from 2-pipe to 1-pipe system Danfoss KSM.. Suntec TA Oil pumps PN91: SUNTEC TA2 / DANFOSS KSM50 PN92/93/510: SUNTEC TA3 / DANFOSS KSM70 PN515: SUNTEC TA4 / DANFOSS KSM100 PN520/525: SUNTEC TA5 / DANFOSS KSM140 Danfoss KSM.. - Page 16 C.I.B. UNIGAS on the pump. For further information, refer to the technical documentation of the pump. Suntec TA.. Danfoss KSM.. Connections to the oil gun Gun with the oil nozzle inside 1 Inlet 2 Return 3 Gun opening 4 Heating wire (only for oil viscosity >...

- Page 17 C.I.B. UNIGAS The oil flow rate can be adjusted choosing a nozzle that suits the boiler/utilisation output and setting the delivery and return pressure values according to the ones quoted on the following charts. FLUIDICS NOZZLE: REFERENCE DIAGRAM (INDICATIVE ONLY)

- Page 18 C.I.B. UNIGAS Oil thermostat adjustment Progressive and fully modulanting oil burners are equipped with electronic multi-thermostat Danfoss MCX, whose operation is con- trolled by thyristor. (for details refer to the attached technical documentation) Fig. 10 - Danfoss MCX Fig. 11 - Probe connections (Danfoss MCX) Burners equipped with double tank All thermostats are located inside the control panel.

- Page 19 C.I.B. UNIGAS TCN - TRS Fig. 12 - Probe connections (Danfoss MCX) and thermostats connections (Burners equipped with double tank) Oil viscosity at 50 °C according to the letter shown in the burner model Menu path > 50 cSt > 110 cSt >...

- Page 20 C.I.B. UNIGAS ADJUSTING AIR AND FUEL RATE ATTENTION: before starting the burner up, be sure that the manual cutoff valves are open. Be sure that the mains switch is closed. ATTENTION: During commissioning operations, do not let the burner operate with insufficient air flow (danger of formation of carbon monoxide);...

- Page 21 C.I.B. UNIGAS Oil Flow Rate Settings by means of Berger STM30../Siemens SQM40.. actuator with the electrical panel open, prime the oil pump acting on the related contactor (see next picture): check the pump motor rotation (page 14) and keep pressing for some seconds until the oil circuit is charged;...

- Page 22 C.I.B. UNIGAS Pressure gauge port Pressure gauge port Fig. 14 Fig. 16 in order to get the maximum oil flow rate, adjust the pressure (reading its value on the PG pressure gauge): checking always the combu- stion parameters, the adjustment is to be performed by means of the SV adjusting cam screw V (see picture) when the cam has reached the high flame position.

- Page 23 C.I.B. UNIGAS Calibration of air pressure switch (only for PN520 - PN525) To calibrate the air pressure switch, proceed as follows: Remove the transparent plastic cap. Once air and heavy oil setting have been accomplished, startup the burner. ...

-

Page 24: Oil Circuit

C.I.B. UNIGAS Oil circuit The fuel is pushed into the pump 1 to the nozzle 3 at the delivery pressure set by the pressure governor. The solenoid valve 2 stops the fuel immission into the combustion chamber. The fuel flow rate that is not burnt goes back to the tank through the return circuit. The spill-back nozzle is feeded at constant pressure, while the return line pressure is adjusted by means of the pressure governor controlled by an actuator coupled to an adjusting cam. -

Page 25: Limitations Of Use

C.I.B. UNIGAS PART II: OPERATION LIMITATIONS OF USE THE BURNER IS AN APPLIANCE DESIGNED AND CONSTRUCTED TO OPERATE ONLY AFTER BEING CORRECTLY CONNEC- TED TO A HEAT GENERATOR (E.G. BOILER, HOT AIR GENERATOR, FURNACE, ETC.), ANY OTHER USE IS TO BE CONSIDE- RED IMPROPER AND THEREFORE DANGEROUS. -

Page 26: Control Panel

C.I.B. UNIGAS Control panel PN91 - PN92 - PN93 - PN510 High flame lamp Low flame lamp Ignition transformer operation CMF Manual operation switch 0= Off 1= High flame 2= Low flame 3= Automatic Fan motor thermal cutout intervention Burner lockout... - Page 27 C.I.B. UNIGAS RN510 High flame lamp Low flame lamp Ignition transformer operation CMF Manual operation switch 0= Off 1= High flame 2= Low flame 3= Automatic Fan motor thermal cutout intervention Burner lockout Burner in stand-by Auxiliary resistors wsitch Heavy oil solenoid lamp operation...

-

Page 28: Routine Maintenance

C.I.B. UNIGAS PART III: MAINTENANCE At least once a year carry out the maintenance operations listed below. In the case of seasonal servicing, it is recommended to carry out the maintenance at the end of each heating season; in the case of continuous operation the maintenance is carried out every 6 months. - Page 29 C.I.B. UNIGAS Fig. 21 1 Inlet 2 Return 3 Lance opening 4 Heating wire (only for oil viscosity > 110 cSt @ 50 °C) 5 Cartdrige-type heater H Cover Fig. 22 L Oil lance E Oil piping connections Removing the oil gun, replacing the nozzle and the electrodes ATTENTION: avoid the electrodes to get in touch with metallic parts (blast tube, head, etc.), otherwise the boiler operation...

- Page 30 To check the flame itensity signal, follow the diagram shown on the next picture. If the measured value is lower than the suggested one, check the photoresistor position, the electrical contacts. Replace the photoresistor if necessary. PN91-PN92 - PN93: LMO44 PN510-PN515-PN520-PN525: LAL2.

