Dhollandia DH-L Series Maintenance & Repair Manual

Cantilever tail lifts

Hide thumbs

Also See for DH-L Series:

- Installation manual (82 pages) ,

- Mounting instructions (67 pages) ,

- Operation manual (41 pages)

Table of Contents

Advertisement

edition

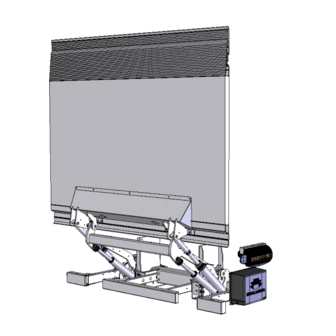

DH-L* cantilever tail lifts

MAINTENANCE & REPAIR MANUAL

Manufacturer:

DHOLLANDIA N.V.

Zoomstraat 9

9160 LOKEREN (Belgium)

Tel : +32 (0)9 349 06 92

Fax : +32 (0)9 349 09 77

e-mail : info@dhollandia.be

website : www.dhollandia.com

Read the manual in its entirety before servicing or repairing the tail lift

Keep this manual in the vehicle cabin, as reference for the tail lift operator and technical personnel

-

-

-

-

DHOLLANDIA

Advertisement

Table of Contents

Summary of Contents for Dhollandia DH-L Series

- Page 1 9160 LOKEREN (Belgium) Tel : +32 (0)9 349 06 92 Fax : +32 (0)9 349 09 77 e-mail : info@dhollandia.be website : www.dhollandia.com Read the manual in its entirety before servicing or repairing the tail lift Keep this manual in the vehicle cabin, as reference for the tail lift operator and technical personnel...

-

Page 2: Table Of Contents

Other important techniques §11.1 Procedure I-SERV-G-003 : hydraulic pressure reading and adjustment §11.2 Procedure I-SERV-G-004 : flushing of pressure relief valve §11.3 Procedure I-SERV-G-005 : check on valve and solenoid function §11.4 Procedure I-SERV-G-006 : flushing and cleaning of valve cartridge DHOLLANDIA... - Page 3 §11.5 Procedure I-SERV-G-007 : testing internal cylinder leaks §11.6 Procedure I-SERV-G-008 : oil replacement, filling and bleeding Decals Prescribed torque values for bolts supplied with tail lift Meaning of safety and warning signs Annexes 53... DHOLLANDIA...

-

Page 4: Understanding Safety And Warning Signs

Prior to operating the tail lift, make sure you understand the safety and warning signs used, and read them in conjunction • with the instructions in this manual. If in doubt, DO NOT operate the tail lift. Contact your national DHOLLANDIA distributor. See page 3 for contact info. • DHOLLANDIA... -

Page 5: Contact Information And Disclaimers

Take notice of the following important disclaimers: • DHOLLANDIA disclaims liability for any personal injury, death, or property damage that results from operating a tail lift that • has been modified from the original design, without explicit written approval from the manufacturer. -

Page 6: Safety Instructions For Maintenance And Repair

Negligence can put the technical personnel, the operator and third parties at great risk, and could result in severe personal • injury or death. Negligence can also cause premature wear or damage to the tail lift. In case of doubt, contact the national DHOLLANDIA distributor for further help and instructions. • DHOLLANDIA... -

Page 7: Identification & Ordering Replacement Parts

On the lift frame On the platform In the pump unit Use this serial number to order replacement parts, or to obtain technical advice from DHOLLANDIA or your local • DHOLLANDIA distributor regarding maintenance, troubleshooting and repair. The following information must be confirmed when ordering replacement parts: •... -

Page 8: Tail Lift Terminology

Center point of maximum load: point up to which the maximum rated capacity of the tail lift is valid. Beyond that point, the maximum safe working load diminishes according to the applicable load charts found near the external control station on the side of the vehicle body. See also section 8 in the OPERATION MANUAL. DHOLLANDIA... -

Page 9: Maintenance

Some steps in the maintenance check list require special skills and specific knowledge, that can be acquired through the • DHOLLANDIA training programs for maintenance and repair. In case of doubt, DON’T go any further, but ask your local DHOLLANDIA distributor for professional advice. - Page 10 Foot controls and their rubber buttons 90 days Condition, operation, routing, securement and condition of the wiring harness Handheld remote control 90 days Condition, operation, condition of holder or magnetic catch, spiral cable and plug(s) DHOLLANDIA SERV-DHL checklist-EUR EN-2019-01 page 1/4...

