Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Woods TURFKEEPER TK60.20

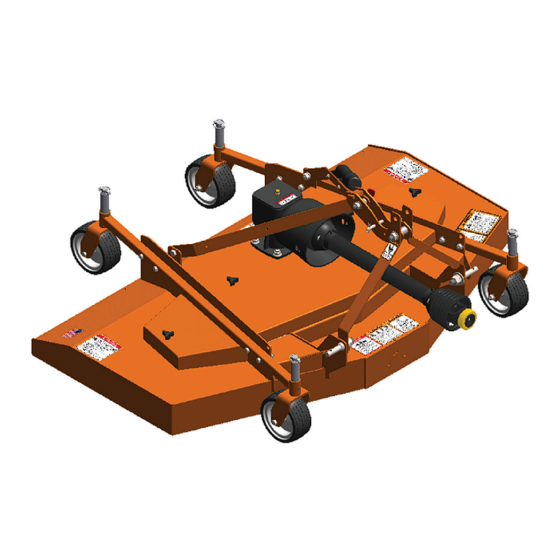

- Page 1 TURFKEEPER™ FINISH MOWER TK60.20 TK72.20...

-

Page 2: Introduction

The dealer must complete the online Product Registration form at the Woods Dealer Website which certifies that all Dealer Check List items have been completed. Dealers can register all Woods product at dealer.WoodsEquipment.com under Product Registration. -

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION..........2 SPECIFICATIONS . -

Page 4: Specifications

SPECIFICATIONS TK60.20 TK72.20 3-Point Hitch Cat.1 Cat. 1 Quick Hitch Compatible Factory Ready Factory Ready Cutting Width 60" 72" Cutting Height Range 1-1/2" - 5" 1-1/2" - 5" Operating Weight with Chain Shielding 481 lbs 538 lbs Deck Plate Thickness 10 GA 10 GA Blade Speed (feet per minute) -

Page 5: Safety 5

SAFETY RULES ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! ■ Always wear relatively tight and belted clothing to avoid entanglement in moving parts. Wear Safety is a primary concern in the design and man- sturdy, rough-soled work shoes and protec- ufacture of our products. -

Page 6: Operation

SAFETY RULES ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! OPERATION ■ Keep hands, feet, hair, and clothing away from equipment while engine is running. Stay clear of ■ Full chain shielding is recommended when op- all moving parts. erating in populated areas or other areas where ■... -

Page 7: Transportation

SAFETY RULES ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! ■ Do not carry children, even with the blade(s) ■ Keep all persons away from operator control shut off. Children could fall off and be seriously area while performing adjustments, service, or injured or interfere with safe machine operation. -

Page 8: Safety & Instructional Decals

SAFETY & INSTRUCTIONAL DECALS ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Replace Immediately If Damaged! CD9092 11 - 20106 - Rear Reflector 3 - Serial Number Plate 12 - 13726 2 - 18869 1 - 15503 5 - 626798 10 - 33347 8 - 1032450 9 - 1004114 DANGER... - Page 9 Replace safety decals if they are missing or illegible. Replacement safety decals can be ordered free from your Woods dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in the United States and Canada call 1-800-319-6637.

-

Page 10: 10 Operation

■ If driveline is too short, please call your Woods dealer for a longer driveline. ■ Keep all persons away from operator control area while performing adjustments, service, or ■... - Page 11 Category 1 Hitch (Figure 2 & 3) 1. Align tractor lower lift arms with mower cantilever hitch pins. 2. Install tractor lower lift arms over cantilever pins and retain with klik pin. 3. Attach tractor top link to mower top link attachment point with top link pin.

-

Page 12: Installation And Removal Of Driveline (Tractor Pto)

10. Remove the mower driveline from the holder and CAUTION connect to the tractor PTO shaft. Be sure the drive- line QD is seated firmly in the tractor PTO spline groove. ■ To avoid damage to cutter or driveline, make sure driveline holder is properly stored before 11. -

Page 13: Shortening Driveline

1. Raise the mower slowly with the tractor hydraulics to 16" at dimension C, Figure 8, or maximum height of tractor lift, whichever is less. 2. Pivot both front caster wheels forward and check that there is clearance between caster wheels and tractor tires. -

