Table of Contents

Advertisement

Quick Links

Fireplace Inserts

Save These Instructions

For Future Reference

P/N 900937-00, Rev. NC, 03/2019

C

US

ML230 - Report # 14-182

INSTALLATION AND OPERATION MANUAL

EPA Certified

Wood-Burning

P900937-00

A French manual is available upon request. Order P/N 900937-01.

Ce manuel d'installation est disponible en francais, simplement en faire la demande. Numéro de

la pièce 900937-01.

• Hot! Do not touch! The glass and surfaces of this appliance will

be hot during operation and will retain heat for a while after

shutting off the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance.

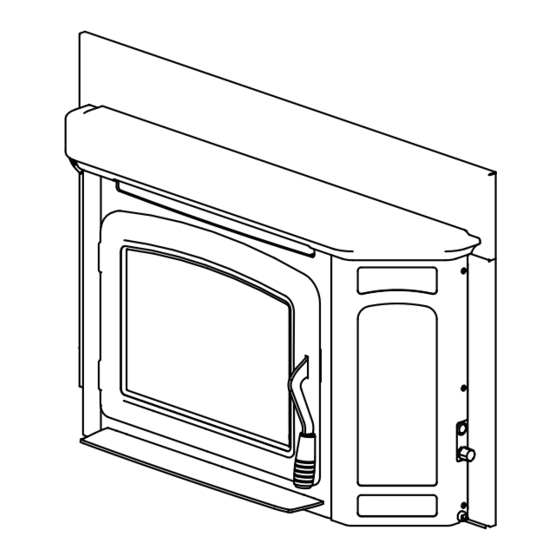

Wood-Burning Fireplace Inserts

Model Montlake™ ML230GL

This appliance must be properly installed and operated in order to prevent the

possibility of a house fire. Please read this entire installation and operation

manual before installing and using your wood fireplace insert. Failure

to follow these instructions could result in property damage, bodily

injury or even death. Contact your local building or fire officials

to obtain a permit and information on any installation re-

quirements and inspection requirements in your area.

WARNING

Montlake™ 230GL

With Innovative Thermal Fin Technology (TFT™)

Advertisement

Table of Contents

Summary of Contents for IronStrike Montlake ML230GL

- Page 1 INSTALLATION AND OPERATION MANUAL EPA Certified Wood-Burning Fireplace Inserts Save These Instructions For Future Reference Montlake™ 230GL P/N 900937-00, Rev. NC, 03/2019 P900937-00 Wood-Burning Fireplace Inserts Model Montlake™ ML230GL With Innovative Thermal Fin Technology (TFT™) A French manual is available upon request. Order P/N 900937-01. ML230 - Report # 14-182 Ce manuel d’installation est disponible en francais, simplement en faire la demande.

-

Page 2: Table Of Contents

CONGRATULATIONS! Post Installation Checks ............... 17 Attaching Control Labels .............. 17 When you purchased your new wood-burning fireplace insert, Paint Curing ................. 18 you joined the ranks of thousands of individuals whose answer Burn-In Period ................18 to their home heating needs reflects their concern for aesthetics, Operating Hints ................ -

Page 3: Important Safety Information

13. Inspect your chimney at least once a month during the burn- IMPORTANT SAFETY AND WARNING ing season to check for soot and creosote accumulations. INFORMATION Any accumulations over 1/8” thick should be removed by a professional chimney sweep. Do not attempt to burn out heavy creosote accumulations with a hot fire. -

Page 4: Testing Information

28. This wood heater has a manufacturer-set minimum low burn 1. A chimney too large for your appliance. rate that must not be altered. It is against federal regulations 2. A chimney with not enough height to produce adequate draft. to alter this setting or otherwise operate this wood heater 3. -

Page 5: Chimney Height Requirements

CHIMNEY HEIGHT REQUIREMENTS NEGATIVE PRESSURE WARNING This appliance is not designed to be operated in a negative pressure. The chimney must extend 3’ (.92m) above the level of roof penetration and a minimum of 2’ (.61m) higher than any roof surface within 10’ In very airtight homes with large kitchen exhaust fans, furnace cold air (3m) (see below). -

Page 6: Required Clearances

Montlake™ ML230GL REQUIRED CLEARANCES Maximum Mantel Depth = 12” (305mm) WARNING: BE ABSOLUTELY SURE THE DISTANCE BETWEEN THE HEATER AND THE SURFACE OF ANY COMBUSTIBLE CONSTRUC- COMBUSTIBLE MANTEL TION IS NOT LESS THAN SHOWN ON THIS PAGE. Top Facing / Trim Model A*(3) E(1) -