- Page 11 Condition inside pump unit, operation, all connections are tight, no signs of overheating Hydraulic circuit general external appearance, valve block and solenoid valves 90 days No visible oil leaks during operation and at rest DHOLLANDIA SERV-DHL checklist-EUR EN-2019-01 page 2/4...

- Page 12 Condition, operation of the device. Condition, routing of the harness(es) to the control box or pump unit, undamaged Platform flags (optional) 90 days Presence, condition, visibility Mechanical platform lock (optional) 90 days Condition, operation, lubricate mechanism DHOLLANDIA SERV-DHL checklist-EUR EN-2019-01 page 3/4...

- Page 13 Make sure you follow the all instructions and safety precautions at all times. Refer to: the OPERATION MANUAL the GENERAL SAFETY INSTRUCTIONS FOR REPAIR AND MAINTENANCE (available via www.dhollandia.com or contact the local distributor) DHOLLANDIA SERV-DHL checklist-EUR EN-2019-01 page 4/4...

-

Page 14: Lubrication And Grease Plans

• into account the intensity of use. All DHOLLANDIA tail lifts are equipped with low maintenance bearings. In normal conditions of use during a single shift, tail • lifts should be lubricated every 90 days, or 1750 cycles, whichever occurs first. -

Page 15: Electric And Hydraulic Diagrams

8. ELECTRIC AND HYDRAULIC DIAGRAMS §8.1 - General DHOLLANDIA tail lifts are regularly being adapted to new vehicle and chassis developments, and specialised customer • requirements. Therefore the electric and hydraulic diagrams applicable to your tail lift might deviate from the generic diagrams contained in this manual. -

Page 16: Tail Lift Terminology: Electric Dc Motor And Starter Solenoid

Thermal fuse TF for starter solenoid inside DC motor Outgoing main terminal R-OMT (+) Terminal of DC motor. (+) Busbar from starter solenoid to (+) terminal of DC motor. (-) Terminal of DC motor. (-) Ground cable of DC motor and solenoids DHOLLANDIA... -

Page 17: Tail Lift Terminology: Pump Unit Of Dh-Lm.10, Dh-Lm.15, Dh

Control valve H for LIFT Control valve S for CLOSE / OPEN Flow valve Pressure gauge coupling LP (low pressure) return line to oil tank HP outlet to LIFT cylinders HP outlet to TILT cylinders Switch plunger of logical 3-way valve 22 21 DHOLLANDIA... -

Page 18: Tail Lift Terminology : Pump Unit Of Dh-Lm.20, Dh

Control valve S for CLOSE / OPEN Flow valve Pressure gauge coupling HP (high pressure) inlet from pump LP (low pressure) return line to oil tank HP outlet to LIFT cylinders HP outlet to TILT cylinders Non-return valve of logical 3-way valve DHOLLANDIA... -

Page 19: Tail Lift Terminology: Pump Unit, Hydraulic Pipes And Cylinders

Electric lock valve O to OPEN / TILT 6, 10 Electric lock valve D to LOWER HP (high pressure) banjo coupling LP (low pressure) banjo coupling 7, 10 Lock valve harness + plug 5, 11 9, 12 5, 11 DHOLLANDIA... -

Page 20: Troubleshooting And Repair

9. TROUBLESHOOTING AND REPAIR §9.1 - Introduction In case of a malfunction, the operator can verify a number of simple points before calling an approved DHOLLANDIA service • agent: Is the battery disconnect switch in the main external control box, switched on? And / or is the cabin switch in the vehicle →... -

Page 21: Tail Lift Moves At Normal Speed, Whilst Operator Doesn't Operate Any Switch Or Button

• Measure voltage at the electrical connection board in the pump unit. • Check the main external control box and its cables for physical damage. • Check the main external control box for defective contacts or short-circuited wiring. DHOLLANDIA... -

Page 22: Tail Lift Doesn't Move Al All, Whilst Operator Tries To Operate External Control Box Or Auxiliary Control

• Verify if the electrical connection board and DC motor in the pump unit are adequately grounded. • Most electrical components, such as the electrically operated valves, and the starter solenoid, mini- relay, DC motor in the pump unit will not function without proper (-) ground link. DHOLLANDIA... -

Page 23: Symptoms Of Weak Batteries Or Damaged Current Supply

• Load test batteries and defective. replace if required. • Replace the thermal fuse TF inside the DC motor, or: 3. No ground via the ground terminal of the starter solenoid • Replace the DC motor. R-GT and thermal fuse TF. DHOLLANDIA... - Page 24 To ensure the reliability of the tail lift over many years, it is essential that the batteries, their charging system, the (+) battery • and (-) ground cables, and fuses are dimensioned sufficiently strong, and fitted with care following DHOLLANDIA installation instructions.

