Subscribe to Our Youtube Channel

Summary of Contents for Hillyard TRIDENT B20SC

- Page 1 Scrubbing machine Use and Maintenance manual ORIGINAL INSTRUCTIONS DOC. 10073891 - Ver. AA - 10-2017...

- Page 2 The descriptions contained in this document are not binding. The company therefore reserves the right to make any modifications at any time to elements, details, or accessory supply, as considered necessary for reasons of improvement or manufacturing/commercial requirements. The reproduction, even partial, of the text and drawings contained in this document is prohibited by law.

-

Page 3: Table Of Contents

17. HOUR METER (TRIDENT B20SC VERSIONS) ................................21 19. FORWARD WORK SPEED (BT VERSIONS) .................................. 22 20. FORWARD WORK SPEED (B AND TRIDENT B20SC VERSIONS) ..........................22 21. FILLING THE SOLUTION TANK ...................................... 22 22. ASSEMBLING THE SQUEEGEE ..................................... 23 ... - Page 4 48. ADJUSTING THE PARKING BRAKE (ONLY FOR BT VERSIONS) ..........................44 49. BRUSH REPLACEMENT (B-BT VERSIONS) .................................. 44 50. BRUSH REPLACEMENT (TRIDENT B20SC VERSIONS) .............................. 44 51. REGULATING MACHINE DIRECTION .................................... 45 52. REPLACING SQUEEGEE BODY RUBBERS .................................. 45 ...

-

Page 5: On Consignment Of The Machine

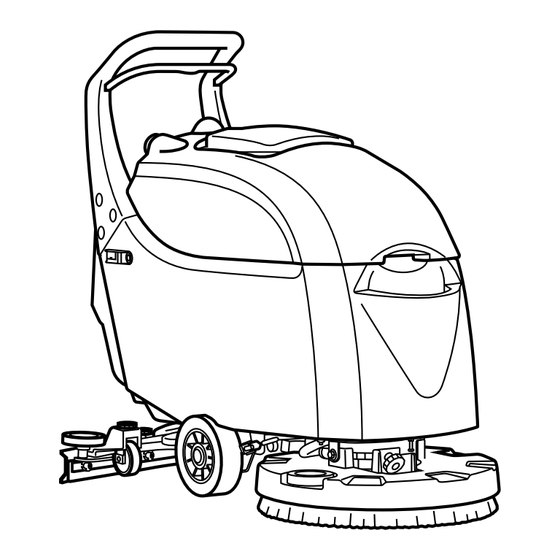

Introductory comment Serial number plate The TRIDENT B20SC is a floor scrubbing machine which, by means of the mechanical action of the rotating brush and the chemical action of a water/detergent solution, can clean any type of flooring. As it advances, it also collects any removed dirt as well as the detergent solution not absorbed by the floor. -

Page 6: Symbols Used On The Machine

SYMBOLS USED ON THE MACHINE Symbol for main switch or key switch (only for B-BT version). Used on the control panel, to indicate the key switch for machine operation on (I) or off (0). ECO mode symbol (only for B-BT version). Used on the control panel to indicate the button that activates the ECO mode of the machine. - Page 7 Used on the control panel to indicate the button that commands the deactivation of the brush motor and of the solenoid valve. Main switch position "ON- NO SOLENOID VALVE" symbol (Only for TRIDENT B20SC version). Used on the control panel to indicate the button that commands the activation of the brush motor but not of the solenoid valve.

- Page 8 SYMBOLS USED ON THE MACHINE Symbol indicating the position of the solution tank drain cap. Symbol indicating the position of the solution tank filter. Symbol indicating the position of the recovery tank drainage tube Detergent flow control symbol. Used on the machine to indicate the position of the lever used to control the flow of the detergent solution present in the water system.

-

Page 9: General Safety Regulations

GENERAL SAFETY REGULATIONS The regulations below must be carefully followed in order to avoid harm to the operator and damage to the machine. WARNING: Read the labels on the machine carefully. Do not cover them for any reason and replace them immediately if they become damaged. - Page 10 Do not mix different types of detergent as this may produce harmful gases. The machine is not suitable for cleaning carpets. Do not place any liquid containers on the machine. Avoid working with the brushes when the machine is standing still, so as not to damage the floor.

