Subscribe to Our Youtube Channel

Summary of Contents for BST ekr CON 100

- Page 1 Web Guiding System Installation and Operating Manual ekr CON 100 MD.461.EN.06 Translation of the Original Manual...

- Page 2 BST GmbH Remusweg 1 D-33729 Bielefeld Tel.: +49 (0) 521 400 70 0 Fax: +49 (0) 5206 999 999 E-Mail: info@bst.group Internet: www.bst.group This documentation is protected by copyright. The translation as well as reproduction and distribution in any form is forbidden without the approval...

-

Page 3: Table Of Contents

Digital Inputs ....................... 27 4.1.6 Output Motor Output Stage .................. 27 4.1.7 Message Output "System OK" .................. 28 4.1.8 Interfaces ........................ 28 4.1.9 Display......................... 29 4.1.10 Weight and Dimensions .................... 29 Power Pack........................ 30 ekr CON 100 – Installation and Operating Manual... - Page 4 Set the Guiding Direction for Center Positioning............ 66 8.5.2 Setting the Gain of the Servo Center Transducer ............ 67 Commissioning the Actuator With Position Feedback.......... 68 8.6.1 Set the Guiding Direction for Center Positioning............ 68 ekr CON 100 – Installation and Operating Manual...

- Page 5 11 Maintenance and Cleaning................ 117 11.1 Safety Instructions .................... 117 11.2 Maintenance Table .................... 118 11.3 Maintenance and Cleaning work ................ 118 11.3.1 Cleaning the Controller Housing ................ 118 11.3.2 Cleaning the Edge Sensor Housing................ 118 ekr CON 100 – Installation and Operating Manual...

- Page 6 Cleaning the Electric Motor Powered Actuator Housing .......... 119 12 Troubleshooting..................... 120 13 Accessories and Spare Parts ................ 124 13.1 Order Address ...................... 124 13.2 Accessories........................ 124 14 Customer Services.................. 125 15 Shutting Down and Disposal................ 126 Index...................... 127 ekr CON 100 – Installation and Operating Manual...

-

Page 7: About This Document

Here you can find how to avoid the danger. ► NOTICE Danger that may lead to damage to assets! There is no risk of injury. Here you can find how to avoid the danger. ► ekr CON 100 – Installation and Operating Manual 7/130... -

Page 8: Symbols

The latest version of these instructions in all available languages as well as further documents on this system can be found in the Internet on our help portal BST.Help. Simply click on the docu- ment number in the table. The link will lead you directly to the se- lected document on BST.Help. -

Page 9: About Safety

The product may only be operated with the components ■ belonging to the system. The only third-party components exempt from the above are those supplied by BST or explicitly approved for use with the system. Parts that are not in perfect condition must immediately be ■... -

Page 10: Non-Intended Infringement Of Guidelines

Non-intended Modification of Electronic Data No virus scanners, firewalls or similar items may be installed on ■ any products of BST GmbH. Virus scanners or other scan or registration programs must not (be able to) access products via networks. Writing, deleting and editing of system data / files on BST ■... -

Page 11: Safety Instructions

Danger of cutting on sharp edges of the material web! Severe cutting injuries caused by the edges of the moving material web. Never touch the edges of moving material webs. ► ekr CON 100 – Installation and Operating Manual 11/130... - Page 12 When returning electronic assembly elements, adhere to DIN ► EN 100015 (“Protection of protection of electrostatic-sensitive devices”). To transport electronic components, only use suitably marked, ► electrically conductive ESD packaging. 12/130 ekr CON 100 – Installation and Operating Manual...

-

Page 13: Qualification Of The Personnel

Operating instructions for the entire system ■ National guidelines, laws and applicable guidelines for protecting ■ employees, general safety at workplaces and for accident pre- vention ekr CON 100 – Installation and Operating Manual 13/130... -

Page 14: Duties Of The Operating Company And Personnel

Only personnel are assigned that are qualified and trained for ■ the respective task The responsibility of the personnel is determined for the task ■ to be completed and that the personnel are informed 14/130 ekr CON 100 – Installation and Operating Manual... -

Page 15: Duties Of The Personnel

4. Initiate first aid measures. 5. Warn the emergency doctor and / or fire brigade. 6. Inform the responsible person at the operating location. 7. Clear the access route for the emergency vehicles. ekr CON 100 – Installation and Operating Manual 15/130... -

Page 16: Personal Protective Equipment

The warranty terms are specified in the sales documentation. 2.8.1 Disclaimer BST GmbH is not liable for damage or defects arising from any in- correct or non-intended use of the product, see Non-intended Use, page 9. Liability for defects does also not apply if the fault originates from... -

Page 17: Exceptions To The Disclaimer

About Safety 2.8.2 Exceptions to the Disclaimer In the cases listed above BST GmbH shall also not be liable (for damages) unless: The damage results from a willful or grossly negligent breach of ■ duty on the part of BST GmbH or its legal representatives or... -

