Table of Contents

Advertisement

Quick Links

DH-LML 22

INSTALLATION MANUAL

Manufacturer:

DHOLLANDIA US, L.L.C.

E-mail : Technical.US@dhollandia.com

270 Southridge Parkway

Bessemer City North Carolina, 28016

website : www.dhollandia.com

Read the manual in its entirety before operating the liftgate

Keep this manual in the vehicle cab, as reference for the driver and liftgate operator

Order ref: xxx Doc: FIT_US installation manual LML_US EN_2020 Rev: 3 Date: SEPTEMBER 1, 2023

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Dhollandia DH-LML 22

- Page 1 DH-LML 22 INSTALLATION MANUAL Manufacturer: DHOLLANDIA US, L.L.C. E-mail : Technical.US@dhollandia.com 270 Southridge Parkway Bessemer City North Carolina, 28016 website : www.dhollandia.com Read the manual in its entirety before operating the liftgate Keep this manual in the vehicle cab, as reference for the driver and liftgate operator...

-

Page 2: Table Of Contents

Installation of the (+) battery cable and (-) ground cable ......................45 11.3 Installation of extra controls ..............................49 11.3.1 Installation of 3-Button Wander Lead – OAE002 (E0784.M.S) ..................50 11.3.2 Installation of cabin cutoff switch – OAE510.15 (E0393.S.15)..................51 PUTTING THE LIFTGATE INTO SERVICE............................. 52 LUBRICATION INSTRUCTIONS ..............................53 DHOLLANDIA... - Page 3 Connections to the main external control box type 3 ....................... 72 16.7 Safe operator position on the platform ............................ 74 16.8 End note ....................................75 16.9 Basic wiring diagrams ................................75 16.10 Checklist for preventative maintenance and repair ......................... 75 DHOLLANDIA...

-

Page 4: Understanding Safety And Warning Signs

Many safety signs and symbols used in this manual are based on international standards, others refer to specific situations or actions. • Consult appendix 16.1 on page 60 for an overview of signs and symbols used in DHOLLANDIA manuals, and their meaning. Make sure you understand these signs and symbols prior to starting the installation. •... -

Page 5: Introduction , Contact Info And Disclaimers

NOTICE • Please confirm you have reviewed the most up-to-date version of this manual prior to operation of the associated DHOLLANDIA liftgate. See below for instructions to download the latest version of the manual. - Page 6 • DHOLLANDIA disclaims any liability for damage arising from modifications to the vehicle in its entirety as a result from installation. All modifications to the vehicle must be done in accordance to instructions issued by the vehicle and body manufacturer •...

-

Page 7: Safety Precautions For Operation

• Safety instructions are a matter of progressive insight. The basics are listed in this manual, but contact the national DHOLLANDIA distributor for a copy of the latest set of instructions [see contact info on page 4], or download the latest edition from the DHOLLANDIA website: www.dhollandia.com →... - Page 8 ALWAYS confirm you have reviewed the most up-to-date version of these manuals prior to installation and operation of the associated DHOLLANDIA liftgate. • In case of doubt, ALWAYS contact the national DHOLLANDIA distributor for further advice, prior to continuing. • ALWAYS wear appropriate Personal Protective Equipment. This includes but may not be limited to: safety glasses with side guards or a wrap-around face shield;...

-

Page 9: Liftgate Terminology

• DHOLLANDIA liftgates are designed as a bolt-on system, and don’t require any welding. See appendix 16.2 on page 62 for prescribed torque values. • If for any reason, trouble-shooting and / or repair might be needed during the installation process, consult and follow the guidelines and safety instructions of the MAINTENANCE MANUAL. -

Page 10: Installation Parameters Terminology

Horizontal dimension from rear of platform to rear of bumper bar lbug Lift BUmper to Ground Vertical clearance of bumper bar to ground Platform Depth Overall platform depth pduf Platform Depth Under Floor Section of the platform that protrudes below the vehicle floor in closed position DHOLLANDIA... - Page 11 Available mounting space for rear truck lights on outside of the tilt cylinders Body Floor Thickness Thickness of the rear sill of the vehicle floor Lift Floor Thickness Max. thickness of the rear sill of the vehicle floor, in the manoeuvre zone the lift arms and tilt cylinders DHOLLANDIA...

