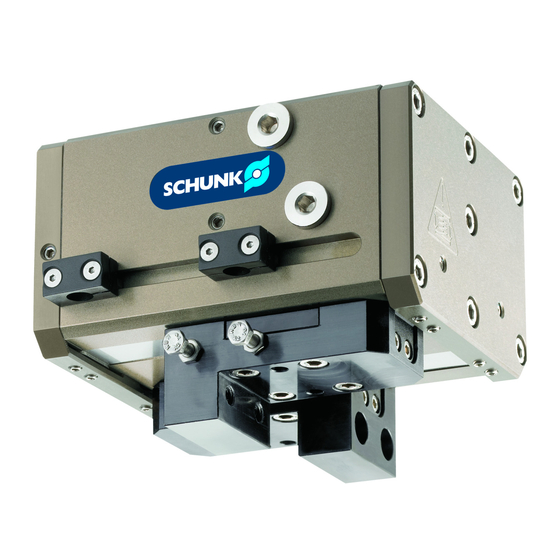

SCHUNK PFH 30 Assembly And Operating Manual

2-finger-parallel-gripper

Hide thumbs

Also See for PFH 30:

- Assembly and operating manual (40 pages) ,

- Repair instructions (2 pages) ,

- Assembly and operating manual (35 pages)

Summary of Contents for SCHUNK PFH 30

- Page 1 Translation of the original manual Assembly and Operating Manual PFH 30-50 2-Finger-Parallel-Gripper...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Module does not achieve the opening and closing times? ....... 25 Maintenance ...................... 26 Notes ........................ 26 Maintenance and lubrication intervals............... 26 Lubricants/Lubrication points (basic lubrication) .......... 26 Disassembly of the module ................ 27 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... - Page 4 9.6.2 Tightening torques for screws .............. 32 10 Assembly drawing.................... 33 11 Seal kit........................ 34 12 Accesories kit...................... 35 13 Translation of original declaration of incorporation .......... 36 14 Annex to Declaration of Incorporation .............. 37 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

-

Page 5: About This Manual

• PFHHigh-temperature (HT) 1.3 Applicable documents • General terms of business* • Catalog data sheet of the purchased product * • Assembly and operating manual of the gripper * 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... - Page 6 About this manual The documents marked with an asterisk (*) can be downloaded on our homepage schunk.com 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

-

Page 7: Basic Safety Notes

• the safety and installation notes are not observed. Avoid any manner of working that may interfere with the function and operational safety of the product. Wear protective equipment. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 8: Personnel Qualification

Due to its technical training, knowledge and experience, service personnel of the manufacturer is able to perform the delegated the manufacturer tasks and to recognize and avoid possible dangers. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 9: Using Personal Protective Equipment

• The effectiveness of the equipotential bonding must be verified by a specialist electrician through regular safety measurements. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 10: Variant Gripping Force Maintenance

Switch off the energy supply. • Ensure there is no residual energy in the system. • Disassemble the gripper carefully. • 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 11: Warranty

• Observe the specified maintenance and lubrication intervals • Observe the ambient conditions and operating conditions Parts touching the workpiece and wear parts are not included in the warranty. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 12: Scope Of Delivery

Scope of delivery 4 Scope of delivery The scope of delivery includes • 2-Finger-Parallel-GripperPFHin the version ordered • Enclosed pack 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 13: Accessories

Flexible Position Sensor • Exact type designation of the compatible sensors see catalog. • Information on handling sensors is available at schunk.com or from SCHUNK contact persons. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 14: Technical Data

Min. ambient temperature [°C] Max. ambient temperature [°C] IP rating Noise emission [dB(A)] ≤ 70 More technical data is included in the catalog data sheet. Whichever is the latest version. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 15: Assembly

Max. screw-in depth [mm] 10 mm 14 mm 15 mm Finger fastening Max. screw-in depth [mm] 18 mm 20 mm 25 mm Gripper fastening from the top 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 16: Air Connection

Product variants are also offered with mechanical gripping force via springs, which also ensure a minimum clamping force in the event of a pressure drop. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... - Page 17 • Close unused main air connections using the screw plugs from the enclosed pack. • For a hose-free direction connection, use the O-rings from the enclosed pack. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

-

Page 18: Mounting The Sensor

• Information on handling sensors is available at schunk.com or from SCHUNK contact persons. 7.3.1 Magnetic switch MMS 30/S brown closer load black blue NOTICE The max. torque for the threaded pins is 30 Ncm. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 19: Inductive Proximity Switch Inw 80/S