Page 18: Design And Function

The integrated network interface also permits the communication of the controller with an external control system (e.g. PLC, PC, machine control system).* * The network connection is currently not supported. 18/130 ekr CON 100 – Installation and Operating Manual... -

Page 19: Function

(in conjunction with the CLS Pro 600 line and contrast sensor) Watchdog ■ Guiding to a printed line or contrast edge with automatic switching to web edge guiding when the printed line / contrast edge is interrupted or lost ekr CON 100 – Installation and Operating Manual 19/130... -

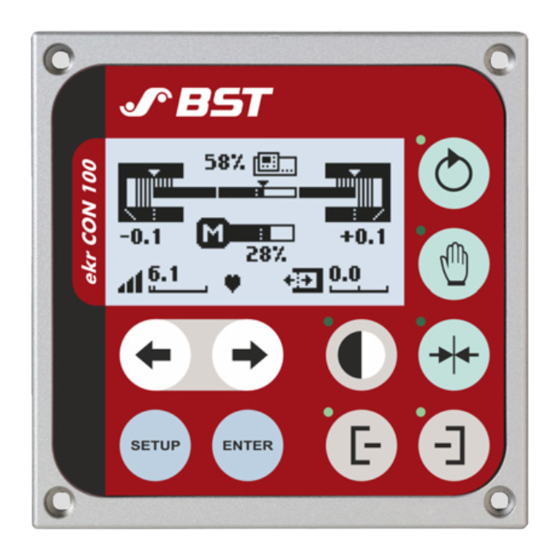

Page 20: Control And Display Elements

Call up / quit setup mode White keys: Move the guiding device manually, Set the guiding setpoint, Set the controller gain, Edit the parameter values For the meanings of the individual keys, see Control Panel, page 20/130 ekr CON 100 – Installation and Operating Manual... -

Page 21: Message Output "System Ok

Motor control timeout Impermissible supply voltage External motor output stage fault A description of the individual faults can be found in the chapters Special Displays, page 81 and Troubleshooting, page 120. ekr CON 100 – Installation and Operating Manual 21/130... -

Page 22: Connectable Components

* from firmware version 1.6.2 (see separate manual, document number MD. 532) ** required for the connection of two (Use e.g. in EcoGuide) CAN-Bus participants to socket X101 / X102 Fig. 3: Connectable components 22/130 ekr CON 100 – Installation and Operating Manual... -

Page 23: Designation Of The Sensors

In this operating manual, the sensors are designated with Sensor 1, Sensor 2 and Sensor 3. In accordance with the BST definition, the following assignment applies between the sensors and the selector keys for the guiding mode:... -

Page 24: Line And Contrast Sensor (Sensor 3)

① of the guiding device must be kept as small as possible. Accessories For accessories and the order address, see Accessories and Spare Parts, page 124. 24/130 ekr CON 100 – Installation and Operating Manual... -

Page 25: Name Plate

Hardware version (e.g. AG) ⑦ Operating voltage Date of manufacture ⑧ (Year, Calendar week) ⑨ Protection type ⑩ Nominal current consumption Data matrix code, ⑪ Code Content = 30 digit serial number (IDC) ekr CON 100 – Installation and Operating Manual 25/130... -

Page 26: Technical Specifications

(with actuator EMS 21, EMS 22, ECO EMS 22) Connection 4-pin micro-style connector M8 Length of connecting cable max. 20 m (with wire cross section 0.5 mm (with actuator EMS 10, EMS 18) max. 5 m (with actuator EMS 21, EMS 22, ECO EMS 22) 26/130 ekr CON 100 – Installation and Operating Manual... -

Page 27: Analogue Inputs

> 1.9 A (EMS 22, ECO EMS 22) > 1.7 A (EMS 21) > 1.1 A (EMS 10, EMS 18) Connection Socket M12 / spring-cage terminal block Brushless motor connection, see chapter X4 - Brushless motor / DC, page 57. ekr CON 100 – Installation and Operating Manual 27/130... -

Page 28: Message Output "System Ok

100 MBit/s (Fast Ethernet), automatic detection, galvanic isolation Internet protocol supported IPv4 Transport layer supported TCP, UDP IP address Adjustable via software Connection 8-pin RJ45 plug Max. length of connecting cable 100 m 28/130 ekr CON 100 – Installation and Operating Manual... -

Page 29: Display

4.1.9 Display LCD graphics module Size 63 mm x 35 mm Resolution 128 x 64 pixels Illumination LED background lighting 4.1.10 Weight and Dimensions Controller Weight approx. 0.55 kg Dimensions (details in mm) Fig. 7: Controller dimensions ekr CON 100 – Installation and Operating Manual 29/130... -

Page 30: Power Pack

The 0 V connection of the power pack has to be connected to the protective conductor system (see the requirements of the IEC 60204-1). The power pack is not included in the web guiding controller scope of delivery. 30/130 ekr CON 100 – Installation and Operating Manual... -

Page 31: Sensors

Repeatable accuracy* Linearity ± 0.2 mm Output signal 0 to 10 V⎓ (±2.5%) (analogue mode) Output signal CAN bus (digital mode) Polarity reversal protection (supply) Short circuit protection (analogue output) Operation display LED (2-coloured) ekr CON 100 – Installation and Operating Manual 31/130... - Page 32 Storage temperature -10 to +70 °C Protection category IP 54 Noise emission < 70 dB Weight < 500 g Housing dimensions See separate product data sheet RoHS conformity * in digital mode 32/130 ekr CON 100 – Installation and Operating Manual...

