Porter-Cable 4212 Instruction Manual

Dovetail jig

Hide thumbs

Also See for 4212:

- Instruction manual (27 pages) ,

- Instruction manual (44 pages) ,

- Instruction manual (44 pages)

Table of Contents

Advertisement

Quick Links

12" (305 mm)

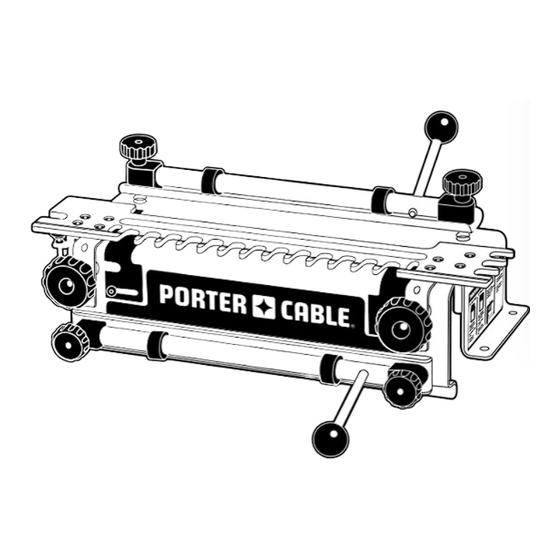

Dovetail jig

Gabarit de queues d'aronde

de 305 mm (12 po)

Guí de 305 mm (12 pulg)

para cola de milano

Instruction manual

Manuel d'instructions

Manual de'instrucciones

Française : Page 28

Español: Página 53

www.deltaportercable.com

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

4210

4212

4216

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Porter-Cable 4212

- Page 1 Guí de 305 mm (12 pulg) para cola de milano Instruction manual Manuel d'instructions Manual de'instrucciones Française : Page 28 Español: Página 53 www.deltaportercable.com INSTRUCTIVO DE OPERACIÓN, CENTROS 4210 DE SERVICIO Y PÓLIZA DE GARANTÍA. LÉASE ESTE INSTRUCTIVO 4212 ANTES DE USAR EL PRODUCTO. 4216...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAFETY GUIDELINES IMPORTANT SAFETY INSTRUCTIONS ADDITIONAL SPECIFIC SAFETY RULES BACKGROUND INFORMATION Dovetail and Box Joint Overview Product Capabilities 4200 Series Dovetail Jig Overview Carton Contents Assembly Additional Tools Required Mounting Instructions OPERATION Clamps Template Mounting Template Support Positioning the Wood Half-Pins Vs. -

Page 3: Safety Guidelines

NOT be modified and/or used for any application other than for which it was designed. If you have any questions relative to its application DO NOT use the tool until you have written Porter-Cable and we have advised you. -

Page 4: Important Safety Instructions

16. AVOID UNINTENTIONAL STARTING. Do not carry a plugged-in tool with finger on switch. Be sure switch is off when plugging in. Keep hands, body and clothing clear of blades, bits, cutters, etc. when plugging in the tool. 17. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension cords marked “Suitable for use with outdoor appliances –... - Page 5 THROUGH DOVETAILS Tails Pins HALF-BLIND DOVETAILS RABBETED HALF-BLIND DOVETAILS BOX (FINGER) JOINT A similar joint, called a box or finger joint, has straight protrusions called fingers on both boards. This joint is used on jewelry boxes and other small boxes. The box joint is strong because it has a large surface area for glue.

-

Page 6: Dovetail And Box Joint Overview

PRODUCT CAPABILITIES The Porter-Cable 4200 series dovetail jig will help you cut these joints efficiently. An accessory kit will enable you to cut miniature versions of these joints for small gift boxes or cubbyhole drawers on a roll-top desk. The 4200 series also has the capability to cut more advanced joints (dovetails that skip pins, wood hinges, end-to-end joints, various types of angle joints, and joints with inlays). -

Page 7: Carton Contents

CARTON CONTENTS DOVETAIL JIGS 4210 4212 Base Base Half-blind & Sliding Dovetail Template Half-blind & Sliding Dovetail Template Through & Box Template Dovetail Bit Dovetail Bit Template Guide Straight Bit Lock nut Template Guide (2) T-handle Hex Wrench Lock Nuts (2) -

Page 8: 4200 Series Dovetail Jig Overview

ACCESSORY KITS 4211 4213 4215 Half-blind & Sliding Dovetail Through and Box Joint 1. Miniature Half-blind, Through, & Template Template Box Template Brackets (2) Brackets (2) 2. Brackets (2) Dado Depth Bracket Half-Blind Depth Bracket 3. Template Guide and Lock Nut (2) Half-blind Depth Bracket Straight Bit 4. -

Page 9: Additional Tools Required

must accept the Porter-Cable template guides supplied with the jig. (Adapters and sub-bases are available for most routers.) must have a 1/2" collet for use with 4210 and 4212 jigs and the 4211 and 4213 accessory kits. ... -

Page 10: Clamps

CLAMPS The 4200 series jigs are equipped with two cam-action clamps (A) Fig. C1 with knobs (B) to adjust for workpiece thickness, and levers (C) for quick clamping and releasing of workpieces. NOTE: Use a scrap board (A) Fig. C2 to prevent misalignment (A) Fig. C3. TEMPLATE MOUNTING You can mount the templates in two positions on the jig(s) which allows the production of multiple types of joints with each template. -

