Table of Contents

Advertisement

Quick Links

Operator's Manual

FLEXTEC

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10091-A

| Issue D ate Jun-15

© Lincoln Global, Inc. All Rights Reserved.

TM

450 CE

For use with machines having Code Numbers:

11776, 11942

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric 11776

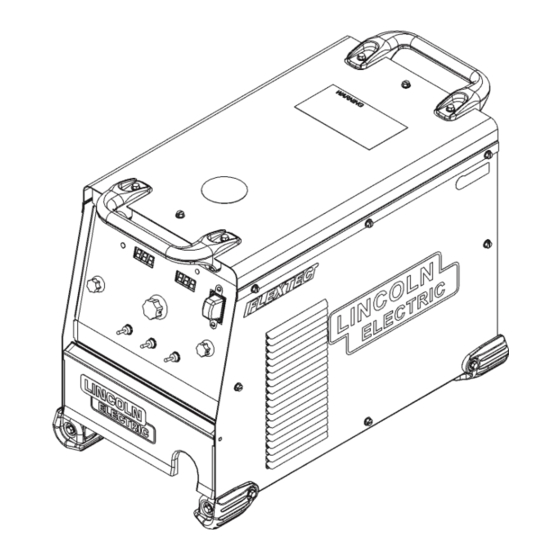

- Page 1 Operator’s Manual FLEXTEC 450 CE For use with machines having Code Numbers: 11776, 11942 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM10091-A | Issue D ate Jun-15...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 NOTES...

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page Installation .......................Section A Technical Specifications ..................A-1 Welding Process, Physical Dimensions ............A-2 Safety Precautions ..................A-3 VRD™ (Voltage Reduction Device) ................A-3 Select Suitable Location..................A-3 Lifting.......................A-3 Stacking ......................A-3 Environmental Limitations ................A-3 Input and Grounding Connections ..............A-3 High Frequency Protection ..................A-3 Input Connection ....................A-4 Input Fuse and Supply Wire Considerations...........A-4 Cable Connections..................A-5... -

Page 8: Installation

INSTALLATION TECHNICAL SPECIFICATIONS - FLEXTEC™ 450 CE POWER SOURCE-INPUT VOLTAGE AND CURRENT Input Amperes Input Voltage ± 10% Model Duty Cycle Power Factor @ Idle Power Rated Output 60% rating 72 Watts 37 / 35 / 34 K3065-1 Max. 380 / 400 / 415 / 3 / 50 / 60 100% rating 29 / 28 / 27 (fan on) - Page 9 INSTALLATION WELDING PROCESS PROCESS OUTPUT RANGE (AMPERES) OCV (U OCV (U 40-500 GMAW (CV) GTAW (CC) 10-500 MMAW (CC) 15-500 FCAW-GS (CV) 40-500 FCAW-SS (CV) 40-500 PHYSICAL DIMENSIONS MODEL HEIGHT WIDTH DEPTH WEIGHT 26.66in (677mm) 130lbs (59kg)* K3065-1 18.80in (478mm) 14.14in (359mm) TEMPERATURE RANGES OPERATING TEMPERATURE RANGE...

-

Page 10: Safety Precautions

INSTALLATION SAFETY PRECAUTIONS LIFTING WARNING Both handles should be used when lifting the FLEX- TEC™ 450 CE. When using a crane or overhead ELECTRIC SHOCK can kill. device a lifting strap should be connected to both han- dles. Do not attempt to lift the FLEXTEC™ 450 CE ONLY QUALIFIED PERSONNEL with accessories attached to it. -

Page 11: Input Connection

INSTALLATION INPUT CONNECTION HIGH TEMPERATURE OPERATION (See Figure A.1) WELDER OUTPUT RATINGS AT 55°C Use a three-phase supply line. A 1.40 inch (36 mm) ELEVATED TEMPERATURES diameter access hole for the input supply is located on the case back. Connect L1, L2, L3 and ground according to the Input Supply Connection Diagram AMPS DUTY CYCLE... -

