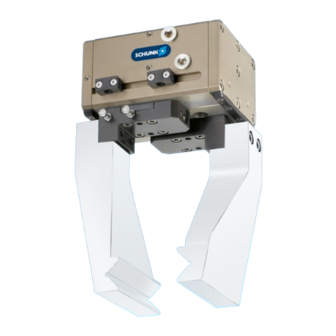

SCHUNK PFH 30 Assembly And Operating Manual

2-finger-parallel-gripper

Hide thumbs

Also See for PFH 30:

- Assembly and operating manual (40 pages) ,

- Repair instructions (2 pages) ,

- Assembly and operating manual (18 pages)

Advertisement

Quick Links

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK PFH 30

- Page 1 Assembly and Operating Manual PFH Mini 2-Finger-Parallel-Gripper Translation of the original manual...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK SE & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 389266 Version: 11.00 | 21/07/2023 | en...

- Page 3 Table of Contents Table of Contents 1 General ..................... 5 About this manual................1.1.1 Presentation of Warning Labels ............. 1.1.2 Applicable documents ..............1.1.3 Sizes..................1.1.4 Variants ................... 1.2 Warranty ................... 1.3 Scope of delivery................. 1.4 Accessories ..................1.4.1 Sensors ..................1.4.2 Seal kit ..................

- Page 4 Magnetic switch MMS 30/S ............21 4.3.2 Inductive proximity switch INW 80/S..........22 4.3.3 Inductive proximity switch IN 5/S ........... 25 4.3.4 Flexible Positioning sensor FPS onto the Type PFH 30......26 5 Troubleshooting................... 27 5.1 Product does not move? ............... 27 5.2 Product does not execute a complete stroke? ..........

- Page 5 General 1 General 1.1 About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual.

- Page 6 1.1.2 Applicable documents General terms of business * Catalog data sheet of the purchased product * The documents labeled with an asterisk (*) can be downloaded from schunk.com. 1.1.3 Sizes This operating manual applies to the following sizes: PFH Mini 30...

- Page 7 INW 80/S Inductive proximity switches INK 120/S Flexible Position Sensor Exact type designation of the compatible sensors see catalog. Information on handling sensors is available at schunk.com or from SCHUNK contact persons. 1.4.2 Seal kit Seal kit for ID number...

- Page 8 Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. Use only original spare parts or spares authorized by SCHUNK. 2.4 Gripper fingers Requirements of gripper fingers Accumulated energy can make the product unsafe and risk the danger of serious injuries and considerable material damage.

- Page 9 Basic safety notes Execute the gripper fingers in such a way that the product reaches either the "open" or "closed" position in a de- energized state. Only change gripper fingers if no residual energy can be released. Make sure that the product and the top jaws are a sufficient size for the application.

- Page 10 Basic safety notes Qualified personnel Due to its technical training, knowledge and experience, qualified personnel is able to perform the delegated tasks, recognize and avoid possible dangers and knows the relevant standards and regulations. Instructed person Instructed persons were instructed by the operator about the delegated tasks and possible dangers due to improper behaviour.

- Page 11 Basic safety notes 2.8 Notes on safe operation Incorrect handling of the personnel Incorrect handling and assembly may impair the product's safety and cause serious injuries and considerable material damage. Avoid any manner of working that may interfere with the function and operational safety of the product.

- Page 12 Basic safety notes 2.11 Disposal Handling of disposal The incorrect handling of disposal may impair the product's safety and cause serious injuries as well as considerable material and environmental harm. Follow local regulations on dispatching product components for recycling or proper disposal. 2.12 Fundamental dangers General Observe safety distances.

- Page 13 Basic safety notes 2.12.2 Protection during commissioning and operation Falling or violently ejected components Falling and violently ejected components can cause serious injuries and even death. Take appropriate protective measures to secure the danger zone. Never step into the danger zone during operation. 2.12.3 Protection against dangerous movements Unexpected movements Residual energy in the system may cause serious injuries while...

