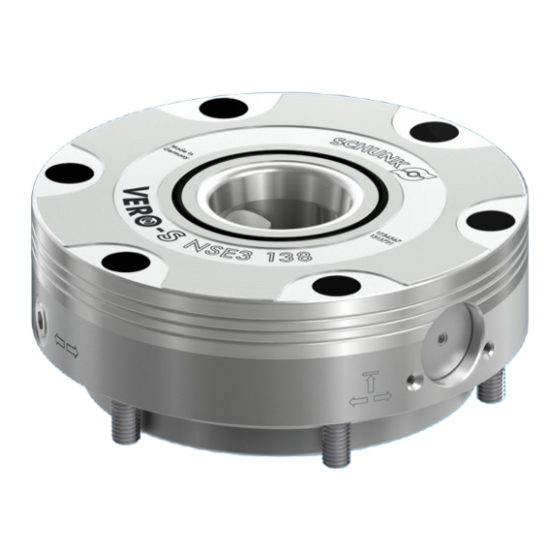

SCHUNK NSE3 Assembly And Operating Manual

Vero-s quick-change pallet system

Hide thumbs

Also See for NSE3:

- Assembly and operating manual (79 pages) ,

- Assembly and operating manual (62 pages) ,

- Assembly and operating manual (60 pages)

Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK NSE3

- Page 1 VERO-S quick-change pallet system NSE3, NSE-T3 Assembly and Operating Manual Translation of Original Operating Manual...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK SE & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 1152197 Version: 11.00 | 09/10/2023 | en...

-

Page 3: Table Of Contents

4.3.3 Size NSE3 138 (except NSE3 138-P and NSE3 138-P-K) ......25 4.3.4 Variants NSE3 138-P and NSE3 138-P-K ..........26 4.3.5 Size NSE-T3 138 ................27 4.3.6 Size NSE3 176 ................28 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 4 8.5 Malfunctions when loading and unloading the change interface with fitted cone seal ... 46 8.6 The cone seal does not seal ..............46 8.7 The media transfer unit of the NSE3 138-P is not working......46 9 Seal kit and part lists ................47 9.1 Sealing Kit List ..................

-

Page 5: General

Dangers for persons! Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. CAUTION Material damage! Information about avoiding material damage. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 6: Applicable Documents

} 7 [/ 44] Parts touching the workpiece and wear parts are not included in the warranty. * A cycle consists of a complete clamping process ("Open" and "Close"). 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 7: Scope Of Delivery

– NSE3 100-75, NSE3 100-75-K: 3 O-rings Ø 4 x 1.5, 4 cover plugs, 2 mounting screws M8, 2 fitting screws M8 – NSE3 138, NSE3 138-K, NSE3 176, NSE3 176-K : 4 O-rings Ø 9 x 1.5, 6 cover plugs, 6 fastening screws M8 –... -

Page 8: Basic Safety Notes

Modifications, changes or reworking, e.g. additional threads, holes, or safety devices, can damage the product or impair its functionality or safety. Structural changes should only be made with the written approval of SCHUNK. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 9: Spare Parts

Only use high-quality cooling emulsions with anti-corrosive additives during processing. Protect the cone seal from direct high spray pressure with cooling emulsion. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 10: Personnel Qualification

Wear protective gloves and safety goggles when handling hazardous substances. Wear close-fitting protective clothing and also wear long hair in a hairnet when dealing with moving components. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 11: Notes On Safe Operation

Do not recommission the product until the malfunction has been rectified. Test the product after a malfunction to establish whether it still functions properly and no increased risks have arisen. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 12: Disposal

Falling loads may cause serious injuries and even death. Stand clear of suspended loads and do not step into their swiveling range. Never move loads without supervision. Do not leave suspended loads unattended. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 13: Protection During Commissioning And Operation

Before starting up the machine or automated system, check that the EMERGENCY STOP system is working. Prevent operation of the machine if this protective equipment does not function correctly. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 14: Notes On Particular Risks

Use a crane or a transport truck when transporting workpieces or clamping pallets. During horizontal or overhead applications, the device or clamping pallet must be secured before loosening to prevent it from falling. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 15 There is a risk of limbs being crushed by moving parts during manual loading and unloading and the clamping procedure. Do not reach into the clamping pin holder. Use loading devices. Wear protective gloves. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 16: Product Description

Noise emission [dB(A)] ≤ 70 Pressure medium Compressed air, compressed air quality according to ISO 8573-1:2010 [7:4:4] Protection class IP 67 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 17 For an air volume of 1000 liters, the compressed air should be prepared with 1 to 2 drops of oil . This corresponds to approx. 1400 clamping cycles with NSE3 138. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 18: Suitability For Welding Applications

