Summary of Contents for Hirose GT43

- Page 1 ETAD-P0398 First edition GT43 Harness Shielding Plate Assembly Process Instruction Manual...

- Page 2 In order to use the product safely, be sure to read this instruction manual before using CAUTION the product. Furthermore, keep this instruction manual in a place where it can be accessed quickly when needed.

- Page 3 FORWARD Thank you very much for purchasing our GT43 harness equipment. This tool is a jig to assemble shielding plate to the external cylinder terminal of the harness product. Be sure to read this instruction manual carefully and fully understand its contents before using the product.

- Page 4 FOR SAFE OPERATION Because of the machine's design, there is always a possibility of contact with moving parts. The operators of the machine and the maintenance personnel who are in charge of maintenance and repair work are required to read the following SAFETY INSTRUCTIONS so as to avoid injury. To fully understand the descriptions given in this Instruction Manual and the warning labels attached on the machine, the warning messages are used in accordance with the below-stated classification.

- Page 5 PRECAUTIONS FOR SAFETY CAUTION Basic safety instructions 1. Be sure to read this Instruction Manual and any other instructions or materials supplied with the unit as accessories. Keep this Instruction Manual and make it available for reference. Safety device and warning labels 1.

- Page 6 5. In the event that your machine fails to perform normally after repair/adjusting works, immediately stop operation. Contact Hirose for service to protect against personal injury.

- Page 7 SAFETY INSTRUCTIONS TO BE FOLLOWED WHEN USING THE TOOLS FOR GT43 SHIELDING PLATE ASSEMBLY 1. To protect against shock hazards, open the cover, if necessary, after turning DANGER the power off and waiting for a minimum of five minutes. 1. To avoid possible accidents resulting in personal injury caused by being...

-

Page 8: Table Of Contents

CONTENTS 1. MODEL AND SPECIFICATIONS ......................1 1-1. Model ............................1 1-2. Specifications ..........................1 2. NAME OF EACH PART .......................... 2 3. INSTALLATION ............................3 3-1. Cable connection, air tube connection, power connection ............3 4. OPERATING PROCEDURE ........................5 4-1. -

Page 9: Model And Specifications

1. MODEL AND SPECIFICATIONS 1-1. Model Product serial number HRS No. GT43-1PS-CSB/CRAD (shielding plate assembly jig) CL 902-5156-0 WGT43-SHIELD/CRAD (shielding plate cable transfer 1 CL 902-5157-0 set) * Dedicated reel stand is not provided with this equipment. In case a reel stand is required, the user is expected to provide one. -

Page 10: Name Of Each Part

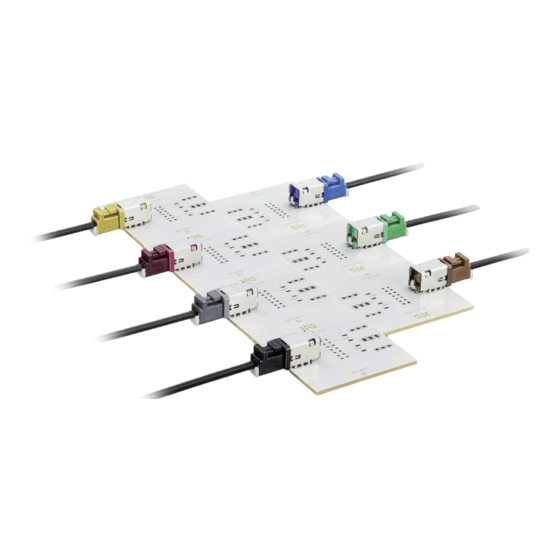

2. NAME OF EACH PART ① GT43-1PS-CSB/CRAD (shielding plate assembly jig) This jig consists of the jig main body and the control box. Air pressure sensor Terminal guide Terminal feeder ② WGT43-SHIELD/CRAD (shielding plate cable transfer 1 set) This jig consists of the jig main body, the control box and the start switch. -

Page 11: Installation

3. INSTALLATION As this product is heavy, handle by two people and take sufficient safety measures CAUTION so that falling or dropping of the machine can be avoided during installation. ■ Precaution for installation Place the cable strip process equipment and the control box on a flat surfaced workbench which can withstand heavy weight. - Page 12 Control box Electrical ④ Connect 2 rectangular connectors (With a label for component plate of the control box for shielding plate conforming equipment) Red box cable transfer 1 set and round shaped connector of the red box to the electrical component plate. ⑤...

