Summary of Contents for ESAB A2 SF

- Page 1 A2 Welding heads with Welding Control Unit PEI A2 SF / A2 SF (Twin)/ A2 SG Instruction manual 0449 375 101 GB 2009- -03- -11 Valid for serial no. 240...

- Page 2 Esab Welding Equipment AB, S--695 81 Laxå, Sweden, gives its unreserved guarantee that welding head A2 SF / A2 SG / A2 SG 4WD from serial number 136 complies with standard EN 60292 and EN 60204, in accordance with the require- ments of directive (89/392/EEC) and addendum (93/68/EEC).

-

Page 3: Table Of Contents

......4.7 Conversion of A2 SF (Submerged arc welding) to MIG/MAG welding . -

Page 4: Safety

SAFETY Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of welding equipment. The following recommen- dations should be observed in addition to the standard regulations that apply to the workplace. - Page 5 WARNING ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE BASED ON MANU- - FACTURER’S HAZARD DATA. ELECTRIC SHOCK - - Can kill Install and earth the welding unit in accordance with applicable standards. Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

-

Page 6: Introduction

2.2.1 Submerged Arc Welding (SAW) For submerged arc welding the A2 SF welding head is always to be used. Submerged arc Light Duty. Submerged arc light duty with a Ø 20 mm connector permits a load up to 800 A (100%). -

Page 7: Technical Data

Technical Data 2.4.1 Welding head A2 SF and A2 SG A2 SF (SAW) A2 SG (MIG/MAG) Rated load 100% 800A AC/DC 600A AC/DC Wire dimensions: solid single wire 1.6--4.0 mm 0.8--2.5 mm flux--cored wire 1.6--4.0 mm 1.2--3.2 mm twin wire 2x1.2--2.0 mm... -

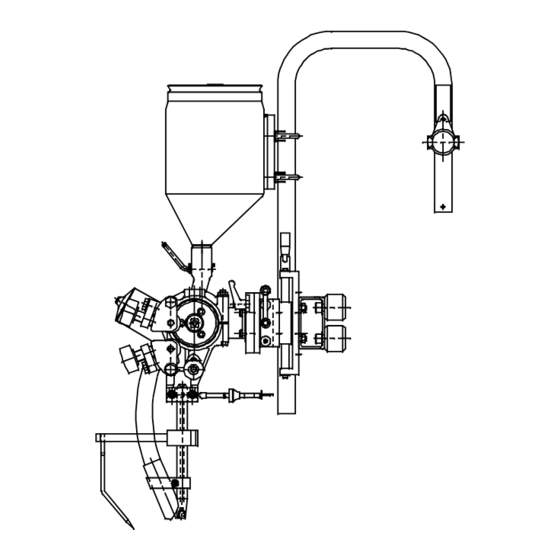

Page 8: Main Components A2 Sf (Saw)

Flux hopper Slide kit, manual Wire feed motor Flux tube Slide kit, motorized Guide pin Carrier for wire drum Main components A2 SF (SAW, Twin) Wire feed unit Connector (Twin) Flux hopper Slide kit, manual Wire feed motor Flux tube... -

Page 9: Main Components A2 Sg (Mig/Mag)

Main Components A2 SG (MIG/MAG) Wire feed unit Connector (MIG/MAG) Slide kit, manual Wire feed motor Slide kit, motorized Carrier for wire drum See on page 10 for a description of the main components. - - 9 - - fhb6d1ea... -

Page 10: Description Of Main Components

Description of Main Components 2.8.1 Wire Feed Unit / Wire Feed Unit with four- -wheel Drive The unit is used for guiding and feeding the welding wire down into the contact tube/connector. 2.8.2 Manual and Motorized Slides The horizontal and vertical position of the welding head is adjusted by way of linear slides. -

Page 11: Installation

INSTALLATION General The installation must be executed by a professional. WARNING Rotating parts can cause injury, take great care. Mounting 3.2.1 Welding head The welding head can easily be mounted on a beam--travelling carriage or on a welding column and boom unit by way of four M12 screws. N.B. -

Page 12: Adjusting The Brake Hub

3.2.3 Wire drum (Accessories) Wire drum (1) is mounted on the brake hub (2). Check that the carrier (3) is pointing upwards. NOTE! The maximum angle for the wire bobbin is 25°. At extreme angles, wear will occur on the brake hub locking mechanism and the wire bobbin will slide off the brake hub. -

Page 13: Connections

Connections 3.4.1 General The A2 Welding Control Unit (PEI) is to be connected by a qualified person. For the connection of A6 GMH, see instruction manual 0460 671 xxx. For the connection of A6 PAV, see instruction manual 0460 670 xxx. 3.4.2 Welding head A2 SG (Submerged arc welding, SAW) 1. - Page 14 3.4.3 Welding head A2 SG (Gas metal arc welding, MIG/MAG) 1. Connect the control cable (7) between the welding power source (8) and the A2 Welding Control Unit (2). 2. Connect the return cable (11) between the welding power source (8) and the work piece (9).

