Summary of Contents for ARIS Nano+

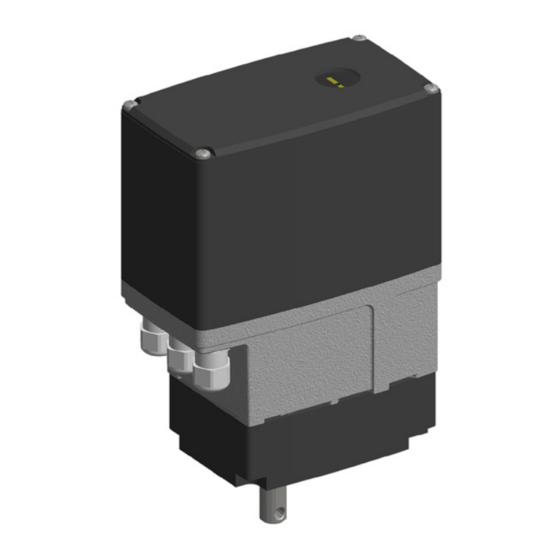

- Page 1 Stellantriebe Original declaration of incorporation with manual for ARIS Actuator Nano + incl. manual for ARIS Microprocessor-Controller PMR-Nano...

-

Page 2: Table Of Contents

Extraordinary situations ................................17 Troubleshooting and repair ............................... 18 Maintenance ..................................... 18 Service ..................................... 18 Accessories ....................................18 Spare parts ....................................18 ARIS Stellantriebe GmbH Rotter Viehtrift 9 Tel.: +49 2241 25186-0 aris@stellantriebe.de 53842 Troisdorf/Germany Fax: +49 2241 25186-99 www.stellantriebe.de... -

Page 3: Identification

SNr: 1539-XXXXX-01001 Actuator type Typ: Nano+ S Voltage/Frequency/Power consumption 230V, 50(60)Hz 12VA 60(50)s/90° 40 Nm Actuating time/Torque UT -15°C/+60°C IP65 Ambient temperature/Protection class Additional built-in parts Made in Germany ARIS Stellantriebe GmbH Rotter Viehtrift 9 D-53842 Troisdorf www.stellantriebe.de Stellantriebe Nano+... -

Page 4: Guidelines And Standards

The actuator components are conform to the state of the art and apply as generally safe at the time they are shipped. This manual serves as basis to install and operate ARIS actuators safety conform. All persons working with or on ARIS actuators must observe this manual and especially its safety advices. -

Page 5: Technical Specification

Under water Safe and accurate use ARIS actuators are factory checked prior to delivery. The final functional testing must be performed within the total system by qualified technical personnel. The ARIS company assumes no liability for possible manufacturing errors and resulting damages or subsequent damages after the actuator has been tested, installed and declared functional correct. - Page 6 Dimensions Nano+ S Round shaft with cross hole (Standard) Cable glands optional H=73 mm/102 mm, (Standard=blind plugs) depending on options Round shaft ISO shaft D-shaft with feather key inner 4-square (Option) (Option) (Option) F05 Ø50 F03 Ø36 Nano+...

- Page 7 Nano+ M Round shaft with cross hole (Standard) ISO shaft Round shaft inner 4-square with feather key (Option) (Option) F05 Ø50 Type 30-40 Nm 50-60 Nm Nano+...

-

Page 8: Performance Data

Expected lifespan and intended disposal ARIS actuators have an expected lifespan of several years, depending on their utilization and application. No longer usable actu- ators must not be dismantled as a whole, but seperately recycled in parts divided by their materials. Non-recyclable components must be disposed according to national disposal regulations. -

Page 9: Packaging

Packaging ARIS actuators are protected by special cardboard packaging at delivery. Safe disposal of packaging Additionally necessary packaging is made by easily separable packaging materials and can be recycled individually: • Wood • Cardboard • Paper • Plastics Installation and mounting •... -

Page 10: Initial Operation

• Cover assembly During the cover assembly make sure that the cover fits correctly. The cover must not show any damages on the joint surface. Tighten cover screws evenly (max. 1.2 Nm). • Housing/Cover CAUTION No additional bores are allowed in the housing and the cover. Initial operation 4.5.1 Electrical connection... -

Page 11: Wiring Diagram

4.5.2 Wiring diagram Options Standard Optionen Current Strom- output ausgang 9 10 1213 1516 5455 – Limit switch, CCW Limit switch, CW Option 24 V DC Auxiliary switch 1 see chapter 5.3.10 Auxiliary switch 2 Potentiometer 1 Steuerelektronik Limit switch, CCW Limit switch, CW +L +R –... -

Page 12: Set Up Limit Switches (Self-Adjusting Switch Cam)

Set up limit switches (Self-adjusting switch cam) The switch cams are turnable by hand and can be fastened by a thread pin, e.g. if strong ADVICE vibrations apply. Apply voltage (see page 10): Actuator rotates in given direction. Switch off voltage when the desired end position has reached (no blocking of gear). Turn switch cam L in rotating direction of the cam shaft E until limit path switch SL clicks. - Page 13 Overview TÜV-Poti Poti Novotechnik SP28 Micro switches Switch cams Electrical connection Connect terminals 18, 19 and 20 according to the desired needs (voltage ≤ 50V); (see page 11). Use only separate, shielded wires. Adjustment Set the limit switch prior to adjustment of the potentiometers SP28. Electrically drive towards both end positions (see chapter 5.2). Match both travel and potentiometer resolution.

