Buchi Lyovapor L-200 Operation Manual

Hide thumbs

Also See for Lyovapor L-200:

- Operation manual (96 pages) ,

- Operation manual (94 pages) ,

- Operation manual (100 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Buchi Lyovapor L-200

- Page 1 Lyovapor™ L-200/L-200 Pro Operation Manual...

- Page 2 CH-9230 Flawil 1 E-Mail: quality@buchi.com BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experience, especially with respect to structure, illustrations and technical details. This manual is copyrighted. Information from it may neither be reproduced, distributed, or used for competitive purposes, nor made available to third parties.

-

Page 3: Table Of Contents

Büchi Labortechnik AG Table of contents Contents About this document......................... 7 Connected devices .......................... 7 Warning notices in this document...................... 7 Symbols ............................... 7 1.3.1 Warning symbols ........................ 7 1.3.2 Mandatory directive symbols .................... 7 1.3.3 Mark-ups and symbols...................... 8 Trademarks............................ 8 Safety .............................. 9 Proper use ............................ - Page 4 Requirements for local network settings ................ 28 5.5.2 Preparing the instrument for app using................ 29 5.5.3 Enabling BUCHI Cloud access .................... 29 Insert SD card (Pro control panel only).................... 29 Operating the control panel...................... 31 Layout of the control panel ........................ 31 Function bar............................ 31 Menu bar............................

- Page 5 Büchi Labortechnik AG Table of contents Operating Pro control panel ...................... 41 Layout of Pro control panel........................ 41 Function bar............................ 41 Other symbols on the control panel .................... 43 Menu bar............................ 43 7.4.1 Start menu ........................... 43 7.4.2 Favourites menu ........................ 44 7.4.3 Method menu ........................ 44 7.4.4...

- Page 6 Table of contents Büchi Labortechnik AG Help with faults .......................... 81 10.1 Troubleshooting .......................... 81 10.2 Faults, possible causes and remedies.................... 81 10.3 Locating leaking manifold valve...................... 82 10.4 Finding a leaking regulating valve or aeration valve................ 82 10.5 Error messages .......................... 83 Taking out of service and disposal....................

-

Page 7: About This Document

If you have any questions after reading this operation manual: Contact BÜCHI Labortechnik AG Customer Service. https://www.buchi.com/contact 1.1 Connected devices In addition to these operating instructions, follow the instructions and specifications in the documentation for the connected devices. -

Page 8: Mark-Ups And Symbols

Büchi Labortechnik AG 1 | About this document Symbol Meaning Symbol Meaning Wear protective gloves Heavy load, do not lift without assistance 1.3.3 Mark-ups and symbols NOTE This symbol draws attention to useful and important information. This character draws attention to a requirement that must be met before the instructions below are carried out. -

Page 9: Safety

— The staff must comply with the local applicable requirements and regulations for safe and hazard-conscious working practices. — Safety-related incidents that occur while using the instrument should be reported to the manufacturer (quality@buchi.com). Operation Manual Lyovapor™ L-200/L-200 Pro 9/92... -

Page 10: Location Of Warning Signs On The Product (Front View)

Büchi Labortechnik AG 2 | Safety BUCHI service technicians Service technicians authorized by BUCHI have attended special training courses and are authorized by BÜCHI Labortechnik AG to carry out special servicing and repair measures. 2.4 Location of warning signs on the product (front view) The following warning symbols are present on the instrument. -

Page 11: Low Internal Pressure

Unauthorized modifications can affect safety and lead to accidents. Use only genuine BUCHI accessories, spare parts and consumables. Carry out technical changes only with prior written approval from BUCHI. Only allow changes to be made by BUCHI service technicians. BUCHI accepts no liability for damage, faults and malfunctions resulting from unauthorized modifications. -

