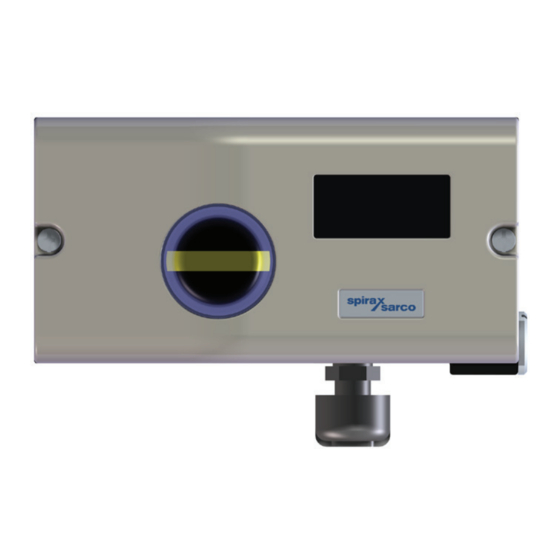

Spirax Sarco SP7-11 Installation And Maintenance Instructions Manual

Smart positioner

Hide thumbs

Also See for SP7-11:

- Manual (64 pages) ,

- Installation and maintenance instructions manual (48 pages) ,

- Quick start manual (13 pages)

Table of Contents

Advertisement

3440750/5

Throughout the document SP7-1* is written

where the information is relevant to all

versions; the SP7-10, SP7-11 and SP7-12.

Where the information is specific it will be

referenced as the version appropriate.

IM-P706-02 CTLS Issue 5

SP7-10, SP7-11 and SP7-12

Smart positioner

Installation and Maintenance Instructions

SP7-10, SP7-11 and SP7-12 Smart positioner

1.

Safety information

2.

General product information

3.

Installation

4.

Commissioning

5.

Operation

6.

Troubleshooting

7.

Maintenance

8.

Approvals

9.

Declaration of conformity

IM-P706-02

CTLS Issue 5

© Copyright 2023

1

Advertisement

Table of Contents

Summary of Contents for Spirax Sarco SP7-11

- Page 1 Operation Troubleshooting Maintenance Throughout the document SP7-1* is written where the information is relevant to all versions; the SP7-10, SP7-11 and SP7-12. Approvals Where the information is specific it will be referenced as the version appropriate. Declaration of conformity SP7-10, SP7-11 and SP7-12 Smart positioner ©...

- Page 2 Date of purchase Original order number iii. Serial number Please return all items to your local Spirax Sarco branch. Please ensure all items are suitably packed for transit (preferably in the original cartons). SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 3: Table Of Contents

4.10 Standard automatic adjustment 4.11 Sample parameters 4.12 Setting the option modules 4.13 Setting the mechanical limit switch with proximity switches 4.14 Setting the mechanical limit switch with 24 V micro-switches SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 4 5.2 SP7-10 HART Parameter Overview 5.3 SP7-11/12 Parameter Overview 6. Troubleshooting 6.1 Error codes SP7-10 6.2 Error Codes SP7-11/12 6.3 Alarm codes 6.4 Message codes 7. Maintenance 8. Approvals 9. Declaration of Conformity SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 5: Safety Information

Fuses should not be installed in the protective earth conductor. The integrity of the installation protective earth system must not be compromised by the disconnection or removal of other equipment. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 6 Before starting work ensure that you have suitable tools and / or consumables available. Use only genuine Spirax Sarco replacement parts. Operators must wear ear protection when commissioning the positioner SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 7 Customers and stockists are reminded that under EC Health, Safety and Environment Law, when returning products to Spirax Sarco they must provide information on any hazards and the precautions to be taken due to contamination residues or mechanical damage which may present a health, safety or environmental risk.