Page 7: Specifications

Montlake™ ML230GL SPECIFICATIONS Flue Size 6” (152 mm) Product Reference Information Log Length 16” W x 18” D Max. Cat. No. Description Ship. Ship. (406mm W x 457mm D Max.) Weight Volume F3832 Montlake 230GL Wood-Burning Insert 390 lb. 26.6 cu. ft. Firebox 17”... -

Page 8: Hearth Protection

Montlake™ ML230GL HEARTH PROTECTION The hearth/floor protection must a be a thermally rated type II UL 1618 Listed Material listed floor protection with a minimum R value of 3.12, or 2.08 per inch k (per inch) r (per inch) Listed Min. Thickness R-Value with a minimum thickness of 1-1/2”... -

Page 9: Insert Installation

HT requirements (2100ºF) per UL 1777 (US). The liner minimum 6” (152 mm) diameter stainless steel listed reline system. must be securely attached to the insert flue collar and the chimney top. IronStrike wood-burning inserts are tested to UL 1482 / ULC S628 and ®... -

Page 10: Chimney Liner Installation

CHIMNEY LINER INSTALLATION Alternate Flue Liner Attachment Method (for short fireplace installations) IMPORTANT NOTE: See Draft Requirements and Selecting a Proper For shorter fireplace firebox installations, where it may be difficult to Venting System on Page 4 to assist you in choosing the proper venting attach the liner to the flue collar on top of the insert, you can complete the final liner attachment from within the insert firebox as follows: system for your installation. -

Page 11: Offset Boxes

Offset Boxes INSTALLATION PROCEDURE FOR MASONRY AND FACTORY- BUILT FIREPLACES Offsets can be handled using an offset box (it aligns flue outlet of insert with the fireplace flue (see Figures 12 and 13). Care should be used to READ THE ENTIRE INSTALLATION INSTRUCTIONS AND CHECK ALL ensure that this adjustable offset box is oriented so it does not angle REQUIRED CLEARANCES PRIOR TO INSTALLING THIS APPLIANCE. -

Page 12: Manufactured Home Installations (Ml230 Only)

MANUFACTURED HOME INSTALLATIONS (ML230GL ONLY) A positive flue connection is required in manufactured home installations (see instructions on Page 10) This appliance is approved for installation into a manufactured (mobile) home. Installation should be in accordance with the Mobile Home Con- struction and Safety Standard, Title 24 CFR, Part 3280 (in Canada CAN/ CSA Z240 MH), or, when such a standard is not applicable, the Standard for Mobile Home Installations, ANSI A225.1. -

Page 13: Typical Installation Figures

Chimney Chimney Termination Termination Rain Cap Rain Cap Masonry Fireplace - Factory Built (ZC) Fireplace Built to UBC Chapter 37 Built to UL-127 (US) or ULC- Standards S610 (Canada) Standards Flashing Requires a minimum of a Requires a minimum of a Flashing positive flue connection positive flue connection (Fig-... -

Page 14: Brick And Baffle Installation

Montlake™ ML230GL BRICK AND BAFFLE INSTALLATION CAUTION: Wear gloves during brick installation in case of sharp 1. Install brick #1-20 in the numbered sequence shown in Figure 17. edges inside the stove or insert. 2. Brick’s 13 and 14 will be located between the steel firebox and rear baffle board (already installed). -

Page 15: Secondary Tube And Baffle Board Replacement

SECONDARY TUBE AND BAFFLE BOARD REPLACEMENT • Gently lift front baffle board upward and place on rear baffle board. See Detail A SEE DETAIL A • Starting front to rear, locate secondary tube retaining pin and rotate RETAINING PIN NOTCHES counter clockwise;... -

Page 16: Timer Replacement

TIMER REPLACEMENT: CHECK: • Inspect timer linkage to ensure it can move freely and is not binding. Turn damper lever counter clockwise and remove from stove. Vertical timer link can be lifted in an upward and downward motion (manually engaging and disengaging timer), which will open and close •... -

Page 17: Post Installation Checks

POST INSTALLATION CHECKS ATTACHING CONTROL LABELS Once the surround panels are in place, apply the included control labels as shown in Figure 23. Check that one of the required surround kits Surround Panels is properly installed per the instructions provided in kit (Instr. # 506033-76). See Page 28 for ordering information. -

Page 18: Paint Curing

OPERATING HINTS PAINT CURING 1. Burn only dry, well-seasoned cord wood. In some states it is illegal If your appliance has plated accessories, be sure to clean it with a to burn wet wood or anything other than clean, dry wood products. household type glass cleaner and a very soft cloth to remove any 2. -

Page 19: Starting And Maintaining A Fire

STARTING AND MAINTAINING A FIRE NEVER USE FLAMMABLE LIQUIDS TO START OR REKINDLE A SOLID FUEL FIRE!! 2. Fully open the primary draft control by placing draft control (wood handle located on left side of the stove) in the highest position. This control determines the amount of air entering the stove. -

