Table of Contents

Advertisement

Quick Links

NON-CATALYTIC UNIT

FIREPLACE INSERT & FREESTANDING

PREPARATIONS

OPERATION

IF THIS HEATER IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY

RESULT.FOR YOUR SAFETY, FOLLOW THE INSTALLATION INSTRUCTIONS.

CONTACT THE AUTHORITY HAVING JURISDICTION (SUCH AS MUNICIPAL

BUILDING DEPARTMENT,

BUREAU, etc.) CONSULT BEFORE INSTALLATION TO DETERMINE THE NEED

TO OBTAIN A PERMIT. KEEP THESE INSTRUCTIONS FOR FUTURE USE.

LISTED BY:

MANUFACTURED BY NEW BUCK CORPORATION

200 ETHAN ALLEN DRIVE

P.O. BOX 69

SPRUCE PINE, N.C. 28777

www.buckstove.com

MODEL 21

MODEL 21

MODEL 21

NON-CAT

NON-CAT

Buck

St ove

Buck

St ove

FEATURES

MAINTENANCE

SAFETY NOTICE

FIRE

DEPARTMENT,

PFS/TECO, COTTAGE GROVE, WI

Buck Stove

INSTALLATION

SAFETY

FIRE

Revised September 2018

MODEL

NON-C

Buck

St ove

Buck

St ove

PREVENTION

MOD

NON

Advertisement

Table of Contents

Summary of Contents for New Buck Corporation 21NC

- Page 1 BUREAU, etc.) CONSULT BEFORE INSTALLATION TO DETERMINE THE NEED TO OBTAIN A PERMIT. KEEP THESE INSTRUCTIONS FOR FUTURE USE. LISTED BY: PFS/TECO, COTTAGE GROVE, WI MANUFACTURED BY NEW BUCK CORPORATION 200 ETHAN ALLEN DRIVE P.O. BOX 69 SPRUCE PINE, N.C. 28777 www.buckstove.com...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Important Instructions ................................2 Stove Parts Identification ..............................3 SECTION I: Introduction ..............................4 Chimney Heights .................................. 5 SECTION II: Masonry Insert Installation ..........................6 Floor Protection ..................................7 Mounting Trim Panels ............................... 8-9 Masonry Insert Installation options ..........................10-11 SECTION III: Pre-Fab Insert Installation ........................... -

Page 4: Important Instructions

INSTALLATION AND OPERATION READ THIS FIRST IMPORTANT INSTRUCTIONS WARNING THESE UNITS GENERATE A LOT OF HEAT, SO TREAT THEM WITH CARE. HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY CAUSE SKIN BURNS. READ ALL INSTRUCTIONS BEFORE INSTALLING AND USING THE APPLIANCE. -

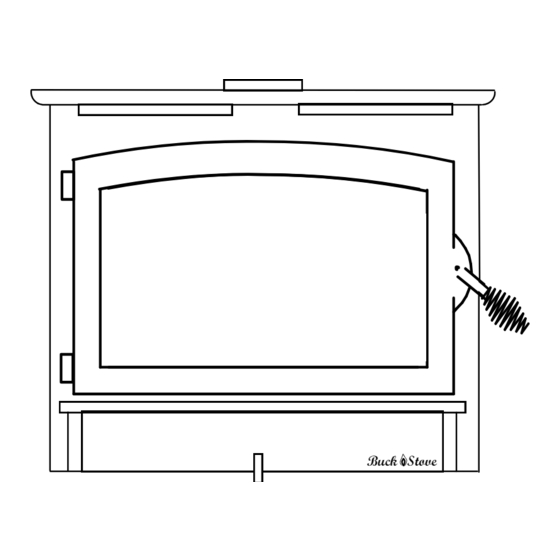

Page 5: Stove Parts Identification

EPA COMPLIANCE STATUS This manual describes installation and operation of the New Buck Corporation Model 21 wood heater. This heater meets the U.S. Environmental Protection Agency’s Emission limits for wood heaters and is in compliance with 2020 particulate emission standard. Under specific test conditions, this heater has been shown to deliver heat at rates ranging from approximately 11,079-28,901 BTU/hr four the Model Efficiency was calculated using CSA B415-1.10 stack loss method. -