-

Page 14: Additional Limit Switches (Self-Adjusting Switch Cam)

ADVICE All potis must generally run under a potential divider circuit. U– 5.3.3 Additional limit switches (Self-adjusting switch cam) The switch cams can be rotateted by hand an can additionally be fi xed with a thread pin, ADVICE e.g. at strong vibrations. Approach desired position. -

Page 15: Mechanical Position Indicator

5.3.5 Mechanical position indicator The mechanical position indicator serves as a reference for the shaft position on the sight-glass and it is adjustable. Adjustment: Adjust the mechanical position indicator by turning the angle pointer (marked with an arrow) and the enclosed arrow labels. Ratio position indicator to valve position on Nano M: Type Pos.ind. -

Page 16: Single Wire Control (230 V Ac Only)

5.3.8 Single wire control (230 V AC only) For use as open/close regulation by external controller or switching appliances with normally open or break contact. The rotation direction reverse is made by a built-in switching relay. 1 2 3 4 5 A B The add-on board with the single wire control is wired at factory. -

Page 17: Power Supply 24 V Dc (Special Edition)

• condition of electric wires. If failure appear, set the actuator out of order and correct the error. If you can not correct the error, contact an ARIS service person. ADVICE More information under: www.stellantriebe.de... -

Page 18: Troubleshooting And Repair

ADVICE More information under: www.stellantriebe.de Maintenance Service ARIS actuators of type Nano have a lifetime lubrication and are generally maintenance-free. Accessories No special tools are required for installation. The required hex wrench is enclosed with the delivery. Spare parts Order spare parts at aris@stellantriebe.de any time. - Page 19 Stellantriebe Manual for ARIS Microprocessor- Controller PMR-Nano 115 V AC / 230 V AC only...

- Page 20 Hardware/firmware state ................................. 29 Menu end ....................................29 Fault message contact ................................29 Error Code ....................................29 Technical data ................................... 30 Declaration of incorporation ..............................31 ARIS Stellantriebe GmbH Rotter Viehtrift 9 Tel.: +49 2241 25186-0 aris@stellantriebe.de 53842 Troisdorf Fax: +49 2241 25186-99...

-

Page 21: Intended Use

Intended use ARIS microprocessor controllers, series PMR-Nano, are used for activating ARIS actuators. They are integrated in the actuator hous- ing. PMR-Nano series microprocessor controllers position the actuator based on a reference input (set point). The PMR controller com- pares the preset set point with the current position of the actuator (actual value). In case the values differ from each other, the actu- ator is moved to the position specified by the set point. -

Page 22: Wiring Diagram

Wiring diagram (Built-in version) Terminal strip for microprocessor controller Actuator motor Limit switch, CCW rotation Limit switch, CW rotation Potentiometer for actual value PMR-Nano In-/Output 0(4)–20 mA (DC) 0(2)–10 V (DC) Fault message output Relay contact Internal wiring (do not modify!) External control and wiring PMR-Nano... -

Page 23: Circuit Board

Circuit board Connection 1 ZW / 2 ZW Motor connection Manual operation / Automatic operation Selection Right Input / Output Menu mA / V Left General information This product is a controller for activation with standard signals. The PMR-Nano control board converts the standard signal in CW or CCW motor activation. -

Page 24: Dip Switches

DIP switches The DIP switches must be set according to the desired configuration. For current input and current output 1 & 4 at ON and 2 & 3 at OFF. For voltage input and output 2 & 3 at ON and 1 & 4 at OFF. 1 &... -

Page 25: Menu

ARIS Intern This setting is made internally by Aris and must not be changed. Depending on the gear, the actual value input must be adjusted. If the setting is incorrect, the right end position can no longer be set or the drive moves incorrectly. Possible source of error! -

Page 26: End Positions

End positions The first menu item is the setting of the end positions. It must be started with the left end position. If there is a change later, you can start with both end positions. Confirming the „End Position“ menu item directly displays the „Left End“ item. After confirmati- on, the end position can be approached. -

Page 27: Analog Input/Output

Analog input/output The analog input and output is selected in the following two menu items. Each submenu item from the input can be combined with each of the four from the output. The correct setting of the DIP switches must be observed. ---Menu--- ---Menu--- ---Menu---... -

Page 28: Start/Stop Hysteresis

---Menu--- ---Menu--- Stop Hysterese Stop Hysterese Back ---Menu--- ---Menu--- Start Hysterese Start Hysterese Back Attention: If both hystereses are selected too low, it can happen, depending on the motor/gear combination, that the controller does not exactly reach the target value, but switches back and forth around it. Note: The highest accuracy is achieved when the entire path is traversed. -

Page 29: Hardware/Firmware State

Hardware/firmware state Both states are displayed here, this is important for support. ---Menu--- FW X.X HW X.X Menu end Back to manual mode at the end of the menu: press the menu button >1s. ---Menu--- PRESS M FOR END CONFIG Fault message contact The PMR has a fault message contact (potential-free). -

Page 30: Technical Data

Technical data Power supply 115 V & 230 V, 50/60 Hz (motor dependent) Special voltage/frequency see nameplate Set value input 0(4)-20 mA (DC) Burden 250 Ohm / 500 mW Reverse polarity protection 0(2)-10 V (DC) Reverse polarity protection Overload protection Actual value output 0(4)-20 mA 0(2)-10 V... -

Page 31: Declaration Of Incorporation

Authorized representative for collection of relevant technical documents: Claudio Usai Quality and product safety ARIS Stellantriebe GmbH Rotter Viehtrift 9 D-53842 Troisdorf This declaration is invalid if the machinery is changed or rebuilt in a manner it was not designed for. - Page 32 ARIS Stellantriebe GmbH Tel.: +49 2241 25186-0 Rotter Viehtrift 9 Fax: +49 2241 25186-99 53842 Troisdorf / Germany aris@stellantriebe.de www.stellantriebe.de Stellantriebe...

Need help?

Do you have a question about the Nano+ and is the answer not in the manual?

Questions and answers