Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK VERO-S NSR3 138

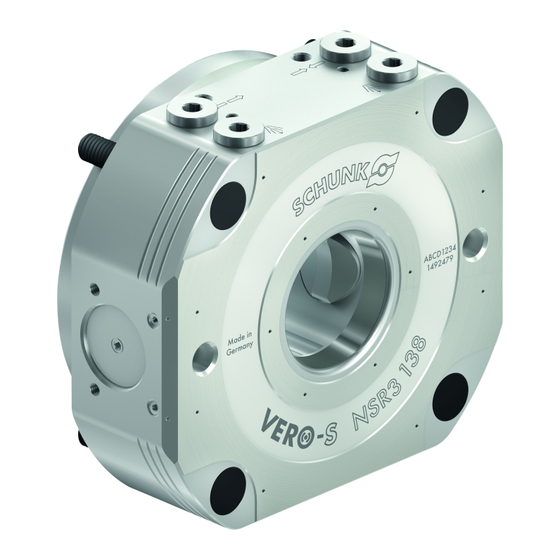

- Page 1 Translation of Original Operating Manual VERO-S Robot Coupling for Pallet Handling NSR3 138 / PKL 138 Assembly and Operating Manual...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 1509378 Version: 02.00 | 25/01/2023 | en...

-

Page 3: Table Of Contents

Table of Contents Table of Contents General........................ 5 Presentation of Warning Labels................ 5 Applicable documents.................. 6 Basic safety notes ..................... 7 Intended use ...................... 7 Not intended use .................... 7 Notes on particular risks .................. 8 Notes on safe operation .................. 10 2.4.1 Holding force and screw strength............ - Page 4 Table of Contents 10 Assembly drawings .................... 49 11 Monitoring ...................... 52 12 Cone seal ........................ 53 13 Declaration of incorporation................... 56 14 Appendix on Declaration of Incorporation .............. 57 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

-

Page 5: General

General 1 General This operating manual is an integral component of the product and contains important information on safe and proper assembly, commissioning, operation, care, maintenance and disposal. This manual must be stored in the immediate vicinity of the product where it is accessible to all users at all times. -

Page 6: Applicable Documents

• General terms of business * • Catalog data sheet of the purchased product * The documents labeled with an asterisk (*) can be downloaded from schunk.com. 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378... -

Page 7: Basic Safety Notes

The VERO-S robot coupling for pallet handling is not being used as intended if, for example: • It is used as load handling or lifting equipment. • it is used for turning applications without consulting SCHUNK. • It is used as a quick-change pallet system for milling applications without consulting SCHUNK. -

Page 8: Notes On Particular Risks

Basic safety notes 2.3 Notes on particular risks • Disconnect the power supply lines and ensure that there is no residual energy in the system before performing assembly, modification, maintenance, or adjustment work. • Do not move parts by hand when the energy supply is connected. - Page 9 Basic safety notes WARNING The system clamps using spring force. Risk of injury due to parts automatically moving to their end positions following actuation of an "emergency stop" or after switching off the power supply. Wait for the system to shut down completely. •...

-

Page 10: Notes On Safe Operation

If the robot coupling is to be operated in an environment with abrasive dusts or corrosive or caustic fumes or fluids, prior approval must be obtained from SCHUNK. Safety during assembly and servicing During assembly, connection, adjustment, commissioning and testing, make sure that no accidental operation of the robot coupling by the fitter or other persons is possible. -

Page 11: Holding Force And Screw Strength

This is why only screws of strength class 12.9 may be used. Only original SCHUNK clamping pins may be used. If the clamping pin is to be used in customer-specific devices, the customer must provide a sufficiently dimensioned pallet coupling or a sufficiently thick mounting material. -

Page 12: Using Personal Protective Equipment

Only allow specialists to remedy malfunctions. Spare parts Only use original SCHUNK spare parts. Environmental regulations The applicable environmental regulations must be observed for all maintenance and repair work. -

Page 13: Warranty

Warranty 3 Warranty If the product is used as intended, the warranty is valid for 24 months from the ex-works delivery date under the following conditions: } 1.2 [ / 6] • Observe the applicable documents, • Observe the ambient conditions and operating conditions •... -

Page 14: Scope Of Delivery

Scope of delivery 4 Scope of delivery • Robot coupling for pallet handling NSR3 138 • Translation of Assembly and Operating Manual • Accessory kit NSR3 138 4 cover plugs 8 O-rings Ø 6 x 1.5 3 screws DIN EN ISO 4762 - M8 x 45 - 10.9 1 fitting screw M8 x 45 4.1 Accessories (see catalog or data sheets when ordering separately) -