Page 6: Section I: Introduction

CAUTION YOUR CHIMNEY OR FLUE MUST BE CORRECTLY SIZED. A CHIMNEY OR FLUE THAT IS TOO SMALL OR LARGE IN DIAMETER, OR TOO SHORT, CAN CAUSE YOUR STOVE TO SPILL SMOKE WHEN DOOR IS OPENED. SECTION I INTRODUCTION Your new MODEL 21 is a non-catalytic unit designed to meet the most stringent emissions standards without the use of a catalytic combustor. -

Page 7: Chimney Heights

CHIMNEY HEIGHTS GREATER LESS THAN THAN 10 FT. 10 FT. 10 FT. 2 FT. 3 FT. 2 FT. 3 FT. METAL CHIMNEY 2 FT. MINIMUM HEIGHT ABOVE THE ROOF WITHIN 10 FT. HORIZONTALLY CHIMNEY “10 FT.” RULE (MINIMUM HEIGHTS) MASONRY CHIMNEY Figure 2 NOTE: MINIMUM CHIMNEY HEIGHT 15 FT. -

Page 8: Section Ii: Masonry Insert Installation

SECTION II MASONRY INSERT INSTALLATION The Model 21 may be installed using an all masonry fireplace built in accordance with the Uniform Building Code and National Fire Protection Association (NFPA). The first step in this type of installation is to determine the acceptability of fireplace and chimney for use with a woodstove. -

Page 9: Floor Protection

Floor Protection: When installing freestanding heater, a floor protector must be use. Floor protector must be 3/8” minimum thickness non-combustible material or equivalent. How to use alternate materials and how to calculate equivalent thickness An easy means of determining if a proposed alternate floor protector meets requirements listed in the appliance manual is to follow this procedure: 1. -

Page 10: Mounting Trim Panels

INSTALLATION PROCEDURE (Use a Listed Direct or Positive Connect)(See Page 6). POSITIONING THE HEATER NOTE: If the three suggested installations have been chosen, certain steps must be followed when installing heater into a masonry fireplace. When positioning heater, the following conditions MUST be met! (See Figure 5). - Page 11 10. If direct connect or positive connect kit is not used, follow instructions in mounting trim panels, steps 1-4c on page 10. 11. Mount top trim panel by drilling mounting holes in center of trim panel mounting brackets, with top end side of top panel overlapping side panel.

-

Page 12: Masonry Insert Installation Options

MASONRY INSERT INSTALLATION OPTIONS This unit (appliance) may be installed into an all masonry fireplace, built in accordance with the Uniform Building Code and the National Fire Protection Association (NFPA 211). NOTE: Check with local building officials for any permits required for installation of this unit and notify your insurance company before proceeding with installation In some cases, such as improperly drawing fireplaces, oversize flue liners are to meet codes in certain areas it is recommended that one of the flowing procedures be followed:... - Page 13 INSULATION OR HIGH TEMPERATURE CAULK REMOVE DAMPER OR WIRE IT OPEN NOTE: New Buck Corporation grants no warranty, implied or stated, for the installation or maintenance of your appliance, and assumes no responsibility of any consequential damage OPTION (B) OPTION (C)

- Page 14 CAUTION THE UNIT IS PAINTED WITH A SPECIALLY FORMULATED HIGH TEMPERATURE PAINT THAT CURES DURING THE FIRST TWO OR THREE FIRINGS. YOU MAY NOTICE A SLIGHT SMOKING EFFECT AND AN ODOR OF BURNING PAINT WHEN YOU BUILD THE FIRST FIRES. THIS IS NORMAL AND IS NOT A CAUSE FOR ALARM.