Page 12: Cable Connections

INSTALLATION CABLE CONNECTIONS See FIGURE A.2 for locating 6-pin and 14-pin con- nectors on the front of the FLEXTEC™ 450 CE. 6-PIN REMOTE CONTROL CONNECTOR Function Wiring 6-pin remote 77 Remote potentiometer, 5K control con- 76 Remote potentiometer, wiper nector for 75 Remote potentiometer, common remote or Trigger, common... -

Page 13: Recommended Electrode And Work Cable For Arc Welding

INSTALLATION RECOMMENDED ELECTRODE AND • Route all cables directly to the work and wire feeder, avoid excessive lengths and do not coil WORK CABLE SIZES FOR ARC WELDING excess cable. Route the electrode and work cables in close proximity to one another to minimize the General Guidelines loop area and therefore the inductance of the weld Connect the electrode and work cables between the... - Page 14 INSTALLATION CONNECTING LF-72 AND LF-74 TO THE FLEXTEC ™ CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS LOCAL REMOTE/LOCAL (REMOTE IF K2329-1 INSTALLED) VOLTMETER POLARITY PROCESS DEPENDENT FLEXTEC™ 450 CE...

- Page 15 INSTALLATION CONNECTING LN-10 AND DH-10 TO THE FLEXTEC™ 450 CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS REMOTE/LOCAL REMOTE VOLTMETER POLARITY PROCESS DEPENDENT LN-10,DH-10 CONTROL SWITCH Setting the DIP Switches SETUP The DIP switches are each labeled with an “ON” arrow showing the on direction for each of the 8 indi- Initial set up of the LN-10, DH-10 control for the sys- vidual switches in each DIP switch (S1 and S2).

- Page 16 INSTALLATION CONNECTING LN-15(K1870-1) TO THE FLEXTEC™ 450 CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS REMOTE/LOCAL LOCAL VOLTMETER POLARITY PROCESS DEPENDENT CONNECTING LN-15(K1871-1) TO THE FLEXTEC™ 450 CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS REMOTE/LOCAL REMOTE VOLTMETER POLARITY PROCESS DEPENDENT FLEXTEC™...

- Page 17 A-10 A-10 INSTALLATION CONNECTING LN-25 PRO AND LN-25 PIPE TO THE FLEXTEC™ 450 CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS REMOTE/LOCAL LOCAL VOLTMETER POLARITY PROCESS DEPENDENT CONNECTING LN-25 PRO DUAL POWER TO THE FLEXTEC™ 450 CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS REMOTE/LOCAL...

- Page 18 OPERATION SAFETY PRECAUTIONS GRAPHIC SYMBOLS THAT APPEAR ON THIS MACHINE Read this entire section of operating instructions before operating the machine. OR IN THIS MANUAL WARNING INPUT POWER ELECTRIC SHOCK can kill. • Unless using cold feed feature, when feeding with gun trigger, the electrode and drive mechanism are always electrically energized and could remain energized several...

-

Page 19: Operation

OPERATION GRAPHIC SYMBOLS THAT PRODUCT DESCRIPTION APPEAR ON THIS MACHINE The FLEXTEC™ 450 CE is a multi-process CC/CV OR IN THIS MANUAL DC inverter and is rated for 450 amps, 38 volts at a 60% duty cycle. The Flextec is intended for both fac- tory and field operation. -

Page 20: Recommended Processes And Equipment

OPERATION RECOMMENDED PROCESSES AND EQUIPMENT RECOMMENDED PROCESSES The Flextec™ 450 CE is designed for CC-MMAW, CC-GTAW (lift tig), CV-GMAW, CV-FCAW-SS and CV-FCAW-GS welding processes. CC- CAG (arc gouging) is also supported in the MMAW mode. PROCESS LIMITATIONS The Flextec™ 450 CE is suitable only for the processes listed. - Page 21 OPERATION CASE FRONT CONTROL DESCRIPTIONS (See Figure B.1) 11. Wire feeder voltmeter polarity selection toggle switch 1. Power Switch 12. Circuit breaker reset button for the 14-pin wire 2. Voltage Display Meter feeder connector 3. Amperage Display Meter 13. 14-pin wire feeder circular connector 4.