-

Page 12: Getting Started

• DHOLLANDIA disclaims any liability for damage arising from modifications to the vehicle in its entirety as a result from installation. All modifications to the vehicle must be done in accordance to instructions issued by the vehicle and body manufacturer •... -

Page 13: Installation Dimensions And Guidelines

• The INSTALLATION DRAWING issued through the order confirmation, will provide you with the critical installation dimensions that should be observed. EXAMPLE • If no installation drawing is available, use the DHOLLANDIA POCKET GUIDE (paper or App) to learn the maximum and minimum installation parameters per type of liftgate. EXAMPLE •... - Page 14 Refer to the POCKET GUIDE (paper or App) for minimum overhang values (at max) and maximum overhang values (at min) • The arm width determines the body dimensions bci, bcw (see below). DHOLLANDIA...

- Page 15 → If platform is mounted directly against the rear frame, dimension is lower. → If platform is mounted with sealing rubbers or other spacer, dimension is higher. DHOLLANDIA...

-

Page 16: Common Installation Dimensions

COMMON INSTALLATION DIMENSIONS • Listed below are common models offered by DHOLLANDIA US and their associated fitting ranges: LML-22 DHOLLANDIA... -

Page 17: Important Guidelines

• Make sure you have the correct installation instructions before starting. If not, contact your national DHOLLANDIA distributor for a copy of the relevant instructions. See contact info on page 4. - Page 18 Incorrect or negligent installation can cause the liftgate to fall off the vehicle chassis once the platform is loaded, and can put the installers, the operators and bystanders at great risk of bodily injury or death. • In case of doubt, don’t continue, but contact your national DHOLLANDIA dealer for further advice. DHOLLANDIA...

-

Page 19: Rear Doors With Container Locks

• Additional guidelines are available for cases where the rear doors sit behind the rear frame of the body and the rear sill of the vehicle floor, or where the locks sit on the outside face of the rear doors. These guidelines can be obtained from your national DHOLLANDIA distributor, or can be downloaded from the DHOLLANDIA website: www.dhollandia.com →... -

Page 20: Methods To Mount Liftframe

• For half width platforms, position the fitting jigs in function of the arm width lac, and the foreseen position of the half platform in the rear body aperture. • Fasten the fitting jigs to the rear sill of the vehicle floor by means of bolts, clamps or spot welding. DHOLLANDIA... -

Page 21: Method With Vertical Platform

• Mount the supports at height pduf below the vehicle floor pduf is confirmed on the INSTALLATION DRAWING and in the POCKET GUIDE. • Next, raise the platform and position it onto the supports. DHOLLANDIA... - Page 22 • If the liftgate is mounted with a seal kit between the closed platform and vehicle body, the position of the platform must be adjusted to suit the thickness of the sealing rubbers See 7.3 on page 22. DHOLLANDIA...

-

Page 23: Impact Of The Seal Kit

• If an INSTALLATION DRAWING is available, the required spacer Q for original DHOLLANDIA seal kits is mentioned on it. • If no drawing is available, the following guidelines can be used. Top & side profile Floor profile 1”... -

Page 24: Method With Horizontal Platform

Make sure the platform is parallel and level with the vehicle floor. • The gap between the rear sill of the vehicle floor and the inboard platform edge will need to be covered by a bridge plate or other techniques. See also 6.3.2 on page 18. DHOLLANDIA... -

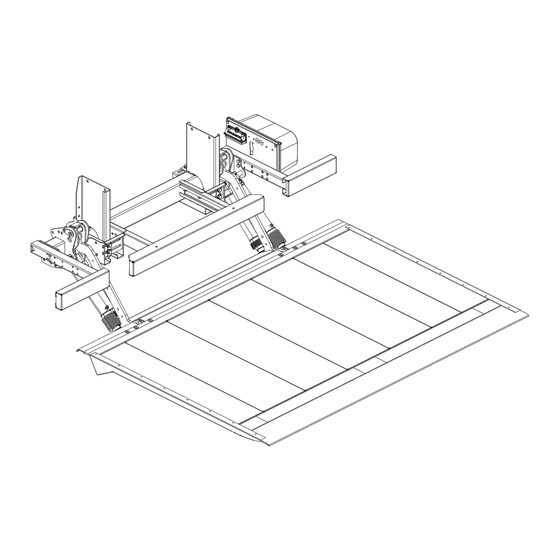

Page 25: Mounting Of The Lift Frame

Mounting plates have slotted holes for easy longitudinal adjustment of the lift frame. Mounting plates and lift frame are mounted together Mounting plates can be mounted on the chassis first, lift frame can be attached to the plates later. DHOLLANDIA... -

Page 26: Positioning Of The Lift Frame With Oam010

Therefore, handle the lift frame with extreme care. Use an adequate wheeled mounting jack to move the lift frame safely, without a risk of collapse. • • Slide the articulation pins through the fitting jigs (or platform Raise the lift frame to the correct mounting height mfc. hands) and the lift arms. DHOLLANDIA... - Page 27 • Make sure the lift frame is positioned in accordance with the INSTALLATION DRAWING or indications in the POCKET GUIDE (paper or App), before drilling or welding the mounting plates to the chassis. • It is not allowed to reduce the width of the mounting plates without prior authorization from DHOLLANDIA. DHOLLANDIA...

