Summary of Contents for Spudnik 6160 WINDROWERS

- Page 1 OWNER / OPERATORS MANUAL 6160 WINDROWERS PART # 290248 This Manual covers Windrowers with Serial Numbers Beginning at: 6160-55-187 Revision: 7/29/2015...

- Page 3 Our mission is to consistently provide high quality, reliable safe and well-designed products serves to meet and exceed the needs of our customers. Service Centers Phone: (208) 785-0480 E-Mail: spudnik@spudnik.com Web Site: www.spudnik.com BLACKFOOT, ID (Corporate Headquarters) 584 West 100 North P.O. Box 1045...

-

Page 4: Table Of Contents

6160 W INDROWER WNER PERATORS ANUAL Table Of Contents Introduction ..............................iv Foreword ..............................v Warranty ..............................vi General ...............................vii Product Characteristics ..........................viii 1. Safety Exemption from Liability .......................1 Warning Symbols and other Instruction Notices ................1 General Guidelines ........................1 Identification of Important Instruction ...................2 Accident Prevention Guidelines ....................2... - Page 5 6160 W INDROWER WNER PERATORS ANUAL Table Of Contents Machine Adjustments ........................16 3.8.1 Intake Nose Blade ......................16 Nose Roller ......................16 Coulters ........................16 Depth Control ......................17 Ridge Relief ......................17 3.8.2 Primary Chain ........................17 3.8.3 Secondary Chain ......................

-

Page 6: Introduction

We strive to put the best quality and workmanship into each of our machines, and hope as you use your SPUDNIK WINDROWER, that you will find this to be true. This manual has been prepared to aid you in the safe operation and service of your machine. -

Page 7: Foreword

ANUAL Foreword This manual is intended to familiarize the user with the SPUDNIK WINDROWER and its designated use. This manual contains important information on how to operate the machine safely, properly, and efficiently. Observing the instructions in this manual help to avoid dangers, reduce repair costs and down-times, and to increase the reliability and service life of the machine. -

Page 8: Warranty

The selling dealer has no authority to make any representation or promise on behalf of Spudnik, or to modify the terms or limitations of this warranty in any way. -

Page 9: General

Unauthorized modification and the use of spare parts, accessories, and ancillary equipment not supplied and/or not approved by SPUDNIK, as manufacturer, can have detrimental effects on the construction of the machine or on the functions and hence impair the machine’s active and/or passive driving and operations safety (accident prevention). -

Page 10: Product Characteristics

SPUDNIK representative. Original spare parts and accessories approved by SPUDNIK are a contribution to safety and overall performance of the machine. The use of other parts may invalidate the liability of SPUDNIK for any consequences arising from such use. Please refer to the ‘Limited Warranty Policy for New Spudnik Machinery’... -

Page 11: Safety

IMPORTANT: Indicates instruction that must be followed to ensure proper operation or installation of SPUDNIK accepts no liability for any damage caused as a equipment result of operators not complying with the designated use of the machine. This also applies to damage of agricultural... -

Page 12: Identification Of Important Instruction

(accident prevention). Errors when carrying out maintenance or repair work. SPUDNIK shall not be liable for any damage caused by the use of parts, accessories, and ancillary equipment not Endangering the operator, or other nearby persons, supplied and/or approved by SPUDNIK. -

Page 13: Towing The Machine

6160 W INDROWER WNER PERATORS ANUAL Section-1 Safety 1.6 Towing the Machine 1.7 Using a PTO (power take off) Risk of injury when hitching up or unhitching machine to Observe the operating instruction of the PTO shaft and from the tractor. manufacturer. -

Page 14: Electrical System And Electronics

6160 W INDROWER WNER PERATORS ANUAL Section-1 Safety 1.8 Electrical System and Electronics 1.9 Hydraulic Systems The hydraulic system is under high pressure. Use only original fuses with the specified current rating. Switch off the machine immediately if a fault occurs in the Make sure that the hydraulic system is depressurized electrical power supply. -

Page 15: Maintenance And Inspection Guidelines

6160 W INDROWER WNER PERATORS ANUAL Section-1 Safety 1.10 Maintenance and Inspection Guidelines The securing of loads and the instruction of crane To prevent accidents, all relevant rules and regulations operators should only be entrusted to experienced concerning safe and competent working must be persons. -

