Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Ronix RC-1012

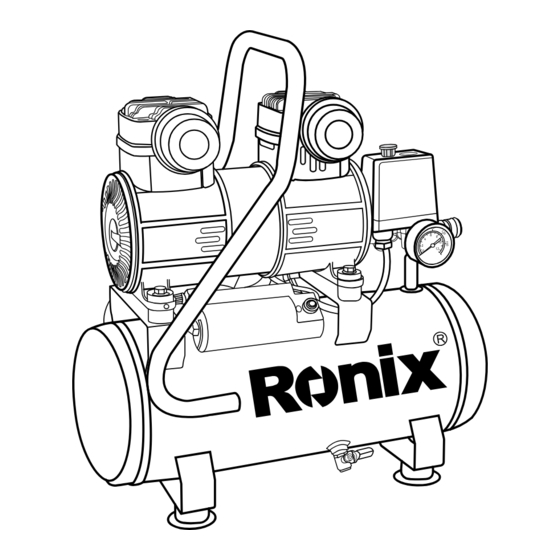

- Page 1 AIR COMPRESSOR 10 LITER RC-1012...

-

Page 2: Product Specifications

PRODUCT SPECIFICATIONS Model RC-1012 1280W Power Voltage 220V Frequency 50Hz No Load Speed 2800rpm Air Tank Capacity 10L Max Pressure 0.8MPa Air delivery 80L/Min Net. Weight 19Kg PARTS LIST Solenoid Valve On/Off Silencer Switch Handle Cylinder Head Vent Valve Motor... -

Page 3: General Power Tool Safety Warnings

GENERAL POWER TOOL SAFETY WARNINGS WARNING! - Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and or serious injury. - Save all warnings and instructions for future reference. - The term “power tool”... -

Page 4: Personal Safety

ELECTRIC SAFETY - Power tool plugs must match the outlet. Never modify the plug in any way. Don’t use any adaptor plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock. - Avoid body contact with earthed or grounded surfaces such as pipe, radiators, ranges and refrigerators. - Page 5 before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents. - Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Page 6 Many accidents are caused by poorly maintained power tools. - Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control. - Use the power tool, accessories and tool bits etc. in accordance with the instruction, taking into account the working conditions and the work to be performed.

-

Page 7: Special Safety Rules

the air compressor serviced before using. Many accidents are caused by poorly maintained products. - Keep the exterior of the air compressor dry, clean and free from oil and free from oil and grease. Always use a clean cloth when cleaning. Never use break fluids, gasoline, petroleum- based products, or any strong solvents to clean the unit. - Page 8 - Entangled or snarled hoses can cause loss of balance or footing and may become damaged. - Use the air compressor only for its intended use. Do not alter or modify the unit from the original design or function. - Always be aware that misuse and improper handling of this product can cause injury to yourself and others.

- Page 9 - Following this rule will reduce the risk of shock, fire, or serious injury. - Make sure your extension cord is in good condition. When using an extension cord, sure to use one heavy enough to carry the current your product will draw.

- Page 10 ASSEMBLY UNPACKING This product requires assembly. Carefully remove the product and any accessories from the box. WARNING! This product requires assembly. Carefully remove the product and any accessories from the box. WARNING! Do not use this product if any parts on the packing list are already assembled to your product when you unpack it.

-

Page 11: Break-In Period

APPLICATIONS Air compressors are utilized in a variety of air variety of air system applications. Match hoses, connectors, air tools, and accessories to the capabilities of the air compressor. You may use this product for the purposes listed below: - Operating some air-powered tools - Operating air accessories such as air nozzles and tire inflators. -

Page 12: Using The Air Compressor

NOTE When the compressor is in the ON position, the air compressor will automatically turn back on when the designated tank air pressure limit. It will also shut off again when the desired limit. It will also shut off again when the desired pressure is reached. WARNING! Never exceed the air tool’s pressure rating as recommended by the manufacturer. -

Page 13: Draining The Tanks

WARNING! Air-powered tools may require more air consumption than this air compressor is capable of providing. Check the tool manual to avoid damage to the tool or risk of personal injury. 1) Control the amount of air flow with the pressure regulator knob. Turning the knob fully counterclockwise will completely stop the flow of air. -

Page 14: Checking The Safety Valve

NOTE Condensate is a polluting material and should be disposed of in compliance with local regulations. 1) If drain valves are clogged, release all air pressure, remove and clean valves, then reinstall. DANGER! Unplug the air compressor and release all air from the tanks before servicing. -

Page 15: General Maintenance

MAINTENANCE WARNING! When servicing use only identical replacement parts. Use of any other parts may create a hazard or cause product damage. WARNING! Always wear eye protection with side shields. Failure to do so could result in objects being thrown into your eyes resulting in possible serious injury. -

Page 16: Bearing Lubrication

abrasive to bearings, brushes, commutators, etc. Consequently, we do not recommend using this product for extended work on these types of materials. However, if you do work with any of these materials, it is extremely important to clean the product using compressed air. BEARING LUBRICATION All of the bearings in this product are lubricated with a sufficient amount of high grade lubricant for the life of the unit under normal operating... - Page 17 Low voltage Check with voltmeter Wrong gauge wire or length of Check for proper gauge wire and cord extension cord length Motor hums but cannot run or Shorted or open motor winding Take compressor to service center runs slowly Defective check valve or unloader Take compressor to service center LOW voltage Check with voltmeter Current limiting...

Need help?

Do you have a question about the RC-1012 and is the answer not in the manual?

Questions and answers