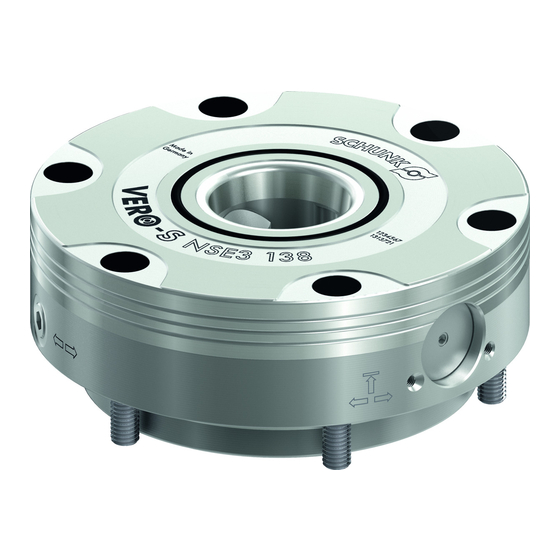

SCHUNK VERO-S NSE3 Series Assembly And Operating Manual

Quick-change pallet system

Hide thumbs

Also See for VERO-S NSE3 Series:

- Assembly and operating manual (79 pages) ,

- Assembly and operating manual (60 pages) ,

- Assembly and operating manual (60 pages)

Summary of Contents for SCHUNK VERO-S NSE3 Series

- Page 1 Translation of Original Operating Manual VERO-S quick-change pallet system NSE3, NSE-T3 Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of contents Table of contents 1 General ........................5 1.1 About this Manual ....................5 1.1.1 Illustration of safety notes ................5 1.1.2 Applicable documents ................... 6 1.1.3 Versions ......................6 1.2 Warranty ........................6 1.3 Scope of delivery ...................... 7 1.4 Accessories ....................... - Page 4 Table of contents 4.3.3 NSE3 138-P, NSE3 138-P-K ................29 4.3.4 NSE-T3 138, NSE-T3 138-K ................31 4.3.5 NSE-T3 138-V1, NSE-T3 138-V1-K, NSE-T3 138-V4, NSE-T3 138-V4-K ..32 4.3.6 Cone seal KVS3 138 ..................34 4.4 Clamping pins SPA 40, SPB 40, SPC 40, SPG 40 ............37 4.4.1 Notes on clamping bolt SPG 40 ..............

-

Page 5: General

General General About this Manual This manual contains important information for the safe, correct use of the product. The manual is an integral part of the product and must be kept accessible by personnel at all times. Personnel must have read and understood this manual before beginning any work. -

Page 6: Applicable Documents

• General terms of business* • Catalogue data sheet of the rotary indexing table * • Technical data sheet for optional attachments * The documents indicated with an asterisk (*) can be downloaded from schunk.com. 1.1.3 Versions This guide applies to the following versions Quick-Change Pallet System •... -

Page 7: Scope Of Delivery

General Scope of delivery The scope of delivery includes: Quick-change pallet system in the variant ordered • Accessory kit – NSE3 138, NSE3 138-K, NSE3 138-P, NSE3 138-P-K: 4 O-rings Ø 9 x 1.5, 6 cover plugs, 6 M8 fastening screws –... -

Page 8: Basic Safety Notes

Implementation of structural changes Modifications, changes or reworking, e. g. additional threads, holes, or safety devices, can damage the product or impair its functionality or safety. • Structural changes should only be made with the written approval of SCHUNK. 04.00|1152197 NSE3, NSE-T3 |en-US... -

Page 9: Spare Parts

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts and spares authorized by SCHUNK. Ambient conditions and operating conditions Required ambient conditions and operating conditions... -

Page 10: Personnel Qualification

Basic safety notes Personnel qualification Inadequate qualification of personnel Work on the product by inadequately qualified personnel can lead to serious injuries and considerable material damage. • Order all work to be performed only by appropriately qualified personnel. • Personnel must have read and understood the complete manual before beginning any work on the product. -

