Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Danfoss BOCK UL-HGX12P

- Page 1 Reciprocating Compressor BOCK UL-HGX ® Operating guide UL-HGX12P/60 S 0,7 UL-HGX12P/90 S 2 UL-HGX12P/75 ML 1 UL-HGX12P/110 ML 2 UL-HGX12P/75 S 2 UL-HGX12P/110 S 3 UL-HGX12P/90 ML 2 Translation of the original instructions AQ450440479309en-US0201...

-

Page 2: Table Of Contents

Short description ....................... 6 Name plate (example) ......................7 Type key (example) ......................7 Areas of application ......................8 Refrigerants ........................8 Oil charge .......................... 8 Limits of application ......................8 © Danfoss | Climate Solutions | 2023.07 2 | AQ450440479309en-US0201... - Page 3 Work to be carried out ..................... 20 Spare parts recommendation/accessories ............... 20 Lubricants / oils ....................... 20 Decommissioning ......................20 Technical data........................ 21 Dimensions and connections ..................22 Declaration of incorporation ..................23 UL-Certificate of Compliance..................25 © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 3...

-

Page 4: Safety

60°C (140°F) on the discharge side or below 0°C (32°F) on the suction side can be reached. - Contact with refrigerant must be avoided. Contact with refrigerant can cause severe burns and skin damage. © Danfoss | Climate Solutions | 2023.07 4 | AQ450440479309en-US0201... -

Page 5: Intended Use

As well as professions with comparable training that enables personnel to assemble, install, maintain and repair refrigeration and air-conditioning systems. Personnel must be capable of assessing the work to be carried out and recognizing any potential dangers. © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 5... -

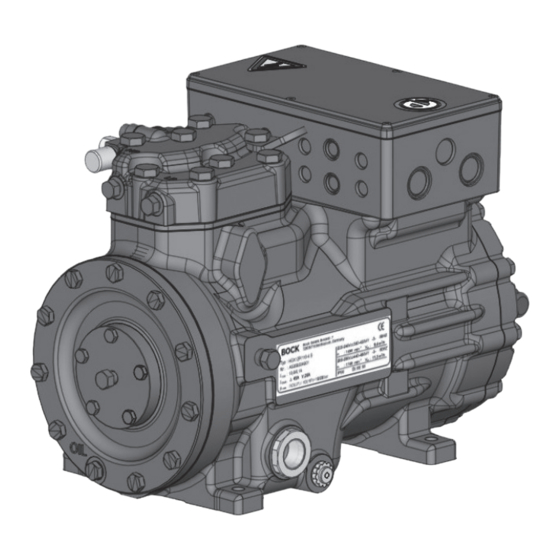

Page 6: Product Description

Oil sight glass Fig. 1 Cylinder cover Discharge shut-off valve Terminal box Drive section Suction shut-off valve Motor section Fig. 2 Dimension and connection values can be found in Chapter 9 © Danfoss | Climate Solutions | 2023.07 6 | AQ450440479309en-US0201... -

Page 7: Name Plate (Example)

HG - Hermetic Gas-cooled (suction gas-cooled) for the normal- / air conditioning applications ² X - Ester oil charge (HFC refrigerant, e.g. R134a, R404A/R507, R407C) ³ Additional declaration for Pluscom compressors S - More powerful motor, e.g. for air-conditioning applications © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 7... -

Page 8: Areas Of Application

Prevent the ingress of air at all costs! Maximum admissible operating pressure (LP/HP) LP = Low pressure 19/28 bar (276/406 psig) HP = High pressure © Danfoss | Climate Solutions | 2023.07 8 | AQ450440479309en-US0201... -

Page 9: Compressor Assembly

Single compressor preferably on vibration damper. Duplex and parallel circuits always rigid. Sun protection: If the compressor is set up outdoors, it has to be protected from direct sunlight. © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 9... -

Page 10: Pipe Connections

A rule of thumb: Always lay the first pipe section starting from the shut-off valve downwards and parallel to the drive shaft. Rigid fixed point Fig. 6 As short as possible © Danfoss | Climate Solutions | 2023.07 10 | AQ450440479309en-US0201... -

Page 11: Operating The Shut-Off Valves

—> Service connection opened / shut-off valve opened. After activating the spindle, generally fit the spindle protection cap again and tighten with 14-16 Nm (10.3-11.8 lb-ft). This serves as a second sealing feature during operation. © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 11... -