Page 14: Driveline Interference Check

IMPORTANT: If attaching with quick hitch, the dis- Table 1: Cutting Height Chart tance between the tractor PTO and gearbox input shaft will increase. Follow the steps as you would Spacers Required Under for a 3-point hitch to ensure proper engagement. Caster Arm Pivot Tube Cut Height 1/2"... -

Page 15: Pre-Operation Checklist

PRE-OPERATION CHECKLIST OPERATING TECHNIQUE (OWNER’S RESPONSIBILITY) CAUTION Review and follow all safety rules and safety de- cal instructions on page 5 through page 9. Starting and Stopping Check that all safety decals are installed and in 1. Power for operating the mower is supplied by the good condition. -

Page 16: Operating Tips

OPERATING TIPS REMOVING MOWER FROM TRACTOR (STORAGE) WARNING Follow cleaning procedure on page 21. ■ Inspect and clear area of stones, branches, or 1. Disengage tractor PTO and raise mower with the other hard objects that might be thrown, caus- 3-point hitch. -

Page 17: Owner Service 17

OWNER SERVICE The information in this section is written for operators When blocking, you must consider overall stability of who possess basic mechanical skills. If you need help, the unit. Just blocking under the unit will not ensure your dealer has trained service technicians available. your safety. - Page 18 Driveshaft Lubrication 4. Insert grease gun and give 2 to 3 full pumps of grease. Lubricate the driveshaft slip joint every 40 operating 5. Locate grease access holes in the tractor end joint hours. Failure to maintain proper lubrication could re- bellows.

-

Page 19: Belt Servicing

BELT SERVICING Install Belt Inspect Belt CAUTION One of the major causes of belt failure is improp- ■ Use care when installing or removing belt from er installation. Before installing a new belt, check the spring-loaded idler. Springs store energy when following: extended and, if released suddenly, can cause personal injury. -

Page 20: Blade Servicing

BLADE SERVICING 1. Follow original sharpening pattern. 2. Do not sharpen blade to a razor edge, but leave ap- proximately 1/64" blunt edge. WARNING 3. Do not sharpen back side of blade. ■ Before dismounting power unit or perform- 4. Sharpen both cutting edges equally to keep blade ing any service or maintenance, follow these balanced. -

Page 21: Cleaning

■ Replace any safety decals that are missing • If this machine is not equipped with full chain or not readable (supplied free by your Woods shielding, operation is recommended to be dealer). stopped when anyone comes within 300 feet (92 m). -

Page 22: Troubleshooting

TROUBLESHOOTING MOWING CONDITIONS PROBLEM POSSIBLE CAUSE SOLUTION Grass cut higher in center Height of mower higher Adjust mower height and attitude of swath than at edge at front than at rear so that mower rear and front are within 1/2 inch of same height. See instructions on page 14. - Page 23 TROUBLESHOOTING BELT CONDITIONS PROBLEM POSSIBLE CAUSE SOLUTION Belt squealing Mower overloading; Reduce tractor ground speed material too tall or heavy but maintain full PTO RPM. Cut material twice, one high pass and then mow at desired height. Cut 90-degrees to first pass. Oil on belt from over lubricating Be careful not to over lubricate.

-

Page 24: 24 Dealer Service

DEALER SERVICE The information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, you may be time and money ahead to replace complete assemblies. -

Page 25: Gearbox Repair

GEARBOX REPAIR Read this entire section before starting any repair. Many steps are dependent on each other. Fill gearbox with SAE 80W or 90W gear lube until it runs out the side level plug. Gearbox capacity is almost 4 pints. Repair to this gearbox is limited to replacing bearings, seals, and gaskets. - Page 26 Incorrect Installation CD9099 CD1092 CD1092 1. Seal 2. Pipe or tube CD1094 3. Seal seat 4. Casting Pipe or tube must press at outer edge of seal Figure 22. Seal Installation Figure 23. Gearbox Stand Assembly 1. Seal 2. Snap ring 3.

- Page 27 Horizontal Shaft Seal Replacement (Figure 24) 9. Support housing in vise in a horizontal position. 1. Disconnect and remove the driveline from the 10. The castle nut (23) and cotter pin (24) are already gearbox. removed with the drive sheave. Remove the snap ring (18), washer (20), and seal (19).