-

Page 15: Operation

OPERATION General Caution: Have you read and understood the safety information ? You must not operate the machine before then ! General safety regulations for the handling of the equipment can be found on page 4. Read through before you start using the equipment! Select wire type and flux powder or shielding gas so that the weld material is as close as possible to the analysis of the base metal. -

Page 16: Loading The Welding Wire (A2 Sf, A2 Sg)

Loading the welding wire (A2 SF, A2 SG) A2 SF (UP) A2 SF (UP, Twin) A2 SG (MIG/MAG) 1. Mount the wire drum according to the instructions on page 12. 2. Check that feed roller (1) and contact jaw or contact tip (3) are of the correct dimension for the selected wire size. - Page 17 8. Feed the wire forward 30 mm with on the control box A2 Welding Control Unit (PEI). 9. Direct the wire by adjusting the knob (5). Always use a guide tube (7) to ensure even feed of fine wire (1.6 -- 2.5 mm). For MIG/MAG welding with wire sizes <...

-

Page 18: Changing The Feed Roller (A2 Sf, A2 Sg)

Changing the feed roller (A2 SF, A2 SG) Single wire Release the knobs (3) and (4). Release the hand wheel (2). Change the feed roller (1). They are marked with their respective wire sizes. Twin wire (Twin- -arc) Change the feed roller (1) with twin grooves in the same way as for single wire. -

Page 19: Contact Equipment For Submerged Arc Welding

Contact equipment for Submerged arc welding 4.4.1 For single wire 1.6 - - 4.0 mm. Light duty (D20) Use welding head A2 SF (UP) where the following are included: Wire feed unit (1), Connector D20 (2) Contact tip (3) (M12 thread). -

Page 20: Contact Equipment For Mig/Mag Welding

Contact equipment for MIG/MAG welding 4.5.1 For single wire 1.6 - - 2.5 mm (D35) Use welding head A2 SG (MIG/MAG) where the following are included: Wire feed unit (1), Connector D35 (2) Contact tip (3) (M10 thread). Tighten the contact tip (3) with a key in order to ensure that a good contact is achieved. -

Page 21: Refilling With Flux Powder (Submerged Arc Welding)

Conversion of A2 SF (Submerged arc welding) to MIG/MAG welding For the conversion kit see instruction manual 0456 756 xxx. Conversion of A2 SF (Submerged arc welding) to Twin- -arc For the conversion kit see instruction manual 0456 757 xxx. - - 21 - -... -

Page 22: Maintenance

MAINTENANCE General Note: All warranty undertakings given by the supplier cease to apply if the customer attempts to rectify any faults on the machine during the warranty period. NB! Before doing any kind of maintenance work, make sure the mains is disconnected. -

Page 23: Fault Tracing

FAULT TRACING General Equipment Instruction manual for A2 Welding Control Unit (PEI). Check that the power supply is connected for the correct mains supply that all three phases are supplying the correct voltage (phase sequence is not important) that welding cables and connections are not damaged that the controls are correctly set that the mains supply is disconnected before starting repairs Possible faults... -

Page 24: Accessories

Ordering no. Fine- -wire straightener 0332 565 880 Conversion kit A2 SF to MIG/MAG welding 0413 526 881 Conversion kit A2 SF to Twin with fine- -wire straightener (LD) 0413 541 882 Pilot lamp (D20) 0153 143 886 Adapter M6/M10... -

Page 25: Dimension Drawing

Dimension drawing A2 SF, Manual Slide kit - - 25 - - dimdoc... - Page 26 A2 SF, Motorized Slide kit - - 26 - - dimdoc...

- Page 27 A2 SG, Manual Slide kit - - 27 - - dimdoc...

- Page 28 A2 SG, Motorized Slide kit - - 28 - - dimdoc...

-

Page 29: Spare Parts List

Welding head A2 SF (SAW, Twin) with PEI 0449 371 881 Welding head A2 SF (SAW, Twin) with PEI, motorised slide and A6 PAV 0449 371 882 Welding head A2 SF (SAW, Twin) with PEI, motorised slide and A6 GMH... - Page 30 Item Ordering no. Denomination Notes 0449370880 Welding head A2 SF (SAW) includes PEI 0449150880 Wire feed unit complete 0449152880 Slide travel kit, manual 90 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable...

