Summary of Contents for Ice SCRUB 80 D

- Page 1 SCRUB 80 D SCRUBBING MACHINES USE AND MAINTENANCE MANUAL ORIGINAL INSTRUCTIONS DOC. 10083798 - Ver. AA - 12-2018...

-

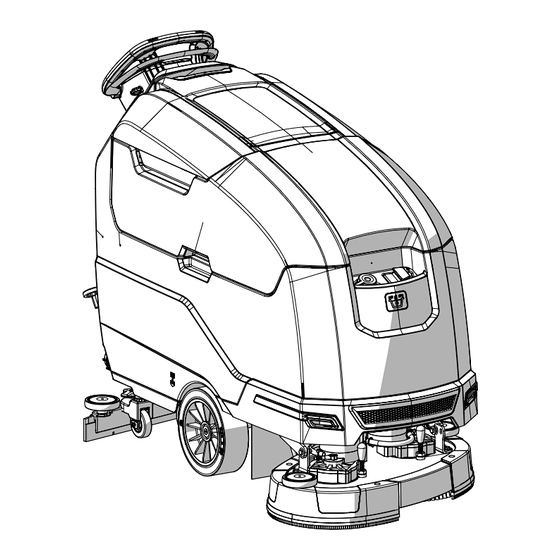

Page 3: Main Machine Components

MAIN MACHINE COMPONENTS The machine's main components are the following: 18. Squeegee body. 19. Water flow adjustment tap. 1. Dead man's lever. 20. Front headlights (optional). 2. Control handlebars. 21. Solution tank filler cap/measuring inlet. 3. ECO-MODE button. 22. Cover cap for FFF quick coupling kit (optional). 4. -

Page 4: Table Of Contents

CONTENTS MAIN MACHINE COMPONENTS ....................3 CONTENTS ..........................4 GENERAL SAFETY REGULATIONS ..................6 SYMBOLS USED IN THE MANUAL ..................6 PURPOSE AND CONTENT OF THE MANUAL .................7 STORING THE USE AND MAINTENANCE MANUAL ...............7 ON CONSIGNMENT OF THE MACHINE ...................7 INTRODUCTORY COMMENT ....................7 IDENTIFICATION DATA ......................7 TECHNICAL DESCRIPTION ......................7 INTENDED USE ..........................7... - Page 5 FILLING THE SOLUTION TANK WITH WATER ....................15 DETERGENT SOLUTION ............................ 15 PREPARING TO WORK ......................16 STARTING WORK ........................17 HOUR METER ..............................17 BATTERY CHARGE LEVEL INDICATOR ......................17 SCRUBBING WITH DRYING ..........................18 SCRUBBING WITHOUT DRYING ........................18 DRYING ................................18 ADJUSTMENT OF THE DETERGENT SOLUTION FLOW .................

-

Page 6: General Safety Regulations

The descriptions contained in this document are not binding. The company therefore reserves the right to make any modifications at any time to elements, details, or accessory supply, as considered necessary for reasons of improvement or manufacturing/commercial requirements. The reproduction, even partial, of the text and drawings contained in this document is prohibited by law. The company reserves the right to make any technical and/or supply modifications. -

Page 7: Purpose And Content Of The Manual

PURPOSE AND CONTENT OF THE MANUAL The aim of this manual is to provide customers with all the information needed to use the machine in the safest, most appropriate and most autonomous way. This includes information concerning technical aspects, safety, operation, downtime, maintenance, spare parts and scrapping. The operators and qualified technicians must carefully read the instructions in this manual before carrying out any operations on the machine. -

Page 8: Serial Number Plate

SERIAL NUMBER PLATE The serial number plate is positioned underneath the electrical system control panel inside the machine. It indicates the general machine characteristics, in particular the serial number. The serial number is a very important piece of information and should always be provided together with any request for assistance or when purchasing spare parts. -