-

Page 11: Machine Preparation

The machine is contained in specific packaging with a pallet for the handling with fork trucks. The packages cannot be placed on top of each other. Gross weight of machine with packaging: version B: 207,23lb version BT: 202,67lb TRIDENT B20SC: 207,23lb The dimensions of the packaging are as follows: A= 40,06in B= 25,98in C= 56,30in 1. -

Page 12: How To Move The Machine

MACHINE PREPARATION 2. HOW TO MOVE THE MACHINE 1. Using a chute, mount the machine on the pallet. Carry out this operation with the rear squeegee and the brush detached from the machine. 2. Check the solution tank and recovery tank are empty; if necessary, empty them 3. -

Page 13: Control Panel Components (Version B)

MACHINE PREPARATION 5. Squeegee vacuum hose 6. Battery charger connector cable cap. 7. Recovery tank drainage tube 8. Control handlebar, with dead man's lever beneath. 9. Vacuum motor tube. 10. Recovery tank lifting handle. 11. Recovery tank cover 6. CONTROL PANEL COMPONENTS (VERSION B) The control panel components are identified as follows: 1. -

Page 14: Control Panel Components (Version Trident B20Sc)

6. Reverse button 7. Proportional solenoid valve control button. 8. Brush coupling/uncoupling button. 8. CONTROL PANEL COMPONENTS (VERSION TRIDENT B20SC) The control panel components are identified as follows: 1. Level indicator for battery/hour meter. 2. Main switch with three positions:. -

Page 15: Battery Maintenance And Disposal

BT version only), and remove the key from the instrument panel. Check that the machine's main switch at the back of the machine is in the “0” position; if not, turn to “0” (for TRIDENT B20SC version only). 3. Make sure the electric system connector (03) is disconnected from the battery connector; if not, disconnect it. - Page 16 MACHINE PREPARATION 10.Remove the vacuum cover and attach to the support designed for this purpose, positioned at the rear of the machine. 11.Remove the recovery tank from the machine, taking care with the drainage hose, and rest on a raised surface in order to avoid accidental damage.

-

Page 17: Connecting The Batteries And Battery Connector

BT version only), and remove the key from the instrument panel. Check that the machine's main switch at the back of the machine is in the “0” position; if not, turn to “0” (for TRIDENT B20SC version only). 4. Make sure the electric system connector (03) is disconnected from the battery connector; if not, disconnect it. - Page 18 MACHINE PREPARATION 7. Remove the recovery tank drainage tube (01) and lay on the ground. 8. Remove the vacuum motor tube (05) from the connector present on the recovery tank. 9. Remove the squeegee vacuum hose (06) from the hole in the recovery tank. 10.

-

Page 19: Connecting The Battery Charger (Versions With Bc)

BT version only), and remove the key from the instrument panel. Check that the machine's main switch at the back of the machine is in the “0” position; if not, turn to “0” (for TRIDENT B20SC version only). 4. Make sure the electric system connector (03) is disconnected from the battery connector; if not, disconnect it. -

Page 20: Battery Charge Level Indicator (B-Bt Versions)

(1) is flashing it indicates that the hour meter is counting the appliance's operating time. 18. BATTERY CHARGE LEVEL INDICATOR (TRIDENT B20SC VERSIONS) The control display is on the rear of the appliance. The graphic symbol that identifies the charge level of batteries appears at the bottom of the control display. -

Page 21: Forward Work Speed (Bt Versions)

Check that the machine's main switch at the back of the machine is in the “0” position; if not, turn to “0” (for TRIDENT B20SC version only). 4. Engage the parking brake by means of the lever on the right side of the machine (only for BT versions). -

Page 22: Assembling The Squeegee

MACHINE PREPARATION WARNING: Always use detergents whose manufacturer's label indicates their suitability for scrubbing machines. Do not use acid or alkaline products or solvents without this indication. Acid or alkaline maintenance detergents can be used, as long as they have pH values between four and ten, and do not contain oxidising agents, chlorine or bromine, formaldehyde, mineral solvents. -

