Summary of Contents for Cuppone Donatello LLKDN435

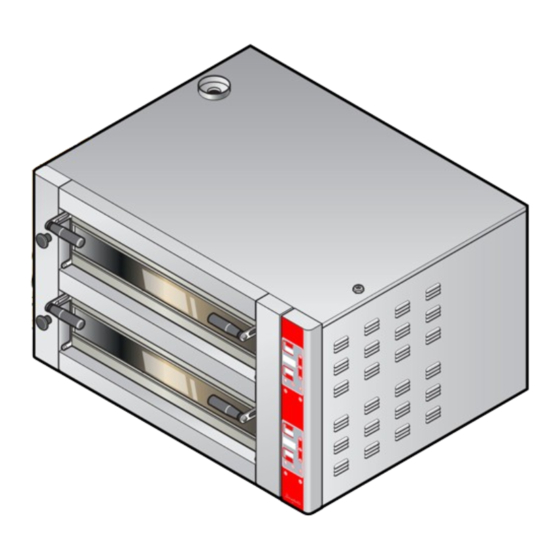

- Page 1 Donatello OVEN Pre-installation and installation manual LLKDN435 LLKDN635 LLKDN635L LLKDN935 Ed. 0121 - 70702530 REV02 Donatello - Pre-installation CP...

-

Page 2: Table Of Contents

Electrical connection ...................27 Pre-testing and final inspection ............36 CUPPONE 1963 Checking the operation and first start-up ........36 Cuppone F.lli S.r.l. Error messages - alarms for mod. CD ..........37 Via Sile, 36 Error messages - alarms for mod. D ...........37 31057 Silea (TV) - ITALY... -

Page 3: Checks Before Purchasing

CHECKS BEFORE PURCHASING Before purchasing the oven and before its installation, check and agree with the owner that, on installation, all the following conditions are met; they are indispensable for the correct and safe installation, operation and maintenance of the oven. Check with the owner if in the place of installation there are the tools to handle the oven easily Fig. - Page 4 Checks before purchasing Survey the installation room to make sure it is • it is possible to maintain a minimum distance between Inform the owner about the necessary electrical adequate. the oven and the walls, other equipment, objects arrangements (activities to be carried out by a combustible materials In case of hot or cold qualified electrician)

- Page 5 Checks before purchasing Evacuation tube, 150 mm in diameter [Ø5,91 in.] (NOT supplied) Max 35°C Max 95°F Min 5°C Max 70% Min 41°F not supplied not supplied Fig. 2 Fig. 3 min. 50 mm [1.97 in.] min. 500 mm extraction [19,7 in.] system draught...

-

Page 6: Oven Technical Data

OVEN TECHNICAL DATA Electrical data Average consumption Customer panel prot. Oven type Supply V Power kW Absorption A Cable type single-phase 230V 25.2 H07RN-F 3G4 2x32 three-phase 400V H07RN-F 5G1 4x16 three-phase 230V 14.6 H07RN-F 4G1,5 3x16 three-phase 208V 16.1 15/4 SOOW CABLE 3x16 three-phase 400V... - Page 7 Donatello LLKDN4351 oven technical data | single oven weight DN 435 single 147 kg - 324 lb weight of packaging + DN 435 single complete oven 167 kg - 368,1 lb oven packaging dimensions DN 435 single 1200x1200x620 [47.24x47.24x 24.41 in.] Ed.

- Page 8 Donatello LLKDN4352 oven technical data | double oven weight DN 435 double 252 kg - 555,5 lb weight of packaging + DN 435 double complete oven 273 kg - 601,8 lb DN 435 double oven packaging dimensions 1200x1200x960 [47.24x47.24xx24.41 in.]...

- Page 9 Donatello LLKDN4352 + LLKDN4351 oven technical data | triple Ed. 0121 - 70702530 REV02 Donatello - Pre-installation CP...