Page 9: Disposal

Unit of TECHNICAL DATA MxL 65 Bt MxL 75 Bt Scrub 80D MxL 70 Bts Meas- urement Rated machine power 1725 1725 1725 1625 Working capacity up to sq.ft/h 17.631 20.591 22.604 17.362 Working width 25,79 30,12 33,07 25,39 Squeegee width 30,8 34,8 38,8... -

Page 10: Symbols Used On The Machine

SYMBOLS USED ON THE MACHINE SYMBOLS PRESENT ON THE REGISTRATION PLATE Direct current symbol: Used on the appliance's registration plate to indicate that the appliance is powered by a DC power supply. Battery symbol: Used on the appliance's registration plates to indicate the mass of the batteries used to power the appliance (expressed in Kg). The value refers to the batteries that the manufacturer offers. -

Page 11: Preparation Of Machine

Machine use warning label: Located on the rear of the machine, to warn the operator which substances cannot be removed with the machine. Solution tank filter daily care warning label: Applied to the machine to remind the operator to clean the solution tank after each use. Moving brush hazard label: Used on the machine to warn the operator not to place his/her hands near the moving brush. -

Page 12: How To Unpack The Machine

HOW TO UNPACK THE MACHINE The machine is shipped in specific packaging. To remove it, proceed as follows: 1. Place the lower part of the outer packaging in contact with the floor. N.B.: Use the pictograms printed on the box as reference. 2. -

Page 13: Type Of Battery To Be Used

To fit the batteries inside the machine, contact an ICE assistance centre technician. The batteries should be connected so as to obtain a total voltage of 24V. WARNING: ICE declines all responsibility for any damage to property or injury persons in the event that the batteries are replaced by an unauthorized technician. -

Page 14: Assembling The Brush (Scrubbing Version)

• Once the recharge cycle has been completed, disconnect the battery charger's cable from the battery connector. • Connect the electrical system connector (7) to the battery connector (8). • Grip the handle (6) and turn the recovery tank to its working position. To recharge the batteries with the on-board battery charger proceed as follows: ATTENTION: the following operations must be carried out by qualified personnel. -

Page 15: Assembling The Squeegee Body

ASSEMBLING THE SQUEEGEE BODY For packaging reasons, the squeegee body comes disassembled from the machine. In order to mount it on the squeegee support, do the following: 1. Make sure the machine is in a safe condition (read “MACHINE SAFETY”). 2. -

Page 16: Preparing To Work

ATTENTION: Acid or alkaline maintenance detergent tank be used with pH values between 4 and 10 and that do not contain: oxidising agents, chlorine or bromine, formaldehyde, mineral solvents. The detergents used must be suitable for use with scrubbing machines. CAUTION: always use low-foam detergent. -

Page 17: Starting Work

STARTING WORK To start working, do as follows: 1. Make all the checks listed in “PREPARING TO WORK”. 2. Go to the driving position, behind the machine. 3. Turn on the machine and turn the key (1) a quarter turn clockwise (Fig.1). 4. -

Page 18: Scrubbing With Drying

the battery “critical charge” threshold is reached, the last indicator bar flashes for about 20 seconds, after which the “battery” symbol begins to flash. SCRUBBING WITH DRYING To perform a scrubbing and drying program, proceed as follows: 1. Make all the checks listed in “PREPARING TO WORK”. -

Page 19: Regulating The Forward Speed

REGULATING THE FORWARD SPEED This machine is equipped with electronic traction control. During work, the forward speed can be adjusted by pressing the operator lever (4) located under the control handlebars (Fig.6). N.B.: The more the lever (4) is pressed, the more the forward speed will increase. REVERSE GEAR This machine is equipped with electronic traction control. -

Page 20: Alarm Screen

3. Bring the machine to the designated place for draining off the dirty water, and empty the recovery tank (see “EMPTYING THE RECOVERY TANK”). ALARM SCREEN In Essential versions, when there is an error, the text AL is shown on the command display followed by a number (Fig.16); this stays visible until the error is resolved. -

