Subscribe to Our Youtube Channel

Summary of Contents for Samson SS AT054U

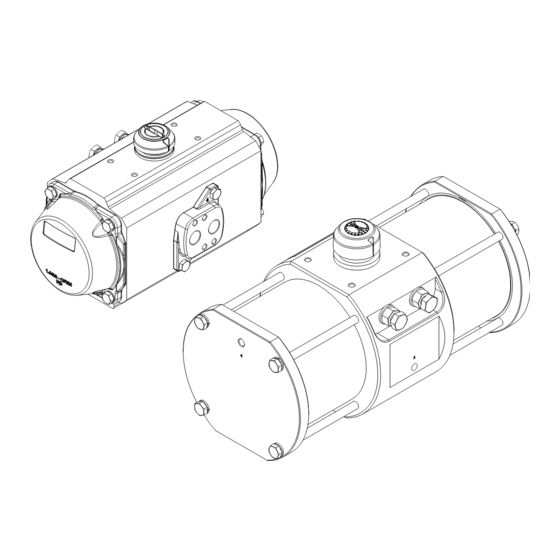

- Page 1 EB 8326 EN Original instructions SAMSON ROTACTOR RP 3171 ® Rack&Pinion actuators SS AT054U → SS AT654U models Edition May 2022...

- Page 2 Note on these mounting and operating instructions These mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling SAMSON devices. The images shown in these instructions are for illustration purposes only. The actual product may vary.

-

Page 3: Table Of Contents

Contents Safety instructions and measures ......................... 1-1 Notes on possible severe personal injury ....................... 1-2 Notes on possible personal injury ......................... 1-2 Notes on possible property damage ......................1-2 Markings on the device ..........................2-1 Actuator nameplate sample .......................... 2-1 Design and principle of operation ........................ - Page 4 EB 8326 EN...

-

Page 5: Safety Instructions And Measures

Revisions and other modifications Revisions, conversions or other modifications of the product Intended use are not authorized by SAMSON. They are performed at the The SAMSON ROTACTOR RP 3171 actuators are designed user‘s own risk and may lead to safety hazards, for example. -

Page 6: Notes On Possible Severe Personal Injury

Î Make sure that the actuator is in the closed position (0°) − The SAMSON actuators are in compliance with the TR CU while disassembling the end caps and the stop screws ha- 10/2011 and TR CU 12/2011. - Page 7 The lubricants to be used depend on the actuator material and operating temperatures. Unsuitable lubricants may corrode and damage the components. Î Use only lubricants approved by SAMSON . Refer to sec- tion 15.3 ‘Lubricants‘. Risk of actuator damage due to incorrectly attached slings.

- Page 8 Safety instructions and measures EB 8326 EN...

-

Page 9: Markings On The Device

Markings on the device 2 Markings on the device 2.1 Actuator nameplate sample ATEX 2014/34/EU: n° INERIS-EQEN 034870/19 UKSI 2016:1107 : CML 21UKEXT1358 I I M M 2 2 E E x x h h I I M M b b X X II 2 G Ex h IIC T6...T5 Gb X II 2 D Ex h IIIC T85°C...T95°C Db X Model / Type:... - Page 10 Markings on the device Note Refer to the Catalogue T 8326 for actuators available options and ordering codes. EB 8326 EN...

-

Page 11: Design And Principle Of Operation

3 Design and principle of operation The actuators can be controlled by different options: − for SS AT054U → SS AT404 direct mounting of control The SAMSON SAMSON ROTACTOR RP 3171 ("S" Series) devices (for example a solenoid valve or a manifold) with actuators are devices for remote operation (on/off or modula- NAMUR interface. -

Page 12: Complementary/Accessory Parts

NOTICE − In case of pressure medium different than Group 2 fluids Risk of actuator damage due to incorrect gearbox stroke according to the PED 2014/68/EU, contact SAMSON. adjustment. − Make sure that the actuator and the gearbox are correctly −... -

Page 13: Shipment And On-Site Tranport

The actuator can be transported using proper lifting equip- 2. Check the shipment for transportation damage. Report ment (e.g. crane or forklift). any damage to SAMSON and the forwarding agent (re- Î Leave the actuator in its transport container or on the pal- fer to delivery note). -

Page 14: Storing The Actuator

Î Observe the storage instructions. Î Observe the rubber components storage instructions (T 3.3.3.1 EN). Î Avoid long storage times. Contact SAMSON in case of different storage conditions or long storage periods. Note It is recommended to regularly check the actuator and the pre- vailing storage conditions during long storage times. -

Page 15: Mounting And Assembly

Î Do not impede the movement of the pinion and the pistons The SAMSON ROTACTOR RP 3171 actuators can be control- by inserting objects into the actuator. led by directly mounted devices or remote control systems. Th- erefore SAMSON actuators have direct mounting interfaces (Fig. - Page 16 Mounting and assembly Before mounting the actuator over the valve, make sure the − When fitting accessories over the actuators, assemble following conditions are met: them in such a way that the emergency controls are easily accessible for emergency manual operation. −...