- Page 31 Item Ordering no. Denomination Notes 0449370881 Welding head A2 SF (SAW) includes PEI 0449150880 Wire feed unit complete 0449151880 Slide travel kit, motorized 180 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable...

- Page 32 Item Ordering no. Denomination Notes 0449370882 Welding head A2 SF (SAW) includes PEI 0449150880 Wire feed unit complete 0449151880 Slide kit, motorized 180 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable 0449330880...

- Page 33 Item Ordering no. Denomination Notes 0449371880 Welding head A2 SF (SAW, Twin) includes PEI 0449150881 Wire feed unit complete 0449152880 Slide travel kit, manual 90 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable...

- Page 34 Item Ordering no. Denomination Notes 0449371881 Welding head A2 SF (SAW, Twin) includes PEI 0449150881 Wire feed unit complete 0449151880 Slide kit, motorized 180 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable...

- Page 35 Item Ordering no. Denomination Notes 0449371882 Welding head A2 SF (SAW, Twin) includes PEI 0449150881 Wire feed unit complete 0449151880 Slide kit, motorized 180 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable...

- Page 36 Item Ordering no. Denomination Notes 0449380880 Welding head A2SG (MIG/MAG) includes PEI 0449150882 Wire feed unit complete 0449152880 Slide travel kit, manual 90 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable 0449330880 Control box - - 36 - - f449380s...

- Page 37 Item Ordering no. Denomination Notes 0449380881 Welding head A2SG (MIG/MAG) includes PEI 0449150882 Wire feed unit complete 0449151880 Slide kit, motorized 180 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable 0449330880 Control box 0460697880 Joint tracking unit A6 PAV, see seperate manual...

- Page 38 Item Ordering no. Denomination Notes 0449380882 Welding head A2SG (MIG/MAG) includes PEI 0449150882 Wire feed unit complete 0449151880 Slide kit, motorized 180 mm 0449155880 Carrier 0449153985 Cable kit L = 5 m 0456493985 Cable 0456504984 Arc welding cable 0449330880 Control box 0460884880 Joint tracking unit A6 GMH, see seperate manual...

- Page 39 Item Ordering no. Denomination Notes 0449 150 880 Wire feed unit complete (Right) 0147 639 882 Wire feed unit 0413 072 881 Bearing housing 0215 701 210 Wedge, flat 0413 517 001 Bracket for motor 0458 225 001 Motor with tacho 0218 810 183 Insulated Hand wheel 0413 510 001...

- Page 40 Item Ordering no. Denomination Notes 0449 150 881 Wire feed unit complete (Right) UP, Twin 0147 639 886 Wire feed unit Twin 0413 072 881 Bearing housing 0215 701 210 Wedge, flat 0413 517 001 Bracket for motor 0458 225 001 Motor with tacho 0218 810 183 Insulated Hand wheel...

- Page 41 Item Ordering no. Denomination Notes 0449 150 882 Wire feed unit complete (Right) MIG/ MAG 0147 639 882 Wire feed unit 0413 072 881 Bearing housing 0215 701 210 Wedge, flat 0413 517 001 Bracket for motor 0458 225 002 Motor with tacho 0218 810 183 Insulated Hand wheel...

- Page 42 Item Orderingno. Denomination Remarks 0147 639 882 Wire feed unit (right mounted) 0156 449 001 Clamp 0212 900 001 Spacer screw 0215 201 209 O--ring D11.3x2.4 0218 400 801 Pressure roller arm 0218 810 181 Handwheel 0218 810 182 Handwheel 0332 408 001 Stub shaft 0153 148 880 Roller 0415 498 001 Thrust roller carrier...

- Page 43 Item Ordering no. Denomination Notes 0147 639 886 Wire feed unit (right mounted) 0156 449 001 Clamp 0156 530 001 Clamp half 0212 900 001 Spacer screw 0215 201 209 O--ring D11.3x2.4 0218 400 801 Pressure roller arm 0218 810 181 Handwheel 0332 408 001 Stub shaft 0218 524 580 Pressure roller Twin...

- Page 44 Item Orderingno. Denomination Notes 0413 072 881 Bearing housing with stub shaft 0413 073 002 Searing housing 0190 726 003 Ball bearing 0334 575 001 Stub shaft 0215 701 014 Betaining ring 0334 576 001 Spacer - - 44 - - f413072s...