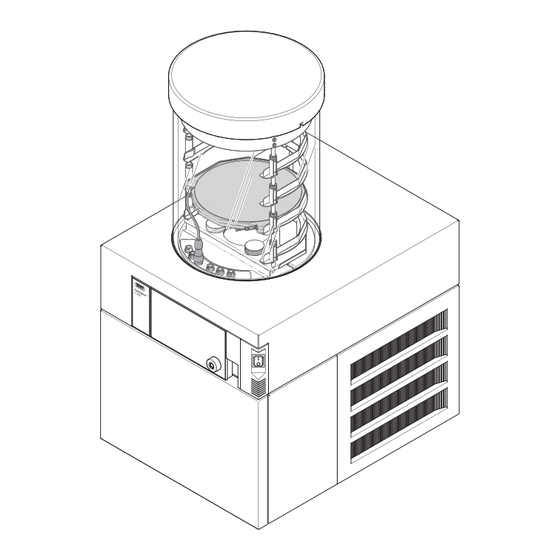

Page 12: Product Description

Büchi Labortechnik AG 3 | Product description 3 Product description 3.1 Description of function The Lyovapor™ is a freeze-dryer in which frozen samples can be gently dried. The basis of freeze-drying is sublimation. Sublimation refers to the process whereby a substance transforms directly from the solid to the gaseous state. -

Page 13: Secondary-Drying Phase

Büchi Labortechnik AG Product description | 3 Controlling the heat transfer prevents the following critical temperatures for amorphous and crystalline materials to be reached: — the glass transition temperature T ' of the frozen preparation — the collapse temperature T —... -

Page 14: Configuration

(Lyovapor™ L-200 Pro only) (48 V, max. 2 A) Ventilation slots On/Off master switch User interface 3.2.2 Rear view [Lyovapor L-200] Fig. 3: Rear view Connections on the rear side Drain hose for condensate (See Chapter 3.2.3 "Connections on the rear side", page 15) -

Page 15: Connections On The Rear Side

Büchi Labortechnik AG Product description | 3 3.2.3 Connections on the rear side Fig. 4: Connections on rear panel Vacuum pump connection Vacuum connection Type plate Refrigerant details Main valve connection Pressure regulating valve connection (24 V, ≤ 0.4 A) (24 V, ≤ 0.4 A) Aeration valve connection Spare (24 V, ≤... -

Page 16: Pro Control Panel

Fig. 6: Pro control panel Touch-screen display Navigation control 3.3 Type plate The type plate identifies the instrument. The type plate is located on the rear of the instrument. Buchi Operations India Private Limited 394230 Surat / India Type xxxxxxxx Volt xxx-xxx... -

Page 17: Scope Of Delivery

Büchi Labortechnik AG Product description | 3 3.4 Scope of delivery NOTE The scope of delivery depends of the configuration of the purchase order. Accessories are delivered as per the purchase order, order confirmation, and delivery note. 3.5 Refrigerant Specification The instrument uses 2 type of compressors to maintain the ice condenser temperature. -

Page 18: Ambient Conditions

Büchi Labortechnik AG 3 | Product description Specification L-200 for 50 Hz L-200 for 60 Hz Minimum system vacuum Typically ≤ 30 mTorr Typically ≤ 30 mTorr (with Pfeiffer Duo 6 vacuum pump / without samples) Optimum control range vacuum 50 to 500 mTorr 50 to 500 mTorr (with Pfeiffer Duo 6 vacuum pump /... -

Page 19: Transport And Storage

Büchi Labortechnik AG Transport and storage | 4 4 Transport and storage 4.1 Transport NOTICE Risk of breakage due to incorrect transportation Make sure that the instrument is fully dismantled. Pack every instrument components properly to prevent breakage. Use the original packaging whenever possible. - Page 20 Büchi Labortechnik AG 4 | Transport and storage Fig. 8: Lifting the instrument Instrument Feet Equipment trolley Castor brakes on trolley Precondition: Make sure that the castor brakes on the equipment trolley are locked on. Lift the instrument – this requires four persons each lifting at one of the points indicated on the front and rear of the instrument.