-

Page 8: General Product Information

Unsurpassed shock absorption and vibration compensation from 10 g to 80 Hz distinguishes the SP7-1 from other products and guarantees reliable operation in nearly any area under the harshest ambient conditions. 2.2 Operating principle Fig. 1 Schematic diagram SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 9 Note : With optional upgrades either, the ‘Installation kit for digital feedback with proximity switches’ m or the ‘Installation kit for digital feedback with 24 V microswitches’ can be used. In both cases though, the mechanical position indication l must be installed. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 10: Label Description

Mech. limits switch Position indicator Approvals 2.4 Principle of operation The SP7-10, SP7-11, SP7-12 is an electronically configurable positioner with communication capabilities designed for mounting on pneumatic linear or rotary actuators. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 11 Label examples ATEX/IECEx NEPSI Fully automatic determination of the control parameters and adaptation to the positioner allow for considerable time savings as well as optimum control behavior. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 12: Installation

Note During installation make sure that the actuator travel or rotation angle for position feedback is implemented correctly. Fig. 3 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 13 10 to 35 mm [0.39 to 1.38 in] 20 to 100 mm [0.79 to 3.94 in]) Washers Screws U-Bolts Washers Nuts 10 Screws 11 Spring washers 12 Clamp plates 13 Follower guide Fig. 4 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 14 Fig. 5 Tighten the screws so that they are hand tight Attach the follower guide (1) and clamp plates (2) with screws (4) and spring washers (3) to the actuator stem. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 15 Set the valve mid stroke and align the lever horizontal (item 6 fig. 6). Then tighten mounting bolt (item 4 fig. 7) (lever moves between the arrow marks item 4 fig. 6). SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 16 Adjust the height of the positioner on the cast iron yoke or columnar yoke until the lever is Fig. 8 horizontal (based on a visual check) at half stroke of the valve. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 17 Select the chosen bolt position in the HMI menu in order to ensure optimum linearization. The default setting is actuator bolt on lever SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 18 Potentiometer lever Actuator bolts Valve stem Valve yoke Positioner Fig. 10 3.1.11 Actuator bolts on the Valve (rear view) Potentiometer lever Actuator bolts Valve stem Valve yoke Positioner Fig. 11 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 19 Four M6 screws each 4, spring washers 3 and washers 2 to fasten the attachment bracket 6 to the positioner Four M5 screws 7, Spring washers 8 and washers 9 to fasten the attachment bracket to the actuator Required tools: Wrench, size 8/10 Allen key, size 3 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 20 Place the adapter in the proper position on the feedback shaft and fasten with threaded pins 2. One of the threaded pins must be locked in place on the flat side of the feedback shaft. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 21 3.1.15 Screwing the positioner onto the actuator Note After mounting, check whether the operating range of the actuator matches the measuring range of the positioner, refer to General on page 14. Fig. 15 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 22 The SP7-1 can be fitted either with proximity switches or micro-switches as limit switches. It is not possible to combine both variants. For the version SP7-10 Control Unit with SP7-10 Remote Sensor, the limit switches are located in the SP7-10 Remote Sensor. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 23 51/52/53 Micro-switches Limit 2 (Option) Note The SP7-10 Remote Sensor can be fitted either with proximity switches or micro-switches as limit switches. It is not possible to combine both variants. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 24 3.3 Electrical connections 3.3.1 Positioner SP7-11/12 Control Unit Electrical Connection Fig. 17 Basic device Options, digital feedback with proximity switches or microswitches Terminal Function/ comments +11/−12 Fieldbus, bus feed +51/−52 Digital feedback Limit 1 with proximity switch (optional) +41/−42 Digital feedback Limit 2 with proximity switch (optional)

- Page 25 < 1.2 mA Output 'logic 1' > 1.2 mA Action Configurable (logic '0' or logic '1') *The analog feeback and digital feedback option have specific locations and can be used together SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 26 Contact surface 10 µm Gold (Au) **Mechanical feedback only possible with mechanical position indicator (housing type '20') Note: Mechanical feedback only possible with either proximity switches or 24V micoswitches; not both. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 27 Li = negligibly small C0 = 2 µF Only for connection to a programming device using Local Communication Interface (LCI) ABB LCI adaptor (Um ≤ 30 Vdc) outside hazardous area SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 28 3.3.3 Electrical data for inputs and outputs (SP7-11) 3.3.3.1 Fieldbus communication PROFIBUS PA Terminals +11/-12 Supply Voltage 9 to 32 Vdc (Power from PA Bus) Maximum voltage 35 Vdc Input current 10.5 mA Current in the event of an error 15 mA (10.5 mA + 4.5 mA)

- Page 29 Ii = 25 mA Li = 100 µH (+51/-52: Limit 1, +41/-42: Limit 2) Pi = 64 mW Proximity switch: Pepperl+Fuchs SJ2-SN Refer to Ex Certificate PTB 00 ATEX 2049 X SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 30: Connection On Device