- Page 45 Item Orderingno. Denomination Remarks 0332 994 883 Flux hopper complete 0332 837 001 Hopper for flux 0153 347 881 Flux valve 00203 017 80 Flux strainer 0443 383 002 Flux hose L= 500 - - 45 - - f332994s...

- Page 46 Item Ordering no. Denomination Notes 0333 852 881 Connector Twin L=275 A6 UP 0333 772 001 Nozzle holder 0417 959 881 Contact equipment L=275, Heavy Duty 0415 032 001 Guide pipe 0334 279 001 Spiral to connector L=366 - - 46 - - f333852s...

- Page 47 Item Ordering no. Denomination Notes 0417 959 881 Contact equipment L=275mm 0443 372 001 Screw 0219 504 307 Beleville spring T = 1.1 0443 344 881 Pipe L = 275 - - 47 - - f417959s...

- Page 48 Item Ordering no. Denomination Notes 0153 299 880 Flux nozzle 0153 290 002 Pipe holder 0153 296 001 Pipe bend 0153 425 001 Wheel - - 48 - - f153299s...

- Page 49 Item Ordering no. Denomination Notes 0145 787 880 Fine wire straightener for twin wire 0145 788 001 Case 0145 789 001 Roller 0145 790 001 Roller 0145 791 001 Searing bushing 0190 240 103 Bearing bushing D12/10 0145 792 001 Screw 0145 793 001 Runner 0145 796 002 Screw 0145 794 001 Knob...

- Page 50 Item Orderingno. Denomination Remarks 0030 465 389 Connector 0145 226 001 Insulating sleeve 0190 680 313 O--ring OR 15.3x2.4 0190 680 303 O--ring OR 5.3x2.4 0190 680 405 O--ring OR 22.2x3 0334 278 880 Insert tube 0334 279 001 Spiral 0146 099 001 Plug 0145 534 882 Contact tube 0145 227 882 Gas nozzle...

- Page 51 Item Orderingno. Denomination Notes 0456 494 884 Solenoid valve with cable 0157 259 001 Contact 0193 021 110 Cable, screened ÖLFLEX, 2x1.5 mm 0456 489 001 PCB Connector, plug 0193 054 002 Solenoid valve 42 V 0192 645 002 Bushing - - 51 - - f456494s...

- Page 52 Item Ordering no. Denomination Notes 0449 152 880 Slide travel kit Manual 0413 518 880 Slide 90 mm 0413 506 880 Rotary slide - - 52 - - f449152s...

- Page 53 Item Orderingno. Denomination Remarks 413 518- -880 Slide 413 519--001 Slide profile 413 524--001 Bearing bushing 413 521--001 Runner 413 522--001 Lead screw 334 537--002 Crank 413 523--001 Axis 190 240--107 Bearing - - 53 - - f413518s...

- Page 54 Item Ordering no. Denomination Notes 413 506- - 880 Rotary slide 413 507- -001 Flange 413 508- -001 Tensioning ring 413 509- -001 Flange 2195 043- -05 Bellleville spring 193 571- -105 Locking piece 193 570- -123 Locking lever - - 54 - - f413506s...

- Page 55 Item Ordering no. Denomination Notes 0449 151 880 Motorised Slide kit 0334 333 882 Motorised Slide 180 mm 0413 506 880 Rotary slide - - 55 - - f449151s...

- Page 56 Item Orderingno. Denomination Notes 0334333882 Slide Inställningslängd = 180 0190509321 Stop screw M5x6 0334341001 End washer L = 60--540 0334323003 Steel shaft L = 180 0334335003 Slide frame L = 180 0334326003 Shaft carrier L = 180 0417699001 Clamp 0334322001 Geared motor 24V, 110 rpm 0334321001...

- Page 57 Item Ordering no. Denomination Notes 0449 155 880 Carrier 0413 596 001 Attachment 0278 300 180 Insulator 2000 V 0413 853 001 Mounting arm 0154 734 001 Clamp 0146 967 880 Brake hub - - 57 - - f449155s...

- Page 58 ESAB subsidiaries and representative offices Europe Asia/Pacific Representative offices NORWAY AS ESAB AUSTRIA BULGARIA CHINA Larvik ESAB Ges.m.b.H ESAB Representative Office Shanghai ESAB A/P Tel: +47 33 12 10 00 Vienna- -Liesing Sofia Shanghai Fax: +47 33 11 52 03...

Need help?

Do you have a question about the A2 SF and is the answer not in the manual?

Questions and answers