-

Page 33: Line And Contrast Sensor Cls Pro 600

RoHS conformity * in digital mode 4.3.2 Line and Contrast Sensor CLS Pro 600 Technical specifications, see separate operating manual of the CLS Pro 600 line and contrast sensor, document number MD.323. ekr CON 100 – Installation and Operating Manual 33/130... -

Page 34: Electric Motor Powered Actuators

1.3 : 1 2.4 : 1 4.2 : 1 EMS 18/F 1.3 : 1 2.4 : 1 16 x 5 4.2 : 1 1.3 : 1 2.4 : 1 4.2 : 1 34/130 ekr CON 100 – Installation and Operating Manual... -

Page 35: Emissions

This product complies with the EC Directive 2011/65 (so-called RoHS* Directive). The limits values for hazardous substances in electrical and electronic equipment specified there are not exceeded by this product. * Abbreviation for Restriction of Hazardous Substances ekr CON 100 – Installation and Operating Manual 35/130... -

Page 36: Transport, Delivery And Storage

Secure the goods to be transported on the transport device so ► that they cannot slip, fall-over, knock or fall down, e.g. using lashing straps and edge protectors. Lift and put the transport goods down carefully. ► 36/130 ekr CON 100 – Installation and Operating Manual... -

Page 37: Scope Of Delivery

On palettes or on a shelf to protect against moisture on the ■ floor Protected against dust and dirt (e.g. covered with film) ■ For permissible ambient temperatures and humidity, see chapter Technical Specifications, page 26. ekr CON 100 – Installation and Operating Manual 37/130... -

Page 38: Installation

Cordon-off the work area in order to prevent access by unau- ► thorized persons (e.g. by setting up barriers). Make sure that all parts of the machine where the BST ► components have to be installed have a sufficient load bearing capacity. -

Page 39: Selecting The Installation Location

Installation Do not climb onto or walk on BST components or unsuitable ► parts of the machine. Ensure that there is sufficient free headroom. If the free head- ► room is restricted, the relevant components causing the height restrictions must be padded and danger-warning signs must be attached to them (yellow / black). -

Page 40: Installing The Controller

Fig. 8: Installation cut-out 6.3.2 Space Requirement for the Connecting Cable The figure shows the free space behind the controller that is required for connecting the cable. Fig. 9: Space requirement for the connecting cable 40/130 ekr CON 100 – Installation and Operating Manual... - Page 41 1. Make the installation cut-out and fixing boreholes (see Installation Cut-Out, page 40). 2. Carefully push the controller into the installation cut-out 3. Screw on the controller with the four M3 ISO 4762 hexagon head screws. ekr CON 100 – Installation and Operating Manual 41/130...

-

Page 42: Electrical Connection

Before connecting, make sure that the mains voltage corres- ► ponds with the details specified on the nameplate of the com- ponents. Select the correct terminals and polarity when connecting the ► power supply. 42/130 ekr CON 100 – Installation and Operating Manual... -

Page 43: Cable Routing

Fig. 11: Separate routing of signal and supply cables ① Cable duct ③ Supply cable ② Signal cable Establish cable connections between the components according ► to the connecting diagram. ekr CON 100 – Installation and Operating Manual 43/130... -

Page 44: Connecting The Cables

After connecting, in both cases check the correct fit of the cable. ► 44/130 ekr CON 100 – Installation and Operating Manual... -

Page 45: Ensuring Equipotential Bonding

(see illustrations). Remove the paint coating in the contact area. ► Through-hole Threaded hole Fig. 12: Use of fan type washers ① Screw ④ Washer ② Nut ⑤ Grounding cable ③ Serrated washer ekr CON 100 – Installation and Operating Manual 45/130... -

Page 46: Connections On The Controller

Fig. 14: Connections on the back of the device You can find the function of the connections in the table on the following page. 46/130 ekr CON 100 – Installation and Operating Manual... -

Page 47: Sockets / Plugs

(see separate operating instructions of the components to be connected). The connector sockets of the controller are not Hot-Plug capable. Before adding or removing system components on the connector ► sockets, electrically isolate the controller. ekr CON 100 – Installation and Operating Manual 47/130... -

Page 48: X100 - Power Supply

Power supply controller reserved blue Ground reserved When using an actuator EMS 21, EMS 22 or ECO EMS 22, the length of the supply cable (wire cross section 0.5 mm must be maximum 5 m. 48/130 ekr CON 100 – Installation and Operating Manual... -