-

Page 21: Installation

Büchi Labortechnik AG Installation | 5 5 Installation 5.1 Installation site NOTICE Instrument damaged if switched on too early. After transporting, wait twelve hours before switching on the instrument. The fluid in the cooling system requires twelve hours to collect in the refrigerant compressor. The installation site must meet the following requirements: —... -

Page 22: Putting The Instrument In Operation

Risk of instrument damage because of not suitable power supply cables. Not suitable power supply cables can cause bad performance or an instrument damage Use only BUCHI power supply cables. Precondition: The electrical installation is as specified on the type plate. - Page 23 Büchi Labortechnik AG Installation | 5 Fit the aeration valve onto the 90° elbow. Precondition: The arrow is pointing in the direction of the vacuum pump. Fit the main valve onto the cross-pipe. Fit the pressure-regulating valve onto the 90° elbow.

-

Page 24: Manual Switch On The Main Valve

Büchi Labortechnik AG 5 | Installation Plug the main valve connector into the socket Main Valve marked 5.3.4 Manual switch on the main valve Use the main valve manual switch to set the vacuum control mode. Fig. 10: Manual switch on main valve Main valve Manual switch on main valve Manual switch positions... -

Page 25: Connecting The Inert Gas (Optional Feature)

Büchi Labortechnik AG Installation | 5 5.3.5 Connecting the inert gas (optional feature) Precondition: Make sure that the pressure of the inert gas matches the technical specifications. See Chapter 3.6 "Technical data", page 17 Fit the inert gas tube onto the gas connection on the pressure regulating valve. -

Page 26: Fitting The Drain Valve Strainer

Büchi Labortechnik AG 5 | Installation Fig. 12: Fitting alternative pressure sensor Connection, ISO-KF 16 External pressure sensor connection Switch the On/Off master switch to Off. Remove the blanking cap from the connection (1). Connect the pressure sensor to the connection (1). External Plug the pressure sensor connecting lead into the socket marked Vacuum Sensor... -

Page 27: Commissioning The Vacuum Pump

Büchi Labortechnik AG Installation | 5 NOTICE Contamination of the device Escaping condensate can contaminate the instrument. Fit the condensate drain hose with a downward slope. Make sure that the drain hose is not immersed in the condensate. Seal the condensate drain hose with the end plug as soon as cleaning of the instrument is completed. -

Page 28: Establishing Lan Connection

Büchi Labortechnik AG 5 | Installation NOTICE Open gas ballast valve. A closed gas ballast valve when using solvents can cause damage to the instrument. Open the gas ballast valve. NOTE To increase the service life of the vacuum pump, operate the vacuum pump with an open gas ballast valve. -

Page 29: Preparing The Instrument For App Using

Büchi Labortechnik AG Installation | 5 In order to use the BUCHI Cloud a DNS server must be configured on the instrument. NOTE If there is no DNS server available enter the IP address for the BUCHI Cloud connection manually. - Page 30 Büchi Labortechnik AG 5 | Installation Fold the control panel forward. Insert the SD card on the underside. Switch on the instrument. ð The status bar shows the SD card symbol. The following data is stored on the SD card: —...

-

Page 31: Operating The Control Panel

Büchi Labortechnik AG Operating the control panel | 6 6 Operating the control panel This section describes the operation of the instrument using the control panel. CAUTION Risk of injury from glass splinters Sharp objects can damage the display. Keep sharp objects away from the display. NOTICE Unnecessary operation hours can affect the lifetime of the instrument. -

Page 32: Menu Bar

Büchi Labortechnik AG 6 | Operating the control panel The functions on the function bar are executed by tapping the relevant function buttons or pressing the navigation control. General function buttons Symbol Description Meaning [Back] The display reverts to the previous view. -

Page 33: Start Menu

Büchi Labortechnik AG Operating the control panel | 6 Menu Meaning Submenu/Action symbol — [Configuration] Process settings menu — Settings — Servicing — Service — System information — [Messages] Notifications menu — Journal 6.3.1 Start menu [Start] On the menu, parameters can be set manually. Changing parameters Select a parameter by turning the navigation control. - Page 34 6 | Operating the control panel Action Option Explanation [Mobile connection View The control panel shows a password for entry in the BUCHI Monitor app. password] View The control unit shows a QR code for [Mobile connection reading by the BUCHI Monitor app. QR code]...

