Table of Contents

Advertisement

Quick Links

Instructions – Parts List

Parts

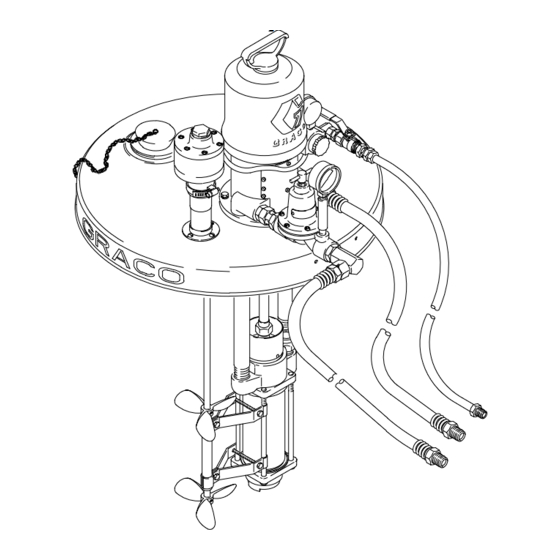

55 GALLON SUPPLY PUMPS

3:1 Presidentr, 4:1 Presidentr,

and 2:1 Monarkr

With drum cover and agitator

Model 220575, Series B

with 3:1 Ratio President Pump

500 psi (3.5 MPa, 35 bar) MAXIMUM FLUID WORKING PRESSURE

∗ Model 230992, Series C

with 4:1 Ratio President Pump

400 psi (2.8 MPa, 28 bar) MAXIMUM FLUID WORKING PRESSURE

Model 230993, Series C

with 2:1 Ratio Monark Pump

200 psi (1.4 MPa, 14.0 bar) MAXIMUM FLUID WORKING PRESSURE

Read warnings and instructions.

See page 2 for table of contents.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 1985, Graco Inc. is registered to I.S. EN ISO 9001

Model 230992 Shown

307745H

04281A

Advertisement

Table of Contents

Summary of Contents for Graco Monark C Series

- Page 1 200 psi (1.4 MPa, 14.0 bar) MAXIMUM FLUID WORKING PRESSURE Read warnings and instructions. See page 2 for table of contents. Model 230992 Shown 04281A GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 Copyright 1985, Graco Inc. is registered to I.S. EN ISO 9001...

-

Page 2: Table Of Contents

D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. D Do not alter or modify this equipment. Use only genuine Graco parts and accessories. - Page 3 WARNING MOVING PARTS HAZARD D The air motor piston can pinch or amputate your fingers. D The rotating blades of the agitator can pinch or amputate your fingers or other body parts and can cause splashing in the eyes or on the skin. D Always shut off the agitator and disconnect the air line before adjusting the angle of the agitator, removing the agitator from the drum, or checking or repairing any part of the agitator.

- Page 4 WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury. D Ground the equipment and the object being sprayed. Refer to Grounding on page 5. D If there is any static sparking or you feel an electric shock while using this equipment, stop spray- ing immediately.

-

Page 5: Setup

Use only metal pails, which are conductive, placed on a grounded surface. Do not place the pail D Accessories are available from your Graco repre- on a nonconductive surface, such as paper or card- sentative. If you supply your own accessories, be board, which interrupts the grounding continuity. -

Page 6: Connecting The Unit And Accessories

The installation shown in Fig. 2 is only a guide for selecting and installing system components and accessories. Contact your Graco representative for assistance in designing a system to suit your particular needs. D The fluid line must include a fluid drain valve (K),... -

Page 7: Operation

Operation Pressure Relief Procedure Flush the pump before first use. The pump is tested with lightweight oil, which is left in to protect the pump parts. If the fluid you are using may be contami- WARNING nated by the oil, flush it out with a compatible solvent. PRESSURIZED EQUIPMENT HAZARD WARNING The system pressure must be manually relieved to... -

Page 8: Adjusting The Unit

Operation 8. Shut off the air to the pump, open the bleed–type 5. When the paint returns through the return line in a master air valve, and open the drain valve (K). steady stream, turn on the air to one gun, open Leave the solvent in the system overnight or, if both fluid shutoff valves (C) near the gun, and possible, all weekend. -

Page 9: Shutdown And Care Of The Pump

6. If you are not using an air line lubricator, manually 2. If using a Graco fluid pressure regulator at the lubricate the motor at least once a day. gun, reverse its regulating key and thread it into the regulator cap as far as it will go. -

Page 10: Parts Drawing

Parts Drawing Model 230992, Series B Model 230993, Series B 4:1 Ratio President Carbon Steel 2:1 Ratio Monark Carbon Steel 55 Gallon Drum System 55 Gallon Drum System Includes items 1 to 4, and 6 to 12 Includes items 2 to 6, and 11 1 or 5 (MONARK PUMP SHOWN) Fig. -

Page 11: Parts List

Parts List Model 230992, Series B 4:1 Ratio President Carbon Steel 55 Gallon Drum System Includes items 1 to 4, and 6 to 12 Model 230993, Series B 2:1 Ratio Monark Carbon Steel 55 Gallon Drum System Includes items 2 to 6, and 11 Ref. - Page 12 Parts Drawing Model 220575, Series B Remove and discard 1/2 x 3/8 npt nipple from outlet of 3:1 Ratio President Stainless Steel air regulator (5a), and replace with 1/2 npt nipple (5c). Then 55 Gallon Drum System connect air regulator assy to pump air inlet. Includes items 1–35 Agitator (3) is tilted at a 6_ angle.

- Page 13 Parts List Model 220575, Series B 3:1 Ratio President Stainless Steel 55 Gallon Drum System Part 223319 RETURN TUBE KIT Includes items 6a–6d Description Part Description 220564 PUMP, President See 308793 for parts 185393 TUBE, return; sst; 1” npt(m) 237309 COVER, drum, 55 gal.

- Page 14 Notes 307745...

-

Page 15: Technical Data

Technical Data Category Model 220575 Model 230992 Model 230993 Ratio Maximum fluid working 500 psi (3.5 MPa, 35 bar) 400 psi (2.8 MPa, 28 bar) 200 psi (1.4 MPa, 14 bar) pressure Maximum air input 166 psi (1.2 MPa, 11.6 100 psi (0.7 MPa, 7 bar) 100 psi (0.7 MPa, 7 bar) pressure... -

Page 16: Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Monark C Series and is the answer not in the manual?

Questions and answers