Page 49: X101, X102 - Can-Bus

View X Socket (female) View X Connector (male) Fig. 16: Contact assignment of the plug connector Contact Function Note +24 V⎓ Power supply +24 V⎓ CAN-H CAN high CAN-GND Ground power supply CAN-L CAN low ekr CON 100 – Installation and Operating Manual 49/130... -

Page 50: X103 - Actuator

Output A to actuator PWM B Output B to actuator 0 V⎓ Ground PWM A Output A to actuator PWM B Output B to actuator Internal Pull UP Identification actuator 0 … 10 V⎓ / 0 … 18 V⎓ Position feedback 50/130 ekr CON 100 – Installation and Operating Manual... -

Page 51: X104 - Network

The network connection is currently not supported! View of the socket from outside Fig. 18: Contact assignment of the network interface Contact Function Note Not used Not used Not used Not used ekr CON 100 – Installation and Operating Manual 51/130... -

Page 52: X105 - Service

The service interface (USB 2.0 Mini-B) is used for programming the controller in the factory. The X105 socket is located behind the round plastic plug (Service). USB 2.0 Mini-B Fig. 19: Programming interface 52/130 ekr CON 100 – Installation and Operating Manual... -

Page 53: Terminal Strips

■ DC motor connection, ■ Connection brushless motor / DC if connection via X103 is not possible (EMS 10, ECO EMS 22) See also Message Output “System OK“, Message output ”System OK“ page 21. ekr CON 100 – Installation and Operating Manual 53/130... -

Page 54: X1 - Digital Inputs

Output (power supply +24 V⎓) for inputs 1 … 7 (max. 0.2 A) Input 1 Input 2 Input 3 See truth table Input 4 (Truth Table, page 116) Input 5 Input 6 Input 7 Ground for inputs 1 … 7 54/130 ekr CON 100 – Installation and Operating Manual... -

Page 55: X2 - Position Feedback Actuator

X103 is not possible Position feedback signal input 0 … 10 V⎓ / 0 … 18 V⎓ (automatic voltage selection depending on the actuator used) Ground Identification actuator Identification of the connected actuator ekr CON 100 – Installation and Operating Manual 55/130... -

Page 56: X3 - Servo Center Transducer

X3 - Servo center transducer Fig. 22: Terminal strip X3 Function Wire color Note Terminal Power supply +12 V⎓ +12 V⎓ brown for OMG 8, CK 37 (Namur A) Namur blue Input OMG 8, CK 37 (Namur B) 56/130 ekr CON 100 – Installation and Operating Manual... -

Page 57: X4 - Brushless Motor / Dc

Output +12 V⎓ (max. 0.1 A) Connection DC motor (EMS 10, ECO EMS 22) Function Wire color Note Terminal EMS 10 ECO EMS 22 Actuator A (+) brown Output A to actuator Actuator B (-) white black Output B to actuator ekr CON 100 – Installation and Operating Manual 57/130... -

Page 58: X5 - Message Output "System Ok

Relay – N/C contact Potential-free changeover contact Relay – Changeover contact If there are no faults, the N/O contact is closed (contact between terminals 42 and 43). Relay – N/O contact 58/130 ekr CON 100 – Installation and Operating Manual... -

Page 59: Service Indications

Bus designation Meaning The module is working correctly. NO ERROR No problems exist. No SYNC message is received. FLASHES x3 SYNC ERROR BUS OFF The interface controller is located in Bus-Off mode. ekr CON 100 – Installation and Operating Manual 59/130... -

Page 60: Status Display Of Power Supply

Internal operating voltage 5 V⎓ not available H12 green Internal operating voltage 5 V⎓ available 7.8.5 Status Display of Message Output "System OK" LED Colour Condition Meaning System failure H190 green System OK (no failure) 60/130 ekr CON 100 – Installation and Operating Manual... -

Page 61: Commissioning

Commissioning Safety Instructions WARNING Danger of death and material damage caused by incorrect com- missioning! Have the commissioning carried out by BST service personnel or ► authorized personnel only. DANGER Danger of death caused by the machine starting up! Parts of your body could be crushed, cut, drawn in or hit. -

Page 62: Requirements

Before opening the controller, switch off the power supply. ► The DIL switch S1 is located behind the plastic plug (Service) on the back of the controller. Fig. 26: DIL switch S1 62/130 ekr CON 100 – Installation and Operating Manual... -

Page 63: Using The Dil Switch

The other end of the tweezers engages on the movable slider. 2. Move both ends of the tweezers towards each other applying a little pressure in order to move the slider to the desired position. ekr CON 100 – Installation and Operating Manual 63/130... -

Page 64: Setting The Dil Switches

(automatic detection) No servo center transducer connected (operating mode Center positioning cannot be selected) Potentiometer, signal input 0 … 10 V⎓ (e.g. position feedback EMS 18) Potentiometer, signal input 0 … 18 V⎓ (e.g. position feedback EMS 21, EMS 22) 64/130 ekr CON 100 – Installation and Operating Manual... -

