Table of Contents

Advertisement

Quick Links

Instructions

CARBON STEEL

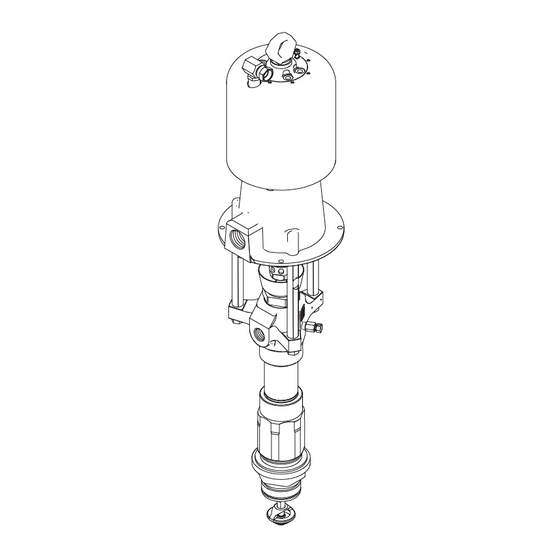

Check–Mate™ 800 Pumps

With Priming Piston and Severe–Duty Rod and Cylinder

Refer to page 2 for Table of Contents.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions. See page 2 for model

numbers and maximum working pressures.

Models 198466

and 246938

Models

237265, 246940

and 246941

PROVEN QUALITY. LEADING TECHNOLOGY.

Models 236471

and 246942

308351N

EN

Advertisement

Table of Contents

Summary of Contents for Graco 198466

- Page 1 Important Safety Instructions Read all warnings and instructions in this manual. Save these instructions. See page 2 for model Models 236471 numbers and maximum working pressures. and 246942 Models Models 198466 237265, 246940 and 246938 and 246941 PROVEN QUALITY. LEADING TECHNOLOGY.

-

Page 2: Table Of Contents

Installation ..............6 Dimensions ..............49 Operation/Maintenance ..........12 Mounting Hole Layout ..........49 Service Troubleshooting ........... 17 Graco Standard Warranty ......... 50 Required Tools ............. 18 Graco Information ............50 Disconnecting the Displacement Pump ....18 List of Models Maximum Fluid... -

Page 3: Symbols

This equipment is for professional use only. • Read all instruction manuals, tags, and labels before operating the equipment. • Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. • Do not alter or modify this equipment. •... - Page 4 WARNING SKIN INJECTION HAZARD Spray from the spray gun/dispense valve, leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury. •...

- Page 5 WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury. • Ground the equipment and the object being sprayed. Refer to Grounding on page 6. •...

-

Page 6: Installation

Installation Grounding WARNING FIRE AND EXPLOSION HAZARD Before operating the pump, ground the system as explained below. Also read the section FIRE AND EXPLOSION HAZARD on page 5. 1. King Pumps: use a ground wire and clamp. See Fig. 2 Fig. - Page 7 Mount the pump (A) to suit the type of installation planned. Fig. 3 on page 8 illustrates a ram- Accessories are available from Graco. If you supply mounted pump in a multi-gun header system. your own accessories, be sure they are adequately Pump dimensions and the mounting hole layout sized and pressure–rated to meet the system’s...

- Page 8 Installation (Air–Powered Pumps) Pump M Fluid Drain Valve (required) 200 Liter (55 Gallon) Air-Powered Ram Electrically Conductive Fluid Supply Hose C Main Air Bleed Valve (required, for pump and ram) Fluid Shutoff Valve Air Line Lubricator (position only) Gun/Valve Swivel Pump Air Bleed Valve (required, for pump) Airless Spray Gun or Dispensing Valve Pump Air Regulator...

- Page 9 Installation (Air–Powered Pumps) drain valve (W) at the bottom of each air line drop, to drain off moisture. WARNING • An air shutoff valve (K) isolates the air line acces- sories for servicing. Locate upstream from all other A main air bleed valve (C), pump air bleed valve air line accessories.

- Page 10 Installation (Hydraulic–Powered Pumps) H Hydraulic Pressure Gauge A Accessory Pump Stand J Flow Control Valve (P/N 218742) K Pressure Reducing Valve B Surge Tank (P/N 218509 or L Drain Line 238983) C 50 mm (2 in.) Diameter Pipe M Hydraulic Return Line D Full Flow, Non-Restrictive Shutoff Valve N Accumulator...

- Page 11 Installation (Hydraulic–Powered Pumps) NOTE: Hydraulic fluid is exhausted from differential hy- CAUTION draulic motors only on the upstroke of the operating cy- cle. The oil return line must have at least twice the flow capacity as the oil supply line. Otherwise, back pressure The Hydraulic Power Supply must be kept clean at on the hydraulic motor piston will slow down the motor all times to avoid damage to the motor and hydraulic...