Page 12: Suction Pipe Filter And Filter Drier

For motor protection use a current-dependent and time-delayed overload protection device for moni- toring all three phases. Set the overload protection device so that it must be actuated within 2 hours, if there is 1.2 times the max. working current. © Danfoss | Climate Solutions | 2023.07 12 | AQ450440479309en-US0201... -

Page 13: Connection For The Driving Motor

Star-delta start Direct start only L1 L2 L1 L2 L1 L2 L1 L2 The connection examples shown refer to the standard version. In the case of special voltages, the instructions affixed to the terminal 96027-11.06-DGbF box apply. L1 L2 96027-11.06-DGbF © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 13... -

Page 14: Circuit Diagramm For Direct Start 230 V ∆ / 400 V Y

Cold conductor (PTC sensor) motor winding Thermal protection thermostat (PTC sensor) Load circuit safety switches Control power circuit fuse High pressure safety monitor Safety chain (high/low pressure monitoring ) Release switch (thermostat) © Danfoss | Climate Solutions | 2023.07 14 | AQ450440479309en-US0201... - Page 15 L1.1 L2.1 L3.1 L1.2 P> Θ Θ Main switch Control voltage switch Compressor motor Compressor contactor INT69 G Electronic trigger unit INT69 G Oil sump heater © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 15...

-

Page 16: Electronic Trigger Unit Int69 G

This would destroy N 43 43 11 X2 1 the trigger unit INT69 G and PTC Θ Θ Θ sensors. Steuerstrom- Steuerstrom- Control circuit kreis kreis Θ Fig. 12 Terminal box © Danfoss | Climate Solutions | 2023.07 16 | AQ450440479309en-US0201... -

Page 17: Function Test Of The Trigger Unit Int69 G

El. data: 115 V - 1 - 60 Hz, 65 - 135 W Connection to the current path of the safety control chain is not permitted. © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 17... -

Page 18: Commissioning

At the end of the evacuation process, the vacuum should be < 1.5 mbar (0.02 psig) when the pump is switched off. Repeat this process as often as is required. © Danfoss | Climate Solutions | 2023.07 18 | AQ450440479309en-US0201... -

Page 19: Refrigerant Charge

Particularly in critical systems (e.g. several evaporator points), measures are recommended such as replacement of liquid traps, solenoid valve in the liquid line, etc. There should be no movement of coolant whatsoever while the compressor is at a standstill. © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 19... -

Page 20: Maintenance

When the compressor is depressurized, undo the fastening screws of the shut-off valves. Remove the compressor using an appropriate hoist. Dispose of the oil inside in accordance with the applicable national regulations. © Danfoss | Climate Solutions | 2023.07 20 | AQ450440479309en-US0201... -

Page 21: Technical Data

220-240 V ∆ / 380-420 V Y - 3 - 50 Hz Voltage 265-290 V ∆ / 440-480 V Y - 3 - 60 Hz Displacement (1450 / 1740 rpm) No. of cylinders Type © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 21... -

Page 22: Dimensions And Connections

Bearb. / Edited Geprüft / Appr. Maß Dimension Passung / Clearance 1 / 8 “ NPTF Connection thermal protection thermostat 1 1 / 8 “- 18 UNEF Connection oil level regulator © Danfoss | Climate Solutions | 2023.07 22 | AQ450440479309en-US0201... -

Page 23: Declaration Of Incorporation

Bock GmbH Authorized person for compiling and handing Alexander Layh over technical documentation: Benzstraße 7 72636 Frickenhausen, Germany Frickenhausen, 04th of January 2021 i. A. Alexander Layh, Global Head of R&D © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 23... - Page 24 Bock GmbH Authorized person for compiling and handing Alexander Layh over technical documentation: Benzstraße 7 72636 Frickenhausen, Germany Frickenhausen, 14th of October 2022 i. A. Alexander Layh, Global Head of R&D © Danfoss | Climate Solutions | 2023.07 24 | AQ450440479309en-US0201...

-

Page 25: Ul-Certificate Of Compliance

11| UL-Certificate of Compliance Dear customer, the Certificate of Compliance can be downloaded by the following QR-Code: https://vap.bock.de/stationaryapplication/Data/ DocumentationFiles/UL-Certificateofconformity.pdf © Danfoss | Climate Solutions | 2023.07 AQ450440479309en-US0201 | 25... - Page 26 © Danfoss | Climate Solutions | 2023.07 26 | AQ450440479309en-US0201...

Need help?

Do you have a question about the BOCK UL-HGX12P and is the answer not in the manual?

Questions and answers