Connection example for IN 80 brown black blue The inductive proximity switches used are equipped with reverse polarity protection and are short-circuit-proof. Make sure that you handle the proximity switches properly: 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... - Page 20 • Note that the leakage current of the individual sensors (ca. 2 mA) is cumulative. Assembly of the proximity switch NOTE By moving laterally, the sensitivity of the switching point may be adjusted more precise. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

- Page 21 (1 for I.D.-, or 6 for O.D.-gripping), until it switches. Control function by actuating the gripper and then the Ø workpiece to be gripped, again. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

-

Page 22: Inductive Proximity Switch In 5/S

Attachment set of stroke control with inductive proximity switches INK 120 / S: Designation ID number HG - PFH 30 0300743 HG – PFH 40 / PFH 50 0300744 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 23: Flexible Positioning Sensor Fps Onto The Type Pfh 30

0301733 More technical data is included in the catalog data sheet. Whichever is the latest version. Assembly and adjustment of the sensor FPS: See separate operating manual. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 24: Troubleshooting

Clean and lubricate product. movement space. Maintenance 26] Pressure drops below minimum. Check air supply. Link Pneumatischer Anschluss Component part defective. Replace component or send it to SCHUNK for repair. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 25: Module Does Not Achieve The Opening And Closing Times

If, despite optimum air connections, the opening and closing times specified in the catalogue are not achieved, SCHUNK recommends the use of quick-air-vent- valves directly at the product. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 26: Maintenance

Lubricant point Lubricant Metallic sliding surfaces microGLEIT GP 360 All seals Renolit HLT 2 Bore hole at the piston Renolit HLT 2 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 27: Disassembly Of The Module

Risk of injury due to spring forces. In case of version for O.D. gripping the cover plates (8) are spring- tensioned (F 210 N). Carefully disassemble the module. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 28: Version With Gripping Force Maintenance Device For I.d. Gripping

Risk of injury due to spring forces. In case of the version for I.D. gripping, the piston (4) is spring- tensioned (F ≤ 210 N). Carefully disassemble the module. • 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... - Page 29 Turn back the set-screws (39) 3 mm back and take out the Ø bushing (6) from the housing (1). The gripper can be maintained now Servicing the module ✔ 30]. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

-

Page 30: Servicing The Module

For version PFH 40 with gripping force maintenance for I.D.gripping (Ident.-No.302 042), mount the cylinder piston by using assembly devices.Mounting devices 32] Vorrichtung 2 Vorrichtung 1 Screw Screw 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... - Page 31 Repeat this procedure from point 3 to 7 for mounting the opposing piston. Further assembly is done in reverse order as described under ”Disassembly of the grippers“ Disassembly of the module 27]. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

-

Page 32: Mounting Devices

PFH 40 / PFH 40-80 41 Nm 10.4 Nm 41 Nm 6.1 Nm 41 Nm PFH 50 / PFH 50-100 83 Nm 25.5 Nm 83 Nm 6.1 Nm 60 Nm 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 33: Assembly Drawing

I.D. gripping O.D. gripping Assembly drawing Wearing part, replace during maintenance. Included in the seal kit. Seal kit can only be ordered completely. not applicable for PFH 30 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 34: Seal Kit

ID.-No. of the seal kit Seal kit for ID number PFH 30 0370759 PFH 40 0370760 PFH 50 0370761 Contents of the sealing kit, Assembly drawing 33]. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 35: Accesories Kit

ID number PFH 30 5510357 PFH 40 5510358 PFH40 High-temperature (HT) 395510358 PFH 50 5510359 PFH50 High-temperature (HT) 395510359 Content of the accessories pack: Assembly drawing 33]. 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 36: Translation Of Original Declaration Of Incorporation

Person authorized to compile the technical documentation: Robert Leuthner, Address: see manufacturer's address Lauffen/Neckar, January 2019 p.p. Ralf Winkler, Manager for development of gripping system components 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... -

Page 37: Annex To Declaration Of Incorporation

Risk of loss of stability 1.3.2 Risk of break-up during operation 1.3.3 Risks due to falling or ejected objects 1.3.4 Risks due to surfaces, edges or angles 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266... - Page 38 1.5.16 Lightning Maintenance 1.6.1 Machinery maintenance 1.6.2 Access to operating positions and servicing points 1.6.3 Isolation of energy sources 1.6.4 Operator intervention 1.6.5 Cleaning of internal parts 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

- Page 39 Supplementary essential health and safety requirements for machinery intended for underground work Supplementary essential health and safety requirements for machinery presenting particular hazards due to the lifting of persons 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

- Page 40 Notes Notes 09.00 | PFH 30-50 | Assembly and Operating Manual | en | 389266...

Need help?

Do you have a question about the PFH 30 and is the answer not in the manual?

Questions and answers