-

Page 12: Operation/Maintenance

Now clear the tip/nozzle or hose. Packing Nut/Wet-Cup Fig.5 Before starting, fill the packing nut (2) 1/3 full with Graco Throat Seal Liquid (TSL) or compatible solvent. See Fig. 5. 308351... - Page 13 Operation Flush the Pump Before First Use The pump is tested with lightweight oil, which is left in to WARNING protect the pump parts. If the fluid you are using may be contaminated by the oil, flush it out with a compatible COMPONENT RUPTURE HAZARD solvent.

- Page 14 Operation Hydraulic–Powered Systems c. Adjust the pressure–reducing valve until you get the desired fluid pressure. Run the pump Refer to the warnings on page 13. until all air is purged from the fluid lines. 1. Supply fluid to the pump, per the requirements of d.

- Page 15 Notes 308351...

- Page 16 Maintenance Shutdown and Care of the Pump CAUTION WARNING Never leave water or water-base fluid in the pump To reduce the risk of serious injury whenever you are overnight. If you are pumping water-base fluid, instructed to relieve pressure, always follow the flush with water first, then with a rust inhibitor such Pressure Relief Procedure on page 12.

-

Page 17: Troubleshooting

Turn on the air or hydraulic power just enough to start the pump. If the pump starts, the obstruction is in the fluid hose or gun. NOTE: If you experience air motor icing, call your Graco distributor. 308351... -

Page 18: Required Tools

Service 4. Disconnect the displacement pump (106) from the Required Tools motor (101) as follows. See Fig. 6. Be sure to note • Torque wrench the relative position of the pump’s fluid outlet (X) to • Bench vise, with soft jaws the motor inlet (Y). -

Page 19: Reconnecting The Displacement Pump

6. Reconnect all hoses. Reconnect the ground wire if it was disconnected. Fill the wet-cup (2) 1/3 full of Graco Throat Seal Liquid or compatible solvent. 7. Turn on the power supply. Run the pump slowly to ensure proper operation. -

Page 20: Displacement Pump Service

Displacement Pump Service NOTE: These instructions are written with the pump Disassembly separating at joint A. If it separates at joints B or C, When disassembling the pump, lay out all the removed disassemble it at that joint, place the intake housing (17) parts in sequence, to ease reassembly. - Page 21 Displacement Pump Service Pull the intake seat (37) and seal (38) out the bottom of the intake valve housing (17). Take care not to drop the check valve assembly (V) as it comes free, and set it aside for later. See Fig.

- Page 22 Displacement Pump Service 9. Remove the seal (8) from the bottom of the cylinder NOTE: The seal (39) is press-fit in the nut (15) and may (10). See Fig. 12. Shine a light into the cylinder to require cutting to ease removal. examine the inside surface for scoring or damage.

- Page 23 Displacement Pump Service 4. Lubricate the piston seal (13*) and install it on the Reassembly piston seat (14). Apply thread sealant to the threads Fig. 16 shows a cutaway of the entire pump. of the seat and the piston guide (11). Screw the guide onto the seat (14).

- Page 24 Displacement Pump Service 7. If the cylinder (10) was removed from the outlet 11. Lubricate the seal (8*) and install it on the bottom of housing (9), lubricate the seal (8*) and place it on the cylinder (10). Slide the intake valve housing (17) the top of the cylinder.

- Page 25 Displacement Pump Service 15. Screw the intake cylinder (19) into the intake 18. Slide the priming piston (21) onto the rod (18) until it housing (17). Using a pipe wrench on the hex of the stops. Hold the rod (18) steady with an adjustable cylinder (19), torque the cylinder to 468–590 N.m wrench on the flats, and screw the seat (22) onto the (345–435 ft-lb).

- Page 26 Displacement Pump Service For Pumps 198466, 237265 and 236471 only THROAT PACKING DETAIL Piston check valve (see Fig. 12). Intake check valve (see Fig. 13). Lubricate. Lips of v-packings must face down. Screw valve plug (20) completely into valve body (29).

- Page 27 Displacement Pump Service For Pumps 246938, 246940, 246941 and 246942 only Servicing the Throat Packings 3. Place the flats of the packing nut (2) in a vise. Unscrew the packing housing (3) and discard it and NOTE: The throat packings are available as a preas- the packings.

-

Page 28: Parts

Parts Part No. 236471 Pump, Series B, 65:1 Ratio, with King Air Motor Part No. 246942 Pump, Series B, 65:1 Ratio, with King Air Motor Part No. 237261 Pump, Series A, 31:1 Ratio, with Bulldog Air Motor Part No. 246940 Pump, Series B, 31:1 Ratio, with Bulldog Air Motor Part No. - Page 29 Parts Part No. 198475 Pump, Series A, 65:1 Ratio, with Quiet King Air Motor Ref. Part No. Description Qty. AIR MOTOR, Quiet King 235525 See 309348 for parts ROD, tie; 271 mm (10.67”) 198476 shoulder to shoulder NUT, hex; M16 x 2.0 106166 NUT, coupling 186925...

