Danfoss DHP-AT Installation Manual

Hide thumbs

Also See for DHP-AT:

- User manual (24 pages) ,

- Installation and service instructions manual (38 pages) ,

- User manual (28 pages)

Summary of Contents for Danfoss DHP-AT

- Page 1 MAKING MODERN LIVING POSSIBLE Installation Guide DHP-AT Installation and service manual www.heating.danfoss.com...

- Page 2 Danfoss A/S is not liable or bound by warranty if these instructions are not adhered to during installation or service. The English language is used for the original instructions. Other languages are a translation of the original instructions. (Directive 2006/42/EC)

-

Page 3: Table Of Contents

Connection diagram ............. . Danfoss Heating Solutions... -

Page 4: About Documents And Decals

Introduction The following documentation is available for this product: ▪ Installation and service instructions containing information on how to install and commission a DHP-AT heat pump. ▪ Information about accessories, technical data, troubleshooting and maintenance. ▪ User instructions on how to operate the unit (the User Guide). -

Page 5: Symbols On Decals

Domestic hot water is the water that you use around the house or office for everyday use, like showers, cleaning, laundry or dishes. Buffer tank Buffer tank is installed for equalisation of the temperature for the heating system and to guarantee suffi- cient energy when defrosting. Danfoss Heating Solutions VMGFI302... -

Page 6: Important Information

Local rules and regulations must be obeyed. Refilling must only be carried out using new refrigerant (for the amount and type of refrigerant see manufacturer’s plate) through the service valves. VMGFI302 Danfoss Heating Solutions... -

Page 7: Electrical Connection

Installation Guide DHP-AT All Danfoss warranties are void if filling with refrigerant not specified by Danfoss A/S, unless there is written Caution consent that the new refrigerant is an, by Danfoss A/S, approved replacement refrigerant. Scrapping When the heat pump is to be scrapped the refrigerant must be extracted for disposal. Local rules and regula- Caution tions related to the disposal of refrigerant must be obeyed. -

Page 8: Transport, Delivery Check And Positioning

If there is a freezing risk, use a heat cable inside the hose. ▪ Make sure that condensate water is not drained out on a footway, which may become slippery or icy. This is important to avoid the risk of personal injury. VMGFI302 Danfoss Heating Solutions... - Page 9 Remember that the heat pump must have a certain amount of space in order to function and for servicing. Otherwise there is a risk that the air will recirculate from exhaust to intake. Avoid this by following the dimen- sions given above. Danfoss Heating Solutions VMGFI302...

-

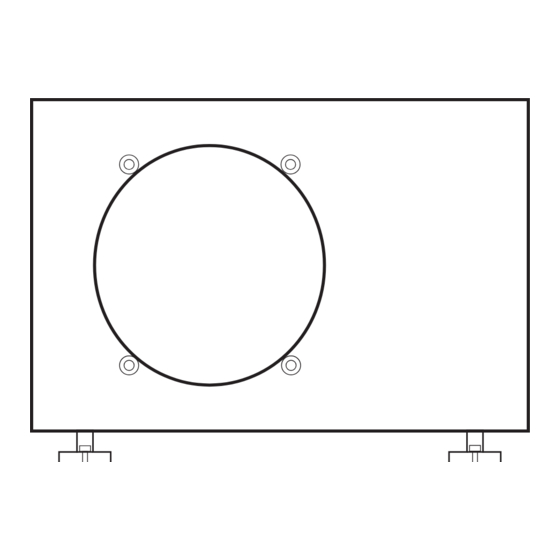

Page 10: The Heat Pump

760 mm Length 1028 mm 1028 mm Width 460 mm 460 mm Fig. 4: Piping connections (rear side) Description Supply line pipe (red label) DN 20 DN 25 Return line pipe (blue label) DN 20 DN 25 VMGFI302 Danfoss Heating Solutions... -

Page 11: Components

Electrical cabinet (internal connections) High pressure valve Top cover Pressure relief valve Rear mesh Low pressure valve Rear panel Evaporator heating belt Right side panel Gas and liquid separator 4-way valve Connection box (external connections) Receiver (refrigerant storage tank) Danfoss Heating Solutions VMGFI302... -

Page 12: Principle Function Description

The internal electrical heater will start in any of the following conditions: ▪ During defrosting cycle (assuming that the parameter value in Menu 13 is set to 1= turned on). ▪ During freeze protection (step 2) VMGFI302 Danfoss Heating Solutions... - Page 13 DHW tank electrical heater (if available) to reach the set point. Considering energy saving, it is recommended to set the DHW tem- perature below 55°C (60°C if there is an electrical heater installed inside the hot water tank). Danfoss Heating Solutions VMGFI302...

