Lincoln Electric DH-10 Operator's Manual

Bench

Hide thumbs

Also See for DH-10:

- Operator's manual (98 pages) ,

- Service manual (98 pages) ,

- Operator's manual (50 pages)

Table of Contents

Advertisement

Quick Links

Operator's Manual

DH-10 Bench

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code:

(ex: 10859)

Serial:

(ex: U1060512345)

IM903

| Issue D ate 7-Aug

© Lincoln Global, Inc. All Rights Reserved.

For use with machines having Code Numbers:

11365

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric DH-10

- Page 1 Operator’s Manual DH-10 Bench For use with machines having Code Numbers: 11365 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM903 | Issue D ate 7-Aug...

- Page 2 351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

- Page 3 SAFETY ARC RAYS can burn. ELECTRIC SHOCK can 4.a. Use a shield with the proper filter and cover kill. plates to protect your eyes from sparks and 3.a. The electrode and work (or ground) circuits the rays of the arc when welding or observing are electrically “hot”...

- Page 4 SAFETY WELDING and CUTTING CYLINDER may explode SPARKS can if damaged. cause fire or explosion. 7.a. Use only compressed gas cylinders 6.a. Remove fire hazards from the welding area. containing the correct shielding gas for the If this is not possible, cover them to prevent process used and properly operating the welding sparks from starting a fire.

- Page 5 SAFETY PRÉCAUTIONS DE SÛRETÉ 6. Eloigner les matériaux inflammables ou les recouvrir afin de prévenir tout risque dʼincendie dû aux étincelles. Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce 7.

- Page 6 Electric for advice or information about their use of our products. We respond to our customers based on the best information in our posses- sion at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such infor- mation or advice.

-

Page 7: Table Of Contents

10-Series Double Head Drives Water Connections (For Water Cooled Guns) ....A-5 10-Series Double Head Drives..................A-5 GMAW Shielding Gas ....................A-6 Gas Guard Regulator ....................A-6 Electrical Installation......................A-6 Input Cable: DH-10 Control to Power Source ...............A-6 Work Cable ........................A-7 Optional Features Installation ..................A-7, A-8 ________________________________________________________________________________ Operation ......................Section B Safety Precautions ......................B-1... -

Page 8: Installation

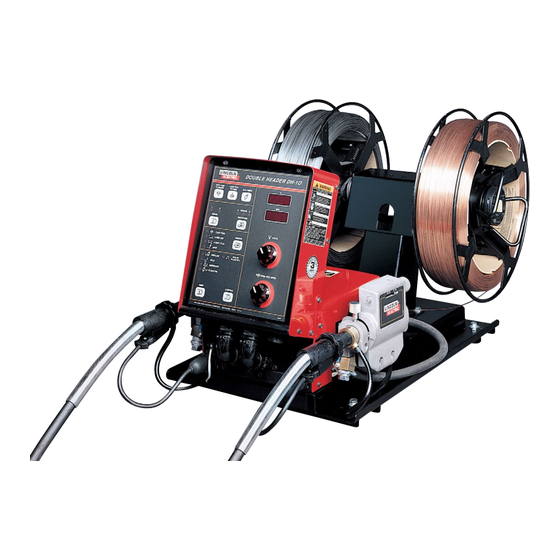

TECHNICAL SPECIFICATIONS –DH-10 Complete Units or Controls & Heads The K1499-5 DH-10 consists of a control and a double head 10 series wire drive assembly premounted on a platform with two 2” O.D. spindle mountings. Specifications for the units follow: CONTROLS SECTION OF COMPLETE UNITS SPEC.#... -

Page 9: General Description

RECOMMENDED PROCESSES AND EQUIPMENT The DH-10 is a modular line of 42VAC input dual head 4-roll wire feeders. A single control with dual procedure presetta- The DH-10 Wire Feeder system is recommended for bility of wire feed speed (in IPM or M/min) and arc voltage... -

Page 10: Electrode Routing

The speed range is set up to match each wire feed washer, lock washer, and Phillips head screw head connected to the DH-10 control by properly set- which were previously removed. ting the switch (S2) code on the control board inside the control box. -