Page 65: Setting The Motor Rotation Direction

EMS 21, the controller EMS 22, (see Setting the DIL Switches, page 64). ECO EMS 22 Change DIL switch S4.6 on the processor board of Drive Module 160 EMS 23 (see separate operating instructions Drive Module 160, EDP no. MD.359). ekr CON 100 – Installation and Operating Manual 65/130... -

Page 66: Commissioning The Actuator Without Position Feedback

If the guiding device moves into one of its end positions then you have to reverse the guiding direction. Reversing the guiding direction Change DIL switch S1.2 on the processor board of the controller ► (see Setting the DIL Switches, page 64). 66/130 ekr CON 100 – Installation and Operating Manual... -

Page 67: Setting The Gain Of The Servo Center Transducer

After a pre-set time (Timeout) has elapsed after pressing the key for the last time, the display of the gain is auto- matically faded out. If control oscillations do not occur we recommend setting the maximum gain. ekr CON 100 – Installation and Operating Manual 67/130... -

Page 68: Commissioning The Actuator With Position Feedback

Reversing the guiding direction Change DIL switch S1.2 on the processor board of the controller ► (see Setting the DIL Switches, page 64). 68/130 ekr CON 100 – Installation and Operating Manual... -

Page 69: Setting Stroke Limitation And Servo-Center Position

⑤ Key for saving the position for the software limit switch 2 ⑥ Current position for software limit switch 2 ⑦ Current position of the actuator (graphical display) ⑧ Current position of the actuator (numeric display) ekr CON 100 – Installation and Operating Manual 69/130... - Page 70 2. Press the Sensor 2 key. The position for software limit switch 2 is stored. The symbol Sensor 2 will be inversely displayed. The new position for software limit switch 2 appears under the symbol. 70/130 ekr CON 100 – Installation and Operating Manual...

- Page 71 The new servo-center position appears under the symbol. Exiting the settings Press the ENTER key. ► The setting menu is closed. ð All edited parameter values are saved. ð The operation screen is displayed. ekr CON 100 – Installation and Operating Manual 71/130...

-

Page 72: Performing The Material Setup

The controller switches to automatic mode. 3. Press the SETUP key. The set gain is displayed at the bottom edge of the display using a bar indicator ① and as a numeric value ②. 72/130 ekr CON 100 – Installation and Operating Manual... - Page 73 After a pre-set time (Timeout) has elapsed after pressing the key for the last time, the display of the gain is auto- matically faded out. If control oscillations do not occur we recommend setting the maximum gain. ekr CON 100 – Installation and Operating Manual 73/130...

-

Page 74: Operation

Signals that are located on the remote control inputs of the controller block the keys on the control panel with counter functions. You can find the function of the individual keys in the following table. 74/130 ekr CON 100 – Installation and Operating Manual... - Page 75 In automatic operating mode: Activate the gain setting Setup mode Accept the set value ENTER and quit the setup mode Arrow keys Decrease / increase the parameter value left / right ekr CON 100 – Installation and Operating Manual 75/130...

-

Page 76: Operation Display

③ Operating display edge sensor (Sensor 2) ④ Displays the setpoint of the web edge ⑤ Actuator operation display ⑥ Status display System OK (heart beats) ⑦ Displays the controller gain 76/130 ekr CON 100 – Installation and Operating Manual... -

Page 77: Operation Display Edge Sensors (Sensor 1/2)

Guiding setpoint = - 6 mm The web edge is located in the The web edge is displaced by center of the sensor scanning -6 mm from the center of the area. sensor scanning area. ekr CON 100 – Installation and Operating Manual 77/130... -

Page 78: Operation Display Line And Contrast Sensor (Sensor 3)

The white bar marks the current position of the line. ③ Contrast guiding: The black bar marks the current position of the contrast transition. ④ The triangle marks the guiding setpoint set. 78/130 ekr CON 100 – Installation and Operating Manual... - Page 79 Guiding setpoint = 50% Guiding setpoint = 75% The contrast transition is The contrast transition is located in the center of the located at 75% of the sensor sensor scanning area. scanning area. ekr CON 100 – Installation and Operating Manual 79/130...

-

Page 80: Actuator Operation Display

① The dashed line marks the zero position of the actuator. ② The black bar marks the current position of the actuator. The value specifies the relative position of the actuator in ③ relation to the end positions. 80/130 ekr CON 100 – Installation and Operating Manual... -

Page 81: Special Displays

Actuator blocked appears in the display next to the operation display of the actuator. Fig. 37: Screen display with blocked actuator After driving the actuator in the opposite direction, the symbol fades out automatically. ekr CON 100 – Installation and Operating Manual 81/130... -

Page 82: Impermissible Supply Voltage

Motor control timeout appears in the display. Fig. 39: Screen display during the motor control timeout After driving the actuator in the opposite direction, the symbol fades out automatically. 82/130 ekr CON 100 – Installation and Operating Manual... -

Page 83: Controller Interlock Active

If a fault occurs in the bus connection between the controller and the actuator then the warning symbol Actuator bus connection fault appears in the display. Fig. 41: Screen display with an active fault in the bus connection for the actuator ekr CON 100 – Installation and Operating Manual 83/130... -