- Page 14 Basic safety notes While paying attention to the actual conditions of the working environment, the potential equalisation must be implemented by a specialist electrician according to the applicable regulations. The effectiveness of the potential equalisation must be verified by executing regular safety measurements. 2.13 Notes on particular risks DANGER Risk of fatal injury from suspended loads!

- Page 15 Secure the end positions of the product with SCHUNK SDV-P pressure maintenance valves. 11.00 | PFH Mini | Assembly and Operating Manual | en | 389266...

- Page 16 Technical Data 3 Technical Data Pressure medium Compressed air, compressed air quality according to ISO 8573-1:2010 [7:4:4] Nominal working pressure [bar] Min. pressure [bar] without gripping force maintenance with gripping force maintenance Max. pressure [bar] without gripping force maintenance with gripping force maintenance Min.

- Page 17 Assembly 4 Assembly 4.1 Mechanical connection Evenness of the The values apply to the whole mounting surface to which the mounting surface product is mounted. Edge length Permissible unevenness < 100 < 0.02 > 100 < 0.05 Tab.: Requirements for evenness of the mounting surface (Dimensions in mm) Mounting The product can be mounted from the bottom or on the side.

- Page 18 Assembly The centering sleeves (5/6) which are required for fixing the gripper, are always enclosed in the enclosed pack. CAUTION The gripper will be damaged if you exceed the maximum depth of engagement for the mounting screws. It is mandatory that you observe the maximum depths of engagement for gripper attachment on base side.

- Page 19 Assembly 4.2 Pneumatic connection CAUTION Damage to the gripper is possible! If the maximum permissible finger weight or the permissible mass moment of inertia of the fingers is exceeded, the gripper can be damaged. A jaw movement always has to be without jerks and bounce. You must therefore implement sufficient reduction and/or damping.

- Page 20 Assembly Tab.: Thread diameter of the air connections Item Connection PFH 30 PFH 40 PFH 50 Hose connection G 1/8“ G 1/8“ G 1/8“ (A = open, B = close) Air purge connection Hose-free direct connection at the base (a = open, b = close)

- Page 21 – The assembly and operating manual and catalog datasheet are included in the scope of delivery for the sensors and are available at schunk.com. Information on handling sensors is available at schunk.com or from SCHUNK contact persons. 4.3.1 Magnetic switch MMS 30/S...

- Page 22 Assembly Gripper open: Switch the gripper to the "open" position. Slide the magnetic switch 1 (1) through the undercut (4) in the T-Nut, until it contacts the cover plate (2). Slide the magnetic switch slowly back again until it switches. Fix the magnetic switch in this position, by thightening the setscrew in the T-nut until it jams.

- Page 23 Assembly Make sure that you handle the proximity switches properly: Do not pull on the cable. Do not allow the sensor to dangle from the cable. Do not overtighten the mounting screw or mounting clip. Please adhere to a permitted bend radius of the cable. (☞ catalog) Avoid contact of the proximity switches with hard objects and with chemicals, in particular nitric acid, chromic acid and...

- Page 24 Assembly Gripper open: Switch the gripper into the "open" position. Slide the proximity switch (2) carefully into the bracket (3) until the sensing distance between proximity switch and monitoring screw (1) is 0.5 mm. Fix the proximity switch in this position by thightening the screws (5).

- Page 25 For being able to use the proximity switch type INK 120/S, the gripper has to be equipped with a special attachment set.This attachment set is also available at SCHUNK. Attachment set of stroke control with inductive proximity switches INK 120 / S:...

- Page 26 Assembly 4.3.4 Flexible Positioning sensor FPS onto the Type PFH 30 Switching cam with mounted magnet Bracket Cylinder crews M3 x 8 Cylinder crews M4 x 6 Cylinder crews M2 x 8 Type ID number AS – PFH 30 0301733 More technical data is included in the catalog data sheet.

- Page 27 Proximity switch defective or set incorrect. Readjust or change sensor. Unused air connections open. Close unused air connections. Component part defective. Replace component or send it to SCHUNK for repair. 5.2 Product does not execute a complete stroke? Possible cause Corrective action Dirt deposits between basic jaws and Disassemble and clean the product.