The connecting terminals are delivered closed and must be unscrewed before inserting the wire. Strip the wires to approximately 6 mm (0.24 in). Connect the wires to the connecting terminals in line with the connection diagram. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 31 Flexible with wire end sleeve no plastic sleeve 0.25 to 0.5 mm (AWG23 to AWG22) Flexible with wire end sleeve with plastic sleeve 0.25 to 0.5 mm (AWG23 to AWG22) SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 32: Connection On Device - Sp7-10 Control Unit With Sp7-1 Remote Sensor

Housing 2 (SP7-10 Remote Sensor) contains the position sensor and is suitable for mounting on linear or part-turn actuators. The following options may be installed, depending on the configuration ordered. Optical position indicator Mechanical feedback contacts designed as proximity switches or microswitchesmicro-switches. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 33 (SP7-10 Control Unit and SP7-10 Remote Sensor housing with the same electric potential); otherwise control deviations could occur with regard to analog position feedback. Use wire end ferrules when connecting. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 34: Connection On Device - Sp7-10 Control Unit For Remote Position Sensor

The SP7-10 Control Unit contains the electronics and pneumatics along with the following options (where applicable): Analog position feedback Digital position feedback Any position sensor (4 to 30 kΩ, with line break detection 4 to 18 kΩ) can be connected. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 35 (SP7-10 Control Unit and remote position sensor housing with the same electric potential); otherwise control deviations could occur with regard to analog position feedback. Use wire end ferrules when connecting. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 36: Pneumatic Connections

The supply air pressure required to apply the actuating force must be adjusted in line with the output pressure in the actuator. The operating range of the positioner is between 1.4 to 6 bar (20 to 90 psi). SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 37 Free of oil, water and dust in accordance with DIN/ISO 8573-1. Pollution and oil content in accordance with Class 3:3:3 Do not exceed the maximum output pressure of the actuator *** Independent of supply pressure SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 38: Commissioning

−57 to 57° Minimum angle 25° Perform standard automatic adjustment in accordance with standard automatic adjustment. Commissioning of the positioner is now complete, and the device is ready for operation. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 39: Operating Modes

Since self-optimization in operating mode 1.0 is subject to several factors during control operation with adaptation, incorrect adjustments could appear over an extended period. Positioning not active. *** For high-speed mode, press ARROW UP and ARROW DOWN simultaneously. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 40: Standard Automatic Adjustment

Check mechanical mounting in accordance with Mechanical mounting on page 14 and repeat the standard automatic adjustment. * The zero position is determined automatically and saved during standard automatic adjustment, counter- clockwise (CTCLOCKW) for linear actuators and clockwise (CLOCKW) for rotary actuators. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 41: Commissioning Sp7-11/12

6. Set dead zone and tolerance band. This step is only required for critical (e.g. very small) actuators. In normal cases you can skip this step. Commissioning of the positioner is now complete, and the device is ready for operation. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 42: Setting The Bus Address

Press UP or DOWN to set the correct value, Press and hold down ENTER until the countdown goes from 3 to 0. Release ENTER. The new bus address is saved. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 43: Request Information

Cyclic communication: Set point in % and the set point status is displayed. Acyclic communication: Displays the communication status. Displays the bus address and operating mode. Displays the software revision. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 44: Operating Modes

Adjust with UP or DOWN ** Manual adjustment* within the sensor range. Adjust with UP or DOWN** * Positioning not active. ** For high-speed mode, press UP and DOWN simultaneously. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 45: Jumper Configuration

Set the jumpers as shown below: Fig. 22 Jumper Number Function Simulation blocked* Simulation enabled Write access blocked Write access activated* * Default setting (in accordance with Fieldbus Foundation standard) SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 46: Standard Automatic Adjustment

Check mechanical mounting in accordance with Mechanical Mounting on page 14 and repeat the standard automatic adjustment. * The zero position is determined automatically and saved during standard automatic adjustment, counter- clockwise (CTCLOCKW) for linear actuators and clockwise (CLOCKW) for rotary actuators. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 47: Sample Parameters

Press and hold down MODE and ENTER simultaneously, additionally quickly press and release ARROW UP 2×, The following is now shown in the display: Release MODE and ENTER. The following is now shown in the display: SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 48: Setting The Option Modules

Attach the housing cover and screw it onto the housing. Tighten the screws so that they are hand-tight. Attach the symbol label to mark the minimum and maximum valve positions on the housing cover. Note: The labels are located on the inside of the housing cover. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 49: Setting The Mechanical Limit Switch With Proximity Switches