- Page 35 Büchi Labortechnik AG Operating the control panel | 6 Submenu Service NOTE While freeze-drying is in progress, no settings can be changed on the Service submenu. Action Option Explanation View The following information on the re- [Refrigerant cir- frigerant circuit is available: cuit] —...

-

Page 36: Messages Menu

Büchi Labortechnik AG 6 | Operating the control panel Action Option Explanation [L-200] View The following information on the L-200 is available: — Serial number — Firmware version — Hours of duty — Status — PCB Temperature — 48 V power supply —... - Page 37 (< 15 min). Symbols on the status bar Symbol Status The instrument is connected to the BUCHI Cloud. The instrument is defrosting. The instrument is starting up. The instrument is in energy-saving mode. Operation Manual Lyovapor™ L-200/L-200 Pro...

-

Page 38: Carrying Out Freeze-Drying

Büchi Labortechnik AG 6 | Operating the control panel Symbol Status Before the freeze-drying process: Load the top-mount drying rack with a frozen sam- ple. After the freeze-drying process: Remove the dried sample from the top-mount dry- ing rack. The system evacuates to the set pressure. The instrument is performing a vacuum test or a leak test. -

Page 39: Editing Parameters While The Process Is Running

Büchi Labortechnik AG Operating the control panel | 6 Enter the required settings for the process parameters. [Start] Tap the function on the function bar. ð The freeze-drying process starts. ð The control panel shows the Start menu with a black background. ð... -

Page 40: Switching Off The Instrument

Büchi Labortechnik AG 6 | Operating the control panel Position the condensate drain hose so that the condensate can be drained off. See Chapter 5.3.9 "Preparing the condensate drain hose", page 26 [Start] Navigate to the menu via the navigation path. [Shut down] Tap the function on the function bar. -

Page 41: Operating Pro Control Panel

Büchi Labortechnik AG Operating Pro control panel | 7 7 Operating Pro control panel This section describes the operation of the instrument using the Pro control panel. CAUTION Risk of injury from glass splinters Sharp objects can damage the display. Keep sharp objects away from the display. - Page 42 Büchi Labortechnik AG 7 | Operating Pro control panel General function buttons Symbol Description Meaning The display reverts to the previous [Back] view. [Cancel] Cancels an operation. [Add to favourites] Adds the selected item to the [[Favourites]] menu. Removes the selected item from the REMOVE [Remove from [Favourites]...

-

Page 43: Other Symbols On The Control Panel

Büchi Labortechnik AG Operating Pro control panel | 7 7.3 Other symbols on the control panel Symbol Description Meaning The assigned method is active and [Closed] cannot be changed. 7.4 Menu bar The menus are represented by symbols on the menu bar. Navigation through the menus is by the input controls. -

Page 44: Favourites Menu

Action Option Explanation [Mobile connection View The control panel shows a password for entry in the BUCHI Monitor app. password] [Mobile connection View The control unit shows a QR code for reading by the BUCHI Monitor app. QR code]... - Page 45 [Network] Enter value The following parameters can be edited: Device name/MAC address/DHCP/ System IP address/Subnet mask/ Gateway/DNS server/BUCHI Cloud/ Server IP address [Delete app con- Confirmation question Resets external connections to the in- strument. nection] Submenu End point determination...