- Page 30 Parts Part No. 198466 Pump, Series A, with Viscount II Hydraulic Motor Part No. 246938 Pump, Series B, with Viscount II Hydraulic Motor Ref. Part No. Description Qty. 198468 MOTOR, Viscount II See 307158 for parts 198471 ROD, tie; 235 mm (9.25”)

- Page 31 Parts Part No. 237265 Pump, Series B, 65:1 Ratio, with Reduced Icing Quiet King Air Motor Part No. 240945 Pump, Series B, 65:1 Ratio, with Quiet King Air Motor Part No. 253376 Pump, Series C, 65:1 Ratio, with Quiet King Air Motor Part No.

- Page 32 Displacement Pump Parts Part No. 246939, Series B Part Part Description Description 189317 ROD, displacement; stainless steel 24 109301 V–PACKING, intake valve; PTFE 237799 25 184196 GLAND, intake valve, female; PACKING NUT/WET-CUP; carbon steel carbon steel 26 109251 V–PACKING, intake valve; 190585 HOUSING, throat seal;...

- Page 33 Displacement Pump Parts 308351...

- Page 34 Displacement Pump Parts Part No. 236611, 198469 and 237945; Series A NOTE: Refer to page 36 for the different packing configurations available. Part Part Description Description 189317 ROD, displacement; stainless 184400 ROD, priming piston; stainless steel 189447 CYLINDER, intake; ductile iron 222995 PACKING NUT/WET- 198470...

- Page 35 Displacement Pump Parts Intake Packing Stack. See page 36. Throat Packing Stack. See page 36. 308351...

- Page 36 Displacement Pump Parts Part No. 236611 and 198469, Series A, Standard UHMWPE/PTFE Packed Displacement Pump THROAT PACKINGS: INTAKE PACKINGS: Part LIPS FACE DOWN LIPS FACE UP Description LUBRICATE PACKINGS 109306 V-PACKING, throat; PTFE 184201 GLAND, throat, female; carbon steel 109256 V-PACKING, throat;...

- Page 37 Notes 308351...

-

Page 38: Technical Data And Performance Chart

Technical Data (Model 236471 and 246942 King Pumps) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before using fluid or solvent in this pump. Category Data Ratio 65:1... - Page 39 Technical Data (Model 236471 and 246942 King Pumps) Performance Charts To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid flow To find Pump Air Consumption (m3/min or scfm) at a specific fluid (lpm/gpm) and operating air pressure (psi/MPa/bar): flow (lpm/gpm) and air pressure (psi/MPa/bar): 1.

- Page 40 Technical Data (Models 240945, 253376, and 198475 Quiet King Pump and Model 237265 Reduced Icing Quiet King Pump) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before using fluid or solvent in this pump.

- Page 41 Technical Data (Models 240945, 253376, and 198475 Quiet King Pump and Model 237265 Reduced Icing Quiet King Pump) Performance Charts To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid flow To find Pump Air Consumption (m3/min or scfm) at a specific fluid (lpm/gpm) and operating air pressure (psi/MPa/bar): flow (lpm/gpm) and air pressure (psi/MPa/bar): 1.

- Page 42 Technical Data (Model 237261, 246940 and 241901 Bulldog Pumps) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before using fluid or solvent in this pump. Category Data Ratio...

- Page 43 Technical Data (Model 237261, 246940 and 241901 Bulldog Pump) Performance Charts To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid flow To find Pump Air Consumption (m3/min or scfm) at a specific fluid (lpm/gpm) and operating air pressure (psi/MPa/bar): flow (lpm/gpm) and air pressure (psi/MPa/bar): 1.

- Page 44 Technical Data (Model 237274 Reduced Icing Quiet Bulldog Pump) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before using fluid or solvent in this pump. Category Data Ratio...

- Page 45 Technical Data (Model 237274 Reduced Icing Quiet Bulldog Pump) Performance Charts To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid flow To find Pump Air Consumption (m3/min or scfm) at a specific fluid (lpm/gpm) and operating air pressure (psi/MPa/bar): flow (lpm/gpm) and air pressure (psi/MPa/bar): 1.

- Page 46 Technical Data (Model 237264 and 246941 Senator Pumps) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before using fluid or solvent in this pump. Category Data Ratio 19:1...

- Page 47 Technical Data (Model 237264 and 246941 Senator Pumps) Performance Charts To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid flow To find Pump Air Consumption (m3/min or scfm) at a specific fluid (lpm/gpm) and operating air pressure (psi/MPa/bar): flow (lpm/gpm) and air pressure (psi/MPa/bar): 1.

- Page 48 Technical Data (Model 198466 and 246938 Viscount II Pumps) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before using fluid or solvent in this pump.

-

Page 49: Dimensions

Dimensions and Mounting Hole Layout Model 236471 Shown All Models, except 198466 and 246938 Model 198466 and 246938 Part No. 236471 1376.7 mm 583.0 mm 793.7 mm 728.5 mm 257.0 mm 1 in. npt(f) 3/4 npsm(f) 246942 (54.20 in.) (22.95 in.) (31.25 in.) -

Page 50: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the 198466 and is the answer not in the manual?

Questions and answers