Table of Contents

Advertisement

Quick Links

Setup and Operation

Advanjet

HV-2000b, Mycronic

For non-contact dispensing of viscous material in industrial environments. For

professional use only.

Not approved for use in explosive atmospheres or hazardous (classified) locations.

26B970

60 psi (0.41 MPa, 4.1 bar) Maximum Fluid Pressure

90 psi (0.62 MPa, 6.2 bar) Maximum Jet Pressure

See page 2 for model information, including

maximum working pressure.

Important Safety Instructions

Read all warnings and instructions in this

manual and all related manuals before

using the equipment. Save these

instructions.

®

Jet Valve

3A8813A

EN

Advertisement

Table of Contents

Summary of Contents for Graco Advanjet 26B970

- Page 1 Setup and Operation ® Advanjet Jet Valve 3A8813A HV-2000b, Mycronic For non-contact dispensing of viscous material in industrial environments. For professional use only. Not approved for use in explosive atmospheres or hazardous (classified) locations. 26B970 60 psi (0.41 MPa, 4.1 bar) Maximum Fluid Pressure 90 psi (0.62 MPa, 6.2 bar) Maximum Jet Pressure See page 2 for model information, including maximum working pressure.

-

Page 2: Table Of Contents

California Proposition 65 ....25 Graco Standard Warranty....26... -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable. - Page 4 Warnings WARNING EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

-

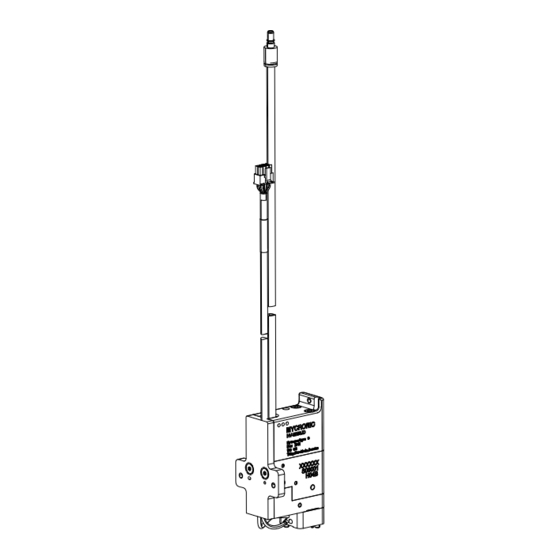

Page 5: Component Identification

Component Identification Component Identification . 1: HV-2000b Components Key: Jet Pressure Air Inlet Harness Heater Block Weep Hole Top Cover 3A8813A... -

Page 6: Nozzle Components

Component Identification Nozzle Components NOTE: Nozzle components are sold separately. See Tools and Accessories on page 17. . 2: Nozzle Components Key: AA Nozzle Plate (bottom) AB Flat Barb Nozzle Plate (top) AC Tilted Barb Nozzle Plate (top) AD Tilted Face Seal Nozzle Plate (top) AE Nozzle AF O-Ring, Nozzle Insert AG O-Ring, Nozzle Plate*... -

Page 7: Controller

Component Identification Controller NOTE: See the HM-2600C Jet Controller Setup and Operation manual for more information on the Jet controller. See Related Manuals on page 2. HM-2600C Front Panel . 3: Controller Front Panel Key: BA Fluid Air Switch: Provides quick ON/OFF control BF Key Pad Arrows: Toggles between settings. - Page 8 Component Identification HM-2600C Rear Panel . 4: Controller Rear Panel Key: CA Jet Harness Connector (HM-2600C) CB Jet Harness Connector (HV-2000C) CC Fluid Pressure Outlet: Connects to the fluid pres- sure air inlet (not included) on the Jet. CD Jet Pressure Outlet: Connects to the Jet Pressure Air Inlet (A) on the Jet.

-

Page 9: Jet Cable Input/Output

Component Identification Jet Cable Input/Output A 15-pin cable is supplied with the HV-2000b Jet Valve. The table below describes the Jet cable pin assignments. . 5: HD-15 Jet Cable Harness Connector HD-15 Jet Cable Pin Assignments Assignment Solenoid Solenoid Heater (internally jumped to pin 15) Heater (internally jumped to pin 11) -

Page 10: Installation

Installation Installation Install the Diaphragm and 4. After the diaphragm (AH) is inserted, the nozzle plate (AA) can be attached to the heater block (C). Nozzle Plate The nozzle plate (AA) has 2 locating pins to guide it onto the heater block (C). Align the nozzle plate (AA) NOTE: The diaphragm (AH) and nozzle plate (AA) are to the locating pins on the heater block (C), with the sold separately. -

Page 11: Install Feed Tubes

Installation Install Feed Tubes NOTE: Feed tubes and syringe brackets are sold separately. See Tools and Accessories on page 17. Rubber Feed Tube 1. Install the syringe bracket using the two screws included to attach to the Jet. 2. Attach the feed tube to the outlet of the syringe. Syringe Syringe Outlet... -

Page 12: Operation

Operation Operation Pressure Relief Procedure Prime the Jet NOTE: The nozzle plate (AA) and diaphragm (AH) must Follow the Pressure Relief Procedure whenever be installed prior to priming the Jet. you see this symbol. 1. Ensure the fluid pressure is OFF. 2. -