- Page 46 Büchi Labortechnik AG 7 | Operating Pro control panel Submenu Service NOTE While freeze-drying is in progress, no settings can be changed on the Service submenu. Action Option Explanation View The following information on the re- [Refrigerant cir- frigerant circuit is available: cuit] —...

-

Page 47: Messages Menu

Büchi Labortechnik AG Operating Pro control panel | 7 Action Option Explanation [L-200] View The following information on the L-200 is available: — Serial number — Firmware version — Hours of duty — Status — PCB Temperature — 48 V power supply —... - Page 48 Büchi Labortechnik AG 7 | Operating Pro control panel Indication on status bar Conditioning is completed. Unload / Load Before the freeze-drying process: Load the top-mount drying rack with a frozen sample. After the freeze-drying process: Remove the dried sample from the top- mount drying rack.

-

Page 49: Editing A Method

The instrument is starting up. The instrument is in the course of a manual freeze-drying process. The instrument is connected to the BUCHI Cloud. Sample protection is active. Reason: the pressure is outside the pressure lim- its. -

Page 50: Changing The Name Of A Method

Büchi Labortechnik AG 7 | Operating Pro control panel [New] Tap the function on the function bar. ð The new method is created. Creating a new method by copying an existing method Navigation path ➔ Method [Method] Navigate to the menu via the navigation path. -

Page 51: Setting The Shelf Loading Temperature

Büchi Labortechnik AG Operating Pro control panel | 7 [Method] Navigate to the menu via the navigation path. Tap the name of the method that you wish to edit. ð The control panel highlights the selected method in green. [General] Tap the action ð... -

Page 52: Setting The Phases Of A Method

Büchi Labortechnik AG 7 | Operating Pro control panel Setting Option Meaning [Step phase] Primary drying/Sec- Sets the type of step phase. ondary drying Enter value Sets the duration of the step in [Term] minutes. [Shelf temperature] Enter value Set the temperature of the heat- able shelves in one step. - Page 53 Büchi Labortechnik AG Operating Pro control panel | 7 Navigation path ➔ Method [Method] Navigate to the menu via the navigation path. Tap the name of the method that you wish to edit. ð The control panel highlights the selected method in green. [Phase] Tap the action ð...

-

Page 54: Deleting A Method

Büchi Labortechnik AG 7 | Operating Pro control panel Phase Setting Option Meaning [Stopper- [Pressure Regulated/Mini- Regulated: the settings for pressure and pressure limits are applied. ing] zone] Minimum: The maximum vacuum is applied to reach the lowest possible pressure. [Pressure] Enter value Sets a target value for the regulated... -

Page 55: Connect The Sensors For Pressure Difference Test (Optional Feature)

Büchi Labortechnik AG Operating Pro control panel | 7 7.8.1 Connect the sensors for pressure difference test (optional feature) Fit the pressure sensor, seal to the connection and fix with the clamp. Plug the pressure sensor electrical connector Internal Vacuum into the socket marked Sensor Fit the pressure sensor, seal to the connection... -

Page 56: Temperature Difference Test

Büchi Labortechnik AG 7 | Operating Pro control panel [End point definition] Tap the setting ð The control panel shows the setting End point definition. [Pressure difference test] ð The control panel shows the pressure difference test. The following settings are available: Setting Option Explanation... -

Page 57: Determining Offset Value

Büchi Labortechnik AG Operating Pro control panel | 7 The optional temperature sensor has been installed. See Chapter 8 "Operating top-mount drying racks", page 63 Place the optional temperature sensor in the sample. [Method] Navigate to the menu via the navigation path. Tap the name of the method that you wish to edit. -

Page 58: Performing Freeze-Drying Using A Method [Pro Control Panel]

Büchi Labortechnik AG 7 | Operating Pro control panel 7.9 Performing freeze-drying using a method [Pro control panel] 7.9.1 Preparing the instrument Time approx. 30min quired: NOTE To minimize the condensation of moisture from the air in the condenser, place a drying rack. -