Page 15: Technical Data

Technical data 5 Technical data 5.1 NSR3 138 Designation / type Robot coupling NSR3 138 1492479 Max. torque Mx with PKL 138 * 1500 Nm Max. torque Mx with PKL 160 * 600 Nm Max. torque Mz * 1600 Nm Pull down force without turbo 8.0 kN Pull down force with Turbo... -

Page 16: Nsr3 138

Technical data 5.2 Calculation of Permissible Transport Load The robot coupling is limited to a maximum permissible torque at the coupling interface. The dynamic load when using the robot system for handling results in acceleration and deceleration forces that have to be taken into consideration for the transport load. To operate the robot coupling with dynamic handling, it is essential for the maximum acceleration of the machine to be known. - Page 17 Technical data Calculating the acceleration force: Maximum permissible torque for NSR3 138: M = 1500* Nm Result of calculation: Taking into account the robot acceleration, the loading weight obtained in the calculation example is permissible. * When using the PKL 138. If the PKL 160 is used, reduced load values apply (} 5.1 [ / 15]).

-

Page 18: Assembly

Assembly 6 Assembly Pre-assembly measures Carefully lift the product out of the packaging (e.g. with suitable lifting equipment). CAUTION Risk of injury due to sharp edges and rough or slippery surfaces Wear personal protective equipment, particularly protective gloves. Check that the delivery is complete and that there is no transport damage. -

Page 19: Screw Tightening Torques

Assembly 6.1 Screw tightening torques For mounting the robot coupling on the robot flange: Screw size Strength class Tightening torque [Nm] 10.9 For fastening the clamping pin to the pallet coupling: Screw size Strength class Tightening torque [Nm] 12.9 For fastening the clamping pallet to the pallet coupling: Screw size Strength class Tightening torque [Nm]... -

Page 20: General Installation Notes

Assembly 6.2 General installation notes Request our installation drawings if doing the installation yourself. If several linked clamping units are mounted, make sure that the flatness and height deviation of the locating surface from module to module (based on a gauge of 200 mm) lies within 0.01 mm. NOTE When connecting the quick-change pallet systems, ensure that it is only possible to completely ventilate the piston chamber via the... - Page 21 Assembly Mounting NSR3 138 A: Cylindrical screw (3x) B: Fitting screw for position orientation diagonally offset C: O-rings for sealing the direct connections on the bottom side D: Customized robot flange E: Locking screw G1/8 The air connection takes place via the G1/8 coupling holes at the side as standard.

- Page 22 Assembly A: Unlocking connection on the bottom side B: Turbo connection on the bottom side C: Cleaning air connections on the bottom side D: Unlocking connection on side G1/8 E: Turbo connection on side G1/8 F: Cleaning air connections on side G1/8 G: Torque pin variant I via mold inclines on both sides H: Torque pin variant II via cylindrical pins I: Air outlets cleaning function...

-

Page 23: Unlocking Connection

Assembly J: Thread M5 K: Holes for mounting screws ISO 4762 - M8 L: Hole for fitting screw M8 M: Locating surface for pallet coupling When the turbo connection is used, the spring-actuated locking procedure is actively supported with air pressure. If the turbo connection is not used, the relevant side of the piston must be able to ventilate. -

Page 24: Air Purge Connection With Cleaning Function

Assembly 6.3.3 Air purge connection with cleaning function For interface cleaning, the NSR3 138 has two side air purge connections with G1/8 connection thread and 2 hose-free direct connections on the bottom side. The side air connections must be closed with G1/8 locking screws when not in use. The hose-free direct connections on the bottom side must be sealed with O-rings (Item 32;... -

Page 25: Pneumatic Circuit Diagram

Assembly 6.3.4 Pneumatic circuit diagram NSR3 138 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378... -

Page 26: Coupling Interface

Assembly A: Actuation with 6 bar (also on the bottom side via hose-free direct connections) B: 15 l/min C: Exhaust air max. 6 bar (also on the bottom side via hose-free direct connections) D: Pneumatic circuit symbols E: 5/3 directional control valve, center position ventilated F: 3/2 directional control valve G: Pressure switch H: Pressure gauge... - Page 27 Assembly Torque pin version I 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 28 Assembly Torque pin variant II 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 29 E: Torque pin variant II: Position orientation by means of alignment pins and fitting bores F: Pallet coupling PKL 160 Only an original SCHUNK clamping pin may be mounted on the coupling interface with the designated mounting screw. (The screw must be tightened with the specified torque } 6.1 [ /...