-

Page 15: Section Iii: Pre-Fab Insert Installation

SECTION III PRE-FAB INSERT INSTALLATION The Model 21 has been tested with the following: Heatilator Security Tempco Preway Marco Woodside Majestic NOTE: The Model 21 may be installed in any of the pre-fabricated fireplaces listed above if they are big enough to accept heater. NOTE: A FULL CHIMNEY LINER IS REQUIRED IN A ZERO CLEARANCE OR PRE - FABRICATED FIREPLACE. -

Page 16: Section Iv: Residential Freestanding Installation

SECTION IV RESIDENTIAL FREESTANDING INSTALLATION TOOLS FOR INSTALLATION Drop cloth, 3/32" Metal drill bit, 5/16" magnetic socket chuck adapter, 5/16" wrench (box or socket) or adjustable wrench, Jigsaw with masonry, metal and wood blades WARNING: DO NOT INSTALL IN A SLEEPING ROOM PREPARING THE STOVE FOR INSTALLATION 1. -

Page 17: Out Side Air Installation

3. Place unit on pad making sure minimumum clearance specifications are met. 4. Lightly mark with a pencil the location of pedestal on protective pad. 5. Next, remove the four (4) screws holding heater to stand. Position heater out of the way of installation area. -

Page 18: Floor Protection

Floor Protection: Floor protection must be 3/8” minimum thickness non-combustible material or equivalent. How to use alternate materials and how to calculate equivalent thickness An easy means of determining if a proposed alternate floor protector meets requirements listed in the appliance manual is to follow this procedure: 1. -

Page 19: Residential Installation

PREPARING THE ROOM HEATER LOCATION 1. Select an installation location that will give the best airflow from the front of the heater to the remainder of the home. 2. Place the protective floor pad in position. 3. Place unit on pad making sure minimum clearance specifications are met. 4. - Page 20 A. Vertical exit using (6" Single Wall minimum 24ga. blued or black pipe and any listed 2100° UL 103 HT. TYPE Chimney) Without optional close clearance shield and pipe shield Model 21 minimum clearance to combustibles Figure 15 Figure 16 BACK WALL BACK WALL CONTEMPORARY CAP...

-

Page 21: Vertical Wall Exit Using Single Wall Pipe And Elbow /Listed 2100° Ul 103 Ht Chimney

HOW TO LOCATE CHIMNEY EXIT AND INSTALL Residential Installation B. Vertical Wall Exit using (6" Single Wall minimum 24ga. blued or black pipe with elbow and any Listed 2100° UL HT chimney and Listed 2100° UL HT. T-Box assembly). Without optional close clearance shields and pipe shield. NOTE: For minimum clearances (See Page 20, Figure 17). - Page 22 B. Vertical wall exit using (6" Single Wall minimum 24ga. blued or black pipe with elbow and any listed 2100° UL 103 HT. TYPE Chimney and Listed 2100° UL HT. T-Box assembly). Without optional close clearance shield and pipe shield. Model 21 minimum clearance to combustibles.

-

Page 23: Vertical Exit Using Dvl Close Clearance Pipe /Listed 2100° Ul 103 Ht Chimney W/Out Close Clearance/Pipe Shields

HOW TO LOCATE CHIMNEY EXIT AND INSTALL Residential and Mobile Home Installation C. Vertical Exit using (6" DVL Close Clearance pipe and any Listed 2100° UL 103 HT chimney). Without close clearance shield and pipe shield. NOTE: For minimum clearances (See Page 22, Figure 19). 1. - Page 24 C. Vertical exit using (6" DVL Close Clearance pipe and any listed 2100° UL 103 HT. TYPE Chimney). Without optional close clearance shield and pipe shield. Model 21 minimum clearance to combustibles. Figure 19 Figure 20 BACK WALL BACK WALL CONTEMPORARY CAP LISTED 2100°...