- Page 17 Mounting and assembly 6. Place the bracket, if any, over the valve flange, tighten all bolts and nuts and apply the correct tightening torque. 7. Assemble the coupling at first into the valve stem before the assembly of the actuator. 8.

- Page 18 Mounting and assembly EB 8326 EN...

-

Page 19: Start-Up

Start-up 6 Start-up The work described in this section is only to be performed by fully trained and qualified personnel. WARNING Risk of personal injury during actuator air exhaust. In case of pneumatic version the actuator is operated with air. As a result, air is exhausted during operation. - Page 20 Start-up EB 8326 EN...

-

Page 21: Operation

Operation 7 Operation The actuator can be operated after connecting it to the supply line and adjusting the stroke. The work described in this section is only to be performed by Double acting actuators require alternate connection ports to fully trained and qualified personnel. be pressurized and vented for stroking. - Page 22 Operation EB 8326 EN...

-

Page 23: Malfunctions

In case of actuator mounted over the valve, check the valve documentation Faulty valve and contact the manufacturer. Note Contact SAMSON after-sales service (samson@samsongroup.com) for malfunctions not listed in the table. 8.2 Emergency action The plant operator is responsible for emergency action to be taken in the plant. EB 8326 EN... - Page 24 Malfunctions EB 8326 EN...

-

Page 25: Service

3. Remove the actuator from the valve referring to section 11 prior agreement by SAMSON‘s After-sales Service. ‘Removal‘. − Only use original spare parts by SAMSON, which comply with the original specifications. EB 8326 EN... -

Page 26: Part List

Service 9.2 Part list Models SS AT054U → SS AT404 19.1 11* 08* 10 221G 222G 17.2 60.1 17.3 17.1 09* 12 19.2 60.1 Fig. 9-1 EB 8326 EN... - Page 27 Service Models SS AT454 → SS AT654 39 19.1 18 08* 10 50.1 221G 222G 13.1 60.1 13.1 13.2 14.1* 13 13.1 19.2 60.1 Fig. 9-2 Table 9-2 UNIT Q.TY NOTE DESCRIPTION PART N° OCTI-CAM (Stop arrangement) STOP CAP SCREW WASHER for models with extra travel stop adjustment WASHER...

- Page 28 BEARING (Piston back) ◊ BEARING (Pinion top) ◊ BEARING (Pinion bottom) ◊ THRUST BEARING (Pinion) ◊ • for SS AT054U ÷ SS AT404 PLUG THRUST WASHER (Pinion) ◊ • O-RING (Stop screw) 11R* ◊ • for models with extra travel stop adjustment...

-

Page 29: Disassembly

Service Refer to Fig. 9-1, Fig. 9-2 and Fig 9-4. − Remove both stop cap screws (02) together with nuts (04) 9.3 Disassembly and washers (03). Î Refer to the Fig. 9-1, Fig. 9-1 and Table 9-2 for parts list. −... - Page 30 Service Table 9-3 SS AT054U → SS AT404 ACTUATOR MODEL NUMBER OF TURNS FOR CAP SCREWS/TIE RODS (13) OR NUTS (13.2) SS AT054U 26 ÷ 28 turns SS AT104 SS AT204 SS AT254 SS AT304 5 ÷ 7 turns SS AT404 SS AT454 SS AT454 →...

-

Page 31: Service Operations

Risk of actuator damage due to the use of unsuitable lubri- cants. The lubricants to be used depend on the actuator material and operating temperatures. Î Only use lubricants approved by SAMSON. Refer to secti- on 15.3 ‘Lubricants‘. 9.5.1 Drive shaft reassembly Refer to Fig. - Page 32 Î In case of spiral spring clip (18) refer to the disassembly in a properly fixed coupling joint. (Fig. 9-15) and reassembly instructions available from SAMSON. − Make sure that the octi-cam (01) is in the right position as − Place the spiral rings (18) by means of by means of a pro- per the Fig.

- Page 33 Fig. 9-16 − For models SS AT454 to SS AT654, carefully place the ac- tuators in a vertical position as per Fig. 9-19: SS AT054U → SS AT404 grease the internal surface of the body extension 90° position 0° position –...

- Page 34 Table 9-4, Fig. 9-22 and Fig. 9-23 depending on the Side B actuator model. Table 9-4 Fig. 9-22 SPRING TYPE FOR MODEL SS AT054U Spring set Side B Side A Models SS AT454 → SS AT654 Internal...

- Page 35 (13.2) tightening 1 turn at a time for each screw in th se- quence shown in Fig. 9-25. Î Refer to the section 15.2 ‘Tightening torques‘. (Table 15.1) SS AT054U → SS AT404 Fig. 9-27 9.5.5 Stop cap screws reassembly SS AT454 →...

- Page 36 Service 9.5.6 Stroke adjustment Refer to Fig. 9-1 and Fig. 9-24. Close position − With the actuator in close position (0° position) referring to Fig. 9-15 for pistons position, screw or unscrew the right stop screw (02) 1 turn at a time until the desired stop posi- tion is achieved.