Coupling stroke: 4.5 mm Coupling force at 0 bar: min. 94 N NSE3 138-P-K 1337167 Loading weight per module: min. 200 N Coupling function can be connected when depressurized 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 19: Assembly

Before starting all work on the product, refer to the cone seal chapter. } 4.3.7 [/ 30] Make sure that components of the gate unit are fitted in accordance with the installation guidelines and safely locked in place. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 20: Fastening And Connection

(SPC 40) must be used (also refer to the chapter "Clamping pins"} 4.4 [/ 31]). 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 21 One pressure pulse is sufficient to increase the force. The pressure line 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

- Page 22 To pull the clamping module out of the installation space, two levering tools (e.g. long cylindrical screws) are screwed diagonally into two existing internal threads of the mounting holes. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 23: Size Nse3 99

Open ⑤ must be sealed against the flat bearing surface with O-rings Ø4.5 x 1.5. Partial installation Full installation All clamping systems of equal height within 0.02 mm Clearance for fitting screw 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 24: Size Nse3 100-75

Open ⑤ must be sealed against the flat bearing surface with O-rings Ø4.5 x 1.5. Partial installation Full installation All clamping systems of equal height within 0.02 mm Clearance for fitting screws 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 25: Size Nse3 138 (Except Nse3 138-P And Nse3 138-P-K)

O-rings Ø9 x 1.5. Partial installation Full installation All clamping systems of equal height within 0.02 mm Clearance for fitting screw for variants with anti-rotation protection 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 26: Variants Nse3 138-P And Nse3 138-P-K

They are actuated on the bottom of the module. O-rings are used in the transfers units for sealing. Partial installation Full installation All clamping systems of equal height within 0.02 mm Clearance for fitting screws (if used) 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 27: Size Nse-T3 138

All clamping systems of equal height within 0.02 mm Clearance for cylindrical pins for variants with anti- rotation protection 5 mm only for variants with anti-rotation protection 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 28: Size Nse3 176

O-rings Ø9 x 1.5. Full installation Partial installation All clamping systems of equal height within 0.02 mm Clearance for fitting screw for variants with anti-rotation protection 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 29: Kvs 40 Cone Seal

Clamping pins clamped, Sealing ring clamped, clamping module closed prepared for loading Clamping slide unlocked Check the cone seal when loading with the clamping pallet. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 30 (2 bar) Direct connection from the installation space with a seal to the cone seal via the O-ring Ø6 x 5.5 (scope of delivery KVS 40) 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 31: Clamping Pins Spa 40, Spb 40, Spc 40, Spg 40

NSE3 99 64 mm NSE3 100-75 75 mm NSE3 138 68 mm NSE-T3 138 68 mm NSE3 176 68 mm 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 32 0471066 > 13 > 18 > 18 > 24 > 16 * The length of the screwed-in thread must not exceed the dimension "G" under any circumstances! 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

- Page 33 Furthermore, the customer workpiece or the clamping pallet must always have the described flatness. The clamping pin type B may deviate in its twisting position by max. +/-10°. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 34: Information To Clamping Pin Spg 40

When connecting the screws from above, a 10 mm longer M12 screw of strength class 12.9 must be used according to the mounting option on the left in the illustration. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 35: Nse3 Dynamic Pressure Monitoring Of The Clamping Slide Position

Before beginning the machining process, ensure that the integrated clamping modules are locked, and that the clamping pallet is placed flat on the bearing surface. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 36: Pneumatics Circuit Diagram

Clamping slide monitoring at 2 bar Air purge / contact monitoring at 2 bar 10 Blow-out air cleaning function, 3 to 6 bar Air purge / exhaust air (M7 connection) integrated 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 37 Check the control components of the monitoring functions at regular intervals. If errors occur in the monitoring control system, you must detect the cause of the error. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 38: Screw Tightening Torques

Screw size Tightening torque (Nm) Tightening torques for the plug and cover conversion parts in the clamping pin mounting Component Plug (basic version) Bottom cover Tightening torque (Nm) 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 39: Afs 138 Electronic Monitoring Systems (Optional)

NSE3 138 without torque pin V1. For size NSE3 138 with torque pin V1 is only possible to mount an AFS3 138 MMS opposite the torque pin slot. - Page 40 Assembly Metallically dense Metallically dense ring contact surface ring contact surface 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 41: Function