Page 59: Changing Parameters While The Process Is Running

Büchi Labortechnik AG Operating Pro control panel | 7 If a gas is being used Precondition: The instrument has been prepared. A method is selected. Fit a top-mount drying rack. See Chapter 8 "Operating top-mount drying racks", page 63. Load the top-mount drying rack with frozen samples. [Start] Navigate to the menu via the navigation path. -

Page 60: Shutting Down The Instrument

Büchi Labortechnik AG 7 | Operating Pro control panel 7.9.6 Shutting down the instrument Time 40min quired: NOTICE Do not use force to remove the ice from the ice condenser. Navigation path ➔ Start Precondition: The freeze-drying process has ended. Position the condensate drain hose so that the condensate can be drained off. -

Page 61: Editing Parameters While The Process Is Running

Büchi Labortechnik AG Operating Pro control panel | 7 7.10.2 Editing parameters while the process is running Navigation path ➔ Start Precondition: The process has been started. [Start] Navigate to the menu via the navigation path. Using the navigation control, navigate to the parameter that you wish to change. [Edit] Tap the function on the function bar. -

Page 62: Switching Off The Instrument

Büchi Labortechnik AG 7 | Operating Pro control panel [Shut down] Tap the function on the function bar. ð The instrument is shutting down. ð Defrosting The status bar shows the remaining time and the status ð After the instrument has shut down, the status bar shows the remaining time and Shutting down the status Put hot water on ice condenser coil for defrosting. -

Page 63: Operating Top-Mount Drying Racks

Büchi Labortechnik AG Operating top-mount drying racks | 8 8 Operating top-mount drying racks 8.1 Operating stoppering acrylic drying chamber Make sure that the groove above the ice condenser is clean, free of dust and not scratched. Check the 300 mm dia. O-ring for damage. Place the 300 mm dia. - Page 64 Büchi Labortechnik AG 8 | Operating top-mount drying racks Align the slots for the shelves. Tighten the fixing screws. Place the rack on the intermediate plate. Slide the shelves into the rack. Press the plug onto the shelf connection and turn the ring counterclockwise at the same time.

- Page 65 Büchi Labortechnik AG Operating top-mount drying racks | 8 Locate the cylinder in the groove above the main plate. Check the O-ring for damage. Screw the hand wheel upwards until the plate inside the lid has pressed the hooks all the way Place the O-ring into the groove of the cover.

-

Page 66: Operating Manifold Acrylic Drying Chamber (Heatable Shelves)

Büchi Labortechnik AG 8 | Operating top-mount drying racks 8.2 Operating manifold acrylic drying chamber (heatable shelves) Make sure that the groove above the ice condenser is clean, free of dust and not scratched. Check the 300 mm dia. O-ring for damage. Place the 300 mm dia. - Page 67 Büchi Labortechnik AG Operating top-mount drying racks | 8 Tighten the fixing screws. Place the rack on the intermediate plate. Slide the shelves into the rack. Press the plug onto the shelf connection and turn the ring counterclockwise at the same time. (option) Turn the temperature sensor electrical connector so that the marks on the connector...

- Page 68 Büchi Labortechnik AG 8 | Operating top-mount drying racks Locate the cylinder in the groove above the main plate. Fit manifold valve onto the connection on the top-mount drying rack. Check the O-ring for damage. Place the O-ring into the groove of the cover. Place the manifold cover on the cylinder.