-

Page 37: Decommissioning

Decomissioning 10 Decomissioning To decommission the actuator for service work or before re- moving it from the valve, proceed as follows: The work described in this section is only to be performed by 1. Put the valve and its accessories out of operation in a safe fully trained and qualified personnel. - Page 38 Decomissioning 10-2 EB 8326 EN...

-

Page 39: Removal

Removal 11 Removal WARNING The work described in this section is only to be performed by Risk of personal injury due to preloaded and compressed fully trained and qualified personnel only. springs. End caps are under tension due to compressed springs. Before removing from the valve, make sure the actuator is put Furthermore incorrect spring cartidges disassembly could re- out of operation. - Page 40 Removal Proceed as follows to remove the actuator from the valve re- ferring to Fig. 11-1, making sure to not expose the plant to any risk: 1. Disconnect any electrical/pneumatic/hydraulic power supply from the actuators and make sure the actuator itself is depressurized.

-

Page 41: Repairs

NOTICE Risk of actuator damage due to incorrect repair work. Î Do not perform any repair work on your own. Î Contact SAMSON after-sales service (samson@samsongroup.com) for repair work. EB 8326 EN 12-1... - Page 42 Repairs 12-2 EB 8326 EN...

-

Page 43: Disposal

Disposal 13 Disposal At the end of their life cycle SAMSON actuators can be com- pletely disassembled and disposed sorting the components by the different materials. Î Observe local, national and international refuse regula- tions. All materials have been selected in order to ensure minimal... - Page 44 Disposal 13-2 EB 8326 EN...

-

Page 45: Certificates

Certificates 14 Certificates The following certificates and documents are available from SAMSON: − EU Declaration of Conformity (page 14-2), − ATEX Directive 2014/34/EU, − SIL Certificate, − Machine Directive 2006/42/EC, − DNV Type Approval, − IP67 and IP68 Degree of protection, −... - Page 46 AIR TORQUE S.p.A. Doc. n° ECDSE via dei Livelli di Sopra, N° 8/11 24060 Costa di Mezzate (Bg) Italy Tel.: +39 035 682299 Fax: +39 035 687791 Issued: 01/2022 - Pag: 1/1 E-mail: info@airtorque.it EU / UK DECLARATION OF CONFORMITY In accordance with Machinery Directive 2006/42/EC and U.K.

-

Page 47: Annex

− SCREWDRIVER Fig. 15-1 15.1.2 Tools dimensions − Stop screws (02) and nuts (04); end cap screws (13). ACTUATOR MODEL Ch 1 (mm) Ch 2 (mm) SS AT054U SS AT104 SS AT204 SS AT254 SS AT304 SS AT404 SS AT454... - Page 48 − Extra travel stop adjustment screws tools (50% and 100% adjustment). Ch 4 ACTUATOR 221G/222G MODEL TYPE Ch 3 (mm) Ch 4 (mm) SS AT054U SS AT104 − Type A Ch 3 SS AT204 SS AT254 SS AT304 SS AT404...

-

Page 49: Tightening Torque

Table 15-2: Extra travel stop adjustment nuts (04R) ACTUATOR MODEL THREAD TIGHTENING TORQUE (Nm) ACTUATOR MODEL THREAD TIGHTENING TORQUE (Nm) 4 ÷ 5 SS AT054U SS AT054U 8 ÷ 9 SS AT104 SS AT104 SS AT204 7 ÷ 8 SS AT204 18 ÷... -

Page 50: Lubricants

Annex 15.3 Lubricants The SAMSON ROTACTOR RP 3171 actuators are factory lubricated for the life of the actuator in normal working conditions. Î Refer to the data sheet [T 8326] for Lubricant type in rela- tion to the different working temperature ranges. -

Page 51: Rubber Products Storage Instructions

(and any other kit with rubber products) properly stored maximum storage life by about 50% and storage at a 10°C into the original SAMSON packaging. In this case the rubber (18°F) lower temperature will increase the maximum storage products should be inspected and tested before the storage life by about 100%. - Page 52 Spare parts and kits with rubber components or testing and re-stored for a further storage period, they If not otherwise specified, the SAMSON spare parts and kits should be repackaged according to this document or with the with rubber components are packaged in polyethylene trans- same original packaging.

- Page 53 The SAMSON Rack and pinion and actuators are packaged in carton boxes and carton or wooded cases. Store all the SAMSON products according to the related IMAT maintenance instruction manuals in order to guarantee the correct product functions and performance.

- Page 54 16-4 EB 8326 EN...

- Page 55 EB 8326 EN 16-5...

- Page 56 EB 8326 EN SAMSON AKTIENGESELLSCHAFT Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany Phone: +49 69 4009-0 · Fax: +49 69 4009-1507 samson@samsongroup.com · www.samsongroup.com...

Need help?

Do you have a question about the SS AT054U and is the answer not in the manual?

Questions and answers