-

Page 28: Fill Gearbox

5. Install spacer (16), lower output bearing (13), shims 3. Slide gearbox onto gearbox stand. When gearbox (17), and snap ring (18) in bottom of housing. is installed on mower, dimension A (from the top of mower deck to the center line of the drive pulley) 6. -

Page 29: Universal Joint Repair

UNIVERSAL JOINT REPAIR 1. Yoke 2. Cup and bearings 3. Snap ring 4. Journal cross CD1386 Figure 28 CD1645A Figure 26. U-Joint Exploded View U-Joint Disassembly 1. Remove external snap rings from yokes in four loca- tions as shown in Figure 27. CD1387 Figure 29 CD1385A... - Page 30 U-Joint Assembly 1. Place seals securely on bearing cups. Insert cup into yoke from outside and press in with hand pressure as far as possible. Insert journal cross into bearing cup with grease fitting away from shaft. Be careful not to disturb needle bearings. Insert another bear- ing cup directly across from first cup and press in as far as possible with hand pressure.

-

Page 31: Assembly

Assembly of this mower is the responsibility of the removing sight plug in the side of box and confirm Woods dealer. It should be delivered to the owner com- oil level even with bottom of sight plug. pletely assembled, lubricated, and adjusted for normal cutting conditions. - Page 32 25, 26, 27 31,38,4,5 3, 67, 4, 5 CD9100 52, 60, 61, 62, 63 34, 35, 37 3. 5/8 NC x 1-1/2 cap screw CD9102 4. 5/8 SAE flat washer 29, 33 5. 5/8 NC lock nut 24. Rear offset links 5/8 SAE flat washer 5/8 NC lock nut 25.

- Page 33 Driveshaft Installation DANGER 1. Orient the driveline with the implement end toward the mower gearbox. The implement end uses the ■ Full chain shielding is recommended when op- female profile tube (large), which is covered by the erating in populated areas or other areas where smaller profile shield (plastic tube).

- Page 34 Install Rear Anti-Scalp Roller (Optional) 1. Kit supplied with roller angle brackets for both TurfKeeper and TurfKeeper Pro mowers. TurfKeeper brackets are 1.50" wide. TurfKeeper Pro brackets are 1.75" wide. 2. Use opposite roller angle bracket for drill template. Position RH roller angle bracket (7) at LH rear cor- ner of deck.

-

Page 35: Dealer Checklists

DEALER CHECKLISTS DEALER PRE-DELIVERY CHECKLIST (DEALER’S RESPONSIBILITY) Inspect the equipment thoroughly after assembly to Check all bolts to be sure they are properly ensure it is set up properly before delivering it to the torqued. customer. Check that all cotter pins and safety pins are properly installed. -

Page 36: Parts Index

PARTS INDEX Turfkeeper Finish Mowers: ™ TK60.20 TK72.20 MAIN FRAME ASSEMBLY ......37 - 38 GEARBOX ASSEMBLY . - Page 37 TK60.20 & TK72.20 MAIN FRAME ASSEMBLY CD9105 AF Parts 37 MAN1299 ( 06/20/2023 )

- Page 38 53591 SAFETY DECAL SET (NOT SHOWN) 613743 613744 MODEL DECAL SET (NOT SHOWN) 613745 613745 WOODS DECAL, 2.50 X 13.13 (NOT SHOWN) HHCS, 3/8 NC X 1-1/2 GR5 ZP 636622RP 636622RP BELT GUIDE, TKXX.20 38 Parts MAN1299 ( 06/20/2023 )

- Page 39 TK60.20 & TK72.20 GEARBOX ASSEMBLY S/N 1000888006500 OR LOWER CD6500 PART DESCRIPTION PART DESCRIPTION 1006648 COMPLETE GEARBOX 39251 SNAP RING 1007861 SNAP RING 20900 SEAL 1007865 SHIM KIT 20888 WASHER, 1.58 X 3.13 X .04 51850 BALL BEARING 20897 SNAP RING INPUT SHAFT 20893 WASHER 25 X 44 X 4 MM...