-

Page 25: Vertical Wall Exit Using Dvl Close Clearance Pipe ,And Elbow /Listed 2100° Ul 103 Ht Chimney And T-Box Assembly W/Out Close Clearance/Pipe Shields

HOW TO LOCATE CHIMNEY EXIT AND INSTALL Residential and Mobile Home Installation D. Vertical Wall Exit using (6" DVL Close Clearance Pipe and Elbow and any Listed 2100° UL HT chimney and Listed 2100° UL HT T-Box assembly). Without optional close clearance shield and pipe shield. NOTE: For minimum clearances (See Page 24, Figure 21). - Page 26 D. Vertical wall exit using (6" DVL Close Clearance pipe with elbow) and any listed 2100° UL 103 HT. TYPE Chimney and Listed 2100° UL HT T-Box assembly). Without optional close clearance shield and pipe shield. Model 21 minimum clearance to combustibles. BACK WALL BACK WALL Figure 21...

-

Page 27: Vertical Exit Using Dvl Close Clearance Pipe /Listed 2100° Ul 103 Ht Chimney With Close Clearance/Pipe Shields

HOW TO LOCATE CHIMNEY EXIT AND INSTALL Residential and Mobile Home Installation E. Vertical Exit using (6" DVL Close Clearance pipe and any Listed 2100° UL 103 HT chimney). With optional close clearance shield and pipe shield. NOTE: For installation of optional close clearance shields and pipe shield (See Page 35). - Page 28 E. Vertical exit using (6" DVL Close Clearance pipe and any listed 2100° UL 103 HT. TYPE Chimney). With optional close clearance shield and pipe shield. Model 21 minimum clearance to combustibles. Figure 23 Figure 24 BACK WALL BACK WALL CONTEMPORARY CAP LISTED 2100°...

-

Page 29: Vertical Wall Exit Using Dvl Close Clearance Pipe ,And Elbow /Listed 2100° Ul 103 Ht Chimney And T-Box Assembly With Close Clearance/Pipe Shields

HOW TO LOCATE CHIMNEY EXIT AND INSTALL Residential and Mobile Home Installation F. Vertical Wall Exit using (6" DVL Close Clearance Pipe and Elbow and any Listed 2100° UL HT chimney and Listed 2100° UL HT T-Box assembly). With optional close clearance shield and pipe shield NOTE: For installation of optional close clearance shields and pipe shield (See Page 35). - Page 30 F. Vertical wall exit using (6" DVL Close Clearance pipe with elbow and any listed 2100° UL 103 HT. TYPE Chimney and Listed 2100° UL HT T-Box assembly). With optional close clearance shield and pipe shield. Model 21 minimum clearance to combustibles. BACK WALL BACK WALL Figure 25...

- Page 31 Ceiling Exit (Using Close Clearance listed chimney) 1. Suspend a plumb bob from ceiling above unit so that weight is hanging in center of flue exit. (A small weight on a string will serve as a plumb bob). Mark ceiling where string is suspended to locate center of chimney hole.

- Page 32 FINAL CHECK 1. Recheck specified clearances. 2. Remove all foreign material from firebox area. 3. Open primary air draft. 4. Plug power cord into a 115V AC outlet when using with optional motor. Do not run cord under unit or in high traffic areas. 5.

-

Page 33: Section V: Alcove Installation

SECTION V ALCOVE INSTALLATION AND CLEARANCES Select an installation location that will give the best airflow from the front of the heater to the remainder of the home PREPARING THE STOVE FOR INSTALLATION 1. Inspect the unit for any obvious physical damage. 2. -

Page 34: Floor Protection

Floor Protection: Floor protection must be 3/8” minimum thickness non-combustible material or equivalent. How to use alternate materials and how to calculate equivalent thickness An easy means of determining if a proposed alternate floor protector meets requirements listed in the appliance manual is to follow this procedure: 1. -