- Page 10 Donatello LLKDN435 oven technical data | capacity 720mm 28,35 in PIZZA PIZZA Ø 35 cm [Ø 13.78 in.] Ø 50 cm [Ø 19,69 in.] 60x40 cm [23,62x15,75 in.] Ø PIZZAS PRODUCTIVITY PER HOUR BATCH ES 40-44 pizzas 10-11 Ø 35 cm [Ø 13.78 in.]...

- Page 11 Donatello LLKDN6351 oven technical data | single oven weight DN 635 single 187 kg - 412,2 lb weight of packaging + DN 635 single complete oven 211 kg - 465,1 lb oven packaging dimensions DN 635 single 1200x1560x620 [47.24x61.42x24.41 in.] Ed.

- Page 12 Donatello LLKDN6352 oven technical data | double oven weight DN 635 double 330 kg - 727,5 lb weight of packaging + DN 635 double complete oven 356 kg - 784,8 lb oven packaging dimensions DN 635 double 1200x1560x960 [47.24x61.42x37.8 in.]...

- Page 13 Donatello LLKDN6352 + LLKDN6351 oven technical data | triple Ed. 0121 - 70702530 REV02 Donatello - Pre-installation CP...

- Page 14 Donatello LLKDN635 oven technical data | capacity 720mm 28,35 in PIZZA PIZZA Ø 35 cm [Ø 13.78 in.] Ø 50 cm [Ø 19,69 in.] 60x40 cm [23,62x15,75 in.] Ø PIZZAS PRODUCTIVITY PER HOUR BATCH ES 60-66 pizzas 10-11 Ø 35 cm [Ø 13.78 in.] 20-22 pizzas 10-11 Ø...

- Page 15 Donatello LLKDN6351L oven technical data | single DN 635L single oven weight kg - 418,8 lb weight of packaging + DN 635L single complete oven 215 kg - 473,9 lb DN 635L single oven packaging dimensions 1560x1200x620 [61.42x47.24x24.41 in.] Ed. 0121 - 70702530 REV02 Donatello - Pre-installation CP...

- Page 16 Donatello LLKDN6352L oven technical data | double DN 635L double oven weight 324 kg - 714,2 lb weight of packaging + DN 635L double complete oven 350 kg - 771,6 lb DN 635L double oven packaging dimensions 1560x1200x960 [61.42x47.24x37.8 in.]...

- Page 17 Donatello LLKDN6352L + LLKDN6351L oven technical data | triple Ed. 0121 - 70702530 REV02 Donatello - Pre-installation CP...

- Page 18 Donatello LLKDN635L oven technical data | capacity 1080mm 42,40 in PIZZA PIZZA Ø 35 cm [Ø 13.78 in.] Ø 50 cm [Ø 19,69 in.] PRODUCTIVITY Ø PIZZAS BATCHE S PER HOUR Ø 35 cm [Ø 13.78 in.] 60-66 pizzas 10-11 Ø...

- Page 19 Donatello LLKDN9351 oven technical data | single oven weight DN 935 single 250 kg - 551,1 lb weight of packaging + DN 935 single complete oven 282 kg - 621,7 lb oven packaging dimensions DN 935 single 1560x1560x620 [61.42x61.42x24.41 in.] Ed.

- Page 20 Donatello LLKDN9352 oven technical data | double ML935/2 oven weight DN 935 double 430 kg - 947,9 lb weight of packaging + DN 935 double complete oven 465 kg - 1025,1 lb oven packaging dimensions DN 935 double 1560x1560x960 [61.42x61.42x37.8 in.]...

- Page 21 Donatello LLKDN9352 +LLKDN9351 |oven technical data | triple Ed. 0121 - 70702530 REV02 Donatello - Pre-installation CP...

- Page 22 Donatello LLKDN935 oven technical data | capacity 1080mm 42,40 in PIZZA PIZZA BAKING-TIN Ø 35 cm [Ø 13.78 in.] Ø 50 cm [Ø 19,69 in.] 60x40 cm [23,62x15,75 in.] Ø PIZZAS PRODUCTIVITY PER HOUR BATCH E S 90-99 pizzas 10-11 Ø...