Page 11: Template Support

TEMPLATE SUPPORT For every type of joint, place wood in the top clamp, whether a workpiece or a scrap piece, to provide support for the router on the template. You can add extra support by inserting a second board (A) Fig. E1 (of the same thickness) in the top clamp to ensure that the template is parallel to the base across its length. -

Page 12: Half-Pins Vs. Half-Tails

Some templates have one line (Fig. H1) while others have several lines to produce multiple types of joints (Fig. H2). Porter-Cable has scribed icons on the templates to indicate which lines go with which joints. -

Page 13: Template Guides

TEMPLATE GUIDES Use the correct template guides provided with this unit to guide the router against the template fingers. To determine the proper guide for a given joint, place the template guide in the slot on the left side of the corresponding template. The guide should have a snug fit in the slot. -

Page 14: Wood Preparation

WOOD PREPARATION Properly preparing the materials for your project is the key to good-looking and tight-fitting joints. You must cut your wood at perfect right angles (Fig. L1). Cuts that are off even one degree will not align correctly (Fig. L2). Also, your workpieces must be flat and not cupped. -

Page 15: Project Layout

PROJECT LAY OUT Keeping track of the outer and inner face of each workpiece and how the different parts mate with each other is very important. Step 1 - Lay out the workpieces face down and label the inside faces with an “I” (Fig. N1). Step 2 - Label the corners “A”, “B”, “C”, and “D”... -

Page 16: Basic Joints

BASIC JOINTS THROUGH DOVETAILS The through dovetail has a look that is visually appealing, especially in boxes and chests. NOTE: For miniature through dovetails, use the 4215 accessory kit. Cut both the pins and tails in the vertical position. Cut the tails first. Use two routers (if possible) - one for the pins and the other for the tails - to make the process quicker and easier. -

Page 17: Cutting The Pins

Step 4 - Reposition the offset guide (A) Fig. P4 flush to the vertical board and secure it. Step 5 - Reposition the scrap board(A) Fig. P5 so that it is flush with the rear edge of the vertical board (B). Step 6- Align the template using the “tails/box”... -

Page 18: Fitting And Troubleshooting

Step 5- Rout between the fingers of the template (Fig. P12). Step 6 - Remove the pin board and check the fit with the tailboard (Fig. P13). THROUGH DOVETAIL TROUBLESHOOTING For joints that are too loose, move the template toward you slightly. For joints that are too tight, move the template away from you slightly. -

Page 19: Fitting And Troubleshooting

Clamp the tailboard (drawer side) in lower clamp (vertical Step 4 - position) on the left side of the base with the outside of the board CENTER facing the jig (A) Fig. Q3. Step 5 - Center the board between the farthest finger on the left and the nearest finger on the right of the board. -

Page 20: Half-Blind Dovetail With A Lipped Front

RABBETED HALF-BLIND DOVETAILS To produce rabbeted half-blind dovetails (drawer front), cut the pins for a half-blind joint after the drawer front has been rabbeted. The depth of the rabbet must be deeper than the half-blind router bit depth guide. NOTE: Cut the tails first. -

Page 21: Cutting The Pins

Step 7 - Mount the dovetail bit and template guide to the router and set the router bit depth using the “half-blind” bit depth guide (Fig. R6). Step 8 - Make a climb-cut from right to left across the outer edge of the tail board to reduce tear-out (Fig. R7). Step 9 - Rout in and out of the fingers of the template from left to right (Fig. -

Page 22: Box Joints

BOX JOINTS Box joints have straight protrusions that interlock and must be held together by glue. The large amount of gluing surface provides the strength necessary for large projects. NOTE: If you are using the 4210 dovetail jig, you will need the 4213 accessory kit to make this joint. You will need the 4215 accessory kit for the miniature box joints. -

Page 23: Cutting The Second Workpiece

Step 4 - Reposition the left offset guide (A) Fig. S4 flush against the workpiece (B). Step 5 - Align the template, using the “tails/Box” template line with the line formed where the scrap board and the workpiece meet. Step 6 - Mount the straight bit and template guide on the router and set the router bit depth using the “tails/box”... -

Page 24: Sliding Dovetails

( 1/4", 3/8" and 1/2"), but you can manually set your router bit depth to any setting. NOTE: Be certain that the router bit will not cut into the base or offset guides during this cut.Everything is provided for this cut in both the 4210 and 4212 jigs. ITEMS NEEDED Dado Template ●... -

Page 25: Tenon Board

Step 4 - Set your router bit depth by using either of the three choices (A, B, or C) Fig. T3 on the left side of the template, or by manually setting the router to another depth. Step 5 - Slowly rout along the slot from left to right (Fig. -

Page 26: Maintenance

We cannot guarantee repairs made or attempted by others. You can also write to us for information at PORTER-CABLE, 4825 Highway 45 North, Jackson, Tennessee 38305 - Attention: Product Service. Be sure to include all of the information shown on the nameplate of your tool (model number, type, serial number, etc.). -

Page 27: Warranty

In addition to the warranty, PORTER-CABLE tools are covered by our: 1 YEAR FREE SERVICE: PORTER-CABLE will maintain the tool and replace worn parts caused by normal use, for free, any time during the first year after purchase. -

Page 28: Française

également des marques de commerce se rapportant à un ou plusieurs produits Porter-Cable ou Delta : Las siguientes son marcas comerciales PORTER-CABLE que distinguen a una o más herramientas y accesorios: un gráfico de color gris y negro; un diseño de F “estrella de cuatro puntas”...

Need help?

Do you have a question about the 4212 and is the answer not in the manual?

Questions and answers