Page 84: Loss Of The Line / Contrast Transition

Fig. 43: Screen display with an active fault in the external motor output stage for the EMS 23 actuator 84/130 ekr CON 100 – Installation and Operating Manual... -

Page 85: Performing The Material Setup

The automatic material setup describes the normal procedure ■ for saving the bright / dark values of the sensors. The manual material setup should always be used if the contrast ■ that has to be scanned is critical. ekr CON 100 – Installation and Operating Manual 85/130... - Page 86 ① Spanner symbol = manual material setup Bright / dark value (numeric display) ② 100.0% = scanning area is completely free 0.0% = scanning area is completely covered ③ Bright / dark value (graphical display) 86/130 ekr CON 100 – Installation and Operating Manual...

-

Page 87: Activating The Material Setup

You can cancel the material setup at any time as follows: Press the SETUP key. ► The material setup is cancelled. The bright / dark values determined are not saved. ð The screen display changes to the operation display. ekr CON 100 – Installation and Operating Manual 87/130... -

Page 88: Procedure For Web Edge Guiding

The dark value measured is displayed. 6. Press the ENTER key. The material setup for the selected sensor is completed. The bright / dark values determined are saved. ð The operation screen is displayed. 88/130 ekr CON 100 – Installation and Operating Manual... - Page 89 The dark value measured is displayed. 7. Press the ENTER key. The dark value will be saved. The material setup for the selected sensor is completed. ð The operation screen is displayed. ekr CON 100 – Installation and Operating Manual 89/130...

-

Page 90: Procedure For Web Center-Line Guiding

The dark value measured is displayed. 9. Press the ENTER key. The bright / dark values determined for sensor 2 are saved. The material setup is completed. ð The operation screen is displayed. 90/130 ekr CON 100 – Installation and Operating Manual... - Page 91 The dark value measured is displayed. 7. Press the ENTER key. The dark value for sensor 1 is saved. The screen display shows the operating step necessary for generating the bright value for sensor 2. ekr CON 100 – Installation and Operating Manual 91/130...

- Page 92 The dark value measured is displayed. 11. Press the ENTER key. The dark value for sensor 2 is saved. The material setup is completed. ð The operation screen is displayed. 92/130 ekr CON 100 – Installation and Operating Manual...

-

Page 93: Selecting The Operating Mode For The Ir 2011/40 Edge Sensor

IR 2011/40 Operating Modes The desired operating mode is selected in the setup menu using a special setting menu. Fig. 46: Setting menu for selecting the IR 2011/40 edge sensor operating mode ekr CON 100 – Installation and Operating Manual 93/130... - Page 94 Scanning of material webs extremely short response times with highly dynamic web 24 mm position errors and high web (± 12 mm) Sensor measuring value follows any web ■ speeds edge position change without delay 94/130 ekr CON 100 – Installation and Operating Manual...

-

Page 95: Operating Mode Selection

The setting menu is closed. The setup menu is displayed. 8. Press the SETUP key, to return to the operation display. 9. Repeat the process for the second edge sensor if desired. ekr CON 100 – Installation and Operating Manual 95/130... -

Page 96: Selecting The Guiding Mode

›› A CLS Pro 600 line and contrast sensor is connected to the controller as sensor 3. Press the Sensor 3 key. ► ð The LED of the key will illuminate. 96/130 ekr CON 100 – Installation and Operating Manual... -

Page 97: Selecting The Operating Mode

The desired guiding mode is selected (see Selecting the Guiding Mode, page 96). Press the Automatic key. ► The LED of the key will illuminate. ð The controller switches to automatic mode. ekr CON 100 – Installation and Operating Manual 97/130... -

Page 98: Center Positioning

Press the Center Positioning key. ► The LED of the key will illuminate. ð The guiding device moves to its central position. 98/130 ekr CON 100 – Installation and Operating Manual... -

Page 99: Watchdog

Fig. 47: Correct arrangement of the capture sensor and the line / contrast sensor ① Capture sensor ② Line and contrast sensor (CLS Pro 600) ③ Capture sensor scanning area ④ Line and contrast sensor scanning area ekr CON 100 – Installation and Operating Manual 99/130... - Page 100 The LED of the key illuminates. The controller switches to automatic mode. 4. Press both arrow keys on the controller at the same time. The guiding setpoint for sensor 3 is reset to the value 0. 100/130 ekr CON 100 – Installation and Operating Manual...

- Page 101 If the capture sensor takes over the guiding in event of losing the printed line or the contrast transition then the LED of the respective key (Sensor 1 or Sensor 2) flashes. ekr CON 100 – Installation and Operating Manual 101/130...

-

Page 102: Setting The Guiding Setpoint

① The triangle marks the guiding setpoint during operation. ② The dashed line marks the centre of the sensor scanning area. ③ The black bar marks the guiding setpoint ④ Numeric display of the guiding setpoint 102/130 ekr CON 100 – Installation and Operating Manual... - Page 103 0. After a pre-set time (Timeout) has elapsed after pressing the key for the last time, the display of the guiding setpoint is automatically faded out. The set value is applied. ekr CON 100 – Installation and Operating Manual 103/130...

