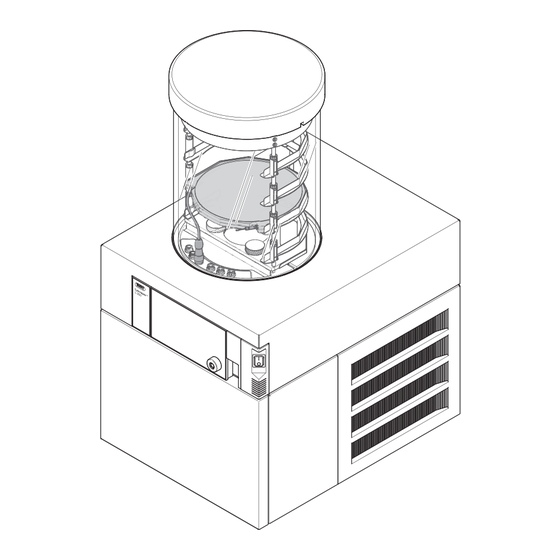

Buchi Lyovapor L-200 Pro Manuals

Manuals and User Guides for Buchi Lyovapor L-200 Pro. We have 4 Buchi Lyovapor L-200 Pro manuals available for free PDF download: Operation Manual

Buchi Lyovapor L-200 Pro Operation Manual (100 pages)

Brand: Buchi

|

Category: Laboratory Equipment

|

Size: 11 MB

Table of Contents

Advertisement

Buchi Lyovapor L-200 Pro Operation Manual (96 pages)

Brand: Buchi

|

Category: Industrial Equipment

|

Size: 25 MB

Table of Contents

Buchi Lyovapor L-200 Pro Operation Manual (94 pages)

Brand: Buchi

|

Category: Laboratory Equipment

|

Size: 8 MB

Table of Contents

Advertisement

Buchi Lyovapor L-200 Pro Operation Manual (92 pages)

Brand: Buchi

|

Category: Laboratory Equipment

|

Size: 11 MB