Page 21: Recommended Maintenance Operations

RECOMMENDED MAINTENANCE OPERATIONS INTERVAL MACHINE COMPONENTS PROCEDURE Clean the vacuum chamber; the squeegee rubber blades; the vacuum nozzle Squeegee (see “CLEANING THE SQUEEGEE BODY”). Empty the debris hopper and clean inside (see “CLEANING THE DEBRIS Debris hopper HOPPER (SWEEPING VERSION)”). Clean the brushes on the brush head body (see “CLEANING THE BRUSH HEAD BODY BRUSHES (SCRUBBING... -

Page 22: Cleaning The Squeegee Body

Before performing any routine or extraordinary maintenance operation, proceed as follows: 1. Take the machine to the maintenance area. N.B.: the place given over to this operation must comply with current environmental protection regulations. 2. Make sure the machine is in a safe condition (see chapter “MACHINE SAFETY MEASURES”). -

Page 23: Draining The Recovery Tank

7. See “INSTALLING THE BRUSH (SWEEPING VERSION)” for instructions on refitting the brushes in the brush head body. N.B.: Check that the bristles are not worn; in the event of excessive wear, replace the brush (the bristles should be at least 10 mm long). "REPLACING THE BRUSH (SWEEPING VERSION)"... -

Page 24: Extraordinary Maintenance Work

EXTRAORDINARY MAINTENANCE WORK REPLACING THE BRUSH (SCRUBBING VERSION) The good condition of the brush guarantees better cleaning of the floor, as well as a longer brush head gearmotor lifespan. To replace the brush, proceed as follows: 1. Go to the front of the machine. 2. -

Page 25: Adjustment Interventions

N.B.: Before using the machine, remember to adjust the squeegee body: see the section titled “ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES”. N.B.: It is recommended to replace both squeegee body blades in order to ensure good results when drying the floor. ADJUSTMENT INTERVENTIONS ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES The careful adjustment of the squeegee body rubber blades guarantees better cleaning of the floor. -

Page 26: Troubleshooting

MACHINE CODE BRISTLE NOTES 422189 PPL 0.3 BLUE BRUSH 422971 PPL 0.6 WHITE BRUSH MxL 65 Bt 422972 PPL 0.9 BLACK BRUSH 422981 ABRASIVE GREY BRUSH 422973 PAD HOLDER 414272 PPL 0.3 BLUE BRUSH 414270 PPL 0.6 WHITE BRUSH MxL 75 Bt 414273 PPL 0.9 BLACK BRUSH... - Page 27 PROBLEM POSSIBLE CAUSE SOLUTION The quantity of detergent solution in Check that the amount of detergent solution present in the machine's water NOT ENOUGH the water system is not sufficient for system is sufficient for the work to be carried out. DETERGENT the work to be carried out.

-

Page 28: Ec Declaration Of Conformity

37059 - S. Maria di Zevio (VR) - Verona - Italia Chapel Lane, Totton, Hampshire, SO40 9AH Tel. +39 045 6060411 - Fax. +39 045 6060417 Tel. 0800 389 3869 - Fax. 023 8042 8318 E-mail: service@fimap.com E-mail: info@ice-clean.com Web: www.fimap.com Web: www.ice-clean.com... - Page 29 37059 - S. Maria di Zevio (VR) - Verona - Italia Chapel Lane, Totton, Hampshire, SO40 9AH Tel. +39 045 6060411 - Fax. +39 045 6060417 Tel. 0800 389 3869 - Fax. 023 8042 8318 E-mail: service@fimap.com E-mail: info@ice-clean.com Web: www.fimap.com Web: www.ice-clean.com...

- Page 32 Industrial Cleaning Equipment Ltd. Sauber House, Unit 3, Rushington Business Park - Chapel Lane, Totton, Hampshire, SO40 9AH Service 0800 389 3869 - Facsmile 023 8042 8318 - Email info@ice-clean.com...

Need help?

Do you have a question about the SCRUB 80 D and is the answer not in the manual?

Questions and answers