-

Page 28: Fixation Of The Mounting Plates Oam010

Straighten the mounting plates, and make sure they stand perpendicular to the lift frame. • The mounting plates should be bolted to the lift frame according to the instructions included in the bolt kit supplied with the liftgate (see below). DHOLLANDIA... - Page 29 DHOLLANDIA...

- Page 30 • Maximize the spread of the mounting bolts over the full surface of the plates overlapping the chassis and subframe. • If the mounting plates are too high and interfere with the subframe or cross-members of the vehicle body, they can be shortened in height, but with respect of the instructions in this section. DHOLLANDIA...

-

Page 31: Fixation Of The Mounting Plates Oam014

It is essential that bolts and nuts used to mount the lift frame to the chassis, are fastened with the required torque. (see values for “shear”). • If you use mounting bolts not supplied by DHOLLANDIA, obtain confirmation of the required torque from your supplier and make sure they guarantee at least an equivalent strength. •... - Page 32 EXAMPLE • Follow these instructions carefully. Contact your national DHOLLANDIA distributor in case of doubt. WARNING • Position the lift frame, mounting plates, bolts and nuts in accordance with the instructions in this manual. • Fasten the mounting bolts with the required torque. See appendix 16.2 on page 62 (values for “shear”).

- Page 33 • Maximize the spread of the mounting bolts. Stay within a range D whereby the 2 extreme bolt positions [# 1-2] on the lift frame don’t protrude beyond the available slotted holes on the mounting plates. Contact your national DHOLLANDIA dealer to clear any deviations (e.g.

-

Page 34: General Remarks

NOTICE WARNING • In case of doubt how to install the tailgate correctly, DO NOT go any further, but ask your local DHOLLANDIA distributor for professional advice. • Negligence can put the technical personnel, the operator, and third parties at great risk, and could result in severe injury or death. -

Page 35: Mounting Of Platform

• ALWAYS observe the safety instructions and precautions contained in the GENERAL SAFETY INSTRUCTIONS FOR INSTALLATION, MAINTENANCE AND REPAIR manual. • In case of doubt, contact the national DHOLLANDIA distributor for further assistance. • Grease the bearings of the lift arms [# 1 – 3 below] and the adjustable extension of the tilt cylinders [# 2] before mounting the corresponding articulation pins. - Page 36 3. Push / pull the piston rod by hand. Open valve Close valve • Operate LIFT and pressurise the lift cylinders gently. Stop as soon as you hear the hydraulic system turn in overpressure. • If applicable, remove the fitting jigs. • Remove the wheeled mounting jack. DHOLLANDIA...

- Page 37 Tilt the platform open to 45° angle. Align the hole in the tilt cylinders with the hole in the platform hands by means of the electrical controls, or manually [see procedure above]. • Mount the pins of the tilt cylinders. The rollers are mounted and the bolts are fastened after the adjustment of the stroke of the tilt cylinders. (see 10.2 on page 39). DHOLLANDIA...

- Page 38 To OPEN the platform, most tilt cylinders are powered in by powerful internal springs (*). The piston rods will react quickly and suddenly when releasing the hydraulic pressure. (*) Exception: in case of option OAH026, the tilt cylinders are powered in by means of hydraulic pressure (power open). DHOLLANDIA...

-

Page 39: Other Mechanical Works

• The end stops [# 2] must result in an adequate pressure of the platform on the sealing rubbers (if applicable). Adjust if required. • Fasten all bolted connections with the required torque. See appendix 16.2 on page 62. DHOLLANDIA... -

Page 40: Platform Stow Position

10.2 PLATFORM STOW POSITION • If applicable, mount the aluminium profiles and rubber platform seals (option OAT001 - OAT005) to the rear frame of the body. See also 7.3 on page 22. Installation DHOLLANDIA... - Page 41 Use the function CLOSE to slide out the tilt cylinders [# 1] to groove on the threaded end [# 2]. If this is not possible, contact the maximum stroke S. your national DHOLLANDIA distributor for longer extensions [# 4]. DHOLLANDIA...