Page 11: Notes On Safe Operation

Basic safety notes • Observe the valid safety and accident prevention regulations. • Wear protective gloves to guard against sharp edges and corners or rough surfaces. • Wear heat-resistant protective gloves when handling hot surfaces. • Wear protective gloves and safety goggles when handling hazardous substances. -

Page 12: Malfunctions

Basic safety notes 2.10 Malfunctions Behavior in case of malfunctions • Immediately remove the product from operation and report the malfunction to the responsible departments/persons. • Order appropriately trained personnel to rectify the malfunction. • Do not recommission the product until the malfunction has been rectified. -

Page 13: Protection During Handling And Assembly

Basic safety notes 2.12.1 Protection during handling and assembly Incorrect handling and assembly Incorrect handling and assembly can make the product unsafe and risk the danger of serious injuries and considerable material damage. • Order all work to be performed only by appropriately qualified personnel. -

Page 14: Protection Against Dangerous Movements

Basic safety notes 2.12.3 Protection against dangerous movements Unexpected movements If the system still retains residual energy, serious injuries can be caused while working on the product. • Switch off the energy supply, ensure that no residual energy remains and secure against inadvertent reactivation. •... - Page 15 Basic safety notes WARNING Risk of injury due to falling device, pallet or workpiece if the clamping pin is loosened inadvertently or as a result of negligence. • During operation, incorrect or negligent loosening of the clamping pin must be prevented using suitable countermeasures (disconnecting the power supply after locking, use of check valves or safety switches).

- Page 16 Basic safety notes WARNING The quick-change pallet system clamps using spring force. Risk of injury due to parts automatically moving to their end positions following actuation of an "emergency stop" or after switching off the power supply. • Wait for the system to shut down completely. •...

- Page 17 Basic safety notes CAUTION There is a risk of limbs being crushed by moving parts during manual loading and unloading and the clamping procedure. • Do not reach into the clamping pin holder. • Use loading devices. • Wear protective gloves. 04.00|1152197 NSE3, NSE-T3 |en-US...

-

Page 18: Product Description

Product description Product description Description of design and version Clamping module Equipment type Basic Torque Torque Cone Media pin V1 pin V4 seal transfer unit version NSE3 138 NSE3 138-K NSE3 138-V1 NSE3 138-V1-K NSE3 138-V4 NSE3 138-V4-K NSE3 138-P NSE3 138-P-K NSE-T3 138 NSE-T3 138-K... - Page 19 Product description NSE-T3 138 1313726 35 kN / 50 kN / 75 kN 7 kN 24 kN NSE-T3 138-K 1313727 35 kN / 50 kN / 75 kN 7 kN 24 kN NSE-T3 138-V1 1313728 35 kN / 50 kN / 75 kN 7 kN 24 kN NSE-T3 138-V1-K...

-

Page 20: Special Approval For Nse3 138

Machinery Directive. If the quick-change pallet system is to be used outside these voltage and current limits, contact your SCHUNK contact person. Technical data for coupling elements of media transfer unit Designation... -

Page 21: Assembly

Assembly Assembly Pre-assembly Request our installation drawings if installing the module in the customer's clamping stations yourself. The installation position must be observed when performing the installation yourself. Partial installation Do not use Full installation NOTICE With installation location 2, the clamping slide can be blocked by chips and dirt. - Page 22 Assembly WARNING Risk of injury due to unexpected movements when installing and removing the cone seal! This can cause components to move unexpectedly when working on the cone seal, resulting in injuries. • Before starting all work on the product, refer to the cone seal chapter.

-

Page 23: Mounting And Connection

Assembly Mounting and connection Flatness If several linked clamping modules are mounted, make sure that the flatness and height deviation of the outer ring bearing surfaces from clamping module to clamping module (with respect to a 200 mm gauge) is ≤ 0.03 mm. The gauge deviation may not exceed ± 0.015 mm. - Page 24 Assembly Ventilation via turbo connection, ventilation via the cover Ventilation via lid in version with cone seal Applies to NSE3 138-K /-V1-K /V4-K /-P-K Turbo connection When using the turbo connection (if supply is connected), the spring actuated locking procedure is actively supported with air pressure, thereby enhancing the achievable pull down force.