-

Page 69: Operating Manifold Acrylic Drying Chamber (Non-Heatable Shelf)

Büchi Labortechnik AG Operating top-mount drying racks | 8 8.3 Operating manifold acrylic drying chamber (non- heatable shelf) Make sure that the groove above the ice condenser is clean, free of dust and not scratched. Check the 300 mm dia. O-ring for damage. Place the 300 mm dia. -

Page 70: Operating Acrylic Drying Chamber (Heatable Shelf)

Büchi Labortechnik AG 8 | Operating top-mount drying racks Fit manifold valve onto the connection on the top-mount drying rack. Check the O-ring for damage. Place the O-ring into the groove of the cover. Place the manifold cover on the cylinder. Carry out freeze-drying. - Page 71 Büchi Labortechnik AG Operating top-mount drying racks | 8 Place the intermediate plate on the ice condenser. Loosen all fixing screws. Align the slots for the shelves. Tighten the fixing screws. Place the rack on the intermediate plate. Operation Manual Lyovapor™ L-200/L-200 Pro 71/92...

- Page 72 Büchi Labortechnik AG 8 | Operating top-mount drying racks Slide the shelves into the rack. Press the plug onto the shelf connection and turn the ring counterclockwise at the same time. (option) Turn the temperature sensor electrical connector so that the marks on the connector and the heatable shelf are parallel Press the temperature sensor electrical connector onto the connection.

-

Page 73: Operating Acrylic Drying Chamber (On-Heatable Shelf)

Büchi Labortechnik AG Operating top-mount drying racks | 8 8.5 Operating acrylic drying chamber (on-heatable shelf) Make sure that the groove above the ice condenser is clean, free of dust and not scratched. Check the 300 mm dia. O-ring for damage. Place the 300 mm dia. -

Page 74: Operating Manifold Drying Rack

Büchi Labortechnik AG 8 | Operating top-mount drying racks Check the O-ring for damage. Place the O-ring into the groove of the cover. Place the cover on the cylinder. Carry out freeze-drying. 8.6 Operating manifold drying rack Make sure that the groove above the ice condenser is clean, free of dust and not scratched. -

Page 75: Operating Manifold Valves

Büchi Labortechnik AG Operating top-mount drying racks | 8 Place the seal on the connection. Fit the manifold drying rack onto the seal and fix it with the clamp. Carry out freeze-drying. 8.7 Operating manifold valves The lever on a manifold valve can be set to the following positions: Position Function A: Lever pointing up... -

Page 76: Cleaning And Servicing

Do not carry out any servicing and cleaning operations that involve opening the housing. Use only genuine BUCHI spare parts in order to ensure correct operation and preserve the warranty. Carry out the service and cleaning operations described in this section to extend the lifetime of the instrument. -

Page 77: Performing A Vacuum Test

Büchi Labortechnik AG Cleaning and servicing | 9 Component Action Interval View Wipe down the display with a damp Monthly cloth. 9.2 Performing a vacuum test The vacuum test checks the performance capacity of the vacuum system. Time max. 10 min quired: Navigation path ➜... - Page 78 Büchi Labortechnik AG 9 | Cleaning and servicing Time 45 min quired: NOTE [Stop] The leak test can be aborted by tapping on the function bar. Precondition: Conditioning of the instrument has been completed. A top-mount drying rack is fitted. The top-mount drying rack does not contain sample.

-

Page 79: Performing Leak Test With A Manifold Drying Rack

Büchi Labortechnik AG Cleaning and servicing | 9 Possible cause Action KF seals damaged Inspect KF seals and replace as neces- sary. Pump oil dirty Service according to manufacturer's in- structions. Leaking manifold valves Replace leaking manifold valve. (manifold acrylic drying chamber only) Locate leaking manifold valve. - Page 80 Büchi Labortechnik AG 9 | Cleaning and servicing ð The leak test is passed if the measured leakage rate is less than the pre-set rate of 10.10 mbar*L/h. NOTE To test the leak-tightness of the manifold drying rack, carry out another leak test with the manifold drying rack installed.