-

Page 30: Pallet Adapters

Assembly 6.4.1 Pallet adapters The pallet coupling PKL 138 (ID 1492512) was designed as a pallet changing interface for the robot coupling NSR3 138. Alternatively, the PKL 160 (ID 0471930) can also be used in conjunction with the robot coupling NSR3 138, but with reduced permissible moment Mx. - Page 31 Assembly 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 32 Assembly A: Clamping pin SPA 40-16 B: Screw-in depth C: Contact surface on robot module D: Lag screw E: Mounting screw DIN EN ISO 4762 - M16 - 12.9 F: Bearing surface for clamping pallet G: Centering slants for torque pin variant I H: Alignment pin 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 33 Assembly 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 34 Assembly A: Clamping pin SPA 40-16 B: Screw-in depth C: Contact surface on robot module D: Lag screw E: Mounting screw DIN EN ISO 4762 - M16 - 12.9 F: Bearing surface for clamping pallet G: Centering slants for torque pin variant I 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 35 Assembly Connection interface between the clamping pallet and pallet coupling PKL 138 * The clamping pallet height must be at least 35 mm. 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 36 Assembly A: Clamping surface of clamping pallet B: Screw-in depth Connection interface between the clamping pallet and pallet coupling PKL 160 * The clamping pallet height must be at least 25 mm. A: Clamping surface of clamping pallet B: Screw-in depth 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

-

Page 37: Specific Pallet Coupling

M16 screw, strength class 12.9. The specified screw torque must be observed } 6.1 [ / 19]. Only original SCHUNK clamping pins may be used. • If the clamping pin is to be used in customer-specific devices, •... - Page 38 3: Screw DIN EN ISO 4762 - M16 - 12.9 4: Customized pallet or device, steel version 5: Customized pallet or device, aluminum version 6: Steel washer (SCHUNK) Tolerances and installation conditions for installation in a customer-specific pallet coupling SPA 40-16 0471064 >...

-

Page 39: Application Example For Automated Pallet Loading

Assembly 6.6 Application example for automated pallet loading The NSR3 138 clamping system was designed for automated pallet loading. The robot coupling, with the handling system, is the interface between the machine work area and pallet rack. Application example for automated pallet loading A: Robots B: Robot flange C: Robot coupling NSR3 138... -

Page 40: Connection And Disconnection Of Transport Loads

Assembly 6.6.1 Connection and disconnection of transport loads The following must be taken into account during automated connection and disconnection of transport loads: • Approach the coupling interfaces between the robot module and robot coupling or clamping pallet and clamping station at an early stage without a tilt angle and eccentricity (see illustration above) •... - Page 41 Assembly Automated connection and disconnection of transport loads A: Position the clamping pallet on the clamping station or remove it from the clamping station B: Traverse path of the movement axes during loading C: Clamping pallet D: Clamping station E: Connect or disconnect pallet coupling F: Robot module unlocked during coupling process, switch on blast air (cleaning function) during loading 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en |...

-

Page 42: Maintenance And Care

Risk of injury and risk of damage to the clamping module when opening the housing cover. If the clamping module has to be disassembled, ship the module to SCHUNK for repair. The cover of the clamping module is spring pre-loaded and must only be removed by trained specialist personnel. -

Page 43: Regular Inspection Of Robot And Pallet Coupling

Maintenance and care 7.1 Regular Inspection of Robot and Pallet Coupling A visual inspection of the robot coupling and the associated PKL pallet coupling for possible damage to the components must be carried out at regular intervals. This visual inspection must be carried out every 50,000 clamping cycles. -

Page 44: Troubleshooting

Defective air connections Check air supply Pressure below minimum Check operating pressure (min. 5 bar) A component is broken (e.g. due to Replace the module or send it to SCHUNK for overloading) repair Excess tensile load on clamping pins Reduce support weight... - Page 45 Troubleshooting The cone seal does not seal Possible cause Solution(s) Sealing ring is damaged or deformed Remove seal and replace sealing ring Sealing ring is damaged Initiate loading and unloading process only when clamping slides are fully retracted Sealing ring insufficiently splayed when Ensure that the components are installed in the closing the clamping module correct position...