Page 23: Assembling The Brush (B-Bt Versions)

WARNING: Check the brush is correctly inserted. If this is not the case, the machine could move in an irregular, sudden manner. 24. ASSEMBLING THE BRUSH (TRIDENT B20SC VERSIONS) To assemble the brushes of the brush head unit, proceed as follows: 1. -

Page 24: Work

WORK 26. PREPARING TO WORK (B-BT VERSIONS) Before beginning to work, it is necessary to: 1. Make sure the recovery tank is empty, otherwise empty it completely. 2. Check that the quantity of detergent solution in the solution tank is correct for the type of work to be carried out;... - Page 25 WORK During the first few meters, check that the speed is appropriate to the work to be carried out; if not, adjust after reading the section "ADJUSTING WORKING SPEED" (valid only for BT versions). During the first few meters, check that the detergent solution is appropriate to the work to be carried out; if not, adjust after reading the section "REGULATING THE DETERGENT SOLUTION (B versions)”...

-

Page 26: Preparing To Work (Trident B20Sc Versions)

WARNING: In order to recommence work, simply press the dead man's lever and the traction motor (BT version) and vacuum motor will restart. PREPARING TO WORK (TRIDENT B20SC VERSIONS) Before beginning to work, it is necessary to: 1. Make sure the recovery tank is empty, otherwise empty it completely. -

Page 27: Regulating The Detergent (B Version)

WORK If only the scrubbing function is needed, simply turn the button (04) on the control panel to "Pos.-02" and the vacuum motor will immediately cease to function. Once the scrubbing cycle is complete, turn the button (04) to "Pos.-01" to return to the scrub and dry function. -

Page 28: Regulating The Detergent (Bt Version)

WARNING! If the machine is switched off with the key operated main switch, the selected detergent flow will remain in the machine memory. 30. REGULATING THE DETERGENT (TRIDENT B20SC VERSION) Firstly, fully open the tap outflow, by means of the lever (01) on the right-hand side at the back of the machine. -

Page 29: Adjusting The Forward Working Speed (Bt Versions)

WORK 31. ADJUSTING THE FORWARD WORKING SPEED (BT VERSIONS) Proceed as follows to adjust the forward speed with the potentiometer: 1. Check that the speed regulation knob (1) is set to minimum. 2. Check that the brush head and squeegee are lifted off the ground 3. -

Page 30: Overflow Device (B-Bt Versions)

WORK If during the scrubbing operation the dead man's lever is released, the traction motor (BT version), the brush motor and the solenoid valve will cease to function. On the control display, the "O" symbol will remain visible. WARNING: In order to recommence work, simply press the dead man's lever and the traction motor (BT version), brush motor and solenoid valve will restart. -

Page 31: Overflow Device (Trident B20Sc Versions)

WARNING: this operation must be carried out wearing gloves to protect against contact with dangerous solutions. 37. EMPTYING THE RECOVERY TANK (TRIDENT B20SC VERSIONS) To regulate the detergent, proceed as follows: 1. First, take the machine to the designated place for draining off the dirty water. -

Page 32: At The End Of Work

AT THE END OF WORK 38. AT THE END OF WORK (B-BT VERSIONS) At the end of work, and before carrying out any type of maintenance, perform the following operations: 1. Switch off "AUTO" mode by pressing the button (01) on the instrument control panel. This will switch off the brush motor and the solenoid valve, while the vacuum motor will remain active for approximately 15 seconds before switching off automatically. - Page 33 AT THE END OF WORK 12. Attach the squeegee body to the squeegee connector. 13. Insert the vacuum hose (07) into the sleeve (08) on the squeegee body. 14. If necessary to empty the solution tank, unscrew the tap-filter (10) on the left-hand side of the machine, and when finished, re tighten.

