Table of Contents

Advertisement

Quick Links

COUNT

DESCRIPTION OF REVISIONS

0

0

名 称

TITLE

GT50 SERIES HANDLING MANUAL

技 術 指 定 書

FORM HC0011-9-1

GT50

Handling Manual

TECHICAL SPECIFICATION

Series

DESIGNED

HIROSE ELECTRIC CO.,LTD.

APPROVED

CHECKED

DESIGNED

WRITTEN

ETAD-T0979-00

CHECKED

DATE

AH.EDASHIGE

20230207

HH.TSUKUMO

20230207

RS.TAKAGI

20230206

RS.TAKAGI

20230206

1 / 20

0

Advertisement

Table of Contents

Summary of Contents for Hirose GT50 Series

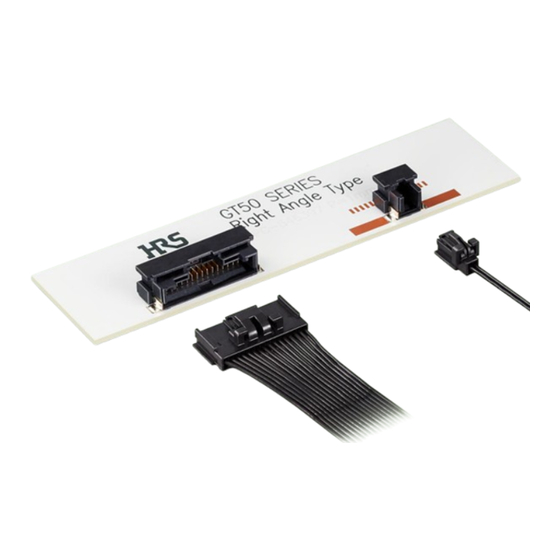

- Page 1 GT50 Series Handling Manual COUNT DESCRIPTION OF REVISIONS DESIGNED CHECKED DATE 名 称 TITLE HIROSE ELECTRIC CO.,LTD. APPROVED GT50 SERIES HANDLING MANUAL AH.EDASHIGE 20230207 CHECKED HH.TSUKUMO 20230207 DESIGNED RS.TAKAGI 20230206 WRITTEN RS.TAKAGI 20230206 技 術 指 定 書 TECHICAL SPECIFICATION...

-

Page 2: Table Of Contents

DEFINITION OF TEST PROBES ....................... 17 RECOMMENDATIONS FOR ELECTRICAL TESTS ............... 17 CRIMP QUALITY STANDARD ......................18 SCOPE ..............................18 10.1 APPLICABLE WIRE ..........................18 10.2 10.3 QUALITY STANDARD ......................... 18 CRIMP PARAMETERS ........................20 HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 2/20 FORM HC0011-9-2... -

Page 3: Scope

All measurements are in millimeters and Forces in Newtons unless otherwise specified. In addition, photographs and illustrations described are representative products of HRS GT50 series, so they differ depending on products. Information of this manual is subject to change without notices. -

Page 4: Parts Description

PARTS DESCRIPTION DESCRIPTION Female housing 【Plug】 Female terminal (Crimp terminal) 【Receptacle】 Male contact Male housing SMT Metal hold down Receptacles exist only in right angle version with SMT metal hold down. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 4/20 FORM HC0011-9-2... -

Page 5: Part Numbers

PART NUMBERS Description Part Number Female terminal GT50-28SCFA Plug X positions GT50-XS-1C Receptacle X positions GT50-XP-1H Note 1: please check with Hirose Sales department for the availability of all part numbers. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 5/20 FORM HC0011-9-2... -

Page 6: Materials

Under: Copper plating: 0.3µm Metal thickness: 0.12±0.01 mm Copper alloy Surface: Gold plating: 0.1µm Female terminal min in contact area, Tin plating 1µm min in crimp and carrier area Under: Nickel plating: 1µm min HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 6/20 FORM HC0011-9-2... -

Page 7: Packaging

405 x 405 x 31 Reel 1000 pcs/reel 2P and 4P Receptacle GT50-16P-1H 405 x 405 x 51 Reel 1000 pcs/reel Plugs GT50-XS-1C Bags 100 pcs/bag Female GT50-28SCFA 570 x 570 x 55 Reel 28000 pcs/reel terminal HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 7/20 FORM HC0011-9-2... -