Page 20: Fuel

6. Once kindling is burning well, larger pieces of wood may be added, FUEL then the door should be fully closed if there was the need to keep it slightly open during start up. This appliance is designed to burn dry seasoned natural wood only (see 7. -

Page 21: Getting The Most Out Of Your Appliance

GETTING THE MOST OUT OF YOUR APPLIANCE ACHIEVING CLEAN, LONG BURNS Recent developments in wood-burning technology have made wood- To achieve long burn times, after having thoroughly preheated the ap- burning a cleaner and more convenient way to heat your home. Overall pliance, let the appliance top cool down to 250 to 325 degrees. -

Page 22: Blower Operation (Optional Kit)

BLOWER OPERATION Blower Operation - The blower can be operated manually or automati- Manual / Auto cally (blower will turn on when the stove or insert is hot and turn off Rocker Switch when the stove or insert is cool). The rocker switch on the control panel allows you to select between manual operation or automatic operation as follows (see Figure 30): MANUAL OPERATION: Turn rocker switch to the manual position (up) -

Page 23: Do's And Don'ts

Smoke Detector Recommended DO’S AND DON’TS Since there are always several potential sources of fire in any home, we recommend installing smoke detectors. If possible, install the smoke DO NOT: Install or operate the appliance before reading this manual. detector in a hallway adjacent to the room (to reduce the possibility of occasional false activation from the heat produced by these appliances). -

Page 24: Maintenance

DOOR GASKET: Periodically check gasket to make sure it is not over- MAINTENANCE compressed. If compressed, replace with a special woven door rope. (Don’t try substituting rope, only use special IHP door rope). PLATED ACCESSORIES: Clean only with a household type glass cleaner Have your product inspected at least once a year by a qualified and a very soft cotton cloth. -

Page 25: Glass Replacement

GLASS CLEANING GUIDELINES MAINTENANCE WARNING: DO NOT CLEAN GLASS WHEN APPLIANCE IS HOT! GLASS REPLACEMENT INSTRUCTIONS Glass on any wood stove or fireplace insert will not stay perfectly clean. (Refer to Figure 32) Here are some guidelines for cleaning and caring for the glass: •... -

Page 26: Troubleshooting

TROUBLESHOOTING Problem Solution POOR DRAFT: Extend chimney in length or have the chimney realigned to the proper size flue. Oversized chimneys normally have poor drafts. Remember, the appliances’ draft depends solely on the natural draft of the chimney (See Draft Requirements on Page 4). -

Page 27: Replacement Parts List

REPLACEMENT PARTS - MODEL MONTLAKE™ 230GL MISCELLANEOUS PARTS (continued) Item # Description ML230GL Taptite Qty 8 (34055) H8390 Contact an IHP dealer to obtain any of these parts. Never use Button Head Screw Qty 8 (34027) H8391 substitute materials. Use of non-approved parts can result in poor performance and safety hazards. - Page 28 REPLACEMENT PARTS - MODEL MONTLAKE™ 230GL 31,35 23,24 18,36,37 NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

-

Page 29: Accessories

ACCESSORIES - MODEL MONTLAKE™ 230GL Model Description ML230 TOP WARMING SURFACE KITS (ONE REQUIRED) TOP-STEEL-ML230 Steel Top - Montlake™ 230GL H8673 TOP-CASTIRON-ML230 Cast Top - Montlake 230GL H8674 DOOR TRIM KITS DRTRM-ML230-NKL Door Trim, Nickel H8346 DRTRM-ML230-BRNKL Door Trim, Brushed Nickel H8347 SURROUND KITS (ONE REQUIRED) ML230-FP2641... -

Page 30: Safety / Listing Label

SAFETY / LISTING LABEL - CONTACT YOUR LOCAL BUILDING OR FIRE OFFICIALS ABOUT MODEL MONTLAKE™ 230GL RESTRICTIONS AND INSTALLATION INSPECTION IN YOUR AREA Listed Factory-built or Masonry Fireplace Accessory/Insert Manufactured By / Fabriqué Par: INNOVATIVE HEARTH PRODUCTS 1502 14th Street NW Auburn, WA 98001 USA "PREVENT HOUSE FIRES"... -

Page 31: Warranty

IHP in writing. IHP must be notified of the claimed defect in writing within 90 days of the date of failure. Notices should be directed to the IHP Warranty Department at 1508 Elm Hill Pike, Suite 108; Nashville, TN 37210 or visit our website at WWW.IRONSTRIKE.US.COM. -

Page 32: Product Reference Information

If you did not purchase your appliance directly from an When ordering repair parts, always give the following information: IHP dealer, then contact us at IronStrike.us.com to find your nearest IHP dealer who will answer your questions or address your concerns.

Need help?

Do you have a question about the Montlake ML230GL and is the answer not in the manual?

Questions and answers