-

Page 25: Nse3 138, Nse3 138-K

Assembly bottom of the module. O-rings are used to seal the channel bores against the bearing surface. NOTE If the media transfer function is used, ensure that the coupling elements are depressurized and ventilated when loading and unloading the clamping pallet. Before starting the machining process, ensure that the change unit rests flat on the bearing surface of the quick-change pallet system and is locked. - Page 26 Assembly openings must be sealed. To do so, insert the Ø 9 x 1.5 O-rings into the module and seal the bottom direct connections against the flat bearing surface. 04.00|1152197 NSE3, NSE-T3 |en-US...

-

Page 27: Nse3 138-V1, Nse3 138-V1-K, Nse3 138-V4, Nse3 138-V4-K

Assembly 4.3.2 NSE3 138-V1, NSE3 138-V1-K, NSE3 138-V4, NSE3 138-V4-K Fastening in the installation space with 6 M8 screws. The assembly module can be positioned by means of two centering diameters of the installation space: Ø 110 H6 in the lower range. For partial and full installation. Ø... - Page 28 Assembly Alternative connection option: Two side G1/8" connections which are free when the lower centering diameter Ø 110 H6 is used. In this case, the bottom openings must be sealed. To do so, insert the Ø 9 x 1.5 O-rings into the module and seal the bottom direct connections against the flat bearing surface.

-

Page 29: Nse3 138-P, Nse3 138-P-K

Assembly 4.3.3 NSE3 138-P, NSE3 138-P-K Fastening in the installation space with 6 M8 screws. The assembly module can be positioned by means of two centering diameters of the installation space: Ø 110 H6 in the lower range. For partial and full installation. Ø... - Page 30 Assembly 04.00|1152197 NSE3, NSE-T3 |en-US...

-

Page 31: Nse-T3 138, Nse-T3 138-K

Assembly 4.3.4 NSE-T3 138, NSE-T3 138-K Fastening in the installation space with 6 M8 screws. The assembly module can be positioned by means of two centering diameters of the installation space: Ø 110 H6 in the lower range. For partial and full installation. Ø... -

Page 32: Nse-T3 138-V1, Nse-T3 138-V1-K, Nse-T3 138-V4, Nse-T3 138-V4-K

Assembly 4.3.5 NSE-T3 138-V1, NSE-T3 138-V1-K, NSE-T3 138-V4, NSE-T3 138-V4- Fastening in the installation space with 6 M8 screws. The assembly module can be positioned by means of two centering diameters of the installation space: Ø 110 H6 in the lower range. For partial and full installation. Ø... - Page 33 Assembly 04.00|1152197 NSE3, NSE-T3 |en-US...

-

Page 34: Cone Seal Kvs3 138

Assembly 4.3.6 Cone seal KVS3 138 To install the cone seal in the NSE3, NSE-T3, the recessed plug must first be removed from the change interface and replaced with the supplied cover with sealing ring The installation takes place according to the following installation description and the illustrations "Operational sequence of installation of cone seal"... - Page 35 Assembly Sequence when inserting the cone seal 04.00|1152197 NSE3, NSE-T3 |en-US...

- Page 36 Assembly Check cone seal for loading with clamping pallet Check cone seal for loading with clamping pallet The air connection for the blow-out air / air purge is achieved via the base M7 connection thread with installation of a screw-in union.

-

Page 37: Clamping Pins Spa 40, Spb 40, Spc 40, Spg 40

If clamping pins are used outside of SCHUNK pallets, for example in customer-specific devices or workpieces, the outer diameter of the part to be clamped must be large enough to completely cover... - Page 38 Assembly Note It must be ensured that the customer's device or the workpiece is covered in a width direction fully covers the outer support area of the quick-change pallet system on both sides. Designation type Min. outer diameter on the support of the workpiece NSE3 138 /-K /-V1 /-V1-K /-V4 68 mm...