Coupling elements must be depressurized during the coupling process. Pressure may only be transmitted to the clamping device when the clamping pallet on the clamping modules is fully locked. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 42 After some minutes, the coupling system is ready. For further information, please visit https://hydraulische-komponenten.de/en/coupling-technology/ coupling-elements.html. How to exchange the system seal of the clutch conversion 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

-

Page 43: Operation

Before starting any work on the product: Switch off the energy supply and secure against re-connection. Ensure that no residual energy remains in the system. Do not actuate media transfer units until loading is completed. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 44: Maintenance And Care

The system may only be commissioned again once the faults have been removed. For example, by replacing the damaged unit. 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 45: Troubleshooting

Increase the pressing force on the coupling connection until a flat contact surface has been achieved on the module Clamping pallet is not flat Check installation position of coupling elements 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 46: Malfunctions When Loading And Unloading The Change Interface With Fitted Cone Seal

Clamping pallet is not resting flat on the Ensure that the media transfer units are modules depressurized and ventilated 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 47: Seal Kit And Part Lists

V1 / V1-K Fitting screw V1 / V1-K Cover plug Parts list key NSE3 99 V1-K NSE3 99-V1-K NSE3 99-K Included in the sealing kit NSE3 99-K 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 48: Size Nse3 100-75

O-ring O-ring O-ring Cylindrical screw Locking screw O-ring Cylindrical screw Countersunk screw Cylindrical pin Parts list key 100-75 NSE3 100-75 Included in the sealing kit NSE3 100-75-K 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 49: Size Nse3 138 And Nse-T3 138

Parts list key NSE3 NSE3 138 -K -Variant NSE-T3 NSE-T3 138 -V4 -Variant all -V1 / -V4 / -P Variants Included in the sealing kit -P -Variant Spare part 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 50: Size Nse3 176

Pressure spring Expander Set screw Locking screw Cylindrical screw all, except V1- variants Cylindrical screw Parts list key -K -Variants Included in the sealing kit -V1 Variants 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 51: Cone Seal Kvs 40 (Id 1313742)

Parts list key X Included in the sealing kit * Component for sealing within the installation space for the Z Included in the supply of blow-out air accessory kit 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 52: Assembly Drawings

Assembly Drawings 10 Assembly Drawings 10.1 Size NSE3 99 NSE3 99, NSE3 99-V1 NSE3 99-K, NSE3 99-V1-K *** NSE3 99-V1, NSE3 99-V1-K 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 53: Size Nse3 100-75

Assembly Drawings 10.2 Size NSE3 100-75 NSE3 100-75 NSE3 100-75-K 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 54: Size Nse3 138

NSE3 138, NSE3 138-V1, NSE3 138-4, NSE3 138-P ** NSE3 138-K, NSE3 138-V1-K, NSE3 138-V4, NSE3 138-V4-K, NSE3 138-P-K *** NSE3 138-V1, NSE3 138-V1-K, NSE3 138-V4, NSE3 138-V4-K, NSE3 138-P, NSE3 138-P-K **** Spare part: System seal red, Accessories: Assembly tool, available for seal replacement... -

Page 55: Size Nse-T3 138

Assembly Drawings 10.4 Size NSE-T3 138 NSE3 138, NSE3 138-V1, NSE3 138-V4 NSE3 138-K, NSE3 138-V1-K, NSE3 138-V4-K *** NSE3 138-V1, NSE3 138-V1-K, NSE3 138-V4, NSE3 138-V4-K 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 56: Size Nse3 176

Assembly Drawings 10.5 Size NSE3 176 NSE3 176, NSE3 176-V1 NSE3 176-K, NSE3 176-V1-K *** NSE3 176-V1, NSE3 176-V1-K 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... -

Page 57: Kvs 40 Cone Seal

Assembly Drawings 10.6 KVS 40 cone seal 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197... - Page 58 11.00 | NSE3, NSE-T3 | VERO-S quick-change pallet system | en | 1152197...

- Page 59 H.-D. SCHUNK GmbH & Co. Spanntechnik KG Lothringer Str. 23 D-88512 Mengen Tel. +49-7572-7614-0 info@de.schunk.com schunk.com Folgen Sie uns I Follow us Wir drucken nachhaltig I We print sustainable...

- Page 60 Type designation: NSA, NSE, E-compact, AV CU, Heinz-Dieter SCHUNK GmbH & Co. Spanntechnik KG certifies that the above-mentioned products, when used as intended and in compliance with the operating manual and the warnings on the product, are safe according to the national regulations and: −...

Need help?

Do you have a question about the NSE3 and is the answer not in the manual?

Questions and answers