Page 16: Acknowledgement Signature

6160 W INDROWER WNER PERATORS ANUAL Section-1 Safety 1.11 Acknowledgement Signature Anyone who will operate and/or maintain the equipment must read and clearly understand ALL Safety, Operating and Maintenance information presented in this manual. Do not operate or allow anyone else to operate this equipment until such information has been reviewed. -

Page 17: Machine Overview

The SPUDNIK 6160 WINDROWER has multiple options and configurations to meet the various needs of potato harvesting. The following sections will cover the machines specifications, overview, sticker and label locations, connection to tractor, operation, maintenance, cleaning and storage, and troubleshooting. -

Page 18: Machine Specifications

6160 W INDROWER WNER PERATORS ANUAL Section-2 Machine Overview 2.2 Machine Specifications OVERALL DIMENSIONS Height 6’-6” Width 23’-6” Length 31’-0” WEIGHT Machine (STD) 27,000LBS / (T-FLOAT) 33,300LBS Tongue (STD) 10,000LBS / (T-FLOAT) 13,500LBS TRACTOR REQUIREMENTS Tractor Power 170HP (MIN) Tractor PTO RPM 1000 Tractor Hydraulics (std windrower) 40GPM... -

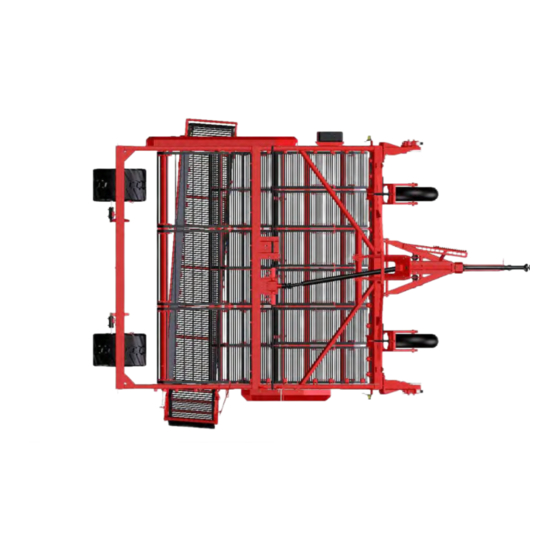

Page 19: Machine Components

6160 W INDROWER WNER PERATORS ANUAL Section-2 Machine Overview 2.4 Machine Components Secondary Chain Vine Chain Digger Nose Primary Chain Depth Wheel Coulter Rear Cross Discharge Rear Axle Rear Cross Rear Cross Discharge Digger Nose PART#: 290248 Revision: 7/29/2015... -

Page 20: Safety Stickers

Center stickers and labels as nearly as possible between the top and bottom on the frame. If stickers and labels become illegible or destroyed, replace them as soon as possible by contacting your local Spudnik dealer. To install labels;... - Page 21 6160 W INDROWER WNER PERATORS ANUAL Section-2 Machine Overview PART#: 290248 Revision: 7/29/2015...

-

Page 22: Operation

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation 3.1 Pre-Operation Checklist 3.2 Connecting / Disconnecting Machine Efficient and safe operation of this machine requires that each 3.2.1 Connecting to Tractor operator reads and understands the operating procedures and Before attaching the windrower to the tractor, verify that the all safety related precautions outlined in this manual. -

Page 23: Disconnecting From Tractor

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation 3.3 Drive Shaft Length The drive shaft needs to telescope when turning the machine or going up and down slopes or uneven terrain. Ensure drive shaft compressed length is not grater than 47-5/8” or drive shaft failure will occur. -

Page 24: Cx3 Introduction

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation 3.5 CX3 Introduction 3.5.4 Emergency Stop Switch Pushing this switch “IN” will disable the CX3 functions but 3.5.1 CX3 Overview leave the screens lit. The E-STOP button does not stop any of The CX3 console is made up of rocker switches, soft keys, two the functions that the tractor controls (PTO, remotes, etc.). -

Page 25: Transportation Of The Machine

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation 3.6 Transporting the Machine RH Primary Shaker; Up = increases right primary shaker speed The machine is designed to be easily moved between Down = decreases right primary shaker speed locations. -

Page 26: Machine Adjustments

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation 3.8 Machine Adjustments Coulters Coulters serve three main functions during the operation of the 3.8.1 Intake machine; Proper adjustment of the intake will help control potato To cut the vines and prevent wrapping on the front edge damage. -

Page 27: Depth Control

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation Depth Control 3.8.2 Primary Chain The digging depth of the machine is controlled with a form of The primary belted chain brings the potatoes out of the depth control. There are two types of depth control; ground and up to the secondary belted chain. -