-

Page 34: At The End Of Work (Trident B20Sc Versions)

AT THE END OF WORK 39. AT THE END OF WORK (TRIDENT B20SC VERSIONS) At the end of work, and before carrying out any type of maintenance, perform the following operations: 1. Switch off the vacuum motor using the switch (01) positioned on the rear of the machine. - Page 35 AT THE END OF WORK 11. Attach the squeegee body to the squeegee connector. 12. Insert the vacuum hose (07) into the sleeve (08) on the squeegee body. 13. If necessary to empty the solution tank, unscrew the tap-filter (10) on the left-hand side of the machine, and when finished, re tighten.

-

Page 36: Daily Maintenance

1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0” (valid for versions TRIDENT B20SC). 2. Disconnect the electrical connector (02) from the battery connector. -

Page 37: Cleaning The Brush (B-Bt Versions)

DAILY MAINTENANCE 2. Disconnect the electrical connector (02) from the battery connector. 3. Engage the parking brake by means of the lever (03) on the right side of the machine (only for BT versions). 4. Remove the vacuum cover (04) and position on the support (05) designed for this purpose, positioned at the rear of the machine. -

Page 38: Cleaning The Brush (Trident B20Sc Versions)

1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0” (valid for versions TRIDENT B20SC). 1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0”... - Page 39 DAILY MAINTENANCE 5. Remove the vacuum hose (05) from the vacuum nozzle (06) on the squeegee body. 6. Loosen the knobs (07) in the squeegee body pre-assembly. 7. Remove the squeegee body from the slits in the squeegee connector. 8. First with a jet of water and then with a damp cloth, thoroughly clean the vacuum chamber of the squeegee body.

-

Page 40: Weekly Maintenance

1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0” (valid for versions TRIDENT B20SC). 1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0”... - Page 41 WEEKLY MAINTENANCE 1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0” (valid for versions B-BT). 2. Make sure the recovery tank is empty, otherwise empty it completely. 3.

-

Page 42: Cleaning The Solution Tank

1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0” (valid for versions TRIDENT B20SC). 1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0”... -

Page 43: Emergency Maintenance

WARNING: During this operation, check there are no people or objects near the brush. 50. BRUSH REPLACEMENT (TRIDENT B20SC VERSIONS) An undamaged brush ensures a better working capacity, to replace it proceed as follows: 1. Make sure the recovery tank is empty, otherwise empty it completely. -

Page 44: Regulating Machine Direction

1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0” (valid for versions TRIDENT B20SC). 1. Switch off the power supply to the machine's electrical system using the main switch (01) located on the rear of the machine, turning the key to position “0”... -

Page 45: Adjusting The Squeegee Inclination

EMERGENCY MAINTENANCE 5. Remove the vacuum hose (05) from the vacuum nozzle (06) on the squeegee body. 6. Loosen the knobs (07) in the squeegee body pre-assembly. 7. Remove the squeegee body from the slits in the squeegee connector. WARNING: This operation must be carried out using gloves to protect against contact with dangerous solutions. -

Page 46: Troubleshooting

1. Check the state of wear and tear of the brushes and, if necessary, replace them. The brushes should be changed when the bristles are about 15mm. For replacing them, see the paragraph “REPLACING TRIDENT B20SC THE BRUSH (B and BT versions)” or else “REPLACING THE BRUSH (... -

Page 47: Disposal

DISPOSAL To dispose of the machine, take it to a demolition centre or an authorised collection centre. Before scrapping the machine it is necessary to remove and separate the following materials and send them to the appropriate collection centres in accordance with the environmental hygiene regulations currently in force: ... -

Page 48: Choosing And Using The Brushes

CHOOSING AND USING THE BRUSHES POLYPROPYLENE BRUSH (PPL) Used on all types of floor, it has good resistance to wear and tear and hot water (no greater than 140°F). PPL is non-hygroscopic and therefore retains its characteristics even when working in wet conditions. NYLON BRUSH Used on all types of floors. - Page 49 NOTES...

- Page 50 NOTES...

- Page 52 HILLYARD INDUSTRIES - PO Box 909 - St.Joseph, Missouri 64502-0909 U.S.A. - Telephone: 816-233-1321 - www.hillyard.com...

Need help?

Do you have a question about the TRIDENT B20SC and is the answer not in the manual?

Questions and answers