- Page 14 Timer defrosting (special condition, faulty coil sensor) If the coil temperature sensor for the heat exchanger fails, and the air temperature is below the value set in Menu 05 , then a timer controlled defrosting cycle will start. VMGFI302 Danfoss Heating Solutions...

- Page 15 The user can change the temperature settings for the supply line, which in turn affects the temperature in the house. Heat curves cannot be selected in manual mode. The user can start and stop house heating/cooling or production of DHW from the operator panel. Danfoss Heating Solutions VMGFI302...

-

Page 16: Check And Safety Functions

The safety valve overflow pipe must have an open connection to the drain and visibly flow into this in a frost-free environment. The safety valve (3) is not an integrated part of the product, but a required external protection function that must installed at commis- sioning and in accordance with local regulations. Refrigerant circuit (4) VMGFI302 Danfoss Heating Solutions... -

Page 17: Heating Curves

The overheat protector is reset by pushing the reset button, which is on the overheat protector inside the unit. This alarm is not auto- matically reset. Heating curves The heat pump will automatically adjust the water temperature according to the following: Danfoss Heating Solutions VMGFI302... - Page 18 When the outside air temperature is -6°C, selecting heat curve 43 and AUTO mode means that the heat pump will adjust the water temperature to 43°C. Heat curve 43 is suitable for radiator heating and heat curve 32 is for under-floor heating (considering any local conditions that may have impact on this recommendation). VMGFI302 Danfoss Heating Solutions...

-

Page 19: System Solution

Hot water tank electrical heater Circulation pump Hot water tank (optional) Safety valve Buffer tank (optional) Expansion vessel Temperature sensor Strainer Supply line 3-way switching valve for hot water Return line Cold water External electrical heater Danfoss Heating Solutions VMGFI302... -

Page 20: Piping Installation

Safety valves must be installed in the system for both the heating circuits and DHW, according to local regula- Caution tions. Connecting cold and hot water lines If necessary, connect the cold water (9) and hot water (10) pipes with all the necessary components to the hot water tank, see the system solution illustration. VMGFI302 Danfoss Heating Solutions... -

Page 21: Connecting Supply And Return Lines

The figures below show how appropriate and inappropriate installations look using this type of hose: Do not twist the flexible hoses as the are installed. At threaded connections, use a counterhold spanner Cut the hose to the correct length to avoid excess bowing-out or stretching at bends Danfoss Heating Solutions VMGFI302... - Page 22 Cut the hose to the correct length to avoid excess bowing-out or stretching and offset the ends so that the hose is installed completely straight Use fixed pipe bends to avoid excess stress on bends next to connections VMGFI302 Danfoss Heating Solutions...

-

Page 23: Electrical Installation

There is no need to take the top off to get inside the electrical connection box. Connecting the operator panel Connect the communication (signalling) cable from the operator panel to the connector marked Operator panel in the heat pump. The cable has prepared connectors that will fit only one way. Danfoss Heating Solutions VMGFI302... -

Page 24: Connecting Circulation Pump

Also, see the diagram inside the connection box. Connecting hot water tank electrical heater Connect the signal cable and the power connection to the hot water tank elec- trical heater (13) according to the picture. VMGFI302 Danfoss Heating Solutions... -

Page 25: Connecting External Electrical Heater

Connect the cable between the heat pump and the 3-way switching valve for hot water (8). The pic- ture below shows a connection example using the LK 3-way switching valve for hot water. The con- nection may be different if using other types of 3-way switching valves for hot water. Danfoss Heating Solutions VMGFI302... -