Page 11: Wire Feed Drive Roll Kits

3) Remove Outer Wire Guide by turning knurled The 350 ampere K126 will feed electrode sizes .062 thumb screws to unscrew from Feedplate. (1.6 mm) to 3/32" (2.4 mm). The 450 ampere K115 will feed 5/64" (2.0 mm) to 3/32" (2.4 mm) electrode. DH-10... -

Page 12: Gun Cable Connection With Standard Connection

Gun Cable Connection with Fast-Mate (1.6mm) to 3/32 (2.4mm) and require the use of the Connection K184 vacuum unit for use with the DH-10. 1. Check that the drive rolls, feeder guide tubes and Gun Cable Connection with Standard gun connector guide tube are appropriate for the Connection electrode size being used. -

Page 13: Gmaw Shielding Gas

2) Connect the electrode lead to the power source output terminal of the desired polarity. 3) Connect the 9-socket plug of the control cable to the mating receptacle on the bottom of the DH-10 control box. 4) Slip the current sensor cover off enough to expose the input connector stud. -

Page 14: Work Cable

DH-10 5-pin Trigger/Dual Procedure receptacle. W ELD CABLE FROM W ELDER OUTPUT STUD Connect the 5-pin plug of the K686-2 Adapter to the DH-10 OPTIONAL FEATURES Wire Feeder Trigger/Dual Procedure 5-socket receptacle. INSTALLATION The 3-pin plug of the K683-1 Dual Procedure switch con-... - Page 15 Feed Speed and Voltage, along with a dual procedure selector switch, when the remote control is connected and REMOTE is selected by the DH-10 Procedure key. The DH-10 A or B procedure light will also be on to indicate which procedure is selected by the remote control.

-

Page 16: Operation

Head is being used. DUTY CYCLE For K1499-5 (DH-10 Bench) with Left Head 35-500 The DH-10 models are rated at 60% duty cycle * for a IPM (0.89-12.7 m/m) & Right Head 55-825 IPM maximum current of 600 amps. - Page 17 Limits Pwr Sources feeding. The Loss of Voltage Sense Shutdown fea- ture is disabled to permit the use of the DH-10 with power source connections that do not connect the work voltage back to the DH-10 through the input Pulse Power 500: power cable.

- Page 18 Selection Limits Pwr Sources The DH-10 Control is set up for Wire Feed Speed dis- play in Metric units (m/min.) or English units (IPM) by setting S1 DIP Switch 6 (Labeled “M”): 1) Closing Trigger initiates gas flow. S1 switch 6 OFF = IPM (as shipped)

-

Page 19: Keypad And Display Operation

Power-Down Save Power to the DH-10 is supplied and controlled from the power source. The DH-10 automatically senses the loss of power when the power source is turned off. - Page 20 Preflow/Postflow and burnback timers are also functional in spot mode. (See “Display Control Keys” in this section). DH-10...

- Page 21 “voltage” as well as “weld preset volt- age”. When the trigger is closed or while welding, When the welding gun trigger is activated, the top DH-10 dis- the top display will display actual arc voltage. The play reads actual welding voltage from 0.0 to 60.0 VDC with...

-

Page 22: Security Modes

Security mode is activated, or deactivate, by shutting IN VOLTS/WFS light will be off. (Settings can be tog- off the input power to the DH-10 with all Timer and gled between minimum and maximum limits by Control settings as desired for both procedures for repeatedly pressing the CONTROL key. -

Page 23: Dual Procedure Remote Control (K1449-5

(K1449-5) remote, both the front panel and remote Procedure selector and switch must be set to “REMOTE” and “Gun Switch” (center) positions. The DH-10 Procedure lights indicate whether A or B is remotely selected. WIRE REEL LOADING - READI-REELS, SPOOLS OR COILS To Mount a 30 Lb. -

Page 24: Feeding Electrode And Brake Adjustment

DRIVE ROLL PRESSURE SETTING Collar “pops up” and that the collar retainers fully engage the retaining groove on the spindle. The DH-10 pressure is factory pre-set to about posi- SPINNER NUT tion “2" as shown on the pressure indicator on the front of the feedplate door. -