-

Page 31: Troubleshooting

ELECTRICAL WIRING DIAGRAMS Electrical diagram 07-345 - Burners type PN 91 - 92 -93 x-.PR... Electrical diagram 07-403 - Burners type PN91 - 92 - 93 x-.MD.. Electrical diagram 11-275 - Burners type PN510 x-.PR... Electrical diagram 11-294 - Burners type PN510 x-.MD... - Page 32 BURNER EXPLODED VIEW ITEM DESCRIPTION ITEM DESCRIPTION ITEM DESCRIPTION NIPPLE 5.2.2 GASKET AIR INTAKE DAMPER ELBOW 5.2.3 GAS BLEEDING VALVE AIR INTAKE DAMPER NIPPLE 5.2.4 THERMOMETER AIR INTAKE PUMP 5.2.5 MUFF LOUVER SHAFT 2.1.1 POWER CONTROLLER COVER LOUVER SHAFT 2.1.2 FRONT CONTROL PANEL REDUCTION ADJUSTING CAM SHAFT...

- Page 34 APPENDIX SIEMENS OIL BURNERS AUTOMATIC CONTROLLER SIEMENS Yellow LMO14 - LMO24 - LMO44 Green The LMO... burner controls are designed for the start-up and supervision of single- or 2-stage forced draught oil burners in intermittent operation. Yellow-burning flames are supervised with photoresistive detectors Colour code table QRB..., blue-burning flames with blue-flame detectors QRC...

-

Page 35: Control Sequence

LMO24 - LMO44 A ´ μC control μC1 μC2 t 3n t 3n t 3n 7130a01e/0700 LMO24 - LMO44 7130d03e/ 0700 µC cont r ol µC 1 µC 2 Alarm device kbr... Cable link (required only when no oil pre-heater is used) BV... - Page 36 Control sequence in the event of fault General unit data If lock-out occurs, the outputs for the fuel valves and the ignition will Mains voltage AC 230 V +10 % / -15 % immediately be deactivated (< 1 second). AC 120 V +10 % / -15 % Cause Response Mains frequency...

- Page 37 Diagnosis of cause of fault After lock-out, the red fault signal lamp remains steady on. µC cont r ol µC 1 µC 2 In that condition, the visual diagnosis of the cause of fault according to the error code table can be activated by pressing the lock-out reset button for more than 3 seconds.

- Page 38 LMO24 - LMO44 General unit data Mains voltage AC 230 V +10 % / -15 % A ´ AC 120 V +10 % / -15 % Mains frequency 50...60 Hz ±6 % External primary fuse (Si) 6.3A (slow) Power consumption 12 VA Mounting orientation optional...

- Page 39 6 in the bottom of the base following burner off time, terminal 11 is live. 6 lateral threaded knockout holes for cable entry glands Pg11 or M20 Permissible afterburn time: during «t13», the flame signal input may still receive a flame signal. Operation End of control program: start position Flame detector and flame simulation test are made automatically during...

-

Page 40: Sequence Diagram

Absorption AC 3.5 VA Mounting position optional Protection IP 40 Perm. input current at terminal 1 Q R C 1 ... AC 5 A max., 20 A peak Perm. current rating of control terminals 3, 6, 7, 9...11, 15...20 4 A max., 20 A peak Internal fuse T6,3H250V according to IEC 127 External fuse... - Page 41 USER MANUAL OF MULTI-THERMOSTAT MCX06C MCX06C is a multi-thermostat with four 100k NTC inputs. It can control up to 4 temperatures showing them (not more than 2 at the same time) on a couple of displays. It is used to check and adjust oil heater temperatures. User interface: Device: ESC button/...

- Page 42 Menu: To enter the menu below, keep pushing ENTER for more than 3 s. Menu code Sub-menu Function Notes code Probes values You can see in sequence the 4 probe values (UP and DOWN keys): the probe code is on display A (Pb1,..., Pb4) and the probe value is on display B (not fitted or out of work probes show “----“).

- Page 43 Set point adjustment: All the parameters inside the Par menu are locked by a password. The user can modify only set points (menu rEG), without using any passwords. The oil viscosity at the nozzle, should be about 1,5° E, which guarantees correct and safe functioning of the burner. The temperature values in the table, guarantee the respect of that parameter and are valid when the pre heating tank is installed on the burner.

- Page 44 C.I.B. UNIGAS S.p.A. Via L.Galvani, 9 - 35011 Campodarsego (PD) - ITALY Tel. +39 049 9200944 - Fax +39 049 9200945/9201269 web site: www.cibunigas.it - e-mail: cibunigas@cibunigas.it Note: specifications and data subject to change. Errors and omissions excepted.

- Page 45 USER MANUAL OF MULTI-THERMOSTAT MCX06C MCX06C is a multi-thermostat with four 100k NTC inputs. It can control up to 4 temperatures showing them (not more than 2 at the same time) on a couple of displays. It is used to check and adjust oil heater temperatures. User interface: Device: ESC button/...

- Page 46 Menu: To enter the menu below, keep pushing ENTER for more than 3 s. Menu code Sub-menu Function Notes code Probes values You can see in sequence the 4 probe values (UP and DOWN keys): the probe code is on display A (Pb1,..., Pb4) and the probe value is on display B (not fitted or out of work probes show “----“).

- Page 47 Set point adjustment: All the parameters inside the Par menu are locked by a password. The user can modify only set points (menu rEG), without using any passwords. The oil viscosity at the nozzle, should be about 1,5° E, which guarantees correct and safe functioning of the burner. The temperature values in the table, guarantee the respect of that parameter and are valid when the pre heating tank is installed on the burner.

Need help?

Do you have a question about the PN91 and is the answer not in the manual?

Questions and answers