Page 8: Mechanical Performances

1.0 ~ 1.7N (2 terminals) Connector unmating force 1.6 ~ 2.2N (4 terminals) 7.9 ~ 12.2N (16 terminals) Connector retention force 25N min Connector polarization force 100N min Mating / unmating cycles number 10 times HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 8/20 FORM HC0011-9-2... -

Page 9: Storage - Handling Of Components

Make sure that the terminals of crimped cables do not become entangled. When bundling or stacking cables, please prevent the terminals from being subjected to any external force. Use caution to ensure that the part is not subjected to any large impacts. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 9/20 FORM HC0011-9-2... - Page 10 Do not place wire harnesses on the floor. Refrain from any handling that may result in terminal damage or deformation. Do not use the housing in case it drops. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 10/20 FORM HC0011-9-2...

-

Page 11: Assembly Process

Please refer to the Crimp Quality Standard (§10) for details on strip length. 2 – Crimp wire in terminal Note 1: Please use the Hirose crimp tool. Note 2: Please refer to the Crimp Quality Standard (§10) and the crimp parameters (§11) by cable to check crimp condition. -

Page 12: Connector Assembly Instructions

Note 2: If the crimped terminal does not enter the housing smoothly, remove and then re-insert it. Angled insertion (Incorrect): Up-down Direction (Incorrect) Right-left Direction (Incorrect) Scoop and twisted insertion (Incorrect) Note:Do not use excessive scooping or twisting when inserting terminals. Scoop Insertion (Incorrect) Twisted (Incorrect) HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 12/20 FORM HC0011-9-2... - Page 13 (circles in red on the picture below). Lock Lever Socket 2 – Make sure that the contact lance is hooked by the housing lance of the socket. Insertion Direction Contact Lance Housing Lance HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 13/20 FORM HC0011-9-2...

-

Page 14: Wiring Harness Assembly Recommendations

The distance to apply tape from the end of connector is 35mm minimum. The bending radius for wires should be at minimum 3 times its outer radius to ensure normal use of our connectors. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 14/20 FORM HC0011-9-2... -

Page 15: Repair Process

For removing the inserted contact from the socket, lift up the housing lance by using a pointed needle, and pull out the cable. Once removed, socket cannot be re-used. Please use a new part after repair is completed. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 15/20... -

Page 16: Electrical Test

During electrical tests, plugs can be clamped in the following areas: (example with GT50-16S-1C) ALLOWED AREA (MIDDLE AREA IS PROHIBITED) LOCATION OF TEST PROBES The test probes should be located in front face as described below: (Example with the 16P) HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 16/20 FORM HC0011-9-2... -

Page 17: Definition Of Test Probes

RECOMMENDATIONS FOR ELECTRICAL TESTS Perform test after insertion of terminals. Avoid any deformation on housing or terminal during electrical test. Replace any damaged housing or terminal with a new one. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 17/20 FORM HC0011-9-2... -

Page 18: Crimp Quality Standard

CRIMP QUALITY STANDARD 10.1 SCOPE This technical specification prescribes crimp condition of GT50-28SCFA (CL760-1001-0). 10.2 APPLICABLE WIRE Applicable wire size: 0.08mm² ~ 0.09mm² Applicable insulation size: 0.66 ~ 0.8mm max. 10.3 QUALITY STANDARD HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 18/20 FORM HC0011-9-2... - Page 19 Note 2: Please confirm that the crimped contact can be inserted to the socket. Note 3: Bell mouth can’t be at the side of wire crimp part and must be within the crimp wide standard. HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 19/20...

-

Page 20: Crimp Parameters

CRIMP PARAMETERS Tensile SEC AREA strength of CONDUCTOR INSULATION WIRE (mm²) TYPE wire-terminal link (minimum) 0.08 / 28 0.50 ~0.56 0.70 max 1.10 ~1.20 0.76 max HIROSE ELECTRIC CO.,LTD. ETAD-T0979-00 20/20 FORM HC0011-9-2...

Need help?

Do you have a question about the GT50 Series and is the answer not in the manual?

Questions and answers