Page 28: Vine Chain

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation 3.8.4 Vine Chain 3.8.7 Slip Clutches The vine chain carries the vines and trash to the ground at the WARNING! rear of the machine. An optional stripper kit or snapper roller can be added to the vine chain to assist in further potato and DO NOT turn the bolts more than a 1/4 of a turn without vine separation. -

Page 29: Strippers

6160 W INDROWER WNER PERATORS ANUAL Section-3 Operation Stripper To reverse the machine; Stripper is available to help remove potatoes from vines that Shut off PTO and wait for machine to come to a complete have traveled up the vine chain. stop. -

Page 30: Maintenance & Service

6160 W INDROWER WNER PERATORS ANUAL Section-4 Maintenance & Service 4.1 Service Record Sheet Copy this page for continued record of service. Refer to the following pages for detailed service recommendations. HOURS SERVICED BY MFR DAILY Vines and trash Hydraulic Leaks ... -

Page 31: Preventative Maintenance

6160 W INDROWER WNER PERATORS ANUAL Section-4 Maintenance & Service 4.2 Preventative Maintenance 4.3 Grease Grease all fittings before each use or when needed with a WARNING! good quality lubricant (Shell Retinax EP2 multipurpose grease or equivalent). DO NOT over grease sealed bearings. Over Place all controls in neutral or off, stop tractor engine, set greasing sealed bearings will damage seal. -

Page 32: Coulter Hubs And Coulter Pivot Points

6160 W INDROWER WNER PERATORS ANUAL Section-4 Maintenance & Service 4.3.4 Coulter Hubs and Coulter Pivot Points 4.6 Gearboxes Coulter hubs and pivot points have a grease WARNING! fitting for applying grease to the bearings. Coulter hubs and pivot points should be DO NOT change or add oil while the gear drive is running. -

Page 33: Belted Chain

6160 W INDROWER WNER PERATORS ANUAL Section-4 Maintenance & Service 4.8 Belted Chain 4.9 Tire and Wheels WARNING! WARNING! Extensive damage to belted chain will occur if a foreign Repair work to the wheels should only be carried out by a object gets caught in the belted chain and the slip qualified tire dealer or tire repair service technician. -

Page 34: Cleaning And Storage

6160 W INDROWER WNER PERATORS ANUAL Section-5 Cleaning and Storage 5.1 Cleaning after every operation 5.3 Storage of the machine In order to keep wear down to a minimum, follow the Perform the actions described above. instructions given below: ... -

Page 35: Troubleshooting

6160 W INDROWER WNER PERATORS ANUAL Section-6 Troubleshooting 6.1 Troubleshooting Procedure Be sure to check all the basic items before working your way into deeper troubleshooting procedures. Verify that the following items are in correct working order before proceeding; Hydraulic hoses are fully connected to tractor and that there are no leaks or faulty couplers/connections. - Page 36 6160 W INDROWER WNER PERATORS ANUAL Section-6 Troubleshooting Area Problem Possible Cause Solution Leaking hydraulic hose. Repair or replace hose. Hydraulic fitting leaking. Check fittings and tighten if loose. Hydraulic controlled components Tighten packing nuts on end of cylinder. If leak Hydraulic creep.

-

Page 37: Miscellaneous Guidelines And Specifications

Reliance on the torque charts below are at the sole pins of the same grade are used. risk of that person. Spudnik is not responsible for any loss claim or damage arising from following the reference torque specifications in these torque charts. -

Page 38: Hydraulic Fitting Torque Guidelines And Specifications

The tightening torques given in the table below should be adhered to when tightening, replacing, or repairing any Hydraulic Fittings. There are two methods to achieve proper ‘clamp load’ to the flare connections used on SPUDNIK machinery; 1. Torque; torque hydraulic fitting using a torque wrench. -

Page 39: Belted Chain Repair Procedure

6160 W INDROWER WNER PERATORS ANUAL Section-7 Miscellaneous Guidelines and Specifications 7.5 Belted Chain Repair Procedure The following illustrates a typical repair of a belted chain. Though belted chain components may vary, the assembly is generally the same. Connecting Rod Drill holes Cover Belt Clip... - Page 46 584 West 100 North P.O. Box 1045 Blackfoot, ID 83221 Phone (208) 785-0480 Fax (208) 785-1497 www.spudnik.com...

Need help?

Do you have a question about the 6160 WINDROWERS and is the answer not in the manual?

Questions and answers