Page 26: Connecting The Power Supply

Connecting the power supply Obey local and national rules and regulations regarding the specification of the power cable. Warning Fig. 10: Connection alternatives Fig. 9: Connect the power cable between the safety circuit breaker and the heat pump (1) VMGFI302 Danfoss Heating Solutions... -

Page 27: Operator Panel

The default setting is house heating/DHW AUTO mode. For more in- formation about the operator panel, see description in the user manual. Information symbols Indicator Power ON/OFF button Keypad Fig. 11: Layout of operator panel Danfoss Heating Solutions VMGFI302... -

Page 28: Commissioning

MENU 02. The default values can be modified as required, this is done by navigating through the menu system. There is no reset function. If the default factory settings (parameter values) are changed, the only way to re- turn to the default settings is to manually set the values presented in section Default settings. VMGFI302 Danfoss Heating Solutions... -

Page 29: Default Settings

Measured value From -30 °C to +99 °C Exhaust gas temperature of compressor (T4) Measured value From -30 °C to +99 °C Shows the number of the operation steps for the expansion valve Measured value 100—480 steps Danfoss Heating Solutions VMGFI302... -

Page 30: Test Operation

Tuning the heating system To obtain a heating system balance and obtain an even and comfortable indoor temperature, the heating system must be adjusted according to the example below. VMGFI302 Danfoss Heating Solutions... -

Page 31: Customer Information

See the checklist and Installation Protocol in the user guide regarding the information that the installer must give the customer. The serial number must always be given for warranty matters. The serial number is found on the exterior of the heat pump cabinet. The serial number must be noted in the Installation Protocol. Danfoss Heating Solutions VMGFI302... -

Page 32: Troubleshooting

Exhaust gas temperature overheat protection Null Frost protection, step 2 (non-fault) Frost protection, step 1 (non-fault) Air temperature sensor (T1) failure Heating coil sensor (T7) failure Cooling coil sensor (T6) failure Exceeded operation range warning (non-fault) VMGFI302 Danfoss Heating Solutions... - Page 33 The location of the internal temperature sensors are shown in the principal diagram below: T2 T3 Fig. 12: Sensor locations Air temperature Cooling coil (external sensor) Buffer tank Heating coil Hot water tank Supply line Exhaust gas temperature Return line Return gas temperature Danfoss Heating Solutions VMGFI302...

-

Page 34: Technical Data

Low pressure 0.14 0.14 High pressure Low speed Fan speed High speed Water volume Condenser 1.15 1.40 Noise dB(A) 64.9 64.5 Sound power at normal operation Sound pressure at normal operation, dB(A) 53.3 52.8 1 metre VMGFI302 Danfoss Heating Solutions... -

Page 35: Working Range Compressor Operation

11) Outdoor unit, sound pressure level measured according to ISO 11203, cuboid-shaped measuring surface, high fan speed. 11.1 Working range compressor operation Lowest and highest temperatures for production of hot water, heating and cooling. The control unit controls the heat pump operating range. Danfoss Heating Solutions VMGFI302... - Page 36 Installation Guide DHP-AT 1. Supply line water temperature °C 2. Air temperature °C 3. Hot water production only 4. Heating 5. Cooling VMGFI302 Danfoss Heating Solutions...

-

Page 37: Circuit Diagram

Installation Guide DHP-AT Circuit diagram Danfoss Heating Solutions VMGFI302... - Page 38 Installation Guide DHP-AT VMGFI302 Danfoss Heating Solutions...

- Page 39 Installation Guide DHP-AT Danfoss Heating Solutions VMGFI302...

-

Page 40: Connection Diagram

Installation Guide DHP-AT Connection diagram VMGFI302 Danfoss Heating Solutions... - Page 41 Installation Guide DHP-AT Danfoss Heating Solutions VMGFI302...

- Page 42 Installation Guide DHP-AT VMGFI302 Danfoss Heating Solutions...

- Page 43 Installation Guide DHP-AT Danfoss Heating Solutions VMGFI302...

- Page 44 Internet: www.heating.danfoss.com Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies.

Need help?

Do you have a question about the DHP-AT and is the answer not in the manual?

Questions and answers