-

Page 13: Operating Procedure

4. OPERATING PROCEDURE 4-1. Pre-working preparation In order to avoid accidents due to sudden unexpected start of the machine, turn CAUTION OFF the power of the jig main body before starting the work. Before starting to work, check air pressure, and make sure that there is no missing connector connection. -

Page 14: Working Method

⑤ Set the monitor select switch of the ⑤ Set the monitor select switch to “9”. control box for the shielding plate assembly jig to “9”. ⑥ Set VOL2 rotary switch to “F”. ⑥ Set the dial of the Vol.2 rotary switch of ⑦... -

Page 15: Ending Work

③ Remove the waste in the shielding plate carrier cut waste receiving box. 5. CONFIRMATION OF THE QUALITY Check each item. Refer to the latest GT43 terminal instruction manual for the details. 5-1 Checking the shielding plate assembly dimensions Wide and height... -

Page 16: Checking The Shielding Plate Cut Off Tab Dimension

• Make sure that the crimping barrel of the shielding plate is covering the outer periphery of male and female terminals. • NG if the mating joints of the barrel is misaligned for half of the barrel width or more or if the left and right barrels are not contacting the terminal. - Page 17 Shielding plate cable transfer 1 set Operational VOL.2 dial Specifications Operational details mode When the start switch is pressed, slide Line Auto only will operate for 1 cycle. When the start switch is pressed, the slide will advance, and when the start Line Step switch is pressed again, the slide will...

-

Page 18: Adjustment And Supplemental Specifications

7. ADJUSTMENT AND SUPPLEMENTAL SPECIFICATIONS When making adjustment of this machine, be sure to make adjustment after CAUTION confirming that the quality of the previous process is satisfactory. 7-1. Adjustment of various speed controllers Because the speed controller is adjusted to the optimum level at the time of shipment from the factory, adjustment is basically not required. -

Page 19: Adjustment Of Cable Clamp Transfer Amount

Shielding plate cut and push cylinder top end side…6 turns release from fully closed state. Shielding plate cut and push cylinder lower end side…6 turns release from fully closed state. Shielding plate cut and push cylinder top end side Shielding plate cut and push cylinder lower end side Terminal feed cylinder forward side…3 turns release from fully closed state. -

Page 20: Control Box Default State

7-3. Control box default state Control box display, in the case of correct origin point return, is described below. (The displayed number will change depending on the number of the monitor select switch.) 〇 Shielding plate assembly jig * While VOL.1 dial is used for internal timer between each operation, change from “5” position, which is the default setting, is not required. - Page 21 〇 Shielding plate cable transfer 1 set * While VOL.1 dial is used for internal timer between each operation, change from “2” position, which is the default setting, is not required. In case monitor select switch is “0”. In case monitor select switch is “2”. * In the case of monitor select switch “1, 3 - 9”, there will be no lamp lit.

-

Page 22: Control Box In-Out Table

7-4. Control box IN-OUT table 〇 Control box for the shielding plate assembly jig IN side Shielding plate cut section Ascend end Shielding plate cut section Descend end Shielding plate crimping section Ascend end Shielding plate crimping section Descend end Carrier cut section Return end Carrier cut section Motion end Transfer pilot section Descend end... - Page 23 Refer to the list below for the display corresponding to the number of the monitor select switch. * Please note that the lamp may be lit by the internal program even for the address to which IN OUT connection is not made.