- Page 39 Assembly * The length of the screwed thread must not exceed the dimension "G" under any circumstances! Usage/arrangement of the different types of clamping pins 04.00|1152197 NSE3, NSE-T3 |en-US...

-

Page 40: Notes On Clamping Bolt Spg 40

Assembly 4.4.1 Notes on clamping bolt SPG 40 The SPG 40 can be used at a clamping area instead of the SPA 40. If there are several clamping areas, only the clamping area with clamping bolt type SPA may be exchanged for the SPG 40. The repeat accuracy increases to <... - Page 41 Assembly Dynamic pressure NSE3 138 / NSE3 138-K / NSE3 138-V1 / NSE3 138-V1-K / NSE3 138-P / NSE3 138-P-K NSE3 138, NSE3 138-V1, Rework on the plug required NSE3 138-V4, NSE3 138-P NSE3 138-K, NSE3 138-V1-K, M7 connection thread NSE3 138-V4-K, integrated NSE3 138-P-K...

-

Page 42: Pneumatics Circuit Diagram

Assembly Pneumatics circuit diagram Pneumatic circuit diagram with media transfer unit for pneumatics, hydraulics, vacuum Unlocking connection Turbo connection Slide monitoring for module "OPEN" Slide monitoring for module "CLAMPED" Media transfer unit 1 for pneumatics and hydraulics as well as vacuum, can be connected when depressurized Media transfer unit 2 for pneumatics and hydraulics as well as vacuum, can be connected when depressurized... - Page 43 Assembly Observe the following when controlling the NSE3 and NSE-T3 quick-change pallet systems: Turbo function: • The actuating pressure for the turbo function must not exceed 6 bar. Clamping slide monitoring with NSE3 138: • The max. pressure for clamping slide monitoring is 2 bar. •...

-

Page 44: Screw Tightening Torques

Assembly control components. Check the control components of the monitoring functions at regular intervals. If errors occur in the monitoring control system, you must detect the cause of the error. Screw tightening torques Tightening torques for mounting clamping pins (Screw quality 12.9) Screw size Tightening torque (Nm) Tightening torques for mounting clamping modules... -

Page 45: Dynamic Pressure Monitoring For Workpiece Planar Contact Monitoring For Nse3-K, Nse-T3-K

Assembly Dynamic pressure monitoring for workpiece planar contact monitoring for NSE3-K, NSE-T3-K With the NSE3 138-K, NSE-T3 138-K, the cone seal can be used for workpiece planar contact monitoring. Step-by-step sequence of the function with series-connected dynamic pressure monitoring of multiple modules. Example with 2 modules: 1 Remove the O-ring on the bearing surface of all clamping modules intended for monitoring, use the O-ring assembly tool... - Page 46 Assembly 04.00|1152197 NSE3, NSE-T3 |en-US...

-

Page 47: Function

Function Function The item numbers specified for the corresponding individual components relate to the drawing in chapter "Drawings" ( 10, Page 57). KVS3 138 cone seal The -K versions of the NSE3 and NSE-T3 quick-change pallet systems are equipped with a cone seal to protect the change interface. - Page 48 Function to the clamping device when the clamping pallet is fully locked on the clamping modules. During the coupling process, make sure that the coupling elements are positioned in alignment to each other. 04.00|1152197 NSE3, NSE-T3 |en-US...

-

Page 49: Operation

In this case, the system must be inspected and damaged parts must be replaced immediately. Only original SCHUNK spare parts may be used! WARNING Risk of injury due to losing pallets or workpieces in the case of incorrect actuation caused by incorrect operation. - Page 50 Operation WARNING Risk of injury due to losing pallets or workpieces if the supply of compressed air drops or fails, and due to the clamping pins immediately closing • Do not reach into the clamping module. • Use pressure maintenance valves. •...

