Spirax Sarco SP7-10 Manual

Hide thumbs

Also See for SP7-10:

- Installation and maintenance instructions manual (48 pages) ,

- Quick start manual (13 pages) ,

- Installation and maintenance instructions (4 pages)

Table of Contents

Advertisement

IM-S51-07

CTLS Issue 1

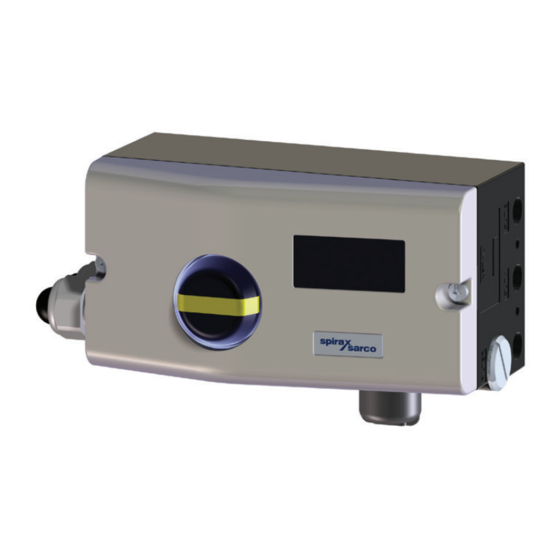

SP7-10, SP7-11, SP7-12 and

SP7-20, SP7-21, SP7-22

Parameterization

Device firmware version 05: SP7-10 / SP7-20

Device firmware version 03: SP7-11 / SP7-12 / SP7-21 / SP7-22

SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization

IM-S51-07 CTLS Issue 1

1

© Copyright 2022

Advertisement

Table of Contents

Summary of Contents for Spirax Sarco SP7-10

- Page 1 SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization Device firmware version 05: SP7-10 / SP7-20 Device firmware version 03: SP7-11 / SP7-12 / SP7-21 / SP7-22 SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1 © Copyright 2022...

-

Page 2: Table Of Contents

2.7 Inhibiting operation 3. Configuration 3.1 General information 3.2 Example 3.3 4.20mA and 4-20mA HART parameter descriptions (SP7-10 and SP7-20) 3.4 HART parameter overview (Graphic) 3.5 Parameter group 1: Standard 3.6 Parameter group 2: Setpoint 3.7 Parameter group 3: Operating range 3.8 Parameter group 4: Messages... - Page 3 Spirax-Sarco Limited. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 4: General Information

The signal word "NOTE" indicates useful or important information about the product. The signal word "NOTE" is not a signal word indicating a danger to personnel The signal word "NOTE" can also refer to material damage. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 5: Intended Use

Using the device in a manner that does not fall within the scope of its intended use, disregarding this manual, using underqualified personnel, or making unauthorized alterations releases the manufacturer from liability for any resulting damage. This renders the manufacturer's warranty null and void. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 6: Operation

%, mA) is also displayed. Designator display This 14-segment display with eight digits indicates the designators of the parameters with their status, of the parameter groups, and of the operating modes. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 7: Description Of Symbols

-Choose an operating mode (Operating level) MODE 'M' -Select parameter group (Configuration level) UP direction arrow DOWN direction arrow Press and hold all buttons for 5 seconds Reset SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 8: Menu Levels

P1.1 CTRL_FIX. The valve position is indicated as a percentage of the operating range (from 0 ... 100%). SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 9 Display of control deviation 1. Press and hold the ARROW UP and ARROW DOWN button. The control deviation is displayed as a percentage (%) of the stroke range. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 10 In this operating mode the valve position is indicated as a percentage (%) of the stroke range. 2.6.4 Operating mode 1.3: Manual adjustment in the sensor range See operating mode 1.2 SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 11: Inhibiting Operation

This inhibit function can only be deactivated when a voltage of 12 ... 30 V is applied at the digital input of the positioner (see Function selection in parameter group 10, on page 49). SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 12: Configuration