- Page 42 If this is not possible, contact your • Put the rubber gaiter back in position and fasten its collar. national DHOLLANDIA distributor for longer extensions [# 4]. • Operate OPEN / CLOSE to align the wholes in the adjustable extensions [# 4] with the holes in the platform hands.

-

Page 43: Adjustment Of The Hydraulic Stabilizing Legs

• If the liftgate must be compliant with EN12642 on Load Security, it is essential to contact DHOLLANDIA prior to ordering the liftgate, to determine the required interfaces. Contact your national DHOLLANDIA distributor for further information. See contact info on page 4. - Page 44 • Operate LEG UP / LEG DOWN minimum 3 times to verify the set-up and operation of the hydraulic stabilizing legs. • Fasten the bolts [# 1-2] with the required torque. See values for “shear” in appendix 16.2 on page 62. DHOLLANDIA...

-

Page 45: Electrical Installation

• Read and follow the instructions FIT-ELEC-GENERAL-… (latest update). If not supplied with the liftgate, these can be downloaded from the “DOWNLOAD” section on our website: www.dhollandia.com → Country & language selection → Downloads → Mounting instructions → General → … select required manual •... -

Page 46: Installation Of The (+) Battery Cable And (-) Ground Cable

(+) battery cable from the main battery fuse to the main battery disconnect switch of the control box (if applicable), or to the incoming main terminal of the starter solenoid 2. and a (-) ground cable, from the negative terminal of the batteries to the negative terminal of the electric motor. DHOLLANDIA... - Page 47 • Make sure this conduit is suitable for automotive purposes, and its class is adapted to possible sources of heat nearby. In case of doubt, contact your national DHOLLANDIA distributor. See page 4 for contact info. • Fasten all connections at both ends of the cables thoroughly. Loose connections can lead to bad contacts and overheating, followed by premature failing of the electrical circuit.

- Page 48 DHOLLANDIA...

- Page 49 • When mounting electrical cables, ALWAYS make sure they make a downward curve as they exit the control box or power pack; so that water can drop off in a natural way. This is an easy way to prevent water ingress through the grommets or cable gland. DHOLLANDIA...

-

Page 50: Installation Of Extra Controls

• Read and follow the instructions FIT-ELEC-OPTION-… (latest update). If not supplied with the liftgate, these can be downloaded from the “DOWNLOAD” section on our website: www.dhollandia.com → Country & language selection → Downloads → Mounting instructions → General → … select required manual... -

Page 51: Installation Of 3-Button Wander Lead - Oae002 (E0784.M.s)

11.3.1 Installation of 3-Button Wander Lead – OAE002 (E0784.M.S) DHOLLANDIA... -

Page 52: Installation Of Cabin Cutoff Switch - Oae510.15 (E0393.S.15)

11.3.2 Installation of cabin cutoff switch – OAE510.15 (E0393.S.15) DHOLLANDIA... -

Page 53: Putting The Liftgate Into Service

Make sure the locking nut of the coil is firmly tightened. • Execute all functions at least 5 times. Makes sure there is no interference or collision between the liftgate and the vehicle. The DHOLLANDIA... -

Page 54: Lubrication Instructions

• Refer to appendix 16.4 from page 65 onwards for relevant grease plan of the liftgate, or download any from the website: www.dhollandia.com → Country & language selection → Downloads → Maintenance & Repair → Grease plans → … select required plan •... -

Page 55: Quality Control And Pdi

• If the operator is allowed to travel up and down on the platform by other means than original foot controls, the installer must mark a safe-work zone of 16 x 16” (400 mm) at a safe distance of 10” (250 mm) removed from the hazardous crushing area between the inboard edge of the platform and the rear sill of the vehicle body. DHOLLANDIA... - Page 56 • If in doubt how to adjust the pressure relief valve, refer to procedure I-SERV-G-003 of the MAINTENANCE AND REPAIR MANUAL, or contact your national DHOLLANDIA distributor for help. See contact info on page 4. •...

-

Page 57: Decals

Affix the safety decals to the liftgate and vehicle body in accordance with the instructions below. • Note: the decals marked as “EXAMPLE” can vary in function of the maximum rated capacity of the liftgate, or the chosen type of external control box. DHOLLANDIA... - Page 58 ❶ ❷ ❸ ❹ DHOLLANDIA...