-

Page 24: How To Adjust Air Pressure Sensor

7-5. How to adjust air pressure sensor While air pressure sensor is provided to the shielding plate assembly jig, this air pressure sensor is adjusted to the optimum state at the time of shipment. Therefore, adjustment is basically not required. The method of air pressure adjustment is described below for reference. -

Page 25: Adjusting The Shielding Plate Assembly Height

⑪ If the threshold value at the left Threshold value bottom of the air pressure sensor is “S” key hold and press between A value and B value or A value and C value, there is no problem. Change the threshold value In case the value is outside of those with “∧... -

Page 26: Maintenance

CAUTION engineer familiar with the machine within the scope of this instruction manual. Furthermore, when replacing parts, be sure to use Hirose genuine parts supplied by us. We will not be responsible whatsoever for any accident occurred due to inappropriate repair or adjustment or due to the use of non-genuine parts. - Page 27 ② Remove two M4 fixing bolts, and then Remove remove assembled parts (carrier guide). Carrier guide ③ Remove two M3 fixing bolts. Cut punch Fixed by two M3 bolts Bottom ⇒ Shielding plate holder Top ⇒ Cut punch Shielding Removing is completed. plate holder ④...

- Page 28 ■ How to replace carrier cut punch and carrier cut die. For replacing the carrier cut punch and the carrier cut die, follow the steps below. ① Remove the carrier cut punch. Carrier cut punch ② Remove the carrier cut die. Carrier cut die This completes the removing.

- Page 29 ② Remove internal crimping punch fixing screws. * If cleaning including removal of the shielding plate can be made in this state, it is OK to attach the guide again without removing the punch. ③ Remove crimping punch A, crimping Cam plate punch B, left/right provisional bending punch, and cam plate.

-

Page 30: List Of Expendable Parts

8-3. List of expendable parts Product serial number Expendable parts Model number Shielding plate holder CL902-5156-0-61 GT43-1PS-CSB/CRAD Shielding plate cut punch CL902-5156-0-62 (Shielding plate assembly jig) Carrier guide CL902-5156-0-63 WGT43-SHIELD/CRAD ― None (Shielding plate cable transfer 1 set) 8-4. List of maintenance parts... -

Page 31: Troubleshooting

9. TROUBLESHOOTING Trouble Cause Check point Action Shielding Shielding plate Set monitor select (If IN7 does not light up.) plate presence/absence switch of the control 1. Remove the sheet metal cover of the jig box to “1”, and see if needless is not detected. - Page 32 (Shielding plate assembly jig) CN1 input/output connector (1/2)) CN1 input/output connector (2/2)) Device Name Name Device Terminal cut (ascend end) Terminal cut (descend end) Crimping (ascend end) Crimping (descend end) Do not use Carrier cut (return end) Carrier cut (motion end) Terminal cut (descend) Transfer pilot Crimping (descend)

- Page 33 CN3 input/output connector (1/2) CN3 input/output connector (2/2) Device Name Name Device Terminal transfer (Shielding plate assembly jig) (advance end) Terminal transfer (return end) Terminal chuck (open end) Terminal chuck (close end) Terminal exist/non-exist sensor Red box Terminal cut confirm sensor Crimping confirm sensor Shielding plate exits/non-...

- Page 34 (Shielding plate cable transfer 1 set) CN1 input/output connector (2/2) CN1 input/output connector (1/2) Device Name Name Device Unit front/rear (return end) Unit front/rear (advance end) Unit up/down (ascend end) Unit up/down (descend end) Do not use Unit front/rear (advance) Unit up/down (descend) Do not use Do not use...

- Page 35 CN3 input/output connector (1/2) CN3 input/output connector (2/2) Device Name Name Device (Shielding plate cable transfer 1 set) Red box Seated sensor N24 to shielding plate crimping jig NG signal from shielding plate crimping jig BUSY signal from shielding plate crimping jig READY signal from shielding plate crimping jig Start signal to shielding...

- Page 36 Version number First edition CAUTION No part of this manual may be reproduced without the written permission of Hirose Electric Co., Ltd. Descriptions in this manual are subject to change without notice. While we took all possible precautions regarding the content of this instruction manual, please let us know in case you have discovered anything disbelieving, incorrect description, or missing statement.

Need help?

Do you have a question about the GT43 and is the answer not in the manual?

Questions and answers