FULL, STROKE, CTRL, FULL adjustment mode PAR, ZERO_POS, LOCKED P1.3 TEST Test Command/Function is INACTIV being run P1.4 EXIT Return to Command/Function is NV_SAVE operating level being run SETPOINT SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 13: Ma And 4-20Ma Hart Parameter Descriptions (Sp7-10 And Sp7-20)

3.3 4.20mA and 4-20mA HART parameter descriptions (SP7-10 and SP7-20) Possible parameter Factory Parameter Display Function Unit setting setting STANDARD Actuator type Actuator type LINEAR, ROTARY - - - LINEAR P1._ ACTUATOR Auto adjust Autoadjust Function P1.0 Automatic FULL,STROKE,CTRL_PAR, AUTO ADJ... - Page 14 Dead angle 100 % 55.0 ... 100.0 100.0 P6.6 BOLT POS Bolt position Actuator position LEVER, STEM LEVER Return to P6.7 EXIT Return Function NV SAVE operating level SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 15 CLIPPING enabled Signal output to 3.8 ... 20.5 4.0 ... 20.0; 3.8 ... 20.5 mA 4.0 ... 20.0 clipping range Return to operating P8.8 EXIT Return Function level SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 16 FREEZE2 P11.3 IP_COMP IP compensation IP compensation ON, OFF P11.4 HART REV HART revision HART Revision 5; 7 Return to operating P11.5 EXIT Return Function NV SAVE level SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 17: Hart Parameter Overview (Graphic)

3.4 HART parameter overview (Graphic) Operating level Parameter "EXIT" Configuration level Fig 2 SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 18: Parameter Group 1: Standard

Stroke time for both directions Control parameters Offset for the I/P module NOTE The mode and scope of the automatic adjustment function can be selected using parameter ADJ MODE. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 19 40 - 49 tolerance band is determined and saved. 50 - 59 PID parameters for fast control < tolerance band is determined and saved. Automatic adjustment is complete. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 20 It is not possible to start the test when the safe position is active (see the FAIL_POS parameter on page 50.) Instead, the message FAIL POS is displayed. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 21 If an error occurs during the check or while saving, the data cannot be saved and an error message is displayed instead (see Chapter "Error codes"). NV_SAVE Saves settings in the non-volatile memory. Selection CANCEL Discards all changes made since the last permanent save operation. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 22: Parameter Group 2: Setpoint

5.6 ... 20 mA, with one decimal. Setpoint Range Min. = 8.3 mA, Max. = 15.6 mA Setting examples Split range configuration between Min. = 12.0 mA, Max. = 20.0 mA SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 23 0 ... 100 % = position 0 ... 100 % Selection Decreasing REVERSE Control signal 20 ... 4 mA, and setpoint 100 ... 0 % = position 0 ... 100 % SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 24 The setpoint ramp is deactivated in the case of any functions which involve approaching the safe position . This even appl ies in the case of errors. The actuator will therefore move without delay Do not reach into the adjustment mechanism. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 25 If an error occurs during the check or while saving, the data cannot be saved and an error message is displayed instead (see Chapter "Error codes"). NV_SAVE Saves settings in the non-volatile memory. Selection CANCEL Discards all changes made since the last permanent save operation. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 26: Parameter Group 3: Operating Range

The operating range must be greater than 10% of the sensor range. NOTE The display of the positioner in operating modes 1.0 through 1.2 always refers to the configured working range and indicates the position in %. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 27 Normally, the zero position is determined automatically and saved during standard Autoadjust. Linear actuators counterclockwise Rotary actuators clockwise CLOCKW Limit stop reached turning clockwise Selection CTCLOCKW Limit stop reached turning counterclockwise SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 28: Parameter Group 4: Messages