Page 35: Alcove Installation Clearances

HOW TO LOCATE CHIMNEY EXIT AND INSTALL Alcove Installation Vertical Exit using (6" DVL Close Clearance pipe and any Listed 2100° UL 103 HT chimney). With optional close clearance shield and pipe shield. NOTE: For installation of optional close clearance shields and pipe shield (See Page 35). NOTE: For minimum clearances (See Page 34, Figure 31). - Page 36 ALCOVE INSTALLATION AND CLEARANCES Vertical exit using (6" DVL Close Clearance pipe and any listed 2100° UL 103 HT. TYPE Chimney). With optional close clearance shield and pipe shield. Model 21 minimum clearance to combustibles. Figure 31 Figure 32 BACK WALL BACK WALL BACK WALL CONTEMPORARY CAP...

-

Page 37: Installation Of Close Clearance Shields

Installation of (Optional) Close Clearance Shields and Pipe Shield 1. Taking close clearance side shields, hold up to side of stove leaving 1/4" gap between shield and top of stove. 2. Make reference mark in center of pre-punched hole in top & bottom of shield. Drill two (2) 3/32"... - Page 38 FINAL CHECK 1. Recheck specified clearances. 2. Remove all foreign material from firebox area. 3. Open primary air draft. 4. Plug power cord into a 115V AC outlet when using with optional motor. Do not run cord under unit or in high traffic areas. 5.

-

Page 39: Wood Heater Safety

SECTION VIII WOOD HEATER SAFETY Certain safety hazards are inherent in any wood heater installation. You should be aware of these so that a safe and proper installation can be made. 1. FAULTY CHIMNEY: An older masonry chimney should be thoroughly checked to be sure there are no holes or weak spots which could allow sparks or hot gases to escape. -

Page 40: Section Vi: Operation And Efficiency

SECTION VI OPERATION/EFFICIENCY 1.“To maximize the efficiency of your wood stove make sure it is sized properly for the space you plan to heat. An oversized stove will burn and be forced to burn at a lower and dirtier burn rate. Consult with your dealer for sizing your stove correctly. -

Page 41: Guide To Burning Qualities Of Wood

GUIDE TO THE DIFFERENT BURNING QUALITIES OF WOOD Type of Ease of Coaling Amount of Wood Starting Qualities Sparks Apple Poor Excellent Fair Good Beech Poor Good Birch Good Excellent Moderate Cherry Poor Excellent Cedar Excellent Poor Many Fair Good Very Few Hemlock Good... -

Page 42: Optional Motor Installation

OPTIONAL MOTOR ASSEMBLY KIT INSTALLATION INSTRUCTIONS STEP 1: REMOVE ACCESS DOOR PANEL LOCATED AT BOTTOM OF UNIT. YOUR MOTOR ASSEMBLY COMES WITH A BRACKET ALREADY ATTACHED TO THE MOTOR. ALIGN THE HOLES IN MOTOR BRACKET WITH HOLES IN MOTOR MOUNT. SECURE BRACKET WITH TWO ½” HEX HEAD SCREWS PROVIDED. - Page 43 MOTOR -THERMOSTAT-RHEOSTAT REPLACEMENT To replace Motor, Thermostat, Rheostat follow steps below. (OPT.)BLOWER KIT #MA5126715 STEP 1 STEP 3 VIEWED FROM ABOVE THERMOSTAT MOTOR BRACKET RHEOSTAT RIGHT SIDE ACCESS DOOR HEARTH SUPPORT PANEL MOTOR INDICATOR LABEL WITH BRACKET REMOVE REPLACE STEP 2 VIEWED FROM SIDE STAIN RELIEF RHEOSTAT...

- Page 44 OPTIONAL MOTOR KIT ASSEMBLY PARTS 1 - MOTOR (NON-CAT) 1 - MOTOR BRACKET 6 - #10 - 16 X 1/2” HEX HEAD 1 - #6 - 32 X 1/2” SLOT HEAD SCREW 5 - 1/8” X 1” BLACK FLAT GASKET WITH ADHESIVE 1 - JUMPER WIRE 4”...