-

Page 25: The Dc Motor Doesn't Run, But The Downward Functions Open/Lower Work Ok

2. Starter solenoid R itself is the DC motor to the vehicle defective. chassis or battery (-) terminal 3. No ground via the ground • If previous is OK, recondition or terminal of the starter replace the DC motor. solenoid R-GT thermal fuse TF. DHOLLANDIA... -

Page 26: The Dc Motor Doesn't Switch Off

DC motor, the pump unit, and any flammable components nearby. • Check the buttons and switches of function LIFT. • Check the wire connections to contact blocks of function LIFT. Verify if un-commanded 12 volt signal is present. DHOLLANDIA... -

Page 27: The Platform Doesn't Lower, The Other Functions Work Ok (For Dh-Lm + Mech-X Wiring System)

(not clogged up with ice, dirt, etc.) • Check if the central flow valve in the main valve block inside the pump unit is moving freely (not clogged up with ice, dirt, etc.). DHOLLANDIA... -

Page 28: The Platform Doesn't Open, The Other Functions Work Ok (For Dh-Lm + Mech-X Wiring System)

• Check if the banjo couplings that connect the HP hydraulic hoses to the lift cylinders are clear (not clogged up with ice, dirt, etc.) • Check if the central flow valve in pump unit moves freely (not clogged up with ice, dirt, etc.). DHOLLANDIA... -

Page 29: The Tail Lift Doesn't Reach Its Max. Rated Lift Capacity (For Dh-Lm + Mech.x Wiring System)

• The hydraulic pump is worn 220 bar, without asking advice from your national nut of the pressure relief valve out (pump body warms up DHOLLANDIA distributor. adjustment screw, and put seal quickly). cap back in place. • The drive shaft between Too high pressure adjustment can cause damage to •... -

Page 30: The Tail Lift Doesn't Reach Vehicle Floor Level

• Check the general condition of the lift frame, lift arms, platform, cylinders and all pivot points. • Look for cracks, deformation in the material and welds. Look for excess wear in the pivot pins and bearings. DHOLLANDIA... -

Page 31: The Platform Lowers Only Very Slowly, When Function Lower Is Activated

• Check if the piston rods of the lift cylinders are not bent, or not seized up in the cylinder heads. NOT OK • Rest the platform on the • Contact the DHOLLANDIA ground. distributor to seek advice. • Dismount the flow valve in •... -

Page 32: The Platform Lowers Shock-Wise, When Function Lower Is Activated

• Check if the piston rods of the lift cylinders are not bent, or not seized up in the cylinder heads. NOT OK • Contact the DHOLLANDIA • Rest the platform on the ground. distributor to seek advice. • Dismount the flow valve of the main valve block in the pump unit. -

Page 33: The Platform Opens Very Slowly, When Function Open Is Activated

• Check if the piston rods of the cylinders are not bent, or not seized up in the cylinder heads. NOT OK • Rest the platform on the • Contact DHOLLANDIA ground. distributor to seek advice. • Dismount the flow valve in • Replace any failed parts by the main valve block in the OEM replacement parts. -

Page 34: The Platform Lifts And Closes Simultaneously, When Function Lift Is Activated

S in the pump unit is CLOSE doesn’t return to the from stock. leaking. neutral 0-position, or: • Contact DHOLLANDIA distributor to seek advice. The • Try and purge valve S • Short-circuit wiring platform must be exchanged or a new lift frame... -

Page 35: The Platform Drifts Down Slowly, Although The Operator Doesn't Push Any Button

Problem solved. • Rest the platform on the ground. • Remove the cartridge of the lock valve that is still leaking. • Check the O-rings of the cartridge. • Replace the O-rings or the cartridge itself. • Test again. DHOLLANDIA... -

Page 36: The Platform Drifts Open Slowly, Although The Operator Doesn't Push Any Button

Problem solved. • Rest the platform on the ground. • Remove the cartridge of the lock valve that is still leaking. • Check the O-rings of the cartridge. • Replace the O-rings or the cartridge itself. • Test again. DHOLLANDIA... -

Page 37: Emergency Operation

Depending on configuration, switch off the cabin switch and / or the main battery disconnect switch in • the external control box. Always work from a position on the side or over the front of the lift frame, never from the area behind • or under the platform. DHOLLANDIA... -