If the tolerance band within the predefined time is again not reached by the new position setpoint, an alarm is triggered. (Parameter TIME_OUT in parameter group 5 must be activated.) CAUTION With active shutdown function there is no alarm message. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 29 Changing the operating range also changes the positions of the switching points with respect to the position of the valves and fittings. Exceed Message when exceeding switch point SW2 FALL_BEL Message when falling below switching point SW2 SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 30 If an error occurs during the check or while saving, the data cannot be saved and an error message is displayed instead (see Chapter "Error codes"). NV_SAVE. Saves settings in the non-volatile memory. CANCEL Discards all changes made since the last permanent save operation. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 31: Parameter Group 5: Alarms

4%. (Position < -4 % or > 104 %). This may indicate improperly adjusted mounting or mechanical wear in a limit stop. ACTIVE Alarm active INACTIVE Alarm not active SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 32 With this parameter you can determine that an alarm is signaled when the travel counter exceeds the specified limit value. The limit value is edited remotely via PC. ACTIVE Alarm for exceeding movement counter limit value INACTIVE No alarm SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 33: Parameter Group 6: Manual Adjustment

Use as large are range as possible. This parameter is not active when the safe position is active. The display then shows the message FAIL POS. Use MIN_VR to determine the lower limit of the operating range. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 34 (sensor range ±45°). No mechanical modifications to the positioner are required. NOTE After changing the actuator type , it is recommended that you run Auto Adjust to prevent linearity errors. Linear actuators Selection Part-turn actuators SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 35 Use this parameter to cut off the unusable range of the valve flow characteristic curve from the point of view of control. The Dead Angle Open is a percentage of the operating range to which the valve is moved if the input signal is 19.84 mA. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 36 If an error occurs during the check or while saving, the data cannot be saved and an error message is displayed instead (see Chapter "Error codes"). NV_SAVE Saves settings in the non-volatile memory. CANCEL Discards all changes made since the last permanent save operation. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 37: Parameter Group 7: Control Parameters

For most actuators, a satisfactory control response is achieved with a KP value in the 2.0 ... 10.0 range. Use the parameter KP UP to adjust the KP value for the upward positioning direction (towards 100 %). SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 38 (up / down). For most actuators, satisfactory control behavior is achieved with a KP value between 2.0 ... 10.0. Use the KP DN parameter to adjust the KP value for the downward positioning direction (towards 0 %). SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 39 TV value should be configured separately for both positioning directions (up / down). Use the TV DN parameter to adjust the TV value for the downward positioning direction (towards 0 %). SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 40 Both offset values should be increased when the actuator stops outside the tolerance band. Use the parameter Y-OFS UP to adjust the Y offset for the upward positioning direction (towards 100 %). SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 41 DEADBAND is reached. The system is only considered balanced once the sensitivity range is reached (see parameter ADJ_MODE) Input value in steps of 0.1% SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 42 NOTE It is not possible to activate the test when the safe position is active (see parameter FAIL_POS on page 50). Instead, the message FAIL POS is displayed. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 43 If an error occurs during the check or while saving, the data cannot be saved and an error message is displayed instead (see Chapter "Error codes"). NV_SAVE Saves settings in the non-volatile memory CANCEL Discards all changes made since the last permanent save operation SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 44: Parameter Group 8: Analog Output

Use this parameter to specify the characteristic curve for the analog feedback. Increasing Position 0 ... 100 % = Signal 4 ... 20 mA Decreasing Position 0 ... 100 % = Signal 20 ... 4 mA SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 45 Output of the current setpoint as current value via analog output. All configurations and CURRENT settings of the analog input and /or output must be taken into consideration. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 46 If an error occurs during the check or while saving, the data cannot be saved and an error message is displayed instead (see Chapter "Error codes"). NV_SAVE. Saves settings in the non-volatile memory. CANCEL Discards all changes made since the last permanent save operation SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 47: Parameter Group 9: Digital Output