Fasten the lower washer with the special adjustment retainer and rotate the upper washer manually. Connect the microswitch. Attach the housing cover and screw it on to the housing. Tighten the screws so that they are hand-tight. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 50: Operation

Operating buttons for menu navigation 5.1.2 Value display with unit This 7-segment display with four digits indicates parameter values or parameter reference numbers. For values, the physical unit (°C, %, mA) is also displayed. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 51 On the configuration level the active operating mode is deactivated. The I/P module is in neutral position. The control operation is inactive SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 52: Sp7-10 Hart Parameter Overview

5.2 HART Parameter Overview Operating level Parameter "EXIT" ENTER ENTER Configuration level MODE ENTER MODE Fig. 24 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 53 100.0 to 10.0 P3.1 range range, max. CLOCKWISE, ZERO_POS Zero position Zero position CTCLOCKWISE P3.2 CTCLOCKWISE Return to EXIT Return Function NV_SAVE P3.3 operating level Parameter description HART continued on next page SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 54 Dead angle 0 % 0.0 to 45.0 P6.4 close Dead angle Dead angle DANG_UP 55.0 to 100.0 100.0 P6.5 open 100% Return to P6.6 EXIT Return Function NV_SAVE operating level SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 55 Readback Converted RB_CHAR DIRECT, RECALC DIRECT P8.4 character. characters TEST Test Test Function NONE P8.5 Return to P8.6 EXIT Return Function operating level Parameter description HART continued on next page SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 56 EXIT Return Function NV_SAVE P11.5 operating level *Activation by Spirax Sarco Service only Note For detailed information on the parameterization of the device, consult the associated configuration and parameterization instructions. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 57: Sp7-11/12 Parameter Overview

5.3 SP7-11/12 parameter overview Remote Level (Bus operator) Working Level (Local Service) Configuration Level Parameter overview Fig. 25 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 58 MAX_VR Max. valve range Operating range, 0.0 to 100.0 max. P6.2 ACTUATOR Actuator type Actuator type LINEAR, ROTARY LINEAR P6.3 SPRNG_Y2 Spring action (Y2) Spring action (Y2) CLOCKWISE, CTCLOCKWISE CTCLOCKWISE SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 59 EXIT Return Return to Function operating level *Activation by Spirax Sarco Service only Note: For detailed information on the parameterization of the device, consult the associated configuration and parameterization instructions. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 60: Troubleshooting

EEPROM. Error codes continued on next page SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 61 After approx. 5 and occurs in the same sec onds, the positioner is position after resetting, the automatically reset. device must be returned for repair to the manufacturer. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 62 (128) Position sensor defective Device moves to safety position Return the device for repair SENS_ERR MEM_ERR Defective memory chip Device does not boot up Return the device for repair. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

-

Page 63: Alarm Codes

PC exceeded. with suitable software). The specified limit value for Reset the counter (only ALARM 7 the travel counter has been possible via a connected PC exceeded. with suitable software). SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 64: Message Codes

SPR_ERR Actual spring action is different from the adjusted one. Time-out; parameter could not be determined within two minutes; TIMEOUT Auto-adjust was automatically stopped. SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 65: Maintenance

7. Maintenance SP7 Series Filter Kit – 3440580 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 66: Approvals

INMETRO Rating: INMETRO Ex ib IIC T6, T4 ... T1 Gb Certification number: NCC 22.0116 X Ambient temperature: T6: -40°C ≤ Tamb ≤ +40°C T4...T1: -40°C ≤ Tamb ≤ +85°C SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... -

Page 67: Declaration Of Conformity

Signed for and on behalf of: Spirax Sarco Ltd, (signature): (name, function): M Sadler Head of Engineering Steam Business Development (place and date of issue): Cheltenham 2022-03-14 GNP237-EU-C/04 issue 1 (EN) Page 1/25 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5... - Page 68 Spirax Sarco Ltd, (signature): (name, function): Neil Morris Compliance Manager Steam Business Development Engineering (place and date of issue): Cheltenham 23 September 2022 GNP237-UK-C/04 issue 1 Page 1 of 1 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 69 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 70 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 71 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

- Page 72 SP7-10, SP7-11 and SP7-12 Smart positioner IM-P706-02 CTLS Issue 5...

Need help?

Do you have a question about the SP7-11 and is the answer not in the manual?

Questions and answers