Page 25: Procedure For Setting Angle Of Feedplate

MAKING A WELD 12) To stop welding, release the gun trigger and then 1) Use only a Lincoln Electric recommended constant pull the gun away from the work after the arc goes voltage DC power source compatible with the DH- out and Postflow time, if used, is over. -

Page 26: Wire Reel Changing

2) Disconnect the gun cable from the gun connector return indicating the unit is ready to operate again. on the DH-10 wire drive unit and lay the gun and Overloads can result from improper tip size, liner, cable out straight. -

Page 27: Explanation Of Prompting And Error Messages

Speed (See “Display Control Keys” in this section). Displayed on WFS display, indicates wire feed over- load. XX indicates time remaining in seconds before unit resets automatically. (See “Wire Feed Overload Protection” in this section and “Avoiding Wire Feeding Problems” in the MAINTENANCE section). DH-10... -

Page 28: Accessories

KP1507 - 040A 3/64” (1.2 mm) KP1507 - 3/64A 1/16” (1.6 mm) KP1507 - 1/16A 3/32” (2.2 mm) KP1507 - 3/32A Aluminum Electrode (For use with Binzel Guns Only) 0.040” (1.0 mm) --------------- 3/64” (1.2 mm) --------------- 1/16” (1.6 mm) --------------- DH-10... - Page 29 K1500-1 for standard Lincoln Innershield gun connection, comparable controls on the DH-10 front panel, when the remote is con- or with Fast-Mate™ guns with K489-2 Fast-Mate Adapter nected and selected by the DH-10 Procedure Key.

- Page 30 DH Wire Feed heads with appropriate K1500 Gun Adapter: K1558-1 Remote Switch Interface Module, the Remote Switch Interface Module can be used with the DH-10 Double K126 (Requires K1500-1) Innershield gun and cable Header wire feeder models, using G3041-2 (or higher) assemblies are rated at 350 amps, 60% duty cycle.

-

Page 31: Maintenance

10 through 30lb (4.5-14kg) Spools accessed from bottom of feeder, using a 3/16" Allen wrench. Continue to loosen the screw until No routine maintenance required. Do not lubricate 2” the feedplate can be easily pulled off of the wire (51mm) spindle. feeder. DH-10... - Page 32 HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

-

Page 33: Troubleshooting

CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. DH-10... - Page 34 3. Damaged control p.c. board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. DH-10...

- Page 35 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. DH-10...

- Page 36 4. Damaged control p.c. board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. DH-10...

- Page 37 5. Damaged control p.c. board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. DH-10...

- Page 38 42 VAC to the wire feeder control box. 3. Damaged input power wiring in the DH-10 control box. 4. Damaged control p.c. board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

- Page 39 Dual procedure switch functions 1. Loose or unconnected dual pro- properly when attached to one side cedure switch. of the DH-10, but will not operate on the other side. 2. Disconnected or damaged wiring between the wire drive and con- trol box.

- Page 40 Authorized Field Service Facility. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. DH-10...

-

Page 41: Procedure For Replacing Pc Boards

If PC board is visibly damaged mechanically, inspect for cause, then remedy before installing a replacement PC board. If there is damage to the PC board or if replacing PC board corrects problem, return it to the local Lincoln Electric Field Service Shop. DH-10... -

Page 42: Diagrams

DIAGRAMS ENCODER PC BOARD ENCODER PC BOARD DH-10... - Page 43 DIAGRAMS DH-10...

-

Page 44: Dimension Print

DIAGRAMS DIMENSION PRINT DH-10... - Page 45 NOTES DH-10...

- Page 46 ● ● ● Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. ● Insulate yourself from work and ground. Spanish ● ● ● No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE...

- Page 47 ● ● ● Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or ● Use ventilation or exhaust to guards off. WARNING remove fumes from breathing zone. ● Spanish Los humos fuera de la zona de res- ●...

- Page 48 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the DH-10 and is the answer not in the manual?

Questions and answers