- Page 28 If, despite optimum air connections, the opening and closing times specified in the catalogue are not achieved, SCHUNK recommends the use of quick-air-vent- valves directly at the product. 11.00 | PFH Mini | Assembly and Operating Manual | en | 389266...

- Page 29 Maintenance 6 Maintenance 6.1 Notes Original spare parts Use only original spare parts of SCHUNK when replacing spare and wear parts. 6.2 Maintenance and lubrication intervals CAUTION Material damage due to hardening lubricants! Lubricants harden more quickly at temperatures above 60°C, leading to possible product damage.

- Page 30 Maintenance 6.4 Disassembling the product 6.4.1 Version without gripping force maintenance device Position of the item numbers } 7 [/ 36] Remove all air feedings. Unscrew the screws (29). Draw off the guiding strip (3) together with the cyl. pins (44) now. Remove the cyl.

- Page 31 Maintenance Remove the screws (32) except for the 4 screws in the corners of the cover plates (8). Clamp the gripper between the cover plates in the vise so that the remaining screws (32) can still be removed. Then carefully unclamp the springs. Remove the springs (43).

- Page 32 Maintenance Remove the screws (32) except for the four screws in the corners of the cover plates (8). Clamp the gripper between the cover plates in the vise so that the four corner screws (32) can still be removed. Then carefully open the vise. WARNING Risk of injury due to spring forces! In the "internal gripping"...

- Page 33 Maintenance 6.5 Servicing and assembling the product 6.5.1 Servicing the product Clean all parts thoroughly and check for damage and wear. Replace all wear parts / seals. The seals are in the enclosed sealing kit. } 1.4.2 [/ 7] Treat all greased areas with lubricant.} 6.3 [/ 29] Oil or grease bare external steel parts.

- Page 34 Maintenance 1. Mount the sockets (6) with seals (21/25) and secure them with the set-screws (39). 2. Push the piston rods (5) and the assembly groups consisting of the gear rack (2), intermediate stop (12) and locating plate (18) into the housing (1) and connect them by mounting the drivers (7).

- Page 35 Device 2 6.5.2.2 Tightening torques for screws Type Item 27/28 Item 29 Item 31 Item 32 Item 46 PFH 30 / PFH 30-60 17 Nm 6.1 Nm 17 Nm 6.1 Nm 17 Nm PFH 40 / PFH 40-80 41 Nm 10.4 Nm...

- Page 36 I.D. gripping O.D. gripping Assembly drawing Wearing part, replace during maintenance. Included in the seal kit. Seal kit can only be ordered completely. not applicable for PFH 30 11.00 | PFH Mini | Assembly and Operating Manual | en | 389266...

- Page 37 8 Translation of the original declaration of incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1 Section B. Manufacturer/ SCHUNK SE & Co. KG Distributor Toolholding and workholding | Gripping Technology | Automation technology Bahnhofstr. 106 - 134...

- Page 38 UKCA declaration of incorporation 9 UKCA declaration of incorporation in accordance with the Supply of Machinery (Safety) Regulations 2008. Manufacturer/ SCHUNK Intec Limited Distributor Clamping and gripping technology 3 Drakes Mews, Crownhill MK8 0ER Milton Keynes We hereby declare that on the date of the declaration the following partly completed machine complied with all basic safety and health regulations found in the "Supply of Machinery (Safety) Regulations 2008".

- Page 39 "on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS)", or fulfill their intended function only as part of one. Therefore products from SCHUNK do not fall within the scope of the directive at this time. REACH Regulation Products from SCHUNK fully comply with the regulations of Regulation (EC) No. 1907/2006...

- Page 40 SCHUNK SE & Co. KG Toolholding and workholding | Gripping Technology | Automation technology Bahnhofstr. 106 - 134 D-74348 Lauffen/Neckar Tel. +49-7133-103-0 Fax +49-7133-103-2399 info@de.schunk.com schunk.com Folgen Sie uns I Follow us Wir drucken nachhaltig I We print sustainable...

Need help?

Do you have a question about the PFH 30 and is the answer not in the manual?

Questions and answers