-

Page 81: Help With Faults

Büchi Labortechnik AG Help with faults | 10 10 Help with faults 10.1 Troubleshooting Problem Possible cause Action Compressor fails to No power supply to compres- Check the power supply and start or switches off switch on the device. Compressor overheated Allow the compressor to cool down. -

Page 82: Locating Leaking Manifold Valve

Büchi Labortechnik AG 10 | Help with faults Malfunction Possible cause Remedy Instrument is not Main valve is incorrectly con- Connect the main valve vented nected. properly (see Chapter 5.3.3 "Fitting the advanced vacuum control unit", page 22). 10.3 Locating leaking manifold valve Navigation path ➔... -

Page 83: Error Messages

Büchi Labortechnik AG Help with faults | 10 10.5 Error messages Error message Possible cause Solution 5014 A power failure for 60 min. Confirm to recover the instrument and continue the process with risk of sample melting. Stop the process in standby, release pressure manually by activating the aeration valve in service menu. - Page 84 5570 Heatable shelf is discon- Connect a functioning shelf at nected. the same connector position. Contact BUCHI Customer Defective component (e.g. Service. heating coil, cable, plug) 5571 Sample temperature sensor Connect a functioning PT-1000 is disconnected.

-

Page 85: Taking Out Of Service And Disposal

Dispose of the appliance properly, if necessary using a professional disposal service. When disposing of equipment observe the local regulations and statutory requirements regarding waste disposal. 11.2 Returning the instrument Before returning the instrument, contact the BÜCHI Labortechnik AG Service Department. https://www.buchi.com/contact Operation Manual Lyovapor™ L-200/L-200 Pro 85/92... -

Page 86: Appendix

12 | Appendix 12 Appendix 12.1 Spare parts and accessories Use only genuine BUCHI consumables and spare parts in order to ensure correct, safe and reliable operation of the system. NOTE Any modifications of spare parts or assemblies are only allowed with the prior written permission of BUCHI. -

Page 87: Further Accessories

Büchi Labortechnik AG Appendix | 12 12.1.2 Further accessories Description Order no. Image Trolley L-200, stainless steel coated 11063692 SD-Card 1 GB 11064730 Connection cable, for vacuum pump 11064934 12.1.3 Spare parts Description Order no. Image User interface L-200 11063578 Pro user interface 11063579 O-Ring Ø... - Page 88 Büchi Labortechnik AG 12 | Appendix Description Order no. Image Vacuum clamp KF 16 11064939 Vacuum seal KF 16 11063455 Vacuum seal KF 25 11063457 Vacuum seal KF 40 11063659 Vacuum flange adapter, stainless steel, 11064870 KF 16 to KF 25 Blind flange KF 16 11064902 Blind flange KF 25...

-

Page 89: Top-Mount Drying Rack Accessories

Büchi Labortechnik AG Appendix | 12 12.1.4 Top-mount drying rack accessories Order no. Image Drying chamber tube, PMMA, for 4 shelves 11063278 L 368 mm, Ø 300 mm Drying chamber tube, PMMA, for 6 shelves 11065093 L 480 mm, Ø 300 mm Top cover, PMMA, without sealing 11062912 Ø... - Page 90 Büchi Labortechnik AG 12 | Appendix Order no. Image Support for rack, stainless steel 11063789 H 4 mm Baseplate, stainless steel, for manifold rack 11064953 Baseplate, PMMA, for manifold rack 11065733 Suction nipple 11065819 For manifold application to create vacuum in sample flasks Ampoule adapter for manifold 11065725...

-

Page 91: Software

Büchi Labortechnik AG Appendix | 12 Order no. Image Manifold flask adapter set, US joint size 11066171 with 12 adapters, incl. filter paper Manifold flask adapter set, US joint size 11067333 with 6 adapters, incl. filter paper Filter round 20mm Set à 100pcs 11065801 Filter for manifold valve Filter round 47mm Set à... - Page 92 We are represented by more than 100 distribution partners worldwide. Find your local representative at: www.buchi.com...

Need help?

Do you have a question about the Lyovapor L-200 and is the answer not in the manual?

Questions and answers