-

Page 104: Optimizing The Controller Gain

Pressing both arrow keys at the same time will reset the gain to a value of 5.0. 6. Press the ENTER key. ð The gain setting is complete. 104/130 ekr CON 100 – Installation and Operating Manual... - Page 105 After a pre-set time (Timeout) has elapsed after pressing the key for the last time, the display of the gain is auto- matically faded out. If control oscillations do not occur we recommend setting the maximum gain. ekr CON 100 – Installation and Operating Manual 105/130...

-

Page 106: Calling Up The Setup Menu

4. Using the arrow keys, select the symbol of the desired setting function or service display. The selected symbol will be inversely displayed. 5. Press the ENTER key. The setting menu or service display selected appears in the display. 106/130 ekr CON 100 – Installation and Operating Manual... - Page 107 Displaying the status of the See Displaying the Status of Digital inputs digital inputs the Digital Inputs, page 112 Displaying the CAN-Bus See Displaying the CAN-Bus CAN-Bus status Status, page 113 ekr CON 100 – Installation and Operating Manual 107/130...

-

Page 108: Displaying System Information

2. Press the ENTER key to quit the service display. The operation screen is displayed. After a pre-set time (Timeout) has elapsed, the service display is automatically quit. The operation screen is displayed. 108/130 ekr CON 100 – Installation and Operating Manual... -

Page 109: Displaying System Components

2. Press the ENTER key to quit the service display. The operation screen is displayed. After a pre-set time (Timeout) has elapsed, the service display is automatically quit. The operation screen is displayed. ekr CON 100 – Installation and Operating Manual 109/130... -

Page 110: Displaying The Dil Switch Settings

Select the servo center transducer ⑥ S1.8 used Namur servo center trans- Namur ducer (e.g. OMG 8, CK 37) EcoGuide EcoGuide No servo center transducer connected (operating mode Center positioning cannot be selected) 110/130 ekr CON 100 – Installation and Operating Manual... - Page 111 2. Press the ENTER key to quit the service display. The operation screen is displayed. After a pre-set time (Timeout) has elapsed, the service display is automatically quit. The operation screen is displayed. ekr CON 100 – Installation and Operating Manual 111/130...

-

Page 112: Displaying The Status Of The Digital Inputs

2. Press the ENTER key to quit the service display. The operation screen is displayed. After a pre-set time (Timeout) has elapsed, the service display is automatically quit. The operation screen is displayed. 112/130 ekr CON 100 – Installation and Operating Manual... -

Page 113: Displaying The Can-Bus Status

2. Press the ENTER key to quit the service display. The operation screen is displayed. After a pre-set time (Timeout) has elapsed, the service display is automatically quit. The operation screen is displayed. ekr CON 100 – Installation and Operating Manual 113/130... -

Page 114: Restoring Factory Default Settings

6. Set DIL switch S1.3 to position OFF. 7. Reinsert the plastic plug. 8. Switch on the power supply. After restoring factory default settings, it is imperative that the DIL switch S1.3 is returned to the OFF position. 114/130 ekr CON 100 – Installation and Operating Manual... -

Page 115: Remote Control (Digital Inputs)

If a remote control signal is at the respective terminal of the controller (+24 V⎓), the corresponding function can no longer be switched via the control panel. ekr CON 100 – Installation and Operating Manual 115/130... -

Page 116: Truth Table

* 1 = controller enable active, 0 = controller interlock active You can have the status of the digital inputs shown in the display with a special service display (see Displaying the Status of the Digital Inputs, page 112). 116/130 ekr CON 100 – Installation and Operating Manual... -

Page 117: Maintenance And Cleaning

Risk of injury and material damage caused by incorrect main- tenance / cleaning! Have the maintenance and cleaning carried out only by ► qualified personnel that have been instructed by BST service personnel or authorized personnel. Carry out the maintenance and cleaning as described in the ►... -

Page 118: Maintenance Table

Clean carefully using a dry, clean and soft cloth (e.g. glasses ► wipe). Use a commercially available liquid cleaner in event of intensive ► soiling. Perform the material setup after cleaning. ► 118/130 ekr CON 100 – Installation and Operating Manual... -

Page 119: Cleaning The Housing Of The Cls Pro 600 Line And Contrast Sensor

The housing of the actuator must be cleaned if soiling can be seen on the outside. Clean using a dry, clean and soft cloth. ► Use a commercially available liquid cleaner in event of intensive ► soiling. ekr CON 100 – Installation and Operating Manual 119/130... -

Page 120: Troubleshooting

Troubleshooting Troubleshooting WARNING Danger to life and assets caused by incorrect rectification of mal- functions! Only allow qualified personnel instructed by BST service staff or ► authorized personnel to rectify malfunctions. Only rectify malfunctions using the following measures or ►... - Page 121 The warning symbol Faulty bus connection on the actuator is shown in the display. Fault in the bus connection between the controller Check the cable connection between the ► and actuator. controller and actuator (Drive Module 160). ekr CON 100 – Installation and Operating Manual 121/130...