-

Page 46: Wearing Parts Kit And Parts Lists

The bearing shells may only be replaced in case of damage as part of maintenance work by SCHUNK. To do so, the quick-change pallet module must be sent to SCHUNK for maintenance. 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en |... -

Page 47: Parts List

Wearing parts kit and parts lists 9.2 Parts list NSR3 138 (ID 1492479) Item Description Quantity Base body NSR3 138 Cover Clamping slide Piston Plug Slide washer O-ring Ø 20 x 1.5 O-ring Ø 42 x 3.5 O-ring Ø 94.5 x 3.5 Round cord section Ø... - Page 48 Wearing parts kit and parts lists PKL 138 (ID 1492512) Item Description Quantity Base body PKL 138 Screw DIN EN ISO 4762 - M12 x 90 - 10.9 Cylindrical pin Ø 12 x 32 Clamping pin SPA 40-16 Screw DIN EN ISO 4762 - M12 x 35 - 12.9 M12 cover plug Washer PKL 160 PKL 160 (ID 0471930)

-

Page 49: Assembly Drawings

Assembly drawings 10 Assembly drawings NSR3 138 * Accessories to be ordered separately 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378... - Page 50 Assembly drawings KVS 40 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 51 Assembly drawings PKL 138 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

-

Page 52: Monitoring

Monitoring 11 Monitoring Robot coupling NSR3 138 is prepared for monitoring the pallet presence and clamping slide positions by the AFS3-R IOL monitoring module (ID 1491363). Pallet presence monitoring is compatible with pallet couplings PKL 138 (ID 1492512) and PKL 160 (ID 0471930). Notes on mounting and teaching the monitoring module can be found in the corresponding operating manual, which is included in the scope of delivery of the AFS3-R IOL. -

Page 53: Cone Seal

Cone seal 12 Cone seal To install the cone seal in the NRS 138, the recessed plug must first be removed from the change interface and replaced with the supplied cover with sealing ring. The installation takes place according to the following installation description and the illustrations "Operational sequence of installation of cone seal"... - Page 54 Cone seal 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

- Page 55 Cone seal A: Sealing ring spread for sealing B: Clamping slide in closed position, without clamping pin C: Sealing ring unclamped, prepared for loading D: Clamping slide unlocked E: Clamping pin clamped, clamping module closed 02.00 | NSR3 138 / PKL 138 | VERO-S Robot Coupling for Pallet Handling | en | 1509378...

-

Page 56: Declaration Of Incorporation

13 Declaration of incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Hersteller/ H.-D. SCHUNK GmbH & Co. Spanntechnik KG Inverkehrbringer Lothringer Str. 23 D-88512 Mengen We hereby declare that on the date of the declaration the following partly completed machine complied with all basic safety and health regulations found in the directive 2006/42/EC of the European Parliament and of the Council on machinery. -

Page 57: Appendix On Declaration Of Incorporation

Appendix on Declaration of Incorporation 14 Appendix on Declaration of Incorporation in accordance with 2006/42/EC, Appendix II, no. 1 B as well as in accordance with the Supply of Machinery (Safety) Regulations 2008. 1. Description of the basic safety and health protection requirements, as per 2006/42/EC, Annex I and per the Supply of Machinery (Safety) Regulations 2008, that apply to and are fulfilled for the scope of the incomplete machine: Product designation Quick-change pallet system... - Page 58 Appendix on Declaration of Incorporation Protection against mechanical hazards 1.3.4 Risks due to surfaces, edges or angles 1.3.5 Risks related to combined machinery 1.3.6 Risks related to variations in operating conditions 1.3.7 Risks related to moving parts 1.3.8 Choice of protection against risks arising from moving parts 1.3.8.1 Moving transmission parts 1.3.8.2 Moving parts involved in the process 1.3.9...

- Page 59 Appendix on Declaration of Incorporation Maintenance 1.6.5 Cleaning of internal parts Information 1.7.1 Information and warnings on the machinery 1.7.1.1 Information and information devices 1.7.1.2 Warning devices 1.7.2 Warning of residual risks 1.7.3 Marking of machinery 1.7.4 Instructions 1.7.4.1 General principles for the drafting of instructions 1.7.4.2 Contents of the instructions 1.7.4.3 Sales literature The classification from Annex 1 is to be supplemented from here...

- Page 60 Translation of Original Operating Manual H.-D. SCHUNK GmbH & Co. Spanntechnik KG Lothringer Str. 23 D-88512 Mengen Tel. +49–7572-7614-0 Fax +49-7572-7614-1099 info@de.schunk.com schunk.com Folgen Sie uns I Follow us...

Need help?

Do you have a question about the VERO-S NSR3 138 and is the answer not in the manual?

Questions and answers