-

Page 22: Power-Up Sequence

(Adjustment is indicated by the meters.) responsibility of the builder/user. Many variables When in Remote Mode, this control sets the maximum beyond the control of The Lincoln Electric welding current of the remote device. For example, full Company affect the results obtained in applying depression of a foot or hand amptrol results in the pre- these programs. - Page 23 OPERATION Thermal Light Amperage Display Meter • This status light indicates when the power source • Prior to STICK or TIG operation (current flow), the has been driven into thermal overload. If the output meter displays preset current value. terminals were "ON", the output will be turned back •...

- Page 24 OPERATION BASIC MODES OF OPERATION • When the Local/Remote is set to Remote, this dial sets the maximum welding amperage. The remote potentiometer than controls the amperage from min- MMAW imum to this pre-set maximum. This weld mode is a constant current (CC) mode fea- turing continuous control from 15 –...

- Page 25 OPERATION CV-INNERSHIELD The remote potentiometer controls the amperage from minimum to this pre-set maximum. This weld mode is a constant voltage (CV) mode fea- CV-GAS turing continuous control from 10 to 45 volts. It is intended for the FCAW-SS welding process. This weld mode is a constant voltage (CV) mode featuring con- Hot Start –...

-

Page 26: Accessories

ACCESSORIES OPTIONS / ACCESSORIES Foot Amptrol® General Options Provides 25 ft. (7.6 m) of remote current control for TIG welding. K2149-1 Work Lead Package. (6-pin plug connection). Order K870 Hand Amptrol® - Provides 25 ft. K1842-10 10ft. Weld Power Cable (Lug to Lug). (7.6 m) of remote current control for TIG welding. -

Page 27: Maintenance

MAINTENANCE SAFETY PRECAUTIONS PERIODIC MAINTENANCE WARNING Thermal Protection Thermostats protect the machine from excessive ELECTRIC SHOCK can kill. operating temperatures. Excessive temperatures may • Only Qualified personnel should be caused by a lack of cooling air or operating the perform this maintenance. machine beyond the duty cycle and output rating. -

Page 28: How To Use Troubleshooting Guide

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 29 COURSE OF ACTION Major physical or electrical damage 1. Contact your local authorized is evident when the sheet metal Lincoln Electric Field Service facil- covers are removed. ity for technical assistance. Machine won’t weld, can’t get any 1. If the displays show an Err ### output.

- Page 30 Included in this section is information about the Status Lights and some basic troubleshooting charts for both machine and weld performance. The status lights on the main control board and the switch pc board are dual-color LED’s. Normal operation for each is steady green. (For Code 11776 only) Error Codes for the FLEXTEC™ 450 CE Error...

- Page 31 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual USING THE STATUS LED TO TROUBLESHOOT SYSTEM PROBLEMS Errors are displayed on the user interface. In addition, there are status lights on the control pc board and the switch pc board that contain error sequences. Included in this section is information about the Status Lights and some basic troubleshooting charts for both machine and weld performance.

-

Page 32: Error Codes

TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual (For Code 11942 only) FLEXTEC™ 450 CE Fault Codes Error Corrective Action Description Possible Cause Code# Input Power Misconnect. Verify the primary reconnect Occurs upon power up when the supply Supply Voltage is too high. voltage to the switch pcb exceeded accept- is properly configured for the input voltage. - Page 33 DIAGRAMS FLEXTEC™ 450 CE...

- Page 34 DIAGRAMS FLEXTEC™ 450 CE...

- Page 35 DIMENSION PRINT FLEXTEC™ 450 CE...

- Page 36 NOTES FLEXTEC™ 450 CE...

- Page 37 NOTES FLEXTEC™ 450 CE...

- Page 38 ● Do not touch electrically live parts or ● Keep flammable materials away. ● Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. ● Insulate yourself from work and ground. Spanish ● No toque las partes o los electrodos ●...

- Page 39 ● Keep your head out of fumes. ● Turn power off before servicing. ● Do not operate with panel open or WARNING ● Use ventilation or exhaust to guards off. remove fumes from breathing zone. Spanish ● Los humos fuera de la zona de res- ●...

- Page 40 Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the 11776 and is the answer not in the manual?

Questions and answers