Page 38: Procedure I-Serv-G-001: Manual Operation Of The Single Acting Valves

(= faster) or less (= slower). V036.H / V037.H Step Closing the valve manually V133.12.H / V133.24.H Turn emergency knob CW (clockwise) to CLOSE the valve manually. Fasten it hand-tight in the closed position. Mount the plastic cap back on top of the cartridge. DHOLLANDIA... -

Page 39: Procedure I-Serv-G-002 : Manual Operation Of The Double Acting Valves (2 Types)

Release the button, or turn the nut CCW (= counter-clockwise) to CLOSE the valve manually. Reinstall the solenoid back in its original position on the cartridge. Reinstall the metal cap back in its original position and fasten it hand-tight. DHOLLANDIA... -

Page 40: Other Important Techniques

Never raise the hydraulic pressure above 3190 psi / • 220 bar, without asking advice from your national DHOLLANDIA distributor. Too high pressure adjustment can cause damage to • the tail lift, and serious bodily injury in case of a Counter-hold the center pressure pressure induced burst in the hydraulic circuit. -

Page 41: Procedure I-Serv-G-004: Flushing Of Pressure Relief Valve

Then behind (see warning box on next assemble the center pressure bolt page). back in its original position. Turn CCW = lower pressure and lift capacity Turn CW = raise pressure and lift capacity DHOLLANDIA... - Page 42 Turning the center pressure screw too far loose (CCW) while the pump is trying to build up pressure, can expel the bolt • forcefully, and disperse oil at high pressure. Failure to follow instructions can cause serious bodily injury. DHOLLANDIA...

-

Page 43: Procedure I-Serv-G-005: Check On Valve And Solenoid Function

To end, close the valve manually hand-tight, orient the solenoid in a position that will not damage the valve harness and plug • during any of the tail lift functions, replace the nut back on the solenoid and tighten firmly. DHOLLANDIA... -

Page 44: Procedure I-Serv-G-006: Flushing And Cleaning Of Valve Cartridge

To end, close the valve manually hand-tight, orient the solenoid in a position that will not damage the valve harness and plug • during any of the tail lift functions, replace the nut back on the solenoid and tighten firmly. DHOLLANDIA... -

Page 45: Procedure I-Serv-G-007 : Testing Internal Cylinder Leaks

4. After 4-5 complete cycles, the LP port of the tilt cylinder should lose no more oil. If OK, the cylinder is good. If not OK, recondition or replace the tilt cylinder. Contact the national DHOLLANDIA distributor, or consult the website to view the “GUIDELINES FOR THE REVISION OF HYDRAULIC CYLINDERS ” and the applicable safety precautions. Confirm that you have reviewed the most up-to-date version of this manual prior to working on hydraulic cylinders. -

Page 46: Procedure I-Serv-G-008 : Oil Replacement, Filling And Bleeding

• tank. TYPES OF OIL Option code Temperature Type of oil, examples For various climate conditions, DHOLLANDIA uses 3 types • of oil. See table Standard Mild to hot ISO VG 22 When filling up oil, make sure that you use the same, or a •... -

Page 47: Decals

NEVER remove or paint over any • decal. Missing, worn or illegible warning decals must be immediately replaced. Get free replacement decals from DHOLLANDIA. Contact your regional DHOLLANDIA distributor. See page 4 for contact info. The operator should comply with all •... - Page 48 EXAMPLE EXAMPLE EXAMPLE DHOLLANDIA...

- Page 49 Tail lift decals used and affixed in areas, other than the rear of the vehicle: • Cabin switch in driver’s cabin to switch electrical power to tail lift on / off (if so equipped) DHOLLANDIA...

- Page 50 Therefore, it is essential that the mounting plates are installed following the instructions of in the installation manual, and bolt • torques are maintained at the prescribed levels as part of the maintenance program. DHOLLANDIA...

-

Page 51: Meaning Of Safety And Warning Signs

14. MEANING OF SAFETY AND WARNING SIGNS WARNING signs MANDATORY ACTION signs Overview and keep visual control over the working Contact your regional DHOLLANDIA distributor. area of the liftgate at all times. General warning sign, used to alert the user to Consult the DHOLLANDIA website. - Page 52 Emergency stop. means of one of the control units). Will cause an immediate stop of the liftgate. Emergency exit. Provision (lever, valve,…) creating an emergency Unlock. Disengage the mechanical locking system. Lock. Engage the mechanical locking system. DHOLLANDIA...

Need help?

Do you have a question about the DH-L Series and is the answer not in the manual?

Questions and answers