-

Page 51: Maintenance And Care

If the clamping module has to be disassembled, send the module to SCHUNK for repair. The back cover of the clamping module is spring preloaded and must only be removed by trained specialist personnel. The cover... -

Page 52: Troubleshooting

Defective air connections Check air supply Pressure below minimum Check operating pressure (min. 5 bar) A component is broken (e.g. due to Replace the module or send it to SCHUNK for overloading) repair Excess tensile load on clamping pins Reduce support weight... -

Page 53: Malfunctions When Loading And Unloading The Change Interface With Fitted Cone Seal

Troubleshooting Malfunctions when loading and unloading the change interface with fitted cone seal Possible cause Solution(s) Cone seal jams when actuated Remove cone seal from the module and clean The pressed down cone seal does not Remove cone seal and clean it. Check return to its original position components for damage. -

Page 54: Wearing Parts Sets And Parts Lists

The bearing shells may only be replaced in case of damage as part of maintenance work by SCHUNK. To do so, the quick-change pallet module must be sent to SCHUNK for maintenance. Parts lists... - Page 55 Wearing parts sets and parts lists O-ring O-ring O-ring Ø 28 x 1 O-ring, Ø 9 x 1.5 O-ring, Ø 9 x 1.5 Slide bearing collar bushing Cylindrical pin Cylindrical screw Compression spring Set-screw Set-screw Set-screw Cylindrical screw G1/8" locking screw Cylindrical pin Cylindrical screw Cylindrical screw...

- Page 56 Wearing parts sets and parts lists Cone seal KVS3 138 (ID 1313742) Item Designation Quantity Mount Thrust washer Cover plate Cover Sealing ring Compression spring Countersunk screw O-ring Ø 28 x 1 O-ring Ø 6 x 1.5 O-ring Ø 6 x 5.5 O-ring Ø...

-

Page 57: Assembly Drawings

Assembly drawings Assembly drawings Assembly NSE3 138, NSE3 138-K, NSE3 138-V1, NSE3 138-V1- 10.1 K, NSE 138-V4, NSE3 138-V4-K, NSE3 138-P, NSE3 138-P-K 04.00|1152197 NSE3, NSE-T3 |en-US... -

Page 58: Assembly Nse-T3 138, Nse-T3 138-K, Nse-T3 138-V1, Nse-T3 138-V1-K, Nse-T3 138-V4, Nse-T3 138-V4-K

Assembly drawings 10.2 Assembly NSE-T3 138, NSE-T3 138-K, NSE-T3 138-V1, NSE-T3 138-V1-K, NSE-T3 138-V4, NSE-T3 138-V4-K 04.00|1152197 NSE3, NSE-T3 |en-US... -

Page 59: Cone Seal Kvs3 138

Assembly drawings 10.3 Cone seal KVS3 138 04.00|1152197 NSE3, NSE-T3 |en-US... -

Page 60: Declaration Of Incorporation

Declaration of Incorporation in accordance with Directive 2006/42/EC, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ H.-D. SCHUNK GmbH & Co. Spanntechnik KG distributor Lothringer Str. 23 D-88512 Mengen We hereby declare that on the date of the declaration the following partly completed... -

Page 61: Appendix On Declaration Of Incorporation, As Per 2006/42/Ec, Annex Ii, No. 1 B

Appendix on Declaration of Incorporation, as per 2006/42/EC, Annex II, No. 1 B Appendix on Declaration of Incorporation, as per 2006/42/EC, Annex II, No. 1 B 1. Description of the basic safety and health protection requirements, as per 2006/42/EC, annex I, that apply to and are fulfilled for the scope of the incomplete machine: Product designation: Quick-Change Pallet System VERO-S... - Page 62 Appendix on Declaration of Incorporation, as per 2006/42/EC, Annex II, No. 1 B 1.4.2.1 Fixed isolating protective equipment 1.4.2.2 Moving isolating protective equipment with locking 1.4.2.3 Adjustable protective equipment that restricts access 1.4.3 Special requirements for non-isolating protective equipment Risks from other hazards 1.5.1 Electrical energy supply 1.5.2...

Need help?

Do you have a question about the VERO-S NSE3 Series and is the answer not in the manual?

Questions and answers