Page 13: Cleaning The Jet

Cleaning the Jet Cleaning the Jet 3. Manually clean the diaphragm ((AH) with a cotton swab or an agitating brush that has been saturated with 91% isopropyl alcohol. Material inside the applicator can be very hot. To 4. When the nozzle (AE) has cooled, set it in a avoid severe burns, wear protective gloves. -

Page 14: Troubleshooting

Troubleshooting Troubleshooting 1. Follow Pressure Relief Procedure on page 12 before checking or repairing the Jet. 2. Check all possible problems and causes before disassembling the Jet. Problem Cause Solution No material coming out of Jet Clogged nozzle (AE) Clean nozzle (AE). nozzle (AE). -

Page 15: Parts

Parts Parts HV-2000b 3A8813A... - Page 16 Parts HV-2000b Ref. Part Description Qty. Ref. Part Description Qty. FITTING, straight, QD, 6 mm MANIFOLD, hv-2000b, clear 1 tubing 60-2266 CYLINDER, assembly, 24† --- SCREW, set, M3-0.5 x 4, flat hammer pt, ss CYLINDER, assembly, lever 130355 WASHER, flat 4†...

-

Page 17: Tools And Accessories

Tools and Accessories Tools and Accessories Pivot Pin Tool, 60-2355 Metal Feed Tube Torque Tool 0.9 N•m, 60-2324 Used with metal feed tubes only. . 11 Part Description Qty. 60-2355 TOOL, spacer, precision Hammer Gap Tool, 09-4115-00 . 14 Part Description Qty. -

Page 18: Nozzle Plate (Top)

Tools and Accessories Nozzle Plate (Top) Nozzle Plate (Bottom) 03-2059-00 Shown . 17 Protective Part Type Qty. Height 03-2058-00C Flat, Countersink 03-4090-03 Protective 3 mm 03-2264-00 Shown 03-4090-06 Protective 6 mm Diaphragm 03-4082-00 Shown . 16 Part Type Seal Qty. . -

Page 19: Nozzle Plate O-Ring

Tools and Accessories Tilted Face Seal O-Ring Nozzle Insert O-Ring . 19 . 21 Part Material Qty. Part Material Qty. NP09-2856 NP09-2830 Silicone NP09-2855 Silicone Nozzle Plate O-Ring NP09-2851 NP09-2853 Nozzle Plate Screws, 60-2300 . 20 Part Material Qty. NP09-2820 Silicone NP09-2854 Silicone... -

Page 20: Syringe Brackets

Tools and Accessories Syringe Brackets 60-2360 60-2359 Used with 35 mm rubber feed tube. Used with 55 mm rubber or metal feed tube. . 23 . 25 Part Description Qty. Part Description Qty. 60-2360 KIT, mount, 10 cc 60-2359 KIT, mount, 30/55 cc 60-2361 Feed Tubes Used with 35 mm rubber feed tube. -

Page 21: Nozzles

Tools and Accessories Nozzles Capillary Nozzles Part Material Type Ball Size Length Orifice (µm) NK-21-050 NK-21-075 NK-21-100 Tungsten Carbide Tapered Capillary Ø 1.6 mm 3 mm NK-21-125 NK-21-150 NK-21-200 NK-25-050 NK-25-075 Tapered Capillary NK-25-100 Tungsten Carbide (Tungsten Carbide Ø 3.0 mm 6 mm NK-25-125 and Ceramic... - Page 22 Tools and Accessories Flat Nozzles Part Material Type Ball Size Length Orifice (µm) NK-34-050 NK-34-064 NK-34-075 NK-34-100 Tungsten Carbide Flat Ø 1.6 mm Flat NK-34-125 NK-34-150 NK-34-200 NK-34-300 NK-35-064 NK-35-075 NK-35-100 NK-35-125 NK-35-150 NK-35-200 Tungsten Carbide Flat Ø 3.0 mm Flat NK-35-300 NK-35-400...

-

Page 23: Dimensions

The Advanjet Jet Valves provide a dovetail rear mounting plate for rigid attachment to a robot’s XYZ stage. An optional mating dovetail mount is available from Graco (P/N 60-2311). See Tools and Accessories on page 17. • The dispense tip relative to the mounting holes and the rear mounting plate dimensions are shown in the following figures. -

Page 24: Hv-2000B Jet

Dimensions HV-2000b Jet . 26: HV-2000b Dimensions Dimensions Dimensions 1.50 in. (38.0 mm) 4.13 in. (104.9 mm) 0.50 in. (12.7 mm) 3.50 in. (88.9 mm) 1.75 in. (44.5 mm) 2.25 in. (57.2 mm) 0.53 in. (13.5 mm) 2.00 in. (50.8 mm) 1.50 in. -

Page 25: Technical Specifications

Technical Specifications Technical Specifications HV-2000b Metric Viscosity range 1-400k mPa-s (cp) Speed Up to 300 drops/second Fluid syringes 5 cc, 10 cc, 30 cc, 55 cc, 150 cc, 6 oz Maximum fluid pressure 0.41 MPa (60 psi) Max Maximum nozzle heater temperature 158 °F 70 °C Operating temperature... -

Page 26: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Advanjet 26B970 and is the answer not in the manual?

Questions and answers