- Page 59 ❺ ❻ ❼ ❽ ❾ DHOLLANDIA...

-

Page 60: Use Of The 'Warning. Liftgate Out Of Service. Do Not Attempt To Operate' Sign

See examples below. The liftgate must not be used again until it has been serviced or repaired by a qualified service technician. • • Place this decal along with the User Manual in the glove box compartment of the vehicle. EF0586.US DHOLLANDIA... -

Page 61: Appendix

16.1 MEANING OF THE SAFETY AND WARNING SIGNS WARNING signs MANDATORY ACTION signs Overview and keep visual control over the Contact your regional DHOLLANDIA distributor. working area of the hydraulic ramp at all times. General warning sign used to alert the user to Consult the DHOLLANDIA website. - Page 62 / or Switch between external and internal controls. cabin switch. This is an operation to be executed manually (as opposed to an electrical function controlled by means of one of the control units). DHOLLANDIA...

-

Page 63: Prescribed Torque Values For Bolts And Nuts

A fall of the liftgate off the chassis can damage the liftgate and / or vehicle chassis and can cause serious bodily injury or death to the operator and any bystanders. • Therefore, it is essential that the mounting plates are installed following the instructions of this manual. DHOLLANDIA... -

Page 64: Electric And Hydraulic Requirements

• The applicable wiring diagrams are saved at the inside of the main external control box, and can be found there for reference. • A copy of the wiring diagrams can also be obtained from the national DHOLLANDIA distributor [see contact info on page 4];... - Page 65 It is important to follow these guidelines with due care. A lot of oils or fluids used in automotive industry, such as transmission fluids and ATF oils, are not suitable for liftgate use. DHOLLANDIA has not tested the potential consequences of oils and fluids with deviating specifications and cannot be held responsible or legally liable for any damage to the liftgate caused by the replenishment with non- compatible oils or fluids;...

-

Page 66: Grease Plans

This annex includes grease plans for the most frequent liftgates DH-LM* 1100-2200 lbs (500–1000 kg). • A copy of the grease plans can also be obtained from the national DHOLLANDIA distributor [see contact info on page 4]; or downloaded from the DHOLLANDIA website: www.dhollandia.com →... - Page 67 DHOLLANDIA...

- Page 68 DHOLLANDIA...

-

Page 69: Connections To The Main External Control Box Type 1

Reserve the wider for the ticker channels. supplied with the liftgate. battery & ground cables. Use the narrower Route the cable in such a way that it cannot for control units, cables of electro valves be damaged or pinched. etc. DHOLLANDIA... - Page 70 DC motor by means of a hexagonal key nr. assigned channels. Push them down into key nr. 13. the groove, make sure the cables don’t overlap the vertical divider lips between the various channels. DHOLLANDIA...

- Page 71 Allen Key nr. 5. At the inside, route all cables so that they Use cable ties to bind the cables together, are protected against damage, pinching protect cables against vibration, and finish and chafing. off in a clean way. DHOLLANDIA...

- Page 72 Insufficient torqueing of the connection bolts can cause overheating and short circuits. Improper sealing can cause water ingress, and premature corrosion to the battery cable connection. • DHOLLANDIA disclaims liability for any personal injury or property damage that results from improper or negligent installation. DHOLLANDIA...

-

Page 73: Connections To The Main External Control Box Type 3

PVC base of the control box to ensure proper sealing. Once this basis is solidly wrapped and sealed, move the gun further away from the basis, and swing it around the incoming pole (3) to obtain complete and even shrinking of the hose on all sides. DHOLLANDIA... - Page 74 Insufficient torqueing of the connection bolts can cause overheating and short circuits. Improper sealing can cause water ingress, and premature corrosion to the battery cable connection. • DHOLLANDIA disclaims liability for any personal injury or property damage that results from improper or negligent installation. DHOLLANDIA...

-

Page 75: Safe Operator Position On The Platform

3 points of contact while travelling on the platform, in accordance with the operation manual.] • The handgrip is normally foreseen by the body builder as part of the design of the box. A DHOLLANDIA alternative can be ordered with spare part ref. M1406. -

Page 76: End Note

16.8 END NOTE • DHOLLANDIA would like to thank you for using our products and leave you with this final notice and warning. • Additional information about this liftgate and many other DHOLLANDIA products is available at the following link: http://www.dhollandia.com/...

Need help?

Do you have a question about the DH-LML 22 and is the answer not in the manual?

Questions and answers