- Page 40 TK60.20 & TK72.20 GEARBOX ASSEMBLY S/N 10008880065001 AND UP CD9318 AA PART DESCRIPTION 611563RP GEARBOX, COMPLETE 637529 BEARING, BALL 39275 SEAL, 35 X 62 X 10 1018326 BEARING, BALL 20900 OIL SEAL 64803 3/16 X 2 COTTER PIN NUT, FLANGE CASTLE 618208 M24 X 2.0P 39325...

- Page 41 TK60.20 & TK72.20 DRIVELINE ASSEMBLY S/N 1000888006500 OR LOWER CD8869 PART DESCRIPTION 601752 COMPLETE DRIVELINE ASY 1044050 LOCK COLLAR REPAIR KIT 1044052 CROSS & BEARING KIT 605261 OUTER YOKE & TUBE 605262 INNER YOKE & TUBE 605263 OUTER SHIELD WITH BEARING 605264 INNER SHIELD WITH BEARING 605784...

- Page 42 TK60.20 & TK72.20 DRIVELINE ASSEMBLY S/N 10008880065001 AND UP CD8869 G PART DESCRIPTION 621089 COMPLETE DRIVELINE 605289 LOCK COLLAR REPAIR KIT 611564 CROSS & BEARING KIT 638217 SHIELD KIT, COMPLETE 42 Parts MAN1299 ( 06/20/2023 )

- Page 43 TK60.20, TK72.20 BLADE & SPINDLE ASSEMBLY TK60.20 TK72.20 DESCRIPTION HHCS 3/8 NC X 12169 12169 1-1/4 GR5 ZP 70005 70005 WASHER, CUP W70072 W70072 KEY, SQUARE SHEAVE 4.00 616067 ----- PD X 1.00 B SHEAVE 4.75 ----- 616064 PD X 1.00 B NUT, 3/8 NC FLANGE 14350 14350...

- Page 44 TK60.20 & TK72.20 REAR CHAIN SHIELDING ASSEMBLY (OPTIONAL) TKP60.40 TKP72.40 DESCRIPTION CHAIN SHIELD KIT, 616077 616076 COMPLETE 613771 ----- SHIELD, CHAIN PLATE ----- 613772 SHIELD, CHAIN PLATE 4763 ----- CHAIN, 3-LINK 1/4 PROOF ----- 4763 CHAIN, 3-LINK 1/4 PROOF 1007855 ----- PIN, 49 TO 51 CHAINS -----...

- Page 45 TK60.20 & TK72.20 REAR ANTI-SCALP ROLLER ASSEMBLY (OPTIONAL) PART DESCRIPTION 618210 REAR ROLLER KIT, COMPLETE 13563 HHCS, 1/2 NC X 6 GR5 1029865 ROLLER, 2 X 4.38 11900 NUT, 1/2 NC FLANGE LOCKNUT 3598 1/2 FLAT WASHER SAE 6697 BOLT, CARRIAGE, 3/8 NC X 1 14350 NUT, 3/8 NC FLANGE LOCKNUT TKP REAR ROLLER...

- Page 46 NOTES 46 Parts MAN1299 ( 06/20/2023 )

-

Page 47: Index 47

INDEX Assembly Operation 10 Dealer Set-up Instructions 31 Adjustment Gearbox Cutting Height 14 Fill Gearbox 28 Cutting Height Chart 14 Install Tractor Top Link 14 Chain Shielding 33 Attaching Mower to Tractor 10 Driveshaft 33 Pre-Operation Checklist 15 Front Roller 33 Front Caster Wheel Interference Check 12 Hitch Kit 32 Front Roller 14... -

Page 48: Appendix

BOLT TORQUE CHART Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for metric hardware. Make sure fastener threads are clean and you start thread engagement properly. -

Page 49: Bolt Size Chart

BOLT SIZE CHART Notice: Chart shows bolt thread sizes and corresponding head (wrench) sizes for standard SAE and metric bolts. SAE BOLT THREAD SIZES 5/16 10mm 12mm 14mm 16mm 18mm METRIC BOLT THREAD SIZES ABBREVIATIONS AG ......Agriculture HT . - Page 50 Woods logo are trademarks of Woods Equipment Company. All other ® trademarks, trade names, or service marks not owned by Woods Equipment Company that appear in this manual are the property of their respec tive companies or mark holders. Specifications subject to change without notice.

Need help?

Do you have a question about the TURFKEEPER TK60.20 and is the answer not in the manual?

Questions and answers