Advertisement

Quick Links

All dimensions are approximate and subject to the limitations of the materials used and the methods of manufacture

Manufacturer:

Dunster House Ltd.

Caxton Road

Bedford

Bedfordshire

England

MK41 0LF

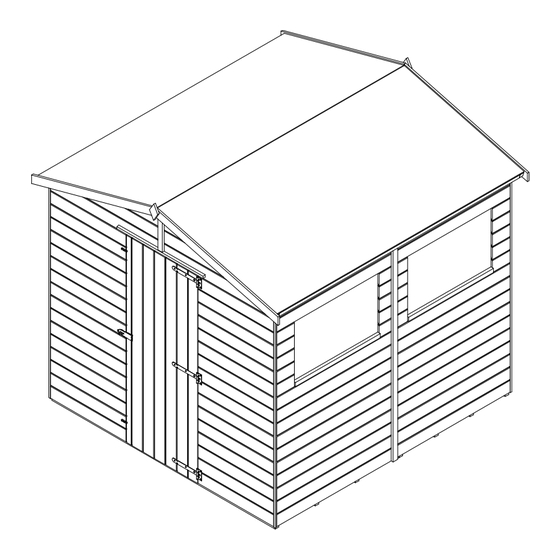

ADAM III SHED - 2.4m x 2.4m

(8ft x 8ft)

H4-2424ASH

Installation Manual

Please read this installation manual carefully

before proceeding with the construction of your shed.

Unique Shed Reference Number

_____________________________

Important!

V1

Customer Service:

cs@dunsterhouse.co.uk

www.dunsterhouse.co.uk

Advertisement

Summary of Contents for Dunster House ADAM III H4-2424ASH

- Page 1 Please read this installation manual carefully before proceeding with the construction of your shed. Important! All dimensions are approximate and subject to the limitations of the materials used and the methods of manufacture Manufacturer: Dunster House Ltd. Caxton Road Bedford Unique Shed Reference Number Bedfordshire...

- Page 2 In the unlikely event that you need to contact us, please do so in writing to: Email: cs@dunsterhouse.co.uk Post: FAO Customer Services, Dunster House Ltd - Factory 1, Caxton Road, Bedford, MK41 0LF Our Customer Services department is open 9:00 - 17:00, Monday to Friday. Please include your Sales Order number starting with SO or your postcode so we can locate your order.

- Page 3 Should you discover a rip or tear, the best course of action is to replace it immediately. At Dunster House, we sell high-grade mineral felt. More information on replacing the shed's roof material can be found here:...

-

Page 4: Pack Contents

Pack Contents PANEL DC - A - 1100x2134 PANEL CC - A - 1100x2134 PANEL DC - B - 1100x2134 PANEL CC - B - 1100x2134 PANEL BM - A - 1150x1897 PANEL AI - A - 1150x1897 PANEL BG - A - 1150x1897 PANEL AA - A - 1150x1897 PANEL FB - 700x1770 - SINGLE DOOR RIGHT MFP - 2440x1220x10... - Page 5 Pack Contents ST-PT3535560 - L = 560mm ST-PT35702230 - L = 2230mm ST-PT3535830 - L = 830mm ST-PT35351210 - L = 1210mm ST-PT35351875 - L = 1875mm ST-PT35352130 - L = 2130mm ST-PT35352200 - L = 2200mm ST-PT35352370 - L = 2370mm ST-PT19452145 - L = 2145mm ST-PT19451855 - L = 1855mm ST-PT2535835 - L = 835mm...

- Page 6 Panels Layout OPTION 1 PANEL CC - B PANEL AA - A PANEL CC - A PANEL AI - A PANEL DC - B PANEL BM - A FRONT PANEL BG - A PANEL DC - A OPTION 2 PANEL CC - B PANEL BG - A PANEL CC - A PANEL BM - A...

- Page 7 Assembly Steps Pre-drill parts before fixing with screws STEP 1: PANELS Items: PANEL BG - A - 1150x1897 Principle of connecting panels PANEL BM - A - 1150x1897 PANEL AA - A - 1150x1897 1a) Line up the panels so that the top and bottom of each panel is PANEL AI - A - 1150x1897 flush with one another.

- Page 8 Assembly Steps Pre-drill parts before fixing with screws STEP 2: FLOOR Joining double bearer (1.1) 2a) Ensure the base is level. Space bearers at the Use 50mm screws. Items: specified distance as shown in the the diagram below (1.0). If the bearer layout consists of double bearers, use 50mm SCREW ST-PT35352200 (Bearer) 50mm screws to secure them as shown in the image to...

- Page 9 Assembly Steps Pre-drill parts before fixing with screws STEP 4: WINDOW SILL Items: 4a) Place the window sill on the bottom of window on outside ST-PT2535835 (Window sill) surface of glass. 50mm SCREW 4b) Use 50mm screws to secure the sill to the frame. Ensure the screws are 50mm from both ends of the window sill and equally spaced.

- Page 10 Assembly Steps Pre-drill parts before fixing with screws STEP 6: PURLINS 6a) Position the middle purlin as shown in the diagram and secure it by using 4x 70mm Items: screws (2x 70mm screws on each end of purlin). ST-PT35702230 (Purlin) 12x 70mm SCREW 6b) Position the remaining purlins in between the center purlin and the side walls.

- Page 11 Assembly Steps Pre-drill parts before fixing with screws STEP 8: HINGES Items: 8a) Position the door in the frame ensuring there is a 5mm gap on each side of the door. The bottom edge of the door should be flush with the bottom shiplap. See image below for PANEL - FB reference (1.0).

- Page 12 Assembly Steps Pre-drill parts before fixing with screws STEP 10: CORNER TRIM 10a) Position the timber trims in each corner of the shed, as shown in the diagram Items: below. Make sure that the end of trim is flush with the bottom wall shiplap. ST-PT15151860 (Corner trim) 40x 30mm NAIL 10b) Fix each corner trim into both panels.

- Page 13 Assembly Steps Pre-drill parts before fixing with screws STEP 12: WIND BRACE 12a) Position the wind braces as shown in the diagram below. Make sure that they Items: are flush with edge of the roof board. ST-PT35351210 (Front+Rear) ST-PT35352370 (Side) 12b) Fix each wind brace by using 35mm screws.

- Page 14 Assembly Steps Pre-drill parts before fixing with screws STEP 14: FASCIA BOARD AND DIAMOND FINIAL 14a) Position the fascia boards to the correct position as shown in the Items: diagram below. Fascia boards should overhang the roof boards by 10mm. ST-PT16701275.75.75 (Fascia board) Fix each fascia board to the wind brace by using 4x 35mm screws.

- Page 15 Assembly Steps CONGRATULATIONS YOUR SHED IS NOW COMPLETE Page 15...

Need help?

Do you have a question about the ADAM III H4-2424ASH and is the answer not in the manual?

Questions and answers