- Page 122 Undefined behaviour of the controller. The controller has been mounted in the immediate Maintain a minimum distance of 100 mm to ► vicinity of high-voltage components or lines. high-voltage components or lines. 122/130 ekr CON 100 – Installation and Operating Manual...

- Page 123 Read the separate operating instructions of the ► CLS Pro 600 line and contrast sensor. CLS Pro 600 line and contrast sensor (EDP no. MD.323). ekr CON 100 – Installation and Operating Manual 123/130...

-

Page 124: Accessories And Spare Parts

118 449 Connecting cable 10 m 154 374 Adapter cable Connection actuator EMS 21, EMS 22 140 932 Connecting cable 10 m Connection actuator EMS 10 167 205 CAN bus distributor Connection of several bus participants 124/130 ekr CON 100 – Installation and Operating Manual... -

Page 125: Customer Services

Serial number and date of manufacture (see name plate) ■ Customer Services Address BST GmbH Service Remusweg 1 D-33729 Bielefeld Germany Tel.: +49 (0) 521 400 70 767 E-Mail: service@bst.group http: www.bst.group ekr CON 100 – Installation and Operating Manual 125/130... -

Page 126: Shutting Down And Disposal

Also note the legal regulations as well as local recycling guidelines for this purpose. Returning the system to BST GmbH is always possible. About this and for all other queries, please contact BST Customer Services, page 125. -

Page 127: Index

Display status .......... 113 generate............ 86 CAN-Bus extension ........ 124 Design ............. 18 CAN-Bus interface........... 28 Digital inputs........... 27, 115 Center positioning .......... 98 Connection............. 54 Cleaning ............ 117 Display status .......... 112 CLS Pro 600 ............. 33 DIL switch............ 62 Setting............ 64 ekr CON 100 – Installation and Operating Manual 127/130... - Page 128 .. 90 Guiding setpoint procedure for web edge guiding.... 88 Display............ 76 Message output .......... 21 Setting............ 102 Message output System OK Connection............. 58 Motor control timeout ........ 82 Motor overcurrent.......... 81 128/130 ekr CON 100 – Installation and Operating Manual...

- Page 129 Product - Use ............ 9 Supply voltage .......... 82 Protection category Switch positions Controller ............ 26 display ............ 110 System Intended use ............ 9 Qualified electricians ........ 13 System components Qualified personnel ........ 13 display ............ 109 ekr CON 100 – Installation and Operating Manual 129/130...

- Page 130 Warranty terms .......... 16 Watchdog .......... 19, 99 function............ 99 Preparation measures........ 100 requirements .......... 99 switch on............ 100 Web center-line guiding ...... 19, 96 Web edge guiding ........ 19, 96 Weight Controller ............ 29 130/130 ekr CON 100 – Installation and Operating Manual...

Need help?

Do you have a question about the ekr CON 100 and is the answer not in the manual?

Questions and answers

Good evening please send moter connection diagram I buy this piston new

The motor connection diagram for the BST EKR CON 100 includes the following:

- Brushless Motor / DC Motor Connection: If connection via terminal X103 is not possible, use an alternate connection method as described for models EMS 10 and ECO EMS 22.

- Terminal X4 is used for connecting the brushless or DC motor.

- Further details can be found under section 7.7.4 for X4 in the manual.

No specific diagram image is provided in the context, only terminal references and connection notes.

This answer is automatically generated

Teg lain nahi pakd rha he

The BST EKR CON 100 may not be picking up the line because the printed line or contrast transition to be scanned is outside the scanning area of the CLS Pro 600 line and contrast sensor. Ensure that the sensor is correctly positioned within the scanning area and refer to the separate operating instructions of the CLS Pro 600 for proper setup.

This answer is automatically generated

Seting karna he

To set up the BST EKR CON 100, follow these steps:

1. Select an Installation Location

- Ensure the location is dry, vibration-free, and level.

- Position ergonomically to allow easy access.

- Avoid direct light on the display.

- Do not install in potentially explosive areas.

2. Install the System

- Do not climb on machine components.

- Ensure sufficient headroom and mark height restrictions with warning signs.

- Install all safety equipment and protective covers after setup.

- Tighten all bolts and remove tools and transport locks.

3. Power and Network Setup

- Use only the approved power pack (Puls GmbH Type ML100.100).

- The Ethernet connection does not support Power over Ethernet (PoE).

- Connect using an 8-pin RJ45 plug with a max cable length of 100m.

4. Controller Setup

- Press the Manual mode key to switch to manual mode (LED illuminates).

- Press the SETUP key to enter setup mode.

- Navigate through the setup menu using the display.

5. Gain Adjustment

- Adjust gain settings for stable guiding operation using arrow keys.

- Press both arrow keys simultaneously to reset gain to 5.0.

- Confirm settings by pressing ENTER.

This completes the setup.

This answer is automatically generated