-

Page 45: Section Vii Maintenance: Brick Layout

SECTION VII MAINTENANCE BRICK LAYOUT NOTE: “This wood heater needs periodic inspection and repair for proper operation. It is against federal regulations to operate this wood heater in a manner inconsistent with operating instructions in this manual.” Page 43... -

Page 46: Secondary Air Tube Replacement / Baffle Board Replacement

MAINTENANCE SECONDARY AIR TUBES REPLACEMENT (Replacing secondary air tubes) COLD STOVE Unplug heater from 115V AC outlet. Put drop cloth down. Empty ashes. Remove air tubes. The (3) secondary air tubes are located in top of burn chamber. (NOTE, front/rear air tubes have 24 holes per tube, middle air tube has 12 holes per tube) On right side of tubes you will find a cotter pin. -

Page 47: Door Gasket Replacement

DOOR GASKET REPLACEMENT (COLD HEATER) To replace deteriorated gaskets, following steps must be taken to ensure proper installation of gaskets. 1. Obtain proper gaskets and silicone glue from your local dealer. 2. Using pliers, remove any worn and deteriorated gaskets. 3. -

Page 48: Check Chimney / Cleaning Heater / Care Of Glass Door

CHECK CHIMNEY A. Chimney should be inspected twice a year. B. The chimney should be cleaned as necessary to remove creosote, soot, leaves, birds’ nests, etc. NOTE: A chimney cap should be installed to prevent moisture from entering chimney, to prevent sparks and burning materials from escaping chimney and to keep birds and foreign materials from entering. -

Page 49: Troubleshooting

SECTION IX TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Sluggish Heater Obstruction in chimney Check for and remove obstruction Improperly sealed trim kit or (a) Check trim kit gasketing direct connect kit seal to fireplace and gasket as necessary to seal unit. Gasket under front bottom of stove if needed. - Page 50 PROBLEM POSSIBLE CAUSE SOLUTION High fuel consumption Improper regulation of draft (a) Close inlet air control as or inlet air much as possible to maintain desired heat output (b) Check gaskets, reinstall fiberglass gasketing round doors and glass as necessary Improper door fitting Check door gasket, check adjustment of door latch...

- Page 51 REPLACEMENT PARTS PAGE 1 NOTE: For replacement parts use only manufacturer’s specified parts. Description Quantity Part No. 1. Door Gold PC212400-G 2. Door Black PC212400-B 3. Door Pewter PC212400-P 4. Door Handle PO210092 5. Retrofit Door Bushing PO210102 6. Thin Spacer PO910104 7.

-

Page 52: Replacement Parts

REPLACEMENT PARTS PAGE 2 NOTE: For replacement parts use only manufacturer’s specified parts. Description Quantity Part No. 20. Primary Air Plate MF201034 21. Screws for Primary Air Plate to Air Control Rod Hex/Washer Slot Machine Screw 10-32 X 1/4” PH103214HWHSM 22. -

Page 53: Limited Warranty

NEW BUCK CORPORATION (NBC) "LIMITED WARRANTY" FOR THE BUCK STOVE PLEASE READ THIS WARRANTY CAREFULLY PRODUCTS COVERED This warranty covers the new Buck Stove heating unit, so long as it is owned by the original purchaser, including optional and standard accessories purchased at the same time, subject to terms, limitations and conditions herein set out. - Page 54 Page 52...

- Page 55 (B) There is no other express warranty. All implied warranties of merchantability and fitness for use are limited to the duration of the Express Warranty. (C) New Buck Corporation is not liable for indirect, incidental or consequential damages in connection with use of product including any cost or expense of providing substitute equipment or service during periods of malfunction or non-use.

Need help?

Do you have a question about the 21NC and is the answer not in the manual?

Questions and answers