-

Page 23: Installation

INSTALLATION Symbols used in the manual and on Safety instructions • Before performing any maintenance, replacing components or carrying out any routine/ the labels applied to the machine • Read this guide carefully before installing the extraordinary cleaning, disconnect the electricity appliance, and keep it with care in an accessible supply. -

Page 24: Transport

Installation Transport Fig. 5 Fitted with personal protection equipment, transport the appli- ance to the installation location. Use a suitable vehicle capable of withstanding the weight of the same. Model single double Model single double DN435 147 kg - 324 lb 252 kg - 555,5 lb DN635L 190 kg - 418,8 lb 324 kg - 714,2 lb... -

Page 25: Positioning

Positioning Fig. 8 The positioning room must comply with the instructions provided page Comply with min. 50 mm measurements shown in the figure. [1.97 in.] min. 500 mm Fig. 9 [19,7 in.] The oven must be placed on a base, built by the Manufacturer or by yourself that: •... -

Page 26: Serial Number Plate Reading

Installation Serial number plate reading Year of production The serial number is on the right hand side of the appliance. Model It provides important technical information that is vital in case of a request for maintenance or repair of the appliance: please MADE IN ITALY do not remove, damage or modify it. -

Page 27: Electrical Connection

Installation Electrical connection Fig. 12 Fig. 12 exclu- The electrical connection must be carried out sively by qualified personnel after reading the safety warnings at the beginning of the manual. Before installing the appliance, check that systems comply with the regulations in force in the country where it is going to be used and with the specifica-... - Page 28 Installation • must be connected to an omnipolar circuit breaker allowing complete disconnection in overvoltage III category conditions. The Manufacturer accepts no liability for failure to comply with the above. If required, the cable can be replaced by the Dealer or its technical service or by a person with similar qualifica- tions to prevent any risk.

- Page 29 Installation AC 230 mod. D Θ Abbreviation Description CTRL.B Oven control board Motor start capacitor Noise filter Fuses Digital input for remote ignition Contactor BF09-MC09 Cooking chamber lights Board cooling fan motor Chimney opening motor PW.B Power board RA1,2,3 Top heating elements RB1,2,3 Bottom heating elements Safety thermostat...

- Page 30 Installation AC 3 N400 mod. D Θ Abbreviation Description CTRL.B Oven control board Motor start capacitor Noise filter Fuses Digital input for remote ignition Contactor BF09-MC09 Cooking chamber lights Board cooling fan motor Chimney opening motor PW.B Power board RA1,2,3 Top heating elements RB1,2,3 Bottom heating elements...

- Page 31 Installation AC 3 230 mod. D Θ Abbreviation Description CTRL Oven control board CTRL.SF Chimney adding board Fuses Safety contactor BF09-MC09 Top res. half power BF09-MC09 Top res. full power BF09-MC09 Bottom res. half power BF09-MC09 Bottom res. full power BF09-MC09 Cooking chamber lights Board cooling fan motor Chimney opening motor...

-

Page 32: Pre-Testing And Final Inspection

Installation Pre-testing and final inspection √ Positioning checks Reference chapter on page... The oven is checked and tested in the Manufacturer’s plant Is the installation room adequate and compliant with regulations? (correct before being delivered to the customer. ventilation, maximum/minimum temperature, etc.) The “production process check sheet”... -

Page 33: Error Messages - Alarms For Mod. Cd

Installation Diagnostics In case of any faults or malfunctioning, the display of the A (mod. CD) B (mod. D) boards can show the following error - alarm messages: Error messages - alarms for mod. CD Displayed Oven behaviour Solution code The heater thermocouple is disconnected or faulty Contact The board and cold coupling temperature probe is faulty... - Page 34 Linda Lewis Kitchens Ltd T/A LLK 3-5 Belgrave Industrial Estate Honeywell Lane Oldham, OL8 2JP 0161 633 5797 www.llkpizzapros.co.uk sales@llkpizzapros.co.uk...

Need help?

Do you have a question about the Donatello LLKDN435 and is the answer not in the manual?

Questions and answers