Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for MIYAWAKI ES12N

- Page 1 ES12N INVERTED BUCKET STEAM TRAP USER'S MANUAL...

-

Page 2: Table Of Contents

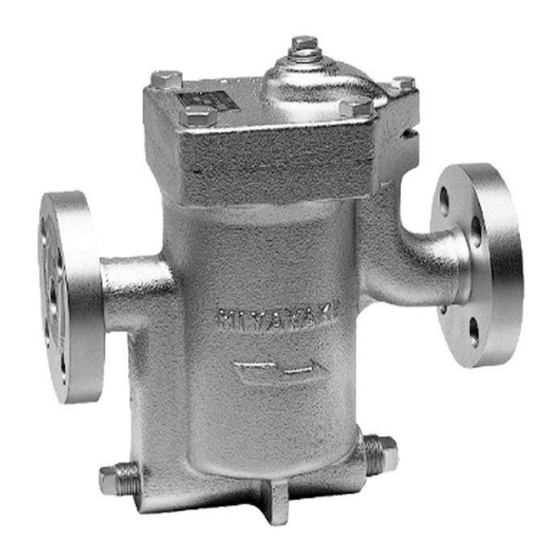

SAFETY GUIDE The model ES12N is a cast iron inverted bucket steam trap for medium condensate loads. In order to get maximum benefit from this product, be sure to read this manual before installing it. The following warnings and cautions are shown at appropriate places in this manual. -

Page 3: Specifications And Markings

Model : Showing the product model name Some pictures and illustrations in this manual are examples of ES12N models. For more details regarding dimensions and other specifications, please refer to the catalog. The model ES12N fully complies with the requirements of the European Pressure Equipment Directive 2014/68/EU. -

Page 4: Construction Details

CONSTRUCTION DETAILS Body Lever B 21. Cover Gasket Cover Eyebolt Pin 22. Cover Bolt Plug Lever A 23. Plug Plug Bracket 24. Plug Valve Seat 25. Seat Gasket Valve Set Bolt 26. Spacer Valve Holder Screen Name Plate 28. C-Ring Bucket Rivet 29. -

Page 5: Installation

INSTALLATION WARNING Pay very careful attention when working in hazardous environments. There is a risk of explosion and the possibility of dangerous gases leaking. Always check whether the pipeline contains flammable, high pressure or high temperature materials before starting to work. ... - Page 6 2) Check the flow direction indicated on the body. 3) When installing the model ES12N, install it so that the flow from the upstream line to the downstream line is horizontal and the name plate is on the top side of the body.

-

Page 7: Operation

OPERATION CAUTION Before starting operation, open the bypass valve or blow valve completely and blow off the scale in the piping. 4.1 Operation procedure 1) After blowing off the scale from the piping, close the bypass valve or blow valve. 2) Open the stop valve on the trap outlet side. -

Page 8: Maintenance

CAUTION When replacing parts, make sure the replacement parts are supplied by MIYAWAKI. The performance of steam traps deteriorates gradually over time due to wear, corrosion or dirt accumulating around the valve and the valve seat. Please conduct periodic diagnosis of traps in order to keep steam control systems and equipment working well. - Page 9 Repairs When a trap fails, it is necessary to clean the internal parts and to replace damaged parts. Take the failed trap apart following the steps below. 5.2.1 Disassembling the trap 1) Untighten the body plug (3), take out the screen (17), check and clean it. 2) Remove the bolts (20 &...

- Page 10 5.2.2 Reassembling the trap 1) Attach the valve holder (7) to the lever A (13), insert the valve (6) into the valve holder (7), and attach the split pin (2 mm) to the valve holder. After bending the tip of the split pin with a nipper, check that the valve holder (7) can be rotated 360°...

- Page 11 4.Plug 22.Bolt 20.Bolt 2.Cover 18.Name Plate 19.Rivet 21.Gasket 25.Gasket 5.Valve Seat 26.Spacer 14.Bracket 16.Set Bolt 15.Pin 28.C-Ring 11.Lever B 7.Valve Holder 6.Valve 12.Eyebolt Pin 13.Lever A 8.Pin 10.Eyebolt 30.Pin 31.Spacer B 9.Bucket 29.Pipe 23.Plug 3.Plug 17.Screen 1.Body 24.Plug...

-

Page 12: Troubleshooting

TROUBLESHOOTING Problem Possible cause Solution Steam leaks or blows The condensate amount in the Remove the plug (4) and pour through. body (1) is extremely small, water into the body (1). and the valve opening state continues due to the sinking of the bucket (9). -

Page 13: Warranty

Problems caused by devices or equipment other than MIYAWAKI’s, or a disallowed use environment When a repair or modification has been performed by anyone other than MIYAWAKI or people who are authorized to make such repairs Intrusion of salt or other substances that promote significant rust or corrosion or problems from fluids that contain the same substances Consumable parts such as Packing, Gasket, O-ring, Diaphragm, etc. -

Page 14: Serial Number (S. No.) Designation

1 7 1 1 → Jan.1, 2017 2 9 X M → Oct. 21, 2029 ● For 9-digit display S.No. □□□□□□□□□ MIYAWAKI identification number Represents the month. Represents the year. (last two digits of the year according to the Western calendar) Example of serial number designation 1 7 1 1 2 C 0 2 0 →... -

Page 15: Guidance For Reading Special Product Name

GUIDANCE FOR READING SPECIAL PRODUCT NAME 〇〇〇-○○-□ Special symbol: The symbol applies only to special products (Please refer to table 1 for details) Model symbol: Product model number Table 1 Symbol description Suffix Special contents Trap for high-pressure gas installed property (only for Gas Trap) Blow valve attached Change of gasket Special face to face dimension... - Page 16 If you have any question, please contact MIYAWAKI, our local authorized agent, or the company where you purchased the product. In the interest of the development and improvement of our products, MIYAWAKI Inc. reserves the right to change the specification of the products without prior notice.

- Page 17 MIYAWAKI GmbH Birnbaumsmühle 65, 15234 Frankfurt (Oder), Germany Tel: +49-335-4007-0097 www.miyawaki.net e-mail: info@miyawaki.de China Importer and Authorized representative: MIYAWAKI WEST Co., Ltd. Room 1705, No.1, Building No.311, Yanxin Road, Huishan Economic Development Zone, Wuxi, Jiangsu, China Tel: +86-510-8359-5125 www.miyawaki-inc.com.cn e-mail: mywkwest@miyawaki-inc.com.cn...

Need help?

Do you have a question about the ES12N and is the answer not in the manual?

Questions and answers