You can use this parameter to define the active state for switch output SW2 (on the plug in module for digital feedback). ACTIV_HI active = output current I > 2 mA ACTIV_LO active = output current I < 1 mA SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 48 (also the changes in other parameter groups). NV_SAVE Saves settings in the non-volatile memory. CANCEL Discards all changes made since the last permanent save operation. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

-

Page 49: Parameter Group 10: Digital Input

Local operation (operating level and configuration level) and external configuration via LCI / ALL_LOCK modem and PC are inhibited. With every attempt to perform local operating actions, the message ALL_LOCK is shown for approx. 5 seconds. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 50: Parameter Group 11: Safe Position

Activating / deactivating the safe position: Press and hold ENTER until the displayed countdown from 3 to 0 is finished. Then release ENTER. The safe position is activated or deactivated, respectively. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 51 . CAUTION For safety reasons, after restoring the positioner to the factory settings you must check whether this parameter has been correctly set. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 52 3.15.4 IP_COMP – IP Compensation This function is reserved for use by Spirax Sarco Service only. 3.15.5 HART_REV – HART version As of firmware version 5, the positioner offers communication via both standard HART 5 and HART 7. To select, use the arrow keys UP or DOWN.

-

Page 53: Profibus Pa And Foundation Fieldbus Parameter Descriptions (Sp7-11, Sp7-12 And Sp7-21, Sp7-22) - Profibus Pa And Foundation Fieldbus Parameter Overview

Dead band 0.10 … 10.00 0.20 TEST Test Test Function INACTIVE P1.4 ADRESS Profibus Address Set Adress 3...125 P1.5* Return to EXIT Return Function NV_SAVE P1.6 operating level SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 54: Profibus Pa And Foundation Fieldbus Parameter Descriptions (Sp7-11, Sp7-12 And Sp7-21, Sp7-22)

ACTUATOR Actuator type Actuator type LINEAR, ROTARY LINEAR CLOCKWISE, P6.3 SPRNG_Y2 Spring action (Y2) Spring action (Y2) CTCLOCKWISE CTCLOCKWISE Return to EXIT Return Function NV_SAVE P6.5 operating level SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 55: Specific Parameters For Digital Bus Communication Versions Only: - P1.5 Adress - Bus Address (Profibus Pa Version Only)

Do not set addresses 1 or 2, as these are reserved for the master. Avoid assigning the same bus address to multiple devices. Input value: Recommended range: 3 ... 125 SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... -

Page 56: P7.4 Gopulse^ Go Pulse (Up)

The value determined by Autoadjust should not be increased, as this may result in overshooting! You can use parameter GOPULSE DN to move the go pulse for adjustment towards 0 %. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1... - Page 57 EEPROM. This compensates for still persists, the device must intermittent errors in the be returned for repair to the communication environment manufacturer. with the EEPROM. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 58 After approx. 5 Internal error. position after resetting, the seconds, the positioner is device must be returned for automatically reset. repair to the manufacturer. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 59 Data cannot be saved locally, as PROFIBUS saves data in the background. Impact: a) Auto adjust function is aborted. b) Saving is not possible. Measure(s): a) Correct values or load factory settings b) Try agail at a later point SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 60 PC exceeded. with suitable software). The specified limit value for Reset the counter (only the travel counter has been possible via a connected PC exceeded. with suitable software). SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 61 Actual spring action is different from the adjusted one. Time-out; parameter could not be determined within two minutes; Autoadjust was automatically stopped. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 62 Increase the dead band (DEADBAND). The work activities are completed. Is the valve function stable? The friction or stiction of the valve is too great. Check the valve. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 63 Work activities are over parameters. after starting Auto adjust! Now is it working? Return the defective Switch the function for the digital positioner for input (FUNCTION) to repair. none. SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

- Page 64 SP7-10, SP7-11, SP7-12 and SP7-20, SP7-21, SP7-22 Parameterization IM-S51-07 CTLS Issue 1...

Need help?

Do